Part of the Auction Sale of the complete roll forming line

Roll forming line PROFIILIKESKUSTrading#18702-1

Details

Product Type

PROFIILIKESKUS

Construction Year

2008

Description

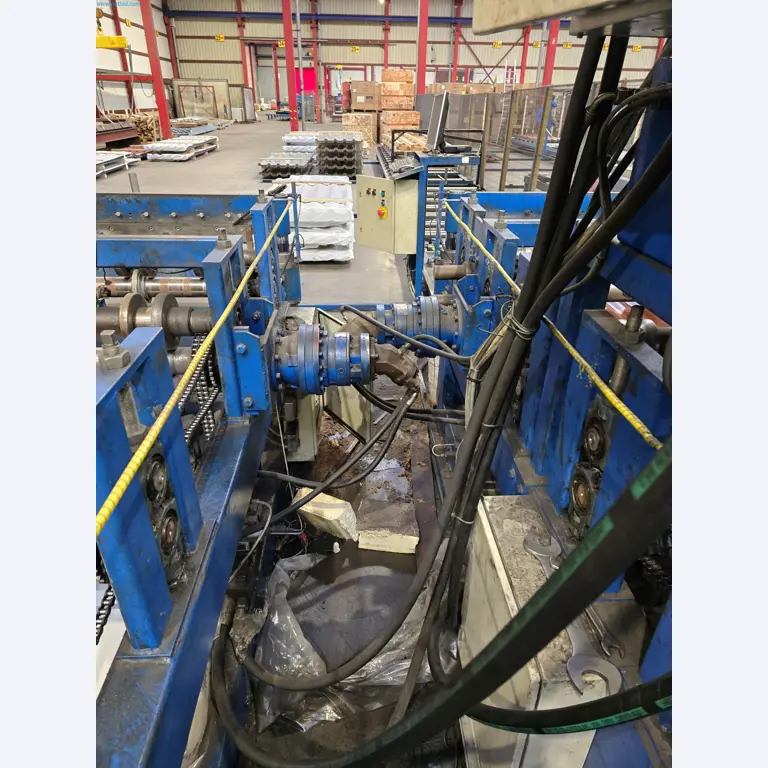

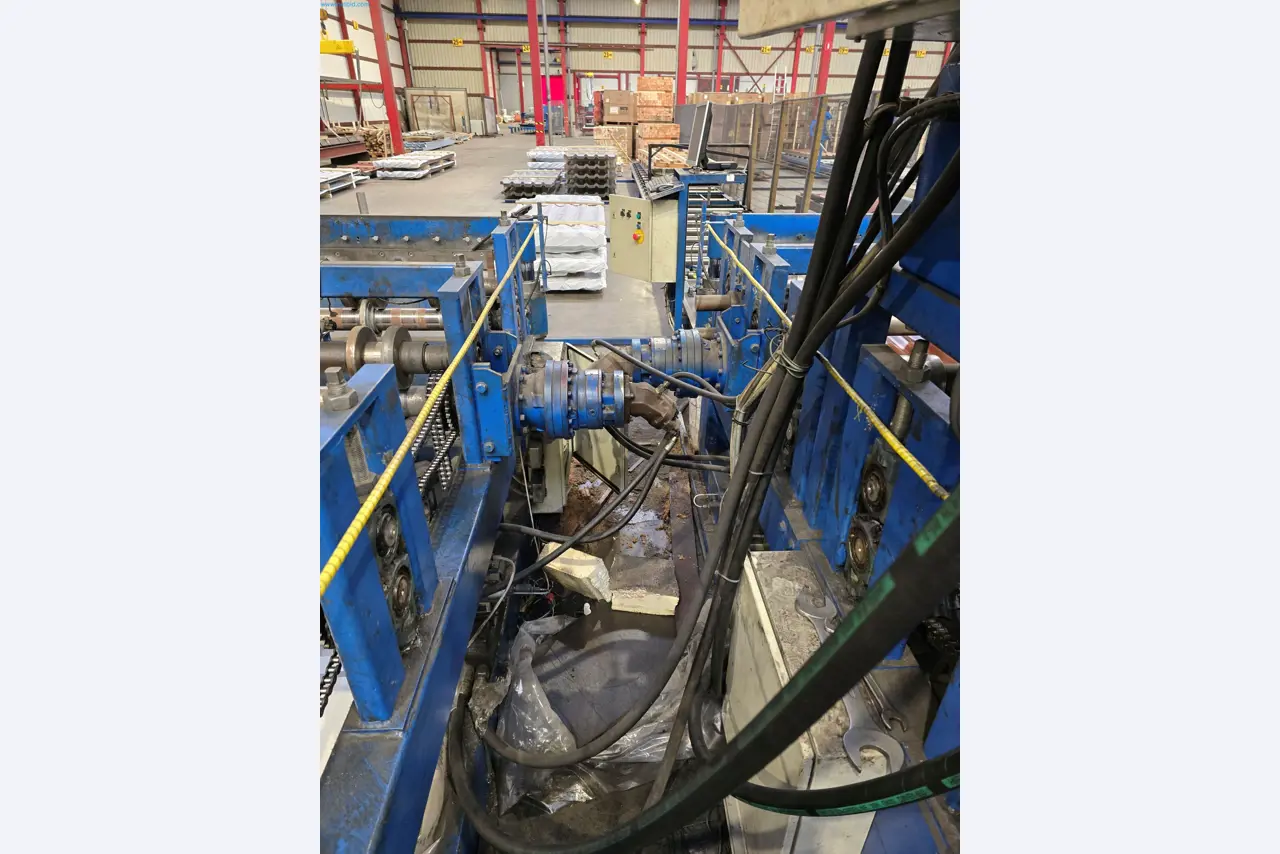

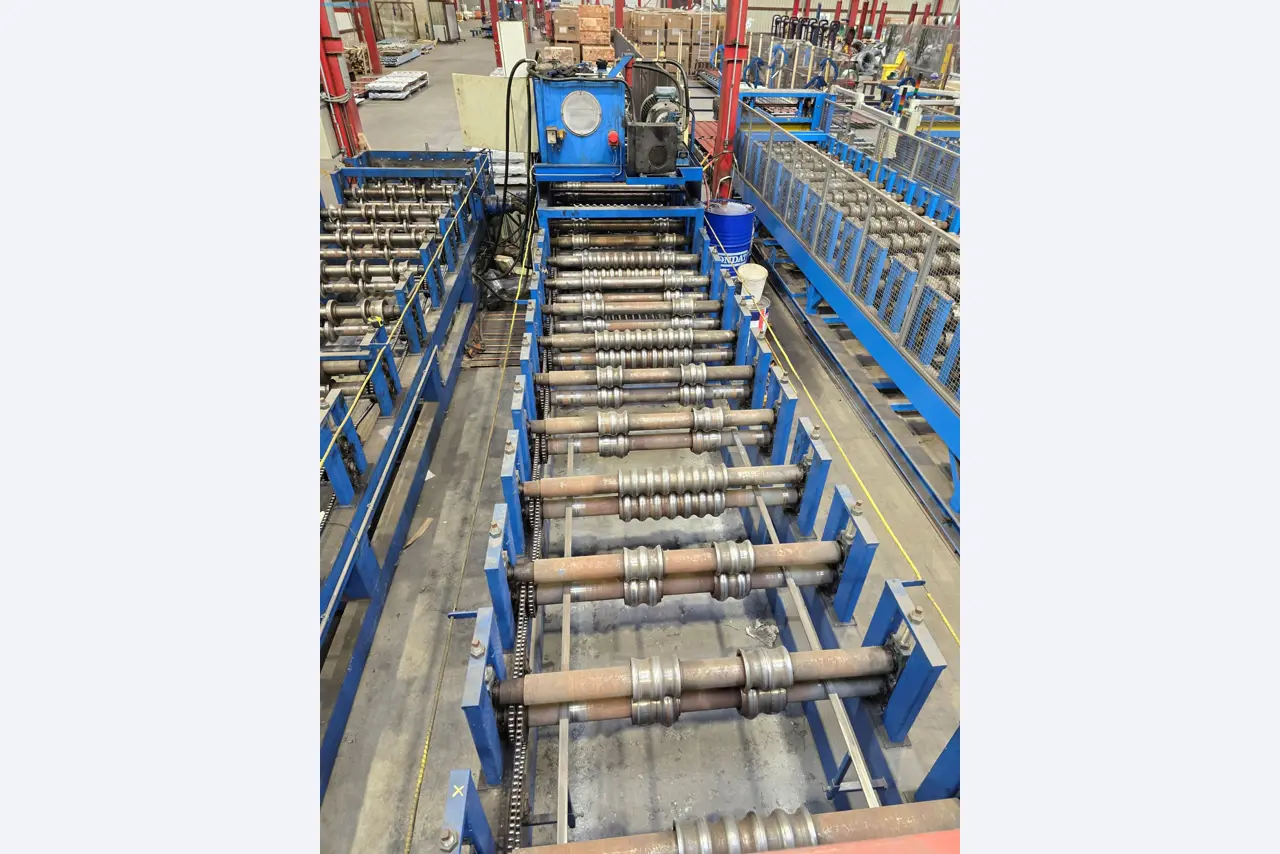

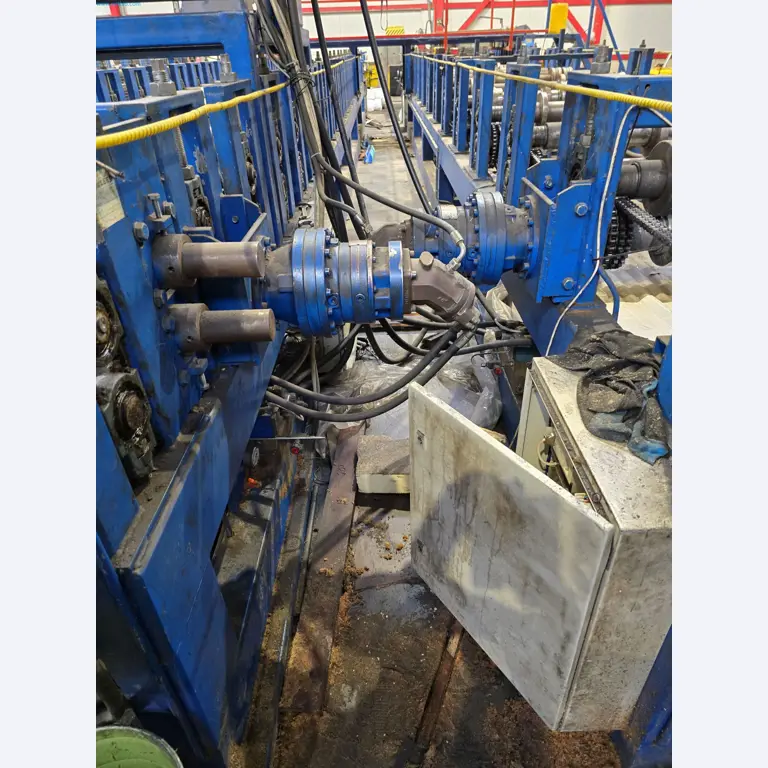

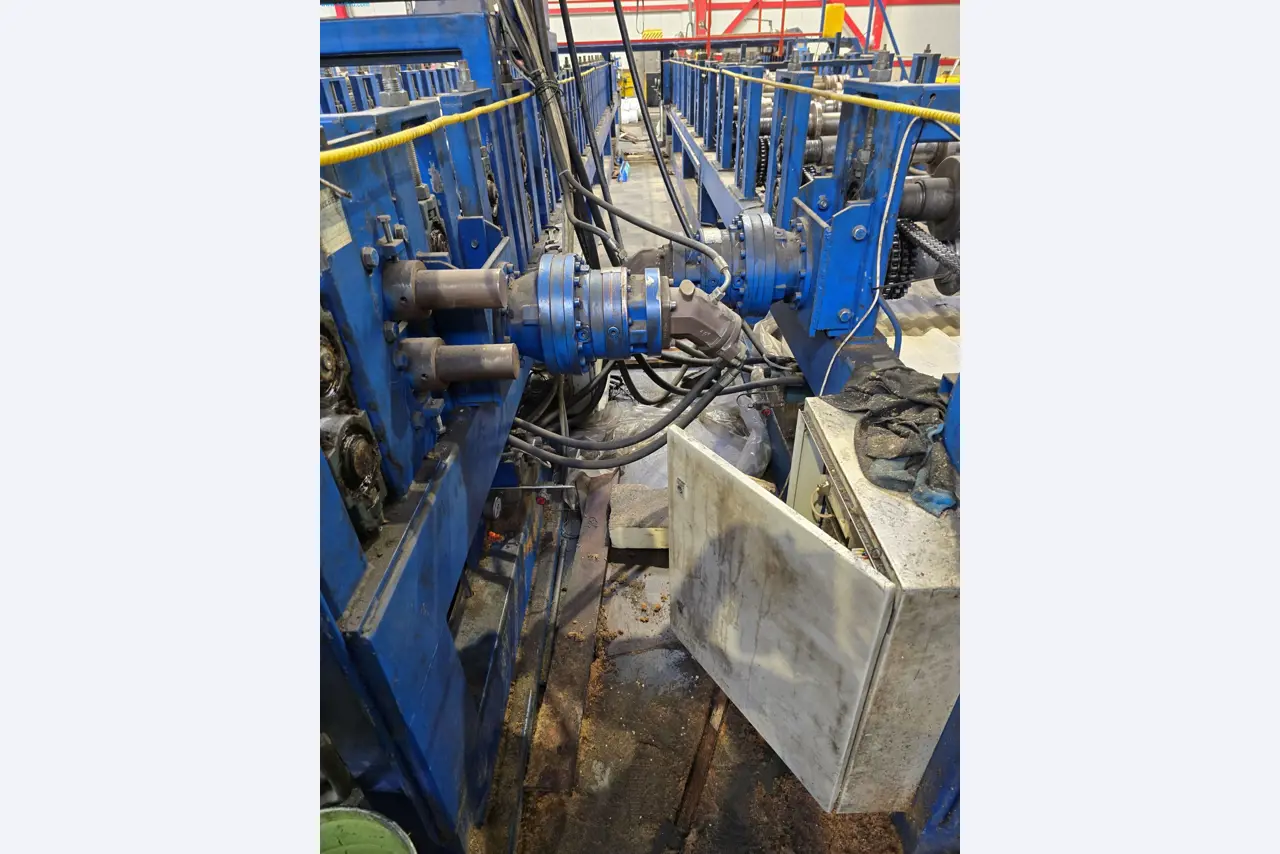

Unique opportunity for a complete roll forming line installation composed of two main roll formers (referenced as being nr A and Nr B):

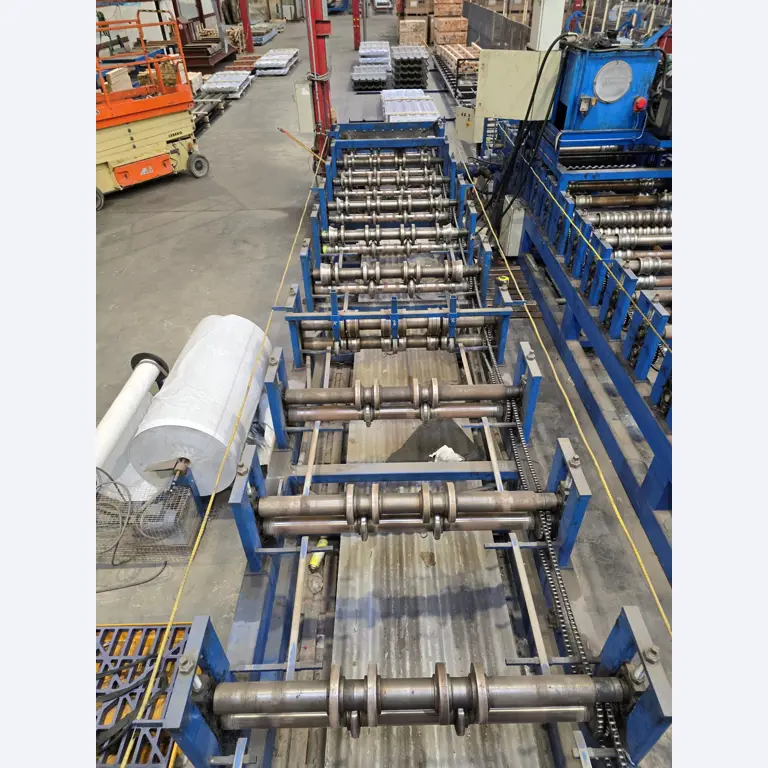

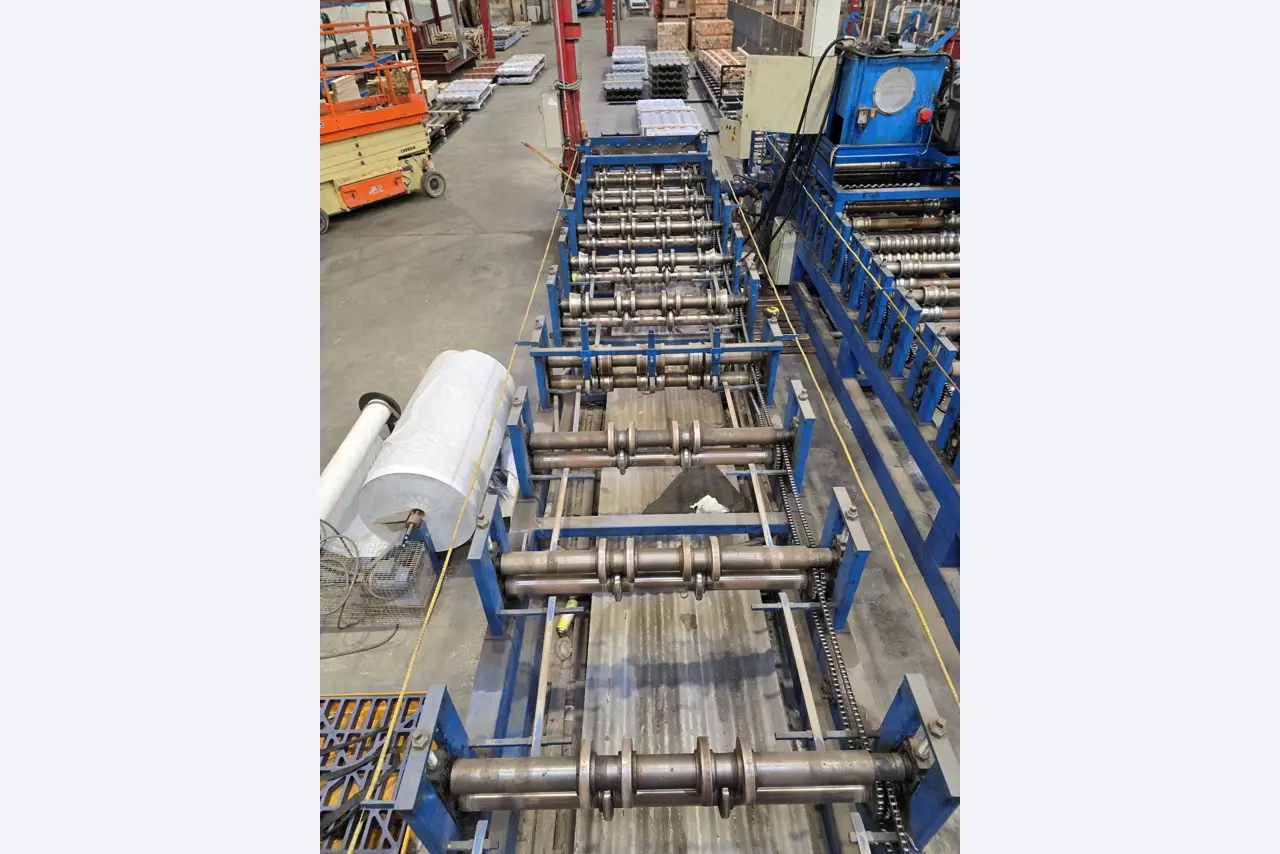

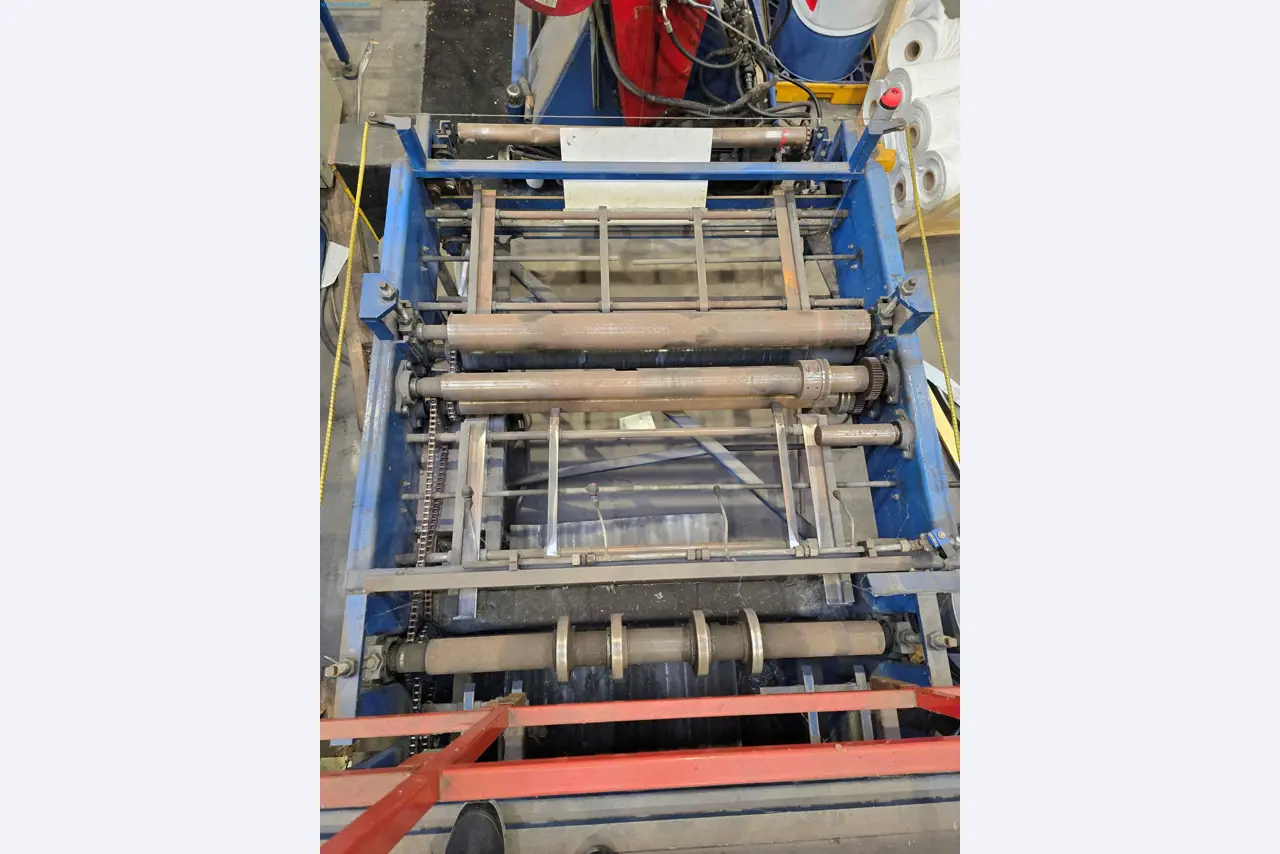

Machine A for making a profile type 18.76.988 (= height 18 mm, center distance between two waves: 76 mm, material thickness: 0.4 to 0.8 mm) with coil width of 1250 mm, finished product of 1064 mm and with coil width of 1000 mm, finished product of 836 mm

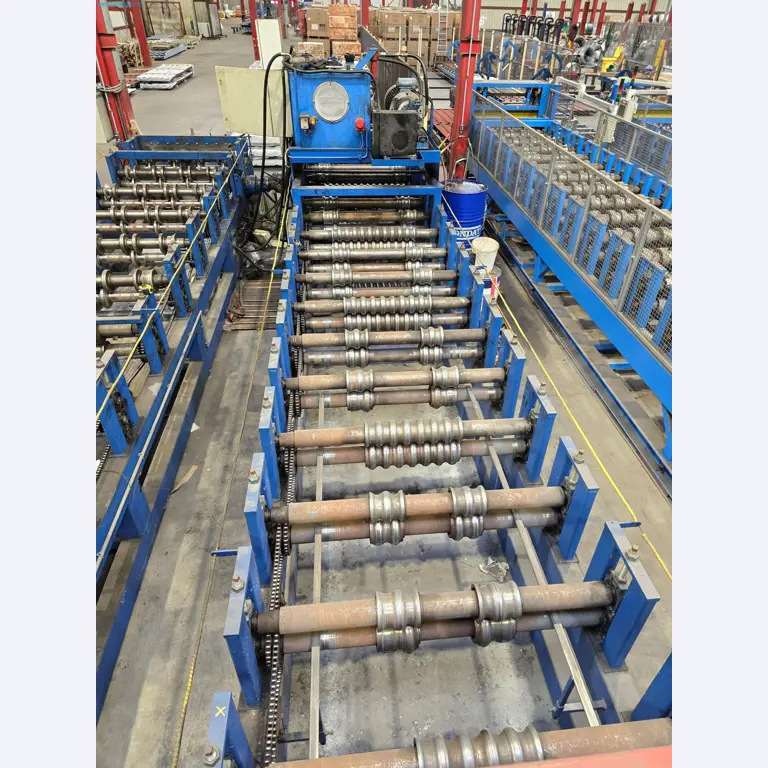

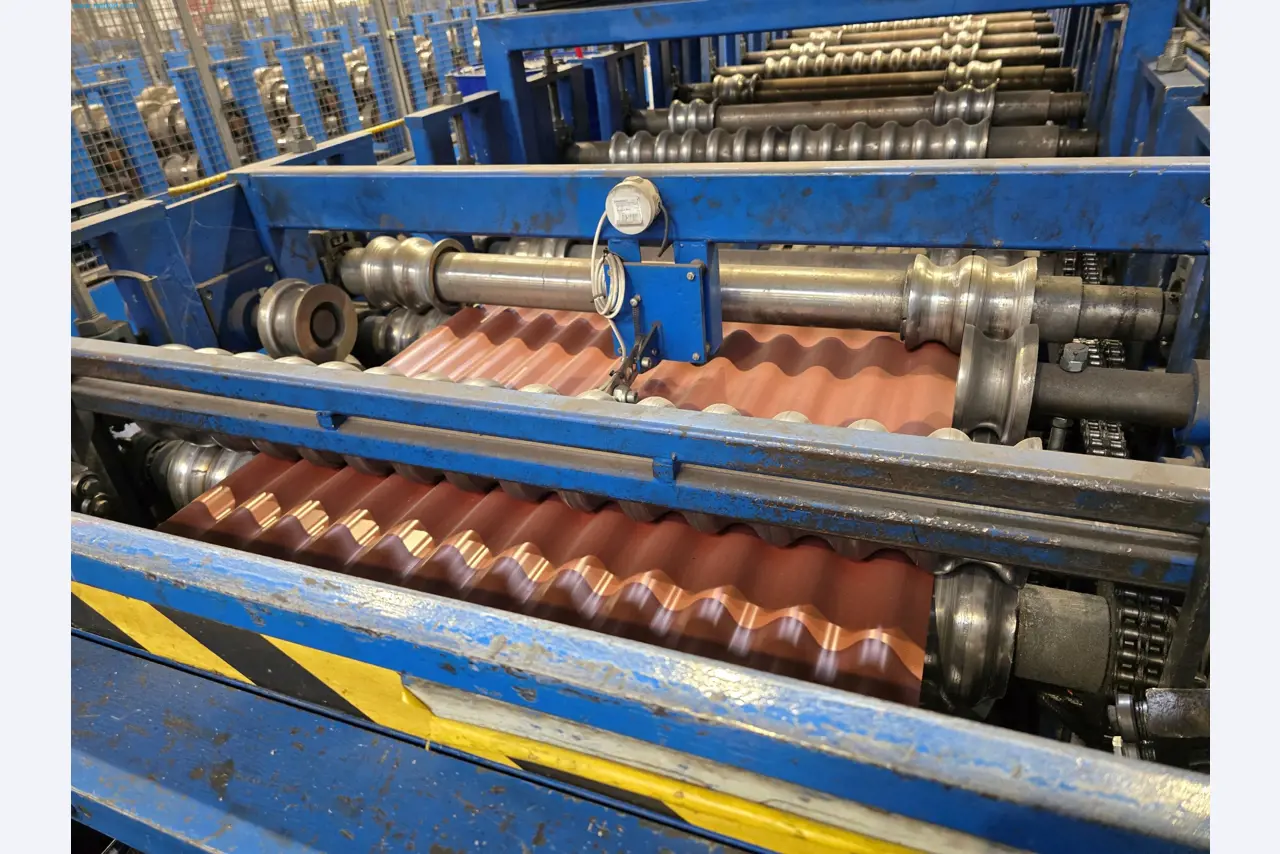

Machine B for making a profile type 45.333.1000 (=height 45 mm, center distance between two trapeze: 333 mm, material thickness 0.4 to 0.8 mm) with coil width of 1250 mm or 1220 mm , finished product of 1000 mm

remark: profile A suitable for roof but profile B suitable for roofing and vertical cladding.

Yom: 2001 for the machines and 2008 for the strip recoiler

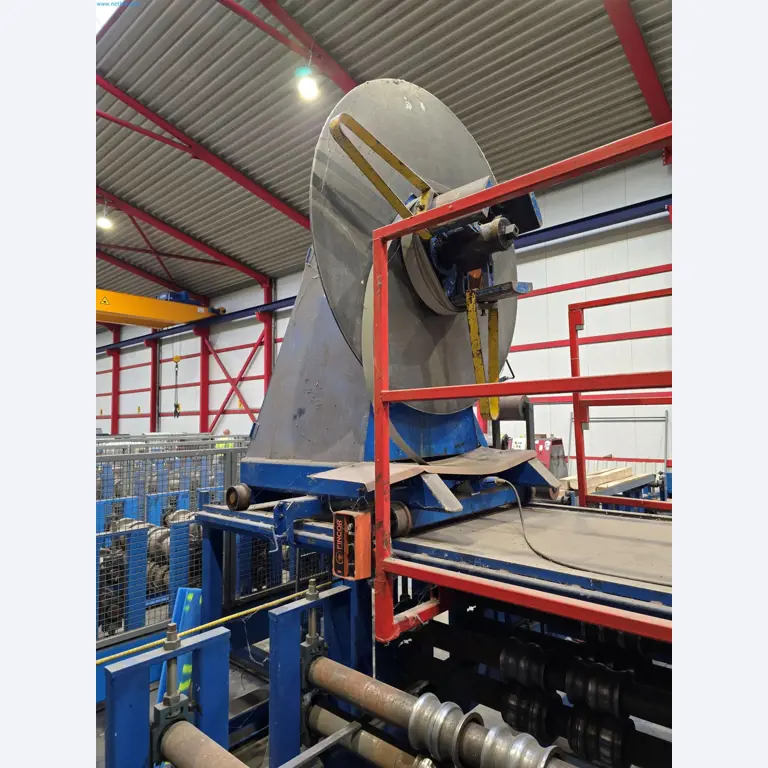

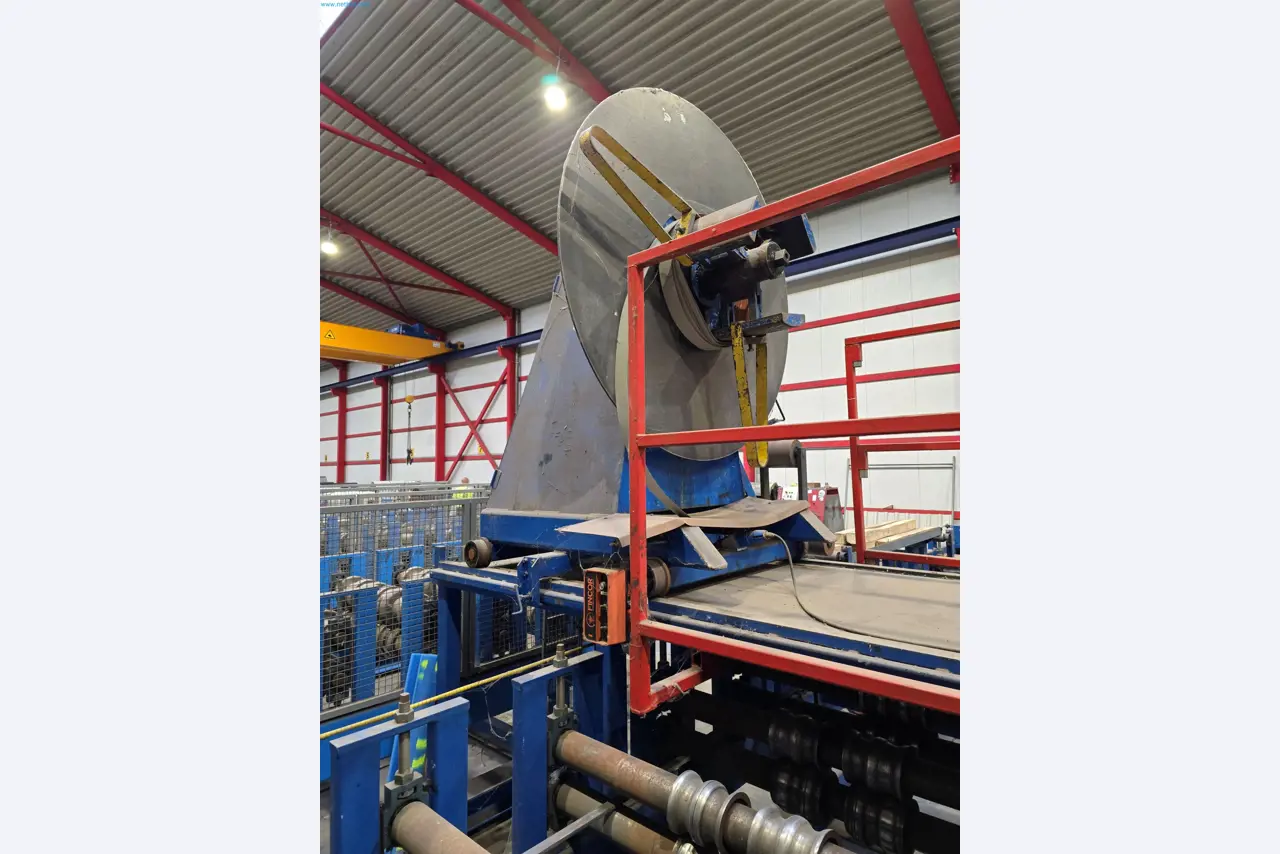

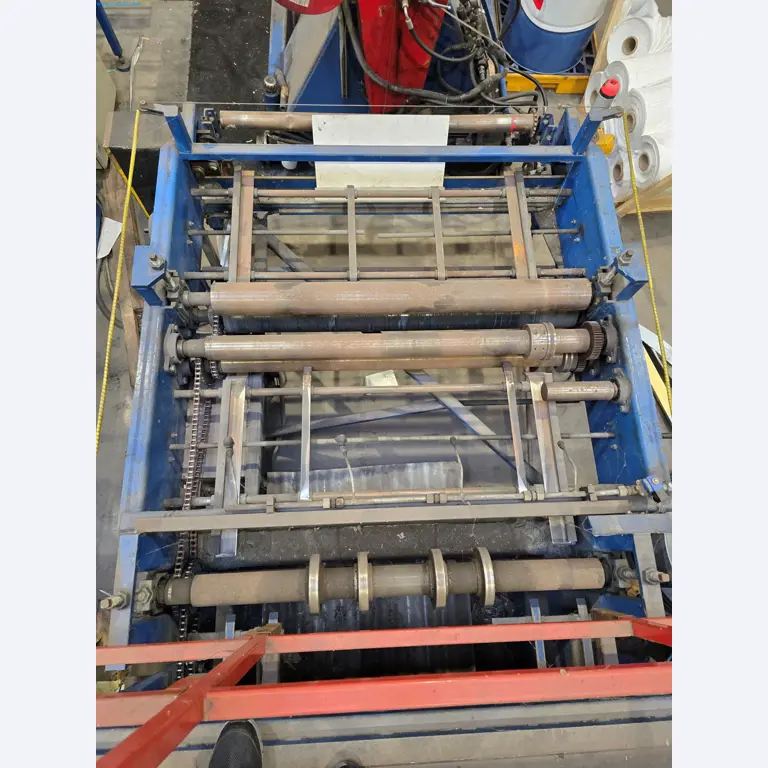

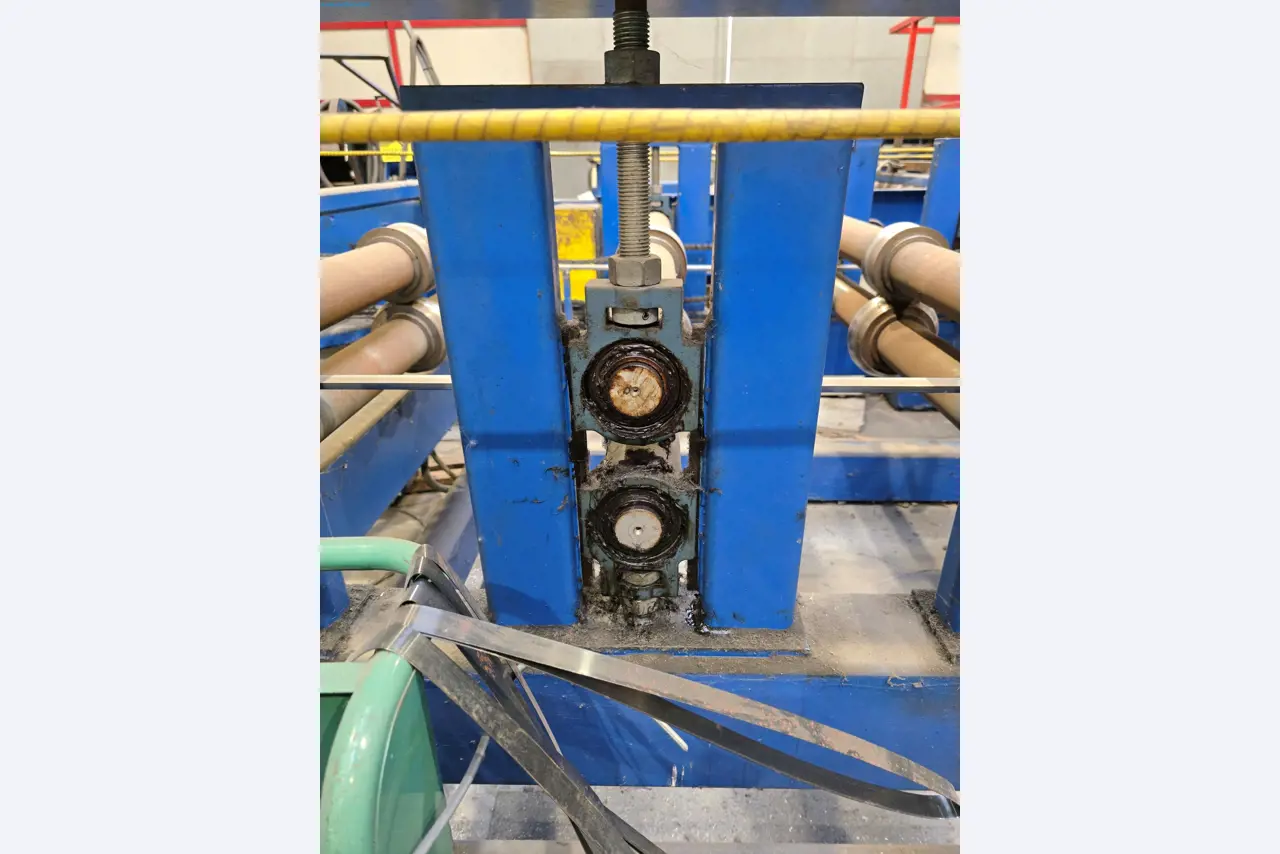

Both roll formers A and B are equipped with one slitting head and one recoiler can be displaced whether above A rollformer or B Rollformer , this is a definitive advantage as it makes possible to process non standard sheet material width.

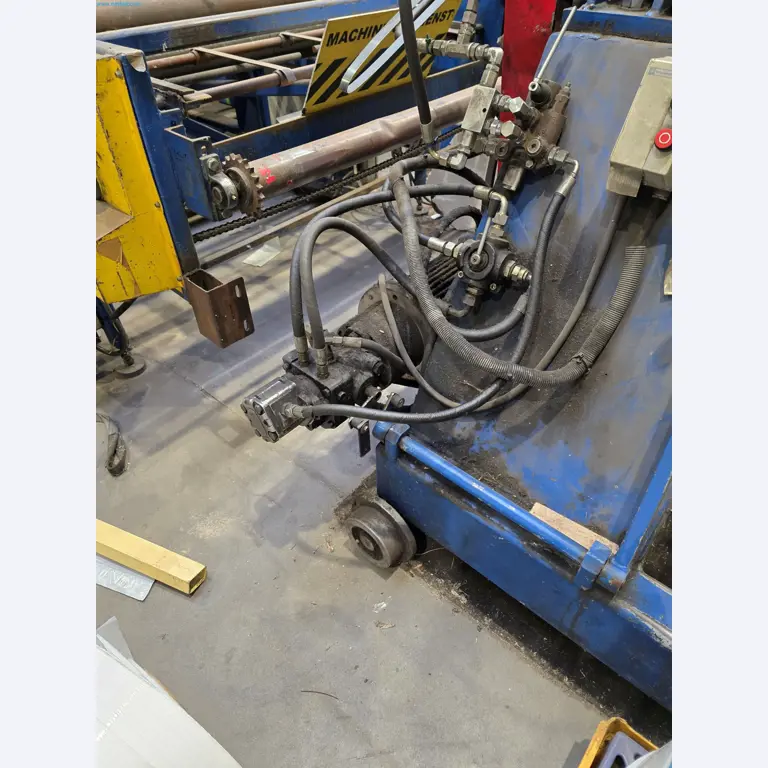

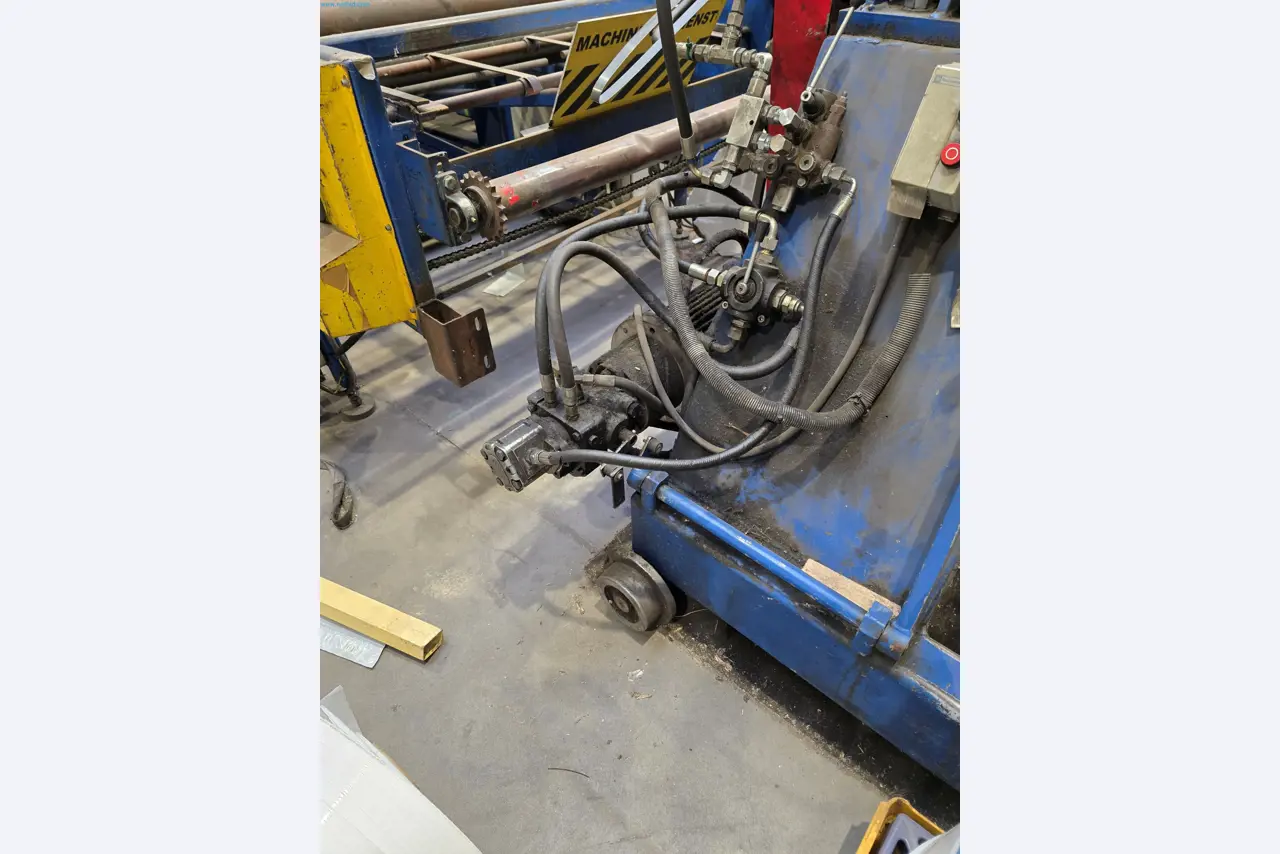

Motors: rollformers and decoilers are operated with hydraulic motors, one central hydraulic unit feeds both line

Scope of supply:

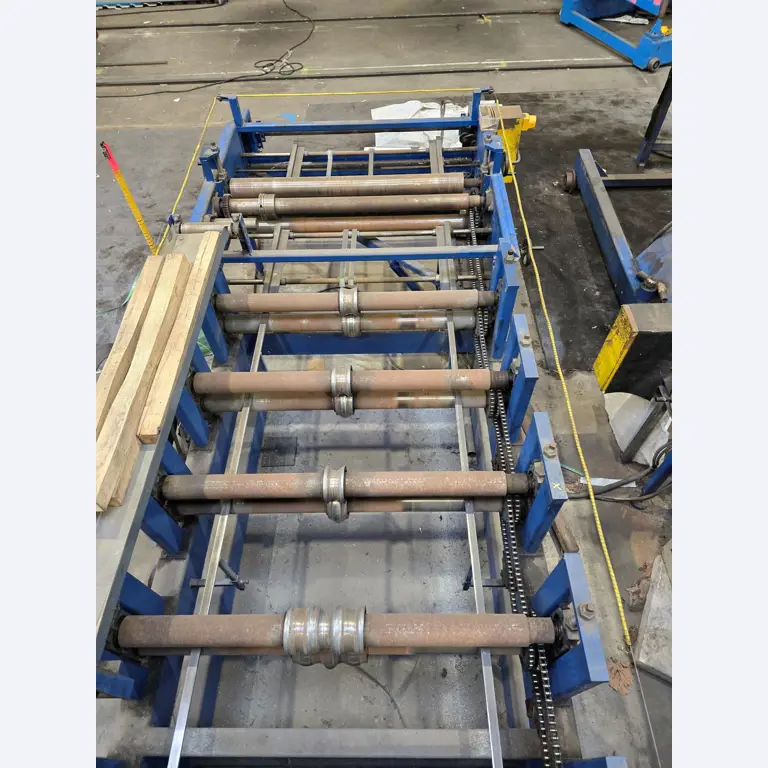

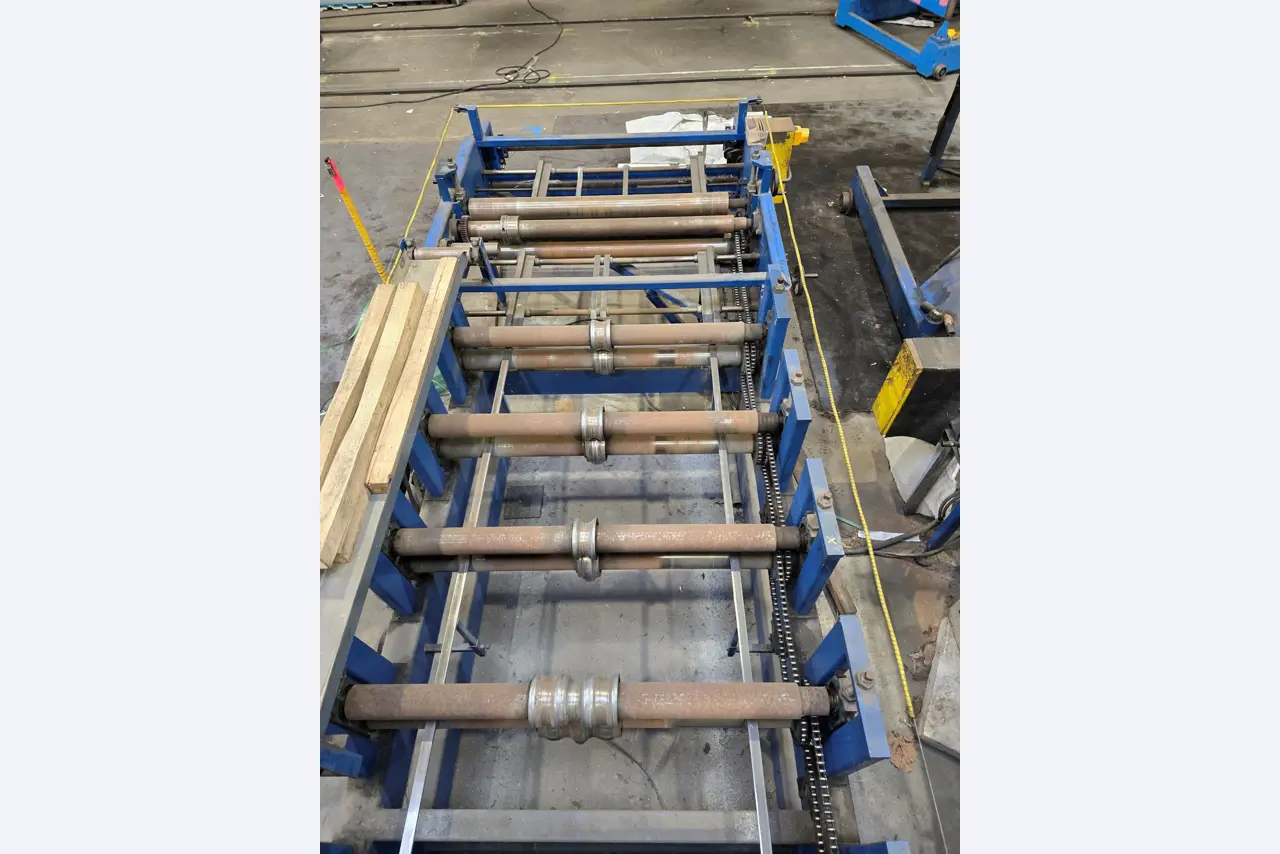

Rollformer type A

Rollformer Type B

Recoiler for the slit material

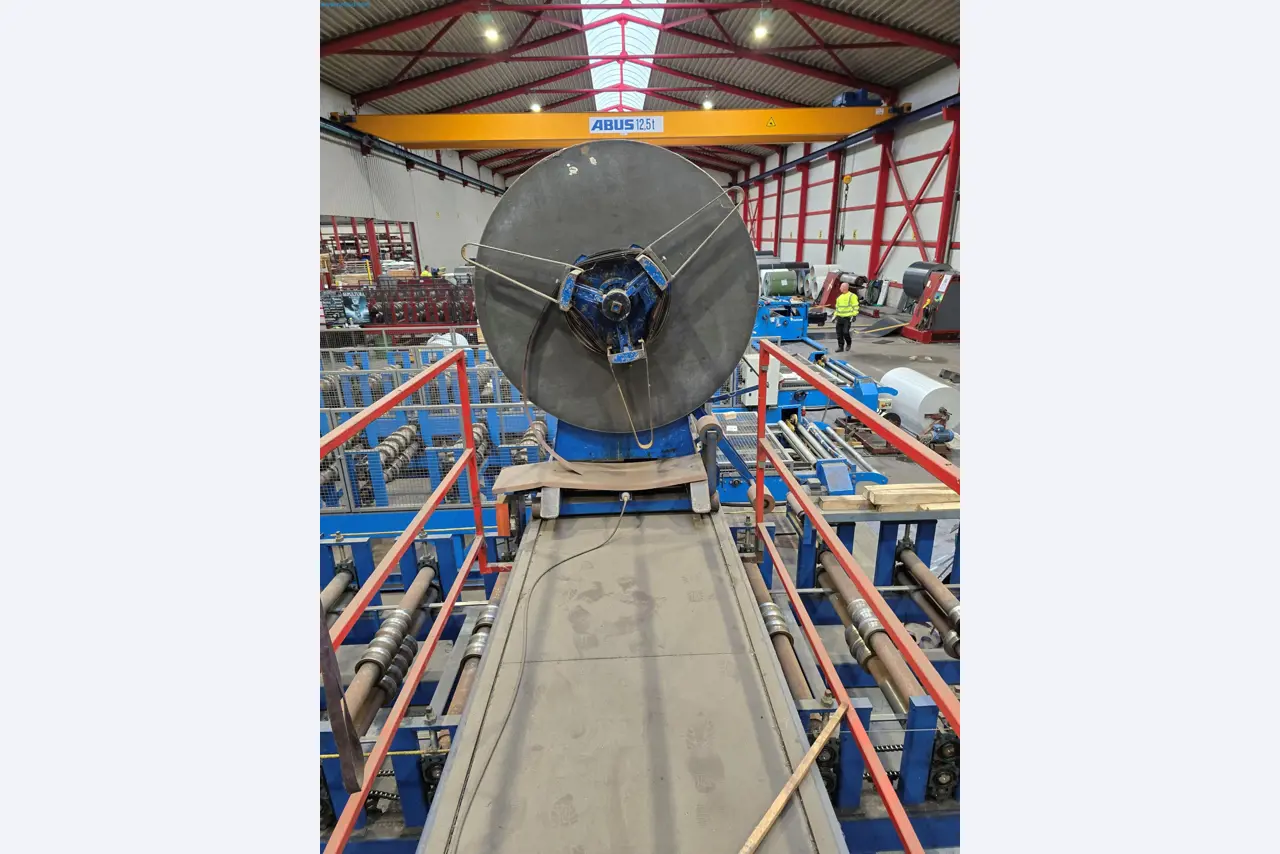

Decoiler 15 tons

Decoiler: 7 tons

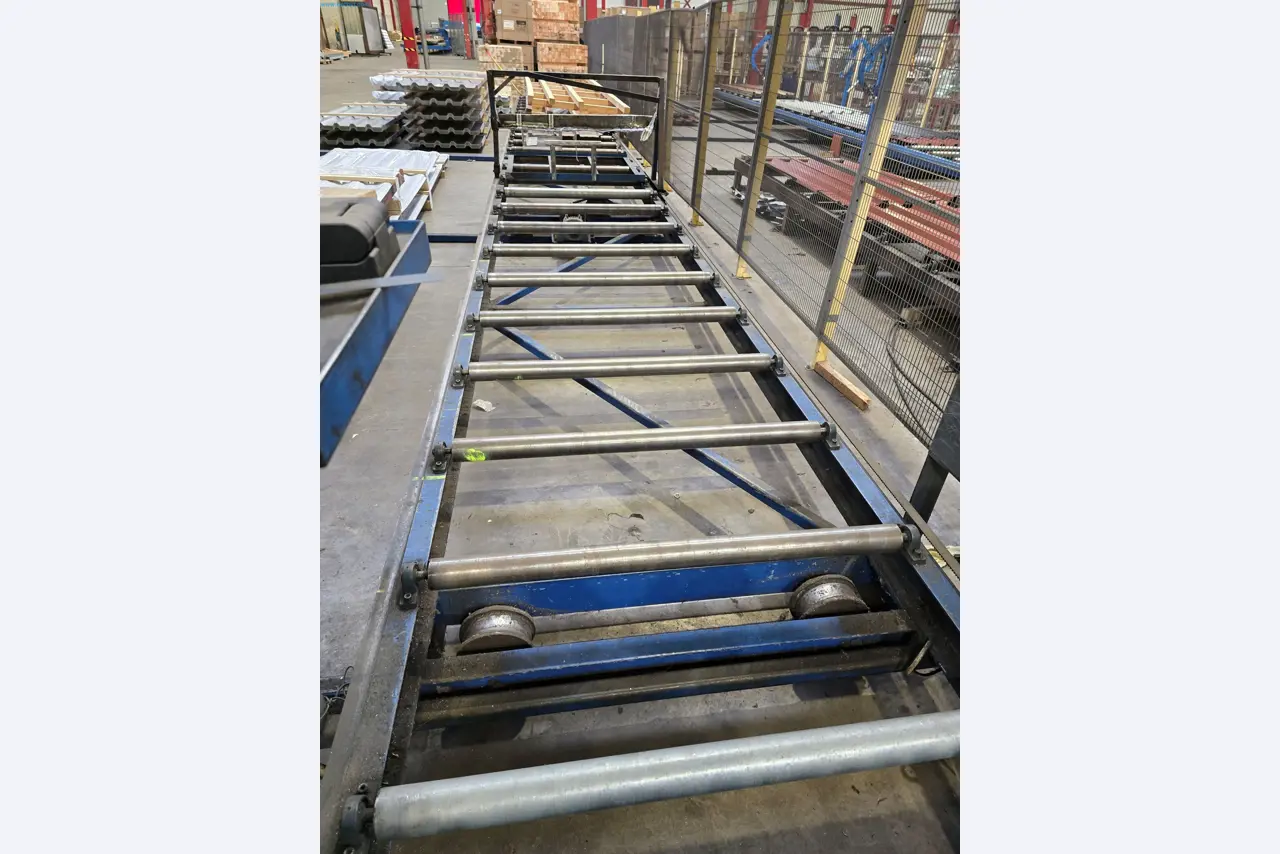

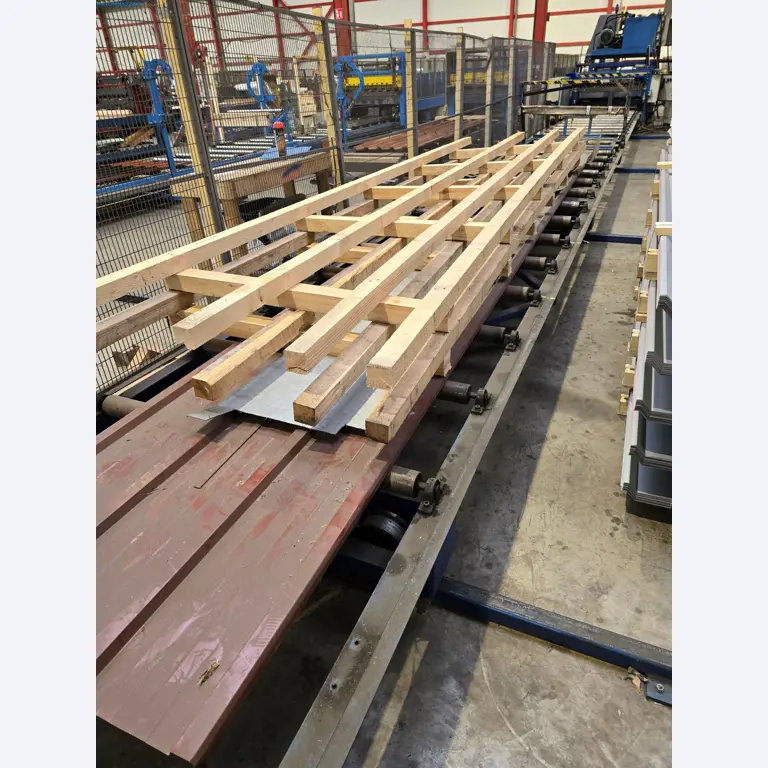

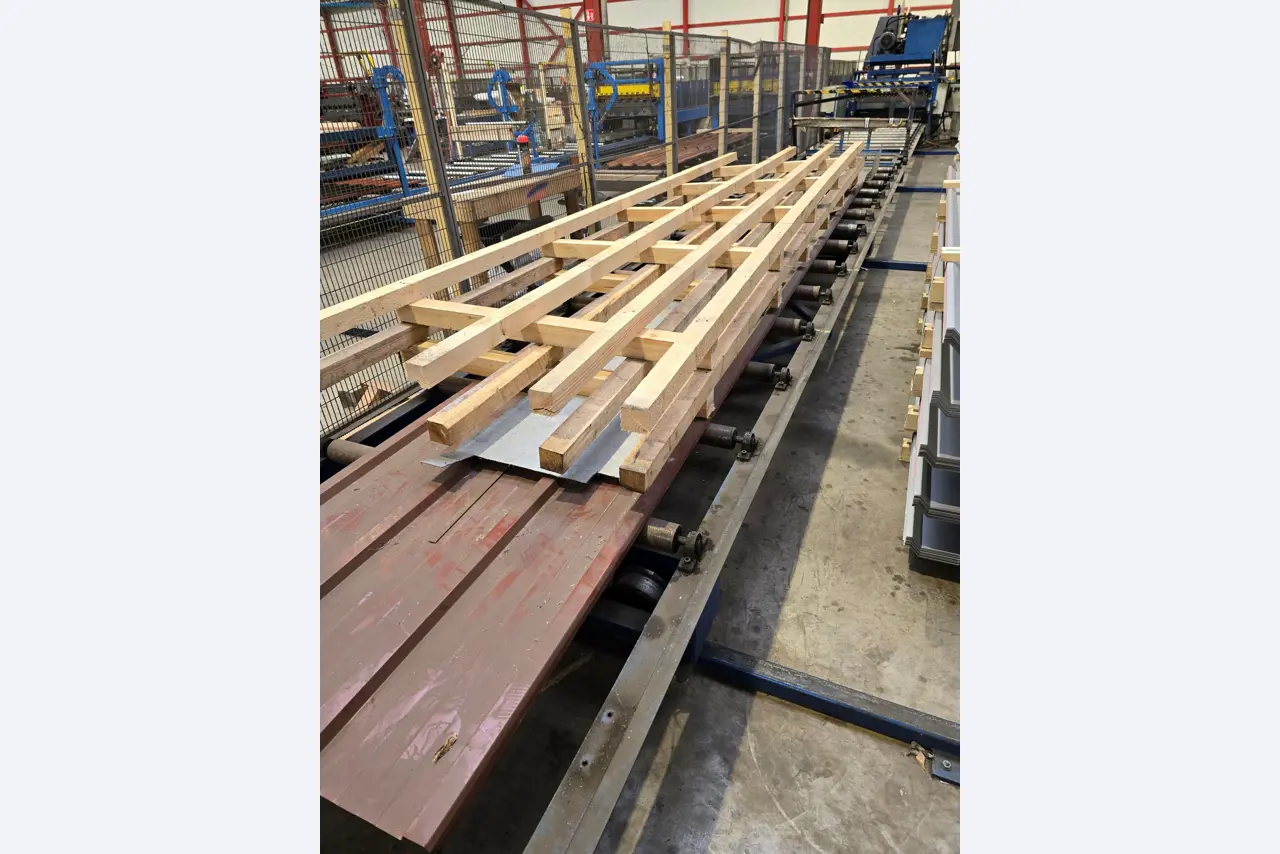

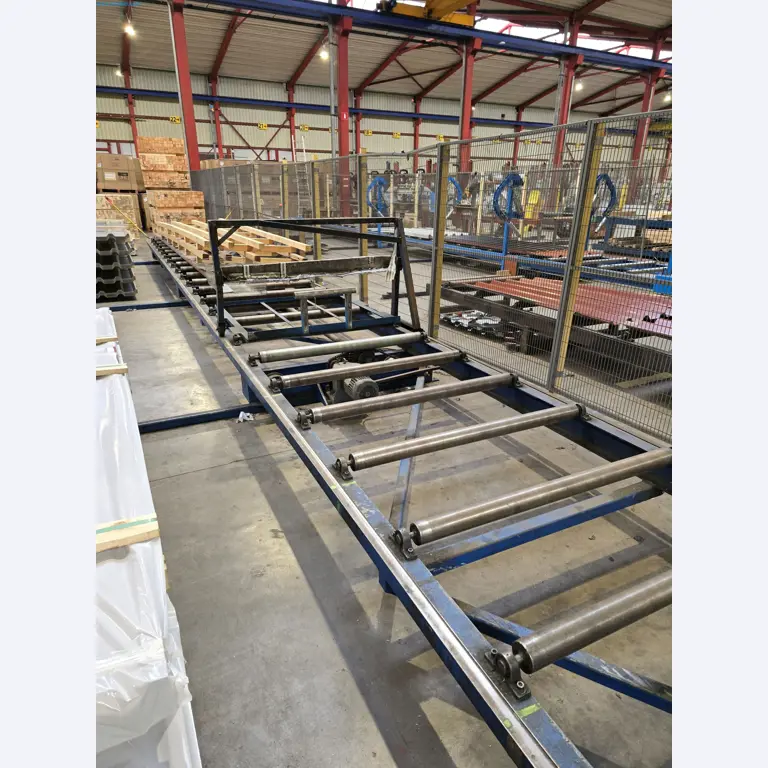

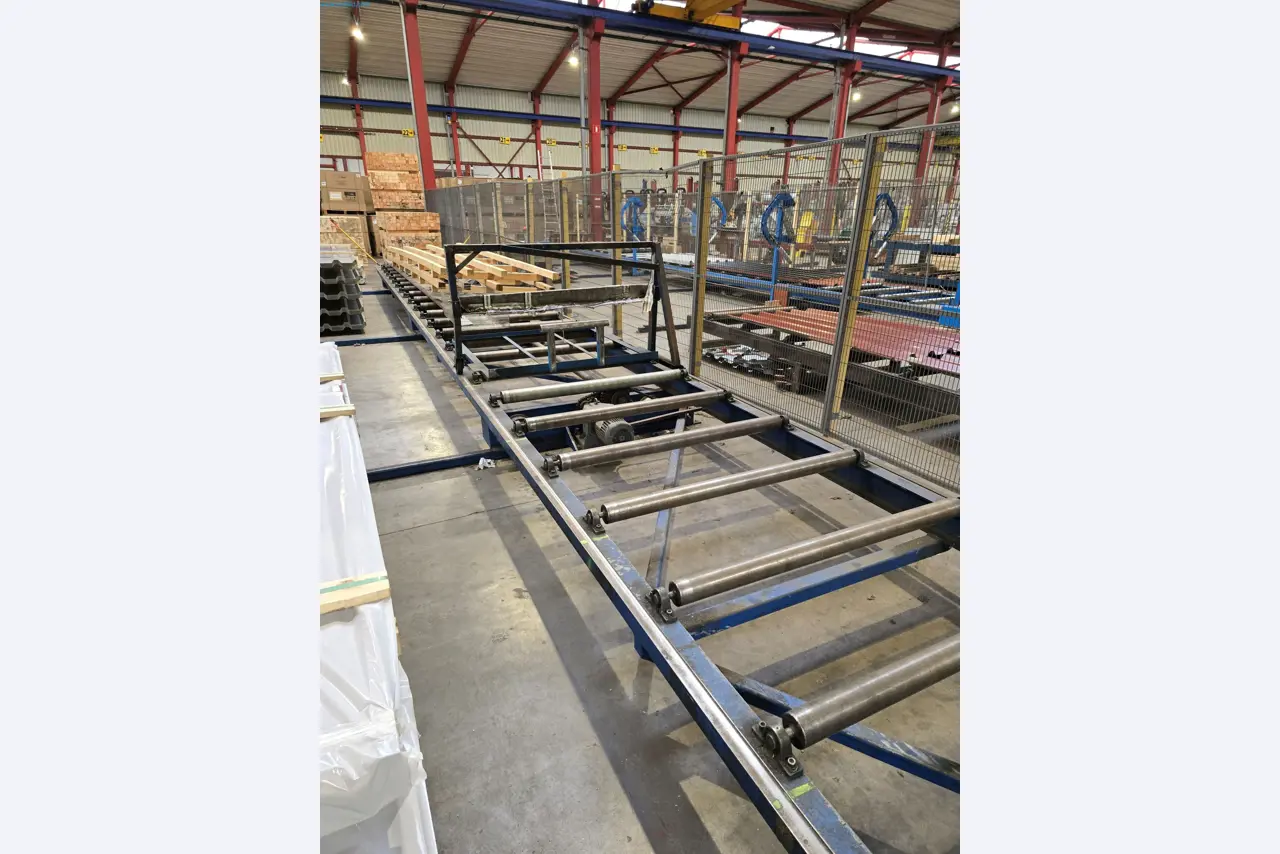

One stacking table (max length of profile is 14 meters) , the table can be used for rollformer A or B

Ground floor space required for the whole installation: approx 30-35 meters length x 5- 6 meters width

Price including dismantling and loading on trucks. Shipping: 3 complete trucks required.

Machine A for making a profile type 18.76.988 (= height 18 mm, center distance between two waves: 76 mm, material thickness: 0.4 to 0.8 mm) with coil width of 1250 mm, finished product of 1064 mm and with coil width of 1000 mm, finished product of 836 mm

Machine B for making a profile type 45.333.1000 (=height 45 mm, center distance between two trapeze: 333 mm, material thickness 0.4 to 0.8 mm) with coil width of 1250 mm or 1220 mm , finished product of 1000 mm

remark: profile A suitable for roof but profile B suitable for roofing and vertical cladding.

Yom: 2001 for the machines and 2008 for the strip recoiler

Both roll formers A and B are equipped with one slitting head and one recoiler can be displaced whether above A rollformer or B Rollformer , this is a definitive advantage as it makes possible to process non standard sheet material width.

Motors: rollformers and decoilers are operated with hydraulic motors, one central hydraulic unit feeds both line

Scope of supply:

Rollformer type A

Rollformer Type B

Recoiler for the slit material

Decoiler 15 tons

Decoiler: 7 tons

One stacking table (max length of profile is 14 meters) , the table can be used for rollformer A or B

Ground floor space required for the whole installation: approx 30-35 meters length x 5- 6 meters width

Price including dismantling and loading on trucks. Shipping: 3 complete trucks required.

Location

- 8680 Koekelare, Belgium

Dates

Inspection

Visits are possible by prior arrangement at devrouw-reyntjens@netbid.com.

Pickup

Collection is possible by prior arrangement at devrouw-reyntjens@netbid.com.

Auction Terms

Special conditions:

- Reserve price includes dismantling and loading on trucks.

- Reserve price includes dismantling and loading on trucks.

Contact Person

Country Manager Benelux & France

Alexandra Devrouw-Reyntjens

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com