Part of the Auction Closure of a toolmaker

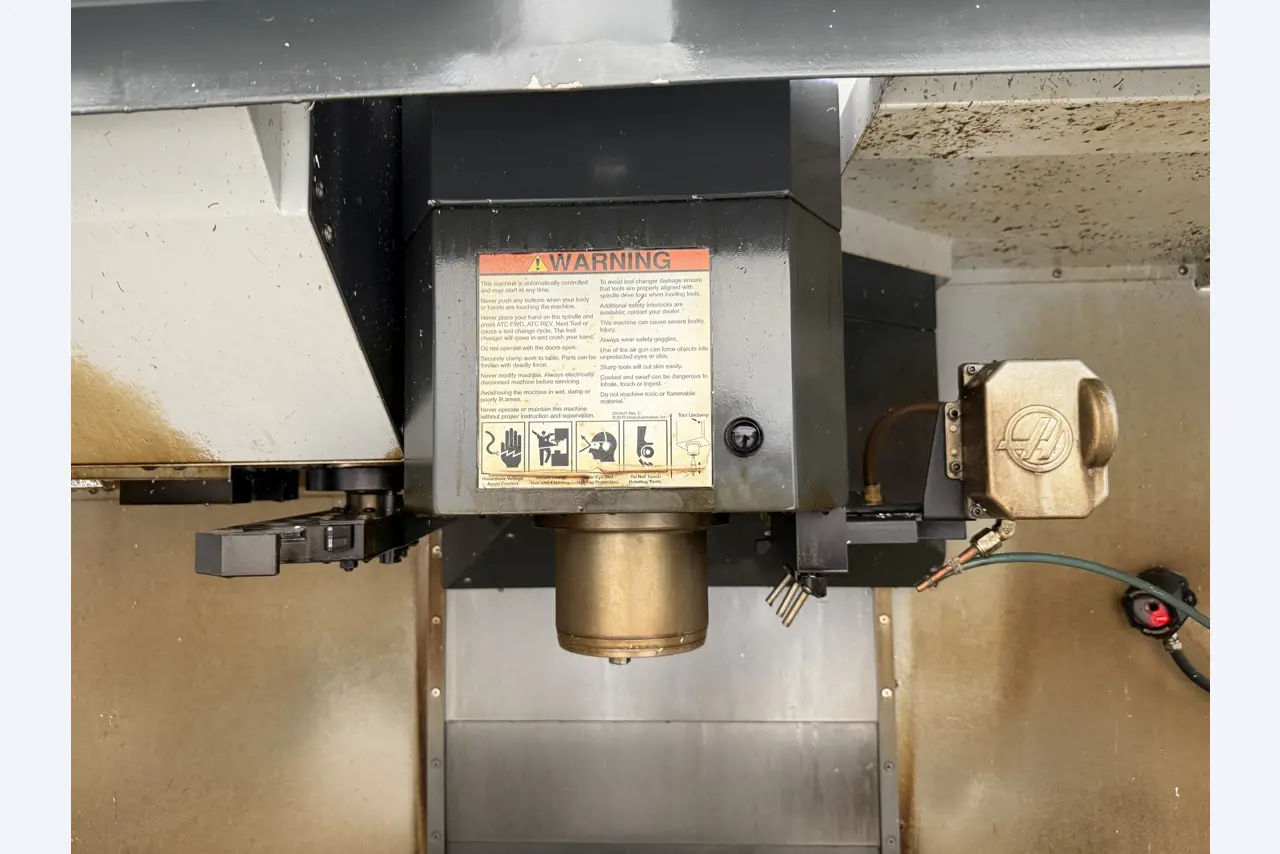

CNC vertical machining center HAAS VF-3SSAUCTION#18632-10

This auction has ended.

Details

Product Type

HAAS

Type

VF-3SS

Construction Year

2011

Description

Maintenance report attached

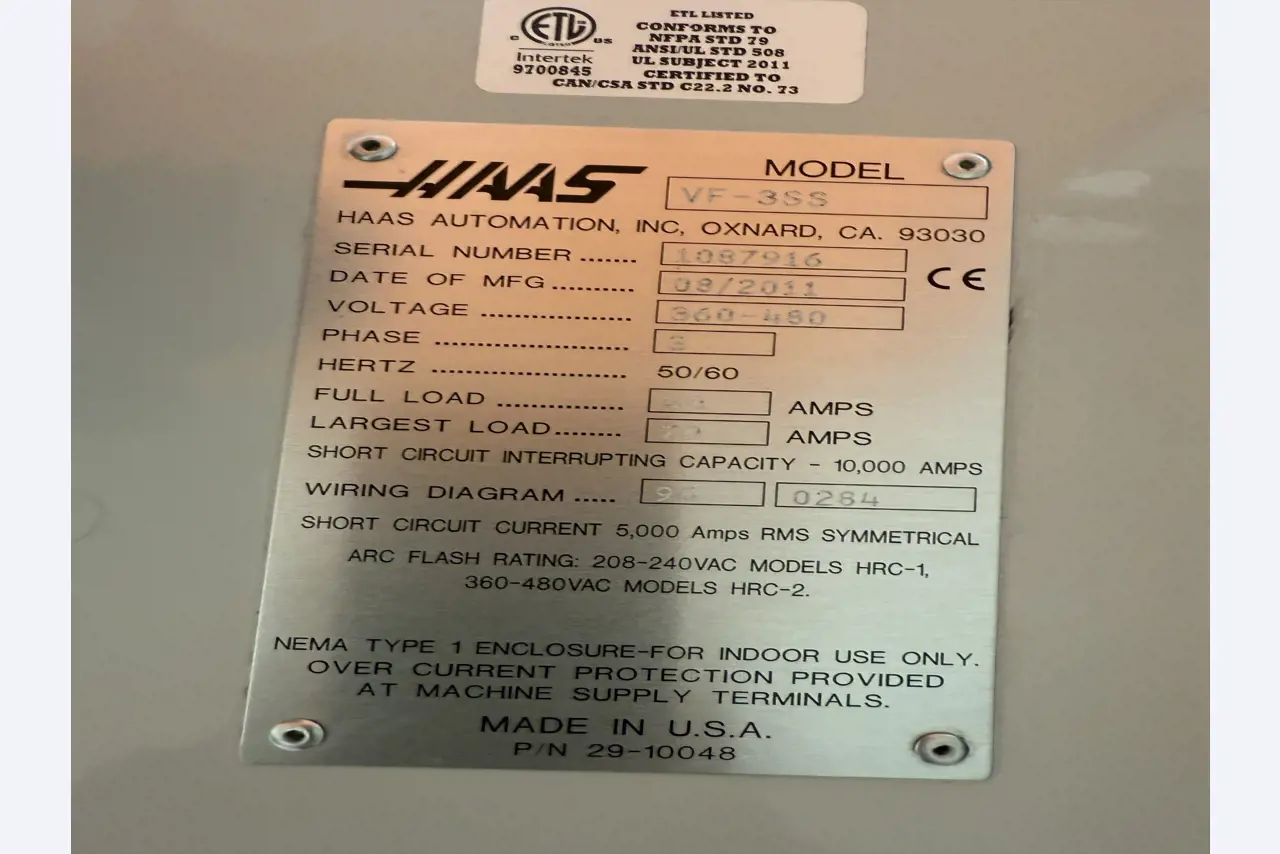

Serial number: 1087916

Operating voltage: 360 - 480 V

Frequency: 50 - 60 Hz

Rated current: 70 A

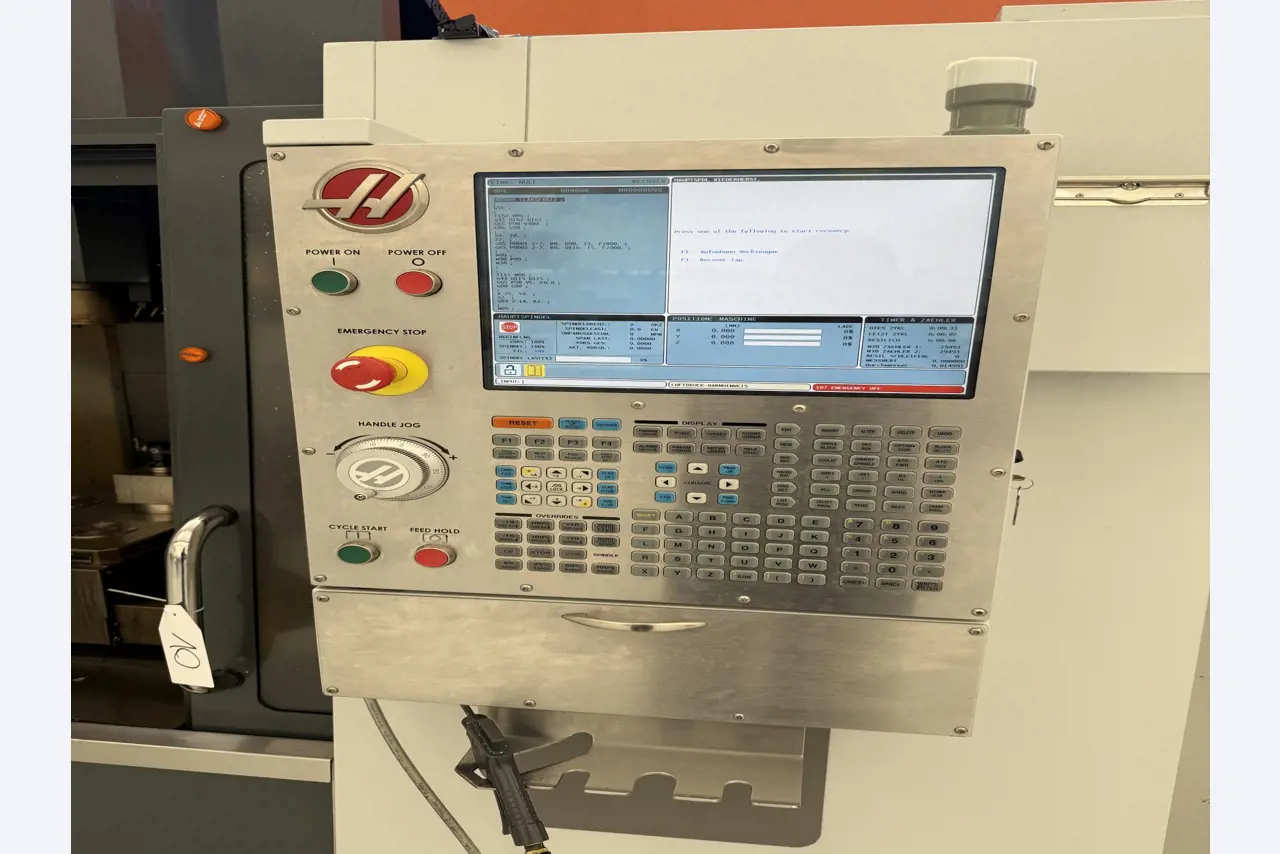

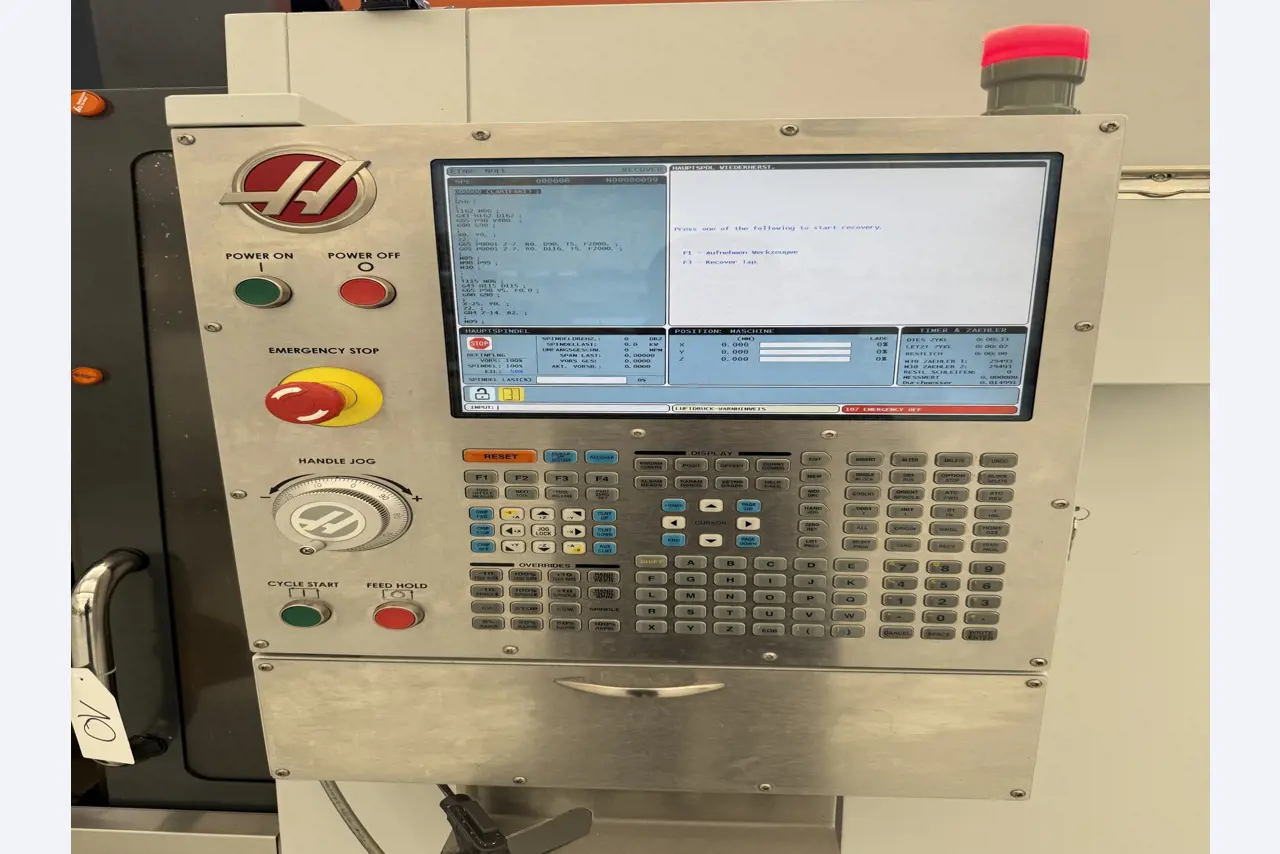

Control unit: HAAS

Table dimensions: 1,200 x 480 mm

With 5 pcs. grooves

Rapid traverse in X, Y, Z-axis: 35.6 MpM

Feed rates in all three axes: 21.2 MpM

Tool holder: SK 40

Travel distances: X: approx. 1,016 mm, Y: approx. 508 mm, Z: approx. 635 mm

Incl. tool changer with 24 plus 1 magazine slots

Plus 5 additional SK 40 tool holders

Spindle running time: 6,722 h

Spindle speed 12,000 rpm

Switch-on time: 3,802 min

Number of tool changes: 266,958

Servo/motor running time: 60,159 min

Motion time: 7,283 min

Spindle speed: 12,000 rpm

Rapid traverse: up to 1,400 ipm (35.6 MpM)

IKZ available, synchronized tapping, 55 gallon cooling system (208 liters) with continuous coolant supply

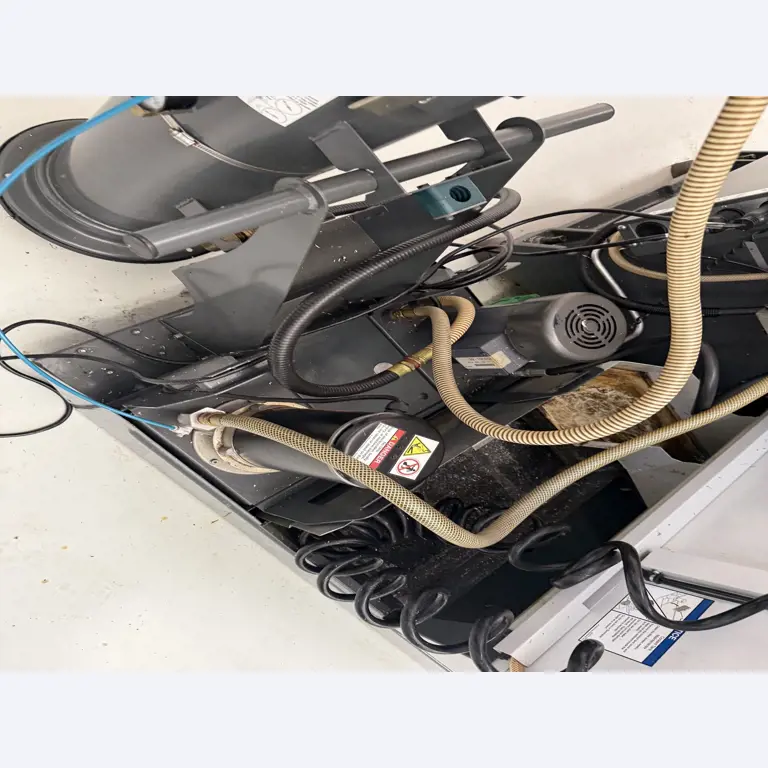

Incl. integrated chip conveyor, coolant system from the manufacturer HAAS

Attention: the clamping systems on the clamping surface are not included in the scope of delivery

Machine can be started up without problems and referencing of the axes is OK

Low battery alarm

Batteries are replaced

According to alarm memory error 134

Spring assembly measured Tightening force of the spindle is measured at 1000 lbs. n.i.O. Should be 1600 - 2300 lbs., possibly the reason for error 134 and from the valve terminal

Spindle speed running no loud noises, slight speed fluctuations, could be due to the encoder, belt and sprockets sprockets are worn due to age

Cambox oil present i.O.

Several tool changes carried out i.O.

Axles can be moved i.O.

Slight running noises from the axles

Wiper from the waycover worn due to age.

Grease lubrication of the axles clogged as the machine has been standing for a long time.

Coolant system could not be tested as no coolant was available.

Tightening force of spring assembly n.i.O.

Slight speed fluctuations could be due to the encoder, belts and sprockets are also worn.

Grease lubrication of the axles clogged.

Wipers worn out.

Disassembly costs: 600,- €

These are incurred if dismantling/loading or the use of dismantling/loading aids is required. The invoice will be settled between you and the service provider on site.

Serial number: 1087916

Operating voltage: 360 - 480 V

Frequency: 50 - 60 Hz

Rated current: 70 A

Control unit: HAAS

Table dimensions: 1,200 x 480 mm

With 5 pcs. grooves

Rapid traverse in X, Y, Z-axis: 35.6 MpM

Feed rates in all three axes: 21.2 MpM

Tool holder: SK 40

Travel distances: X: approx. 1,016 mm, Y: approx. 508 mm, Z: approx. 635 mm

Incl. tool changer with 24 plus 1 magazine slots

Plus 5 additional SK 40 tool holders

Spindle running time: 6,722 h

Spindle speed 12,000 rpm

Switch-on time: 3,802 min

Number of tool changes: 266,958

Servo/motor running time: 60,159 min

Motion time: 7,283 min

Spindle speed: 12,000 rpm

Rapid traverse: up to 1,400 ipm (35.6 MpM)

IKZ available, synchronized tapping, 55 gallon cooling system (208 liters) with continuous coolant supply

Incl. integrated chip conveyor, coolant system from the manufacturer HAAS

Attention: the clamping systems on the clamping surface are not included in the scope of delivery

Machine can be started up without problems and referencing of the axes is OK

Low battery alarm

Batteries are replaced

According to alarm memory error 134

Spring assembly measured Tightening force of the spindle is measured at 1000 lbs. n.i.O. Should be 1600 - 2300 lbs., possibly the reason for error 134 and from the valve terminal

Spindle speed running no loud noises, slight speed fluctuations, could be due to the encoder, belt and sprockets sprockets are worn due to age

Cambox oil present i.O.

Several tool changes carried out i.O.

Axles can be moved i.O.

Slight running noises from the axles

Wiper from the waycover worn due to age.

Grease lubrication of the axles clogged as the machine has been standing for a long time.

Coolant system could not be tested as no coolant was available.

Tightening force of spring assembly n.i.O.

Slight speed fluctuations could be due to the encoder, belts and sprockets are also worn.

Grease lubrication of the axles clogged.

Wipers worn out.

Disassembly costs: 600,- €

These are incurred if dismantling/loading or the use of dismantling/loading aids is required. The invoice will be settled between you and the service provider on site.

Location

- 73642 Welzheim

Dates

Inspection

Please register in advance at lau@netbid.com

Pickup

Tue, 17.06.2025 - Fri, 20.06.2025

09:00 - 16:00

Tue, 17.06.2025 - Thu, 19.06.2025

08:00 - 15:00

Loading of the machines is only possible on these days after prior arrangement. Please refer to the corresponding items for the respective prices.

Tue, 17.06.2025 - Thu, 19.06.2025

08:00 - 15:00

A loading of the machines is only possible on these days by prior arrangement. the respective prices can be found in the corresponding items

Auction Terms

Sale only to traders/dealers!

Highest bidder/ auction winner is requested to submit a copy of the business registration within 3 working days, otherwise the knockdown is considered canceled.

Any warranty/regulation in relation to this offer is expressly excluded.

The seller is also not liable for claims for damages - regardless of the legal basis; however, this does not apply to claims for damages arising from grossly negligent or intentional breach of obligations by the seller or its vicarious agents or for injury to life, limb and health or essential contractual obligations.

Highest bidder/ auction winner is requested to submit a copy of the business registration within 3 working days, otherwise the knockdown is considered canceled.

Any warranty/regulation in relation to this offer is expressly excluded.

The seller is also not liable for claims for damages - regardless of the legal basis; however, this does not apply to claims for damages arising from grossly negligent or intentional breach of obligations by the seller or its vicarious agents or for injury to life, limb and health or essential contractual obligations.

Contact Person

Auction Coordination Assistant

Christopher Lau

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com