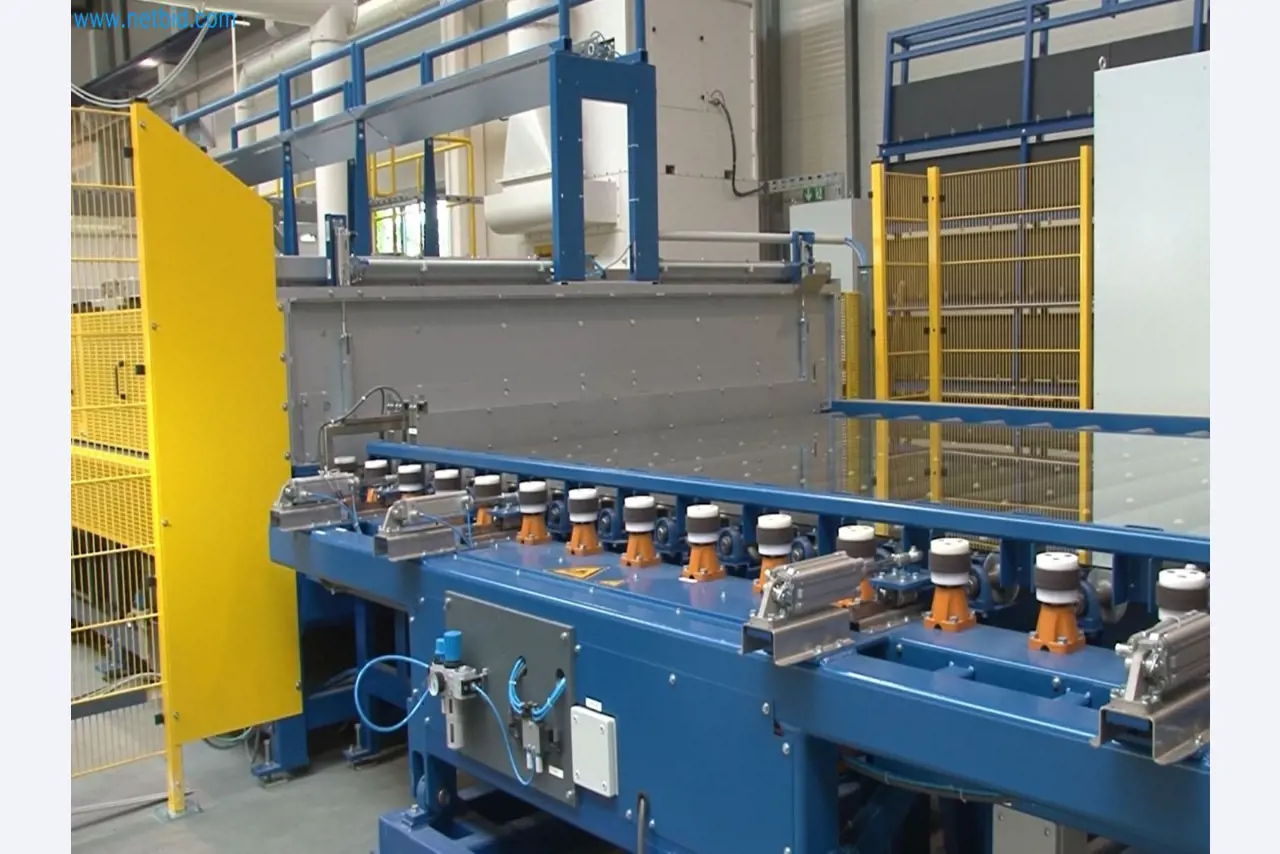

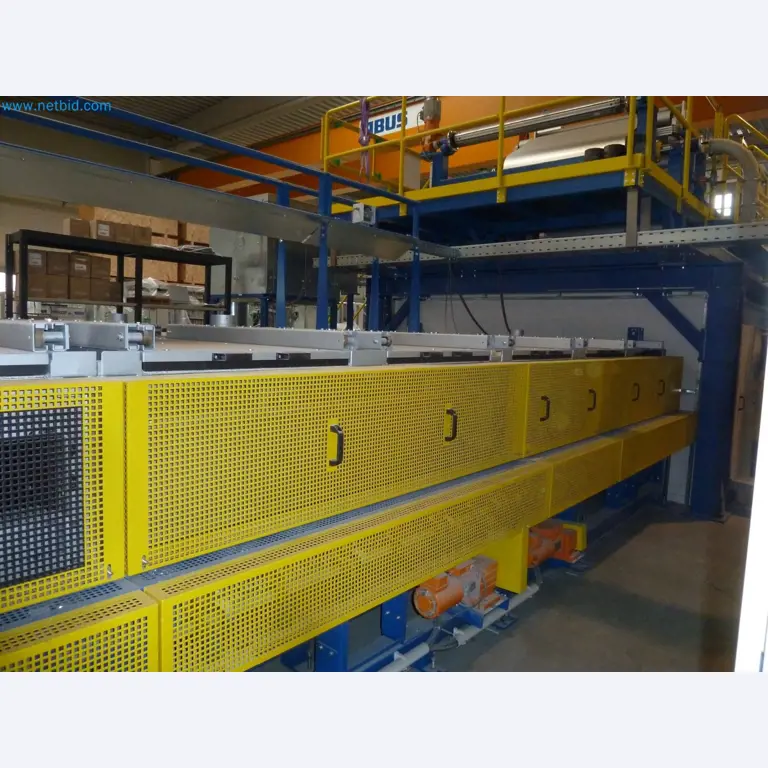

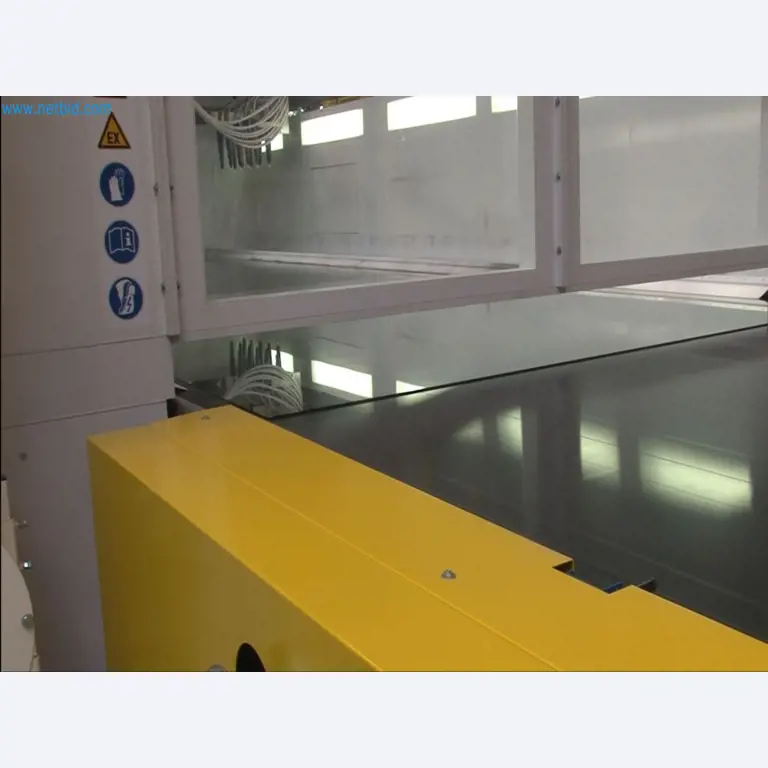

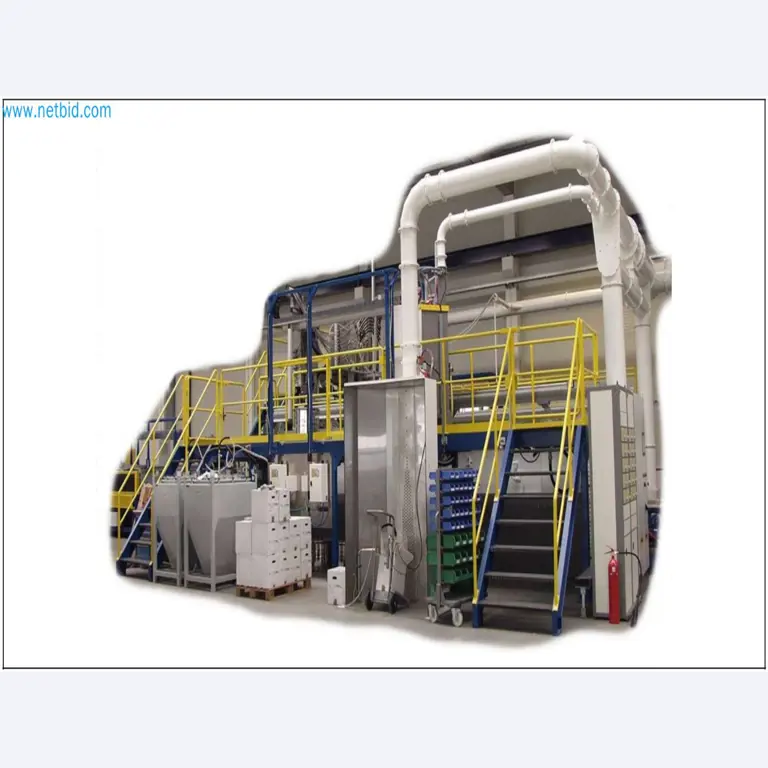

Part of the Auction Sale of a powder coating line! Like NEW! (Showroom machine)

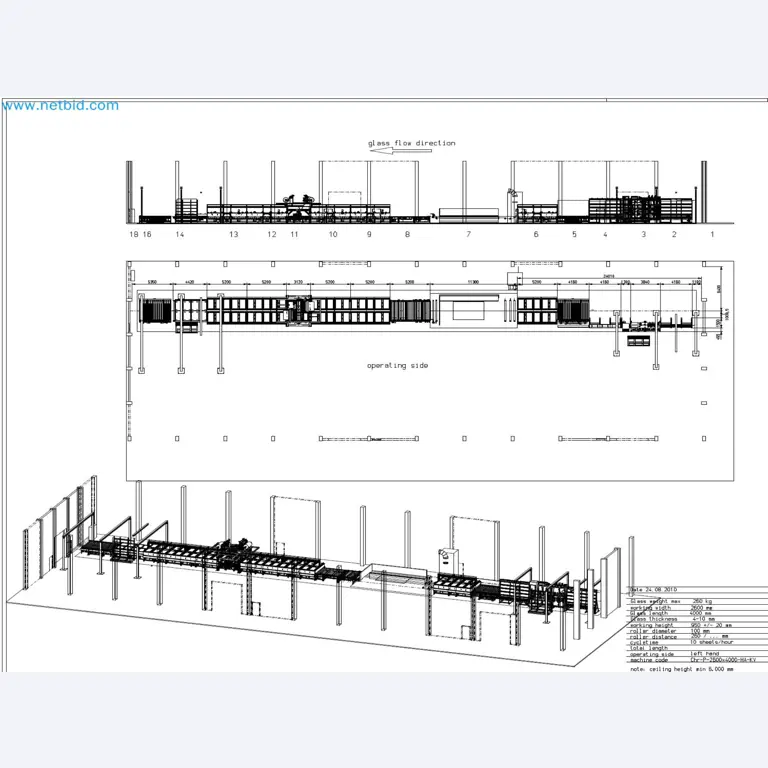

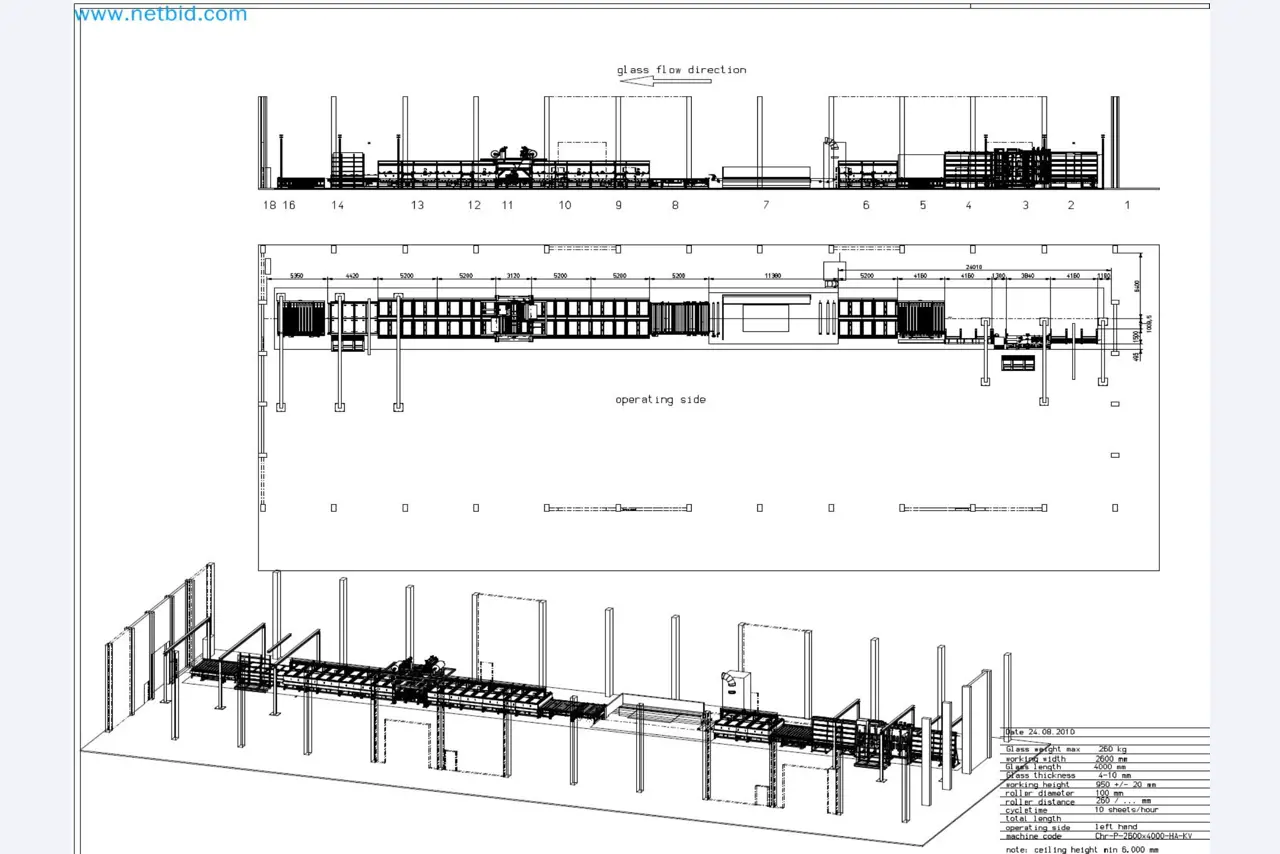

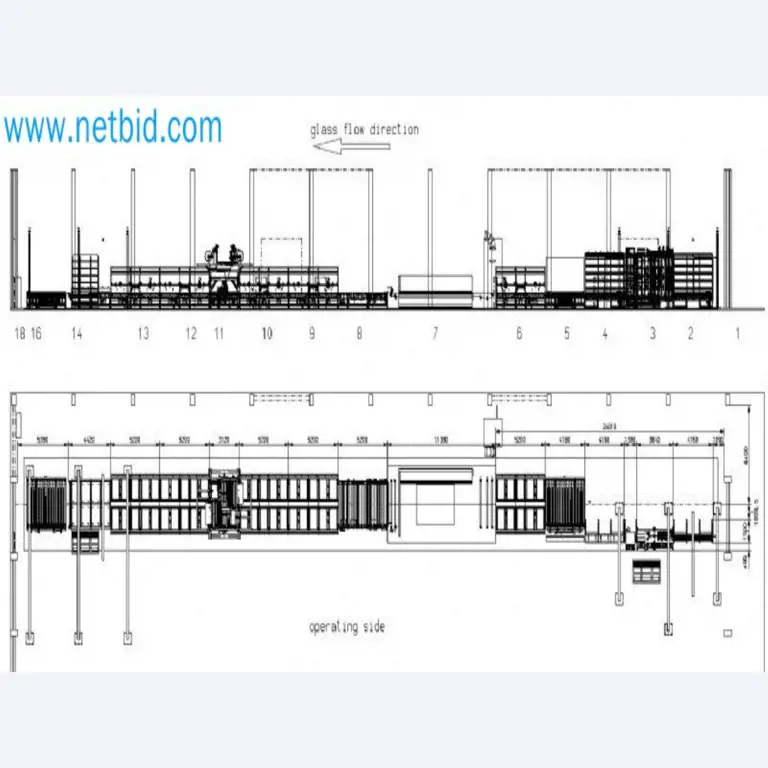

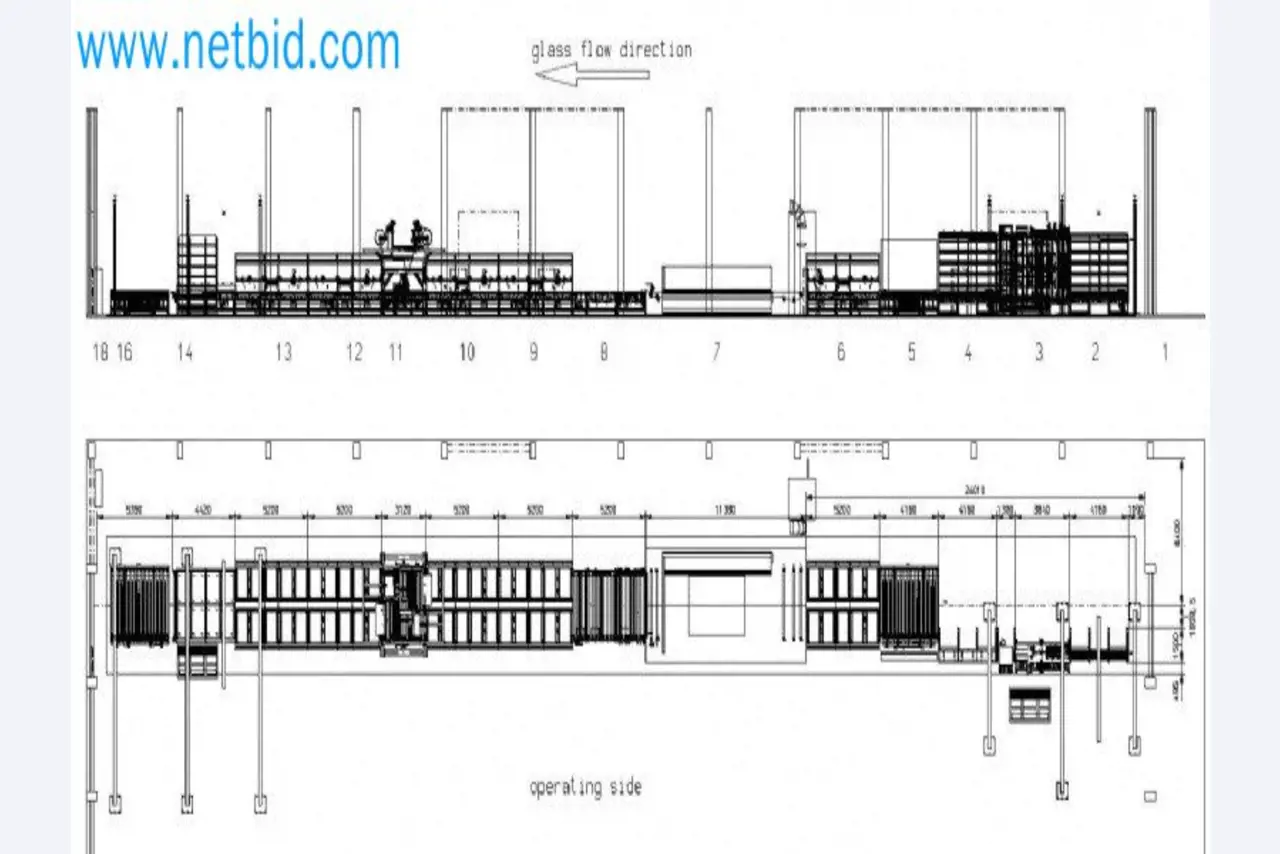

Powder Coating and Safety Glass Line (Award is subject to approval) Klöpper Maschinentechnik C-2600x4000-HA-KTRADING#18856-1

Details

Product Type

Klöpper Maschinentechnik

Type

C-2600x4000-HA-K

Construction Year

2012

Description

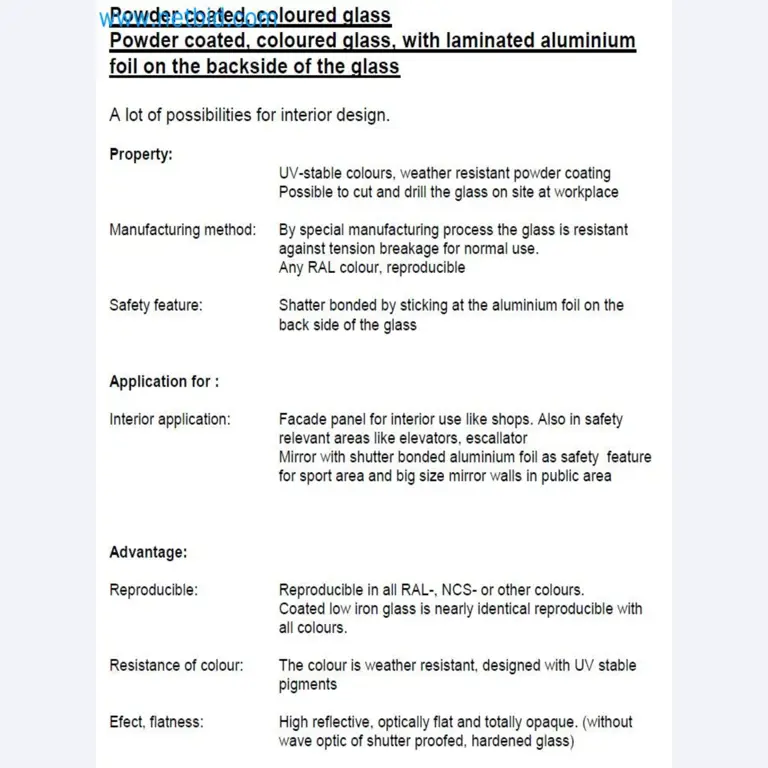

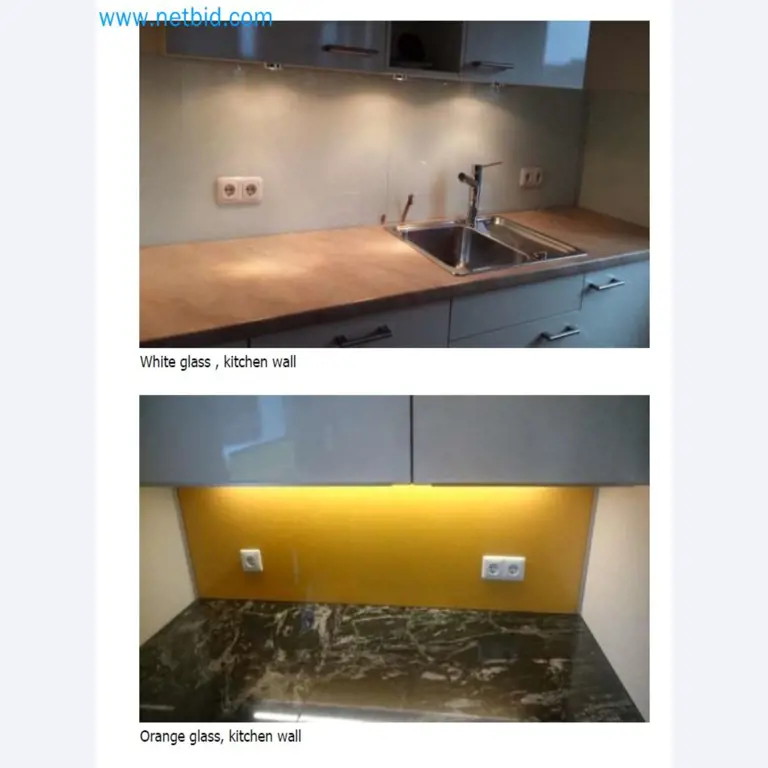

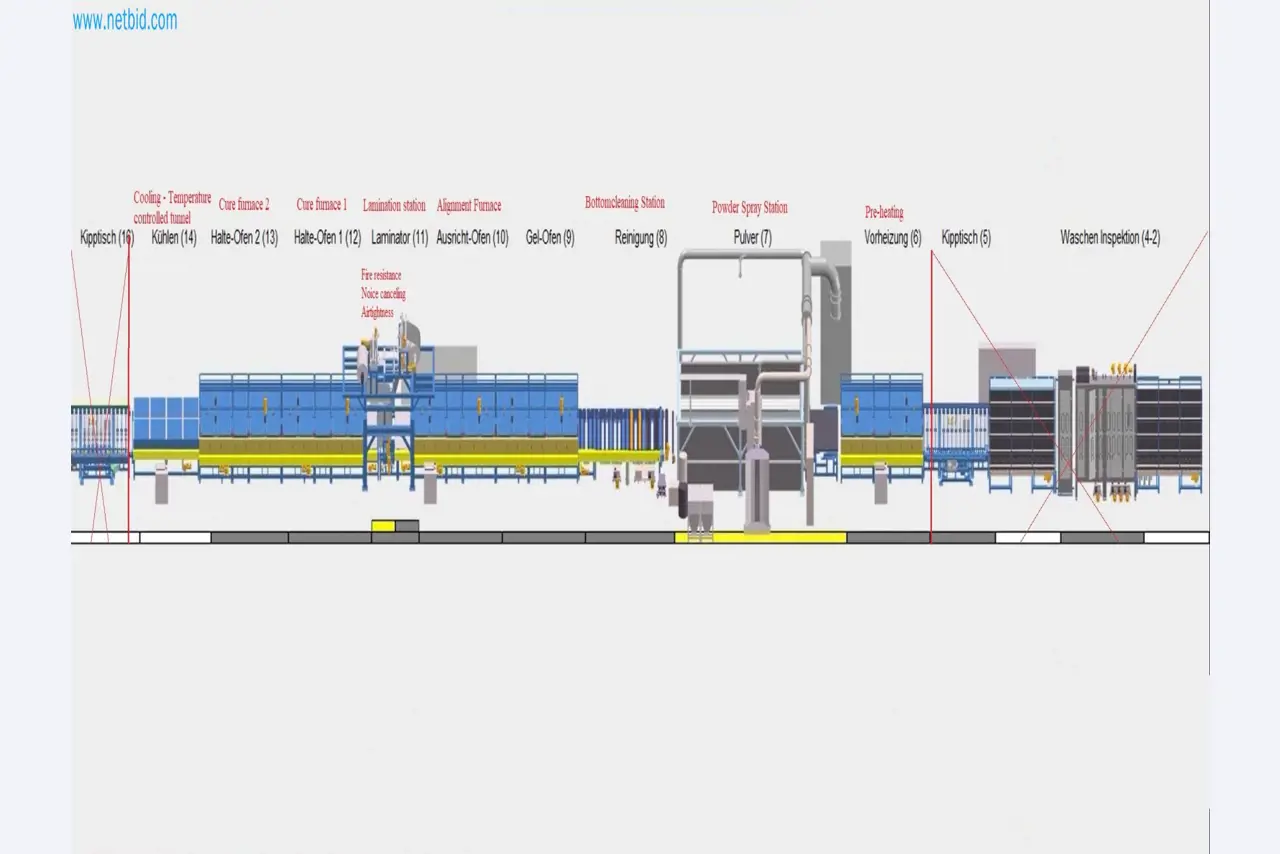

Powder Coating and Powder Coating Safety (Lamination) Line.

The below sizes and types can be processed on the line:

Material width: 2.600mm, 2550mm or 1300 mm, (from to: different sizes are possible, but the dimensions need to be fixed)

Material length max./min.: 3.660 mm / 2000 mm

Material thickness single unit max./min.: 12 mm / 4 mm

Production capacity of Powder Coating and Powder Coating Safety Line:

Cycle time: 10 Batch / hour for an average size of 2600 x 4000 x 4 mm

Capacity of Powder Coating Safety ”Material” approx. 740 m² in 8 hrs product with a batch sizes of 2.600 x 4.000 x 4mm (without changing colour) at theoretical operation of 90 %:

Regular powdered painted “material” product

“Material” width, max./min.: 2.600 mm / 360 mm

“Material” length max./min.: 3.660 mm / 765 mm

“Material” thickness single unit max./min.: 12 mm / 4 mm

Regular powdered painted “material” (without “lamination” foil) depends on the size up to 4 pieces can be driven as Batch

• Optional Single station ( not in lay-out drawing) in front of the line - Primer station Pyrosil HE500

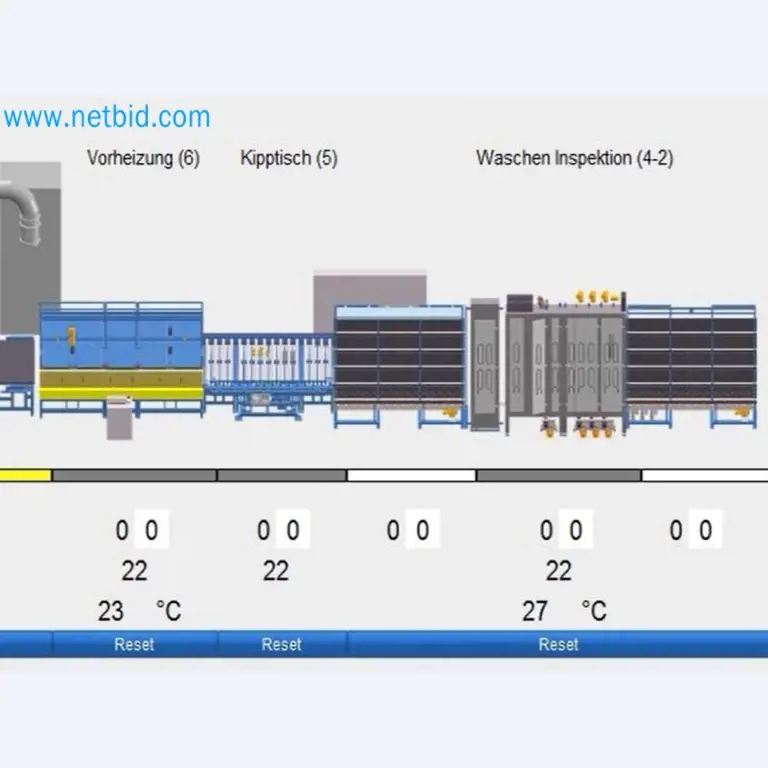

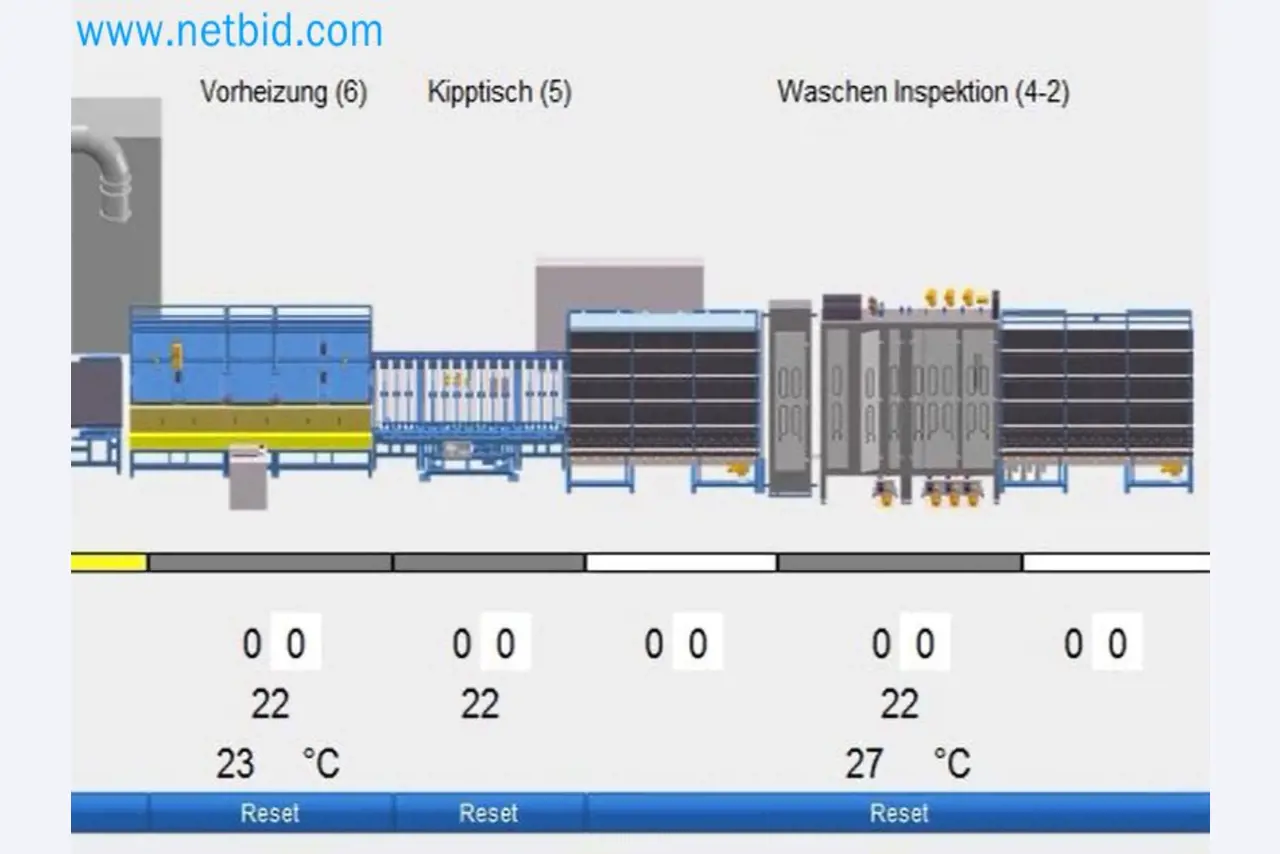

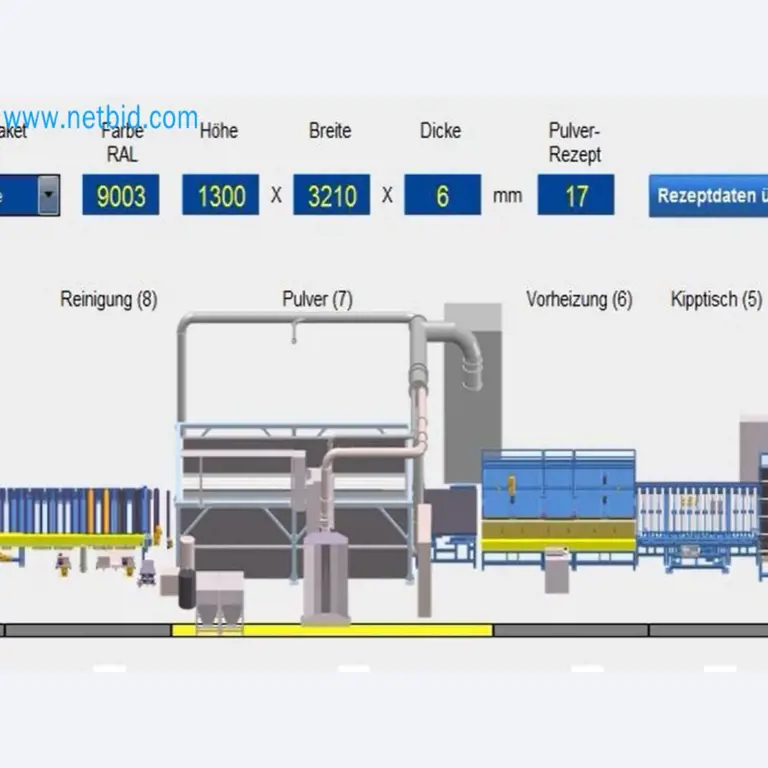

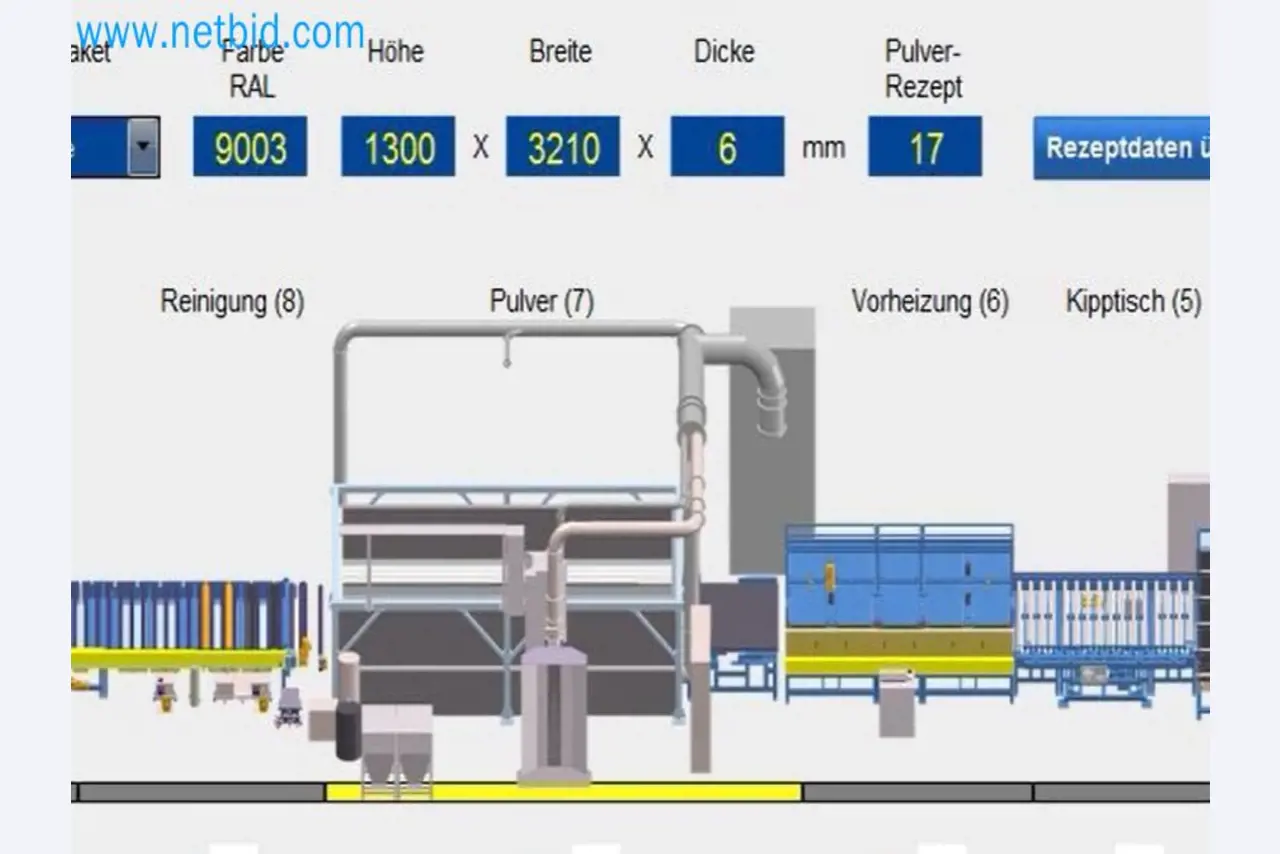

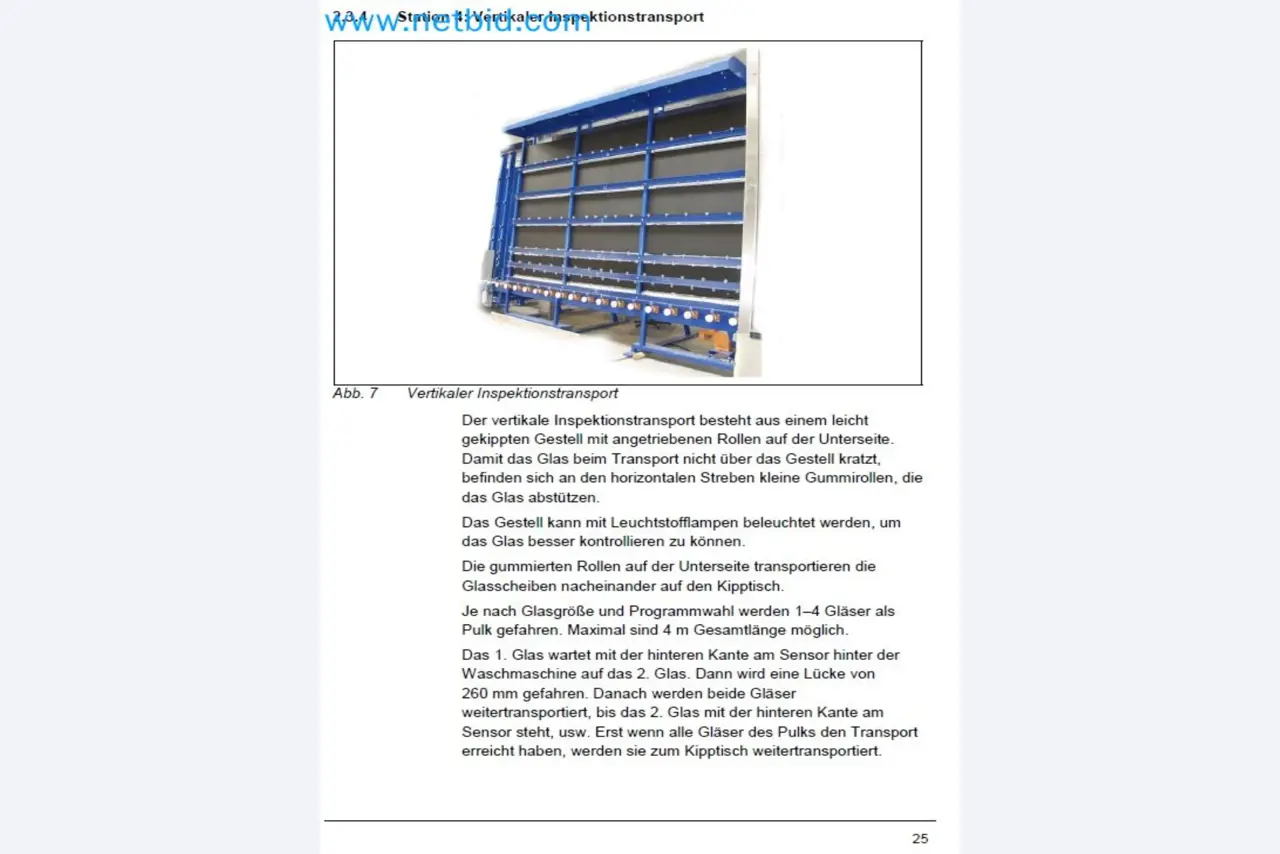

• Position 5 Line input Inspection lighting-zone vertical and tilting table conveyer ( can be an optional position for quality control).

• Position 6 Pre-heating furnace 50-65°C for better painting result

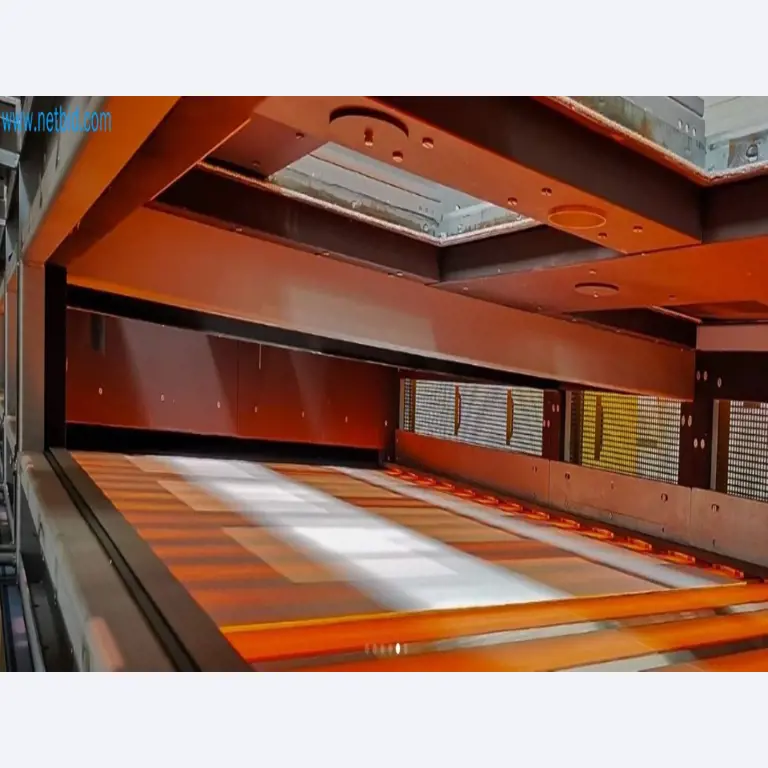

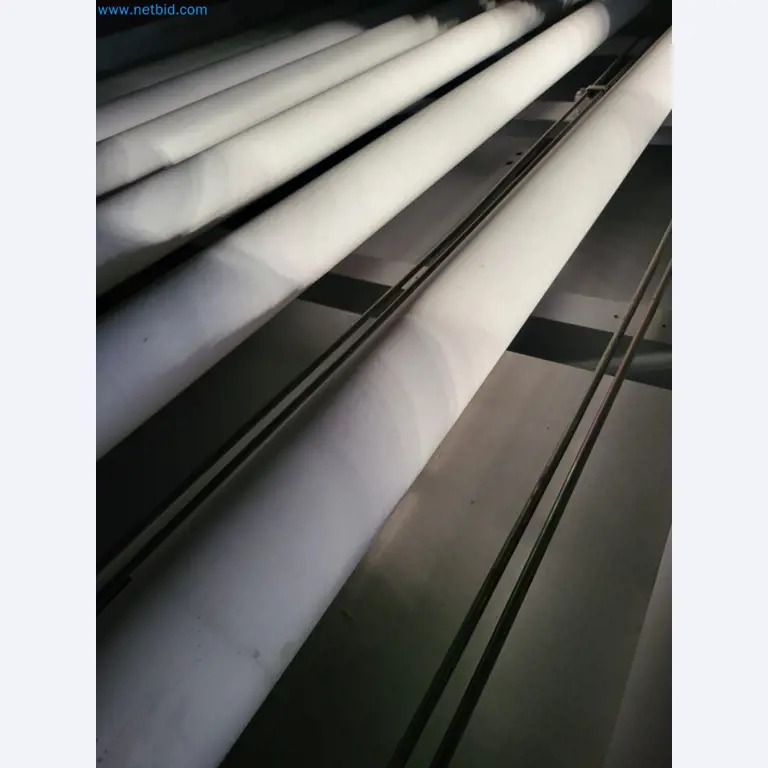

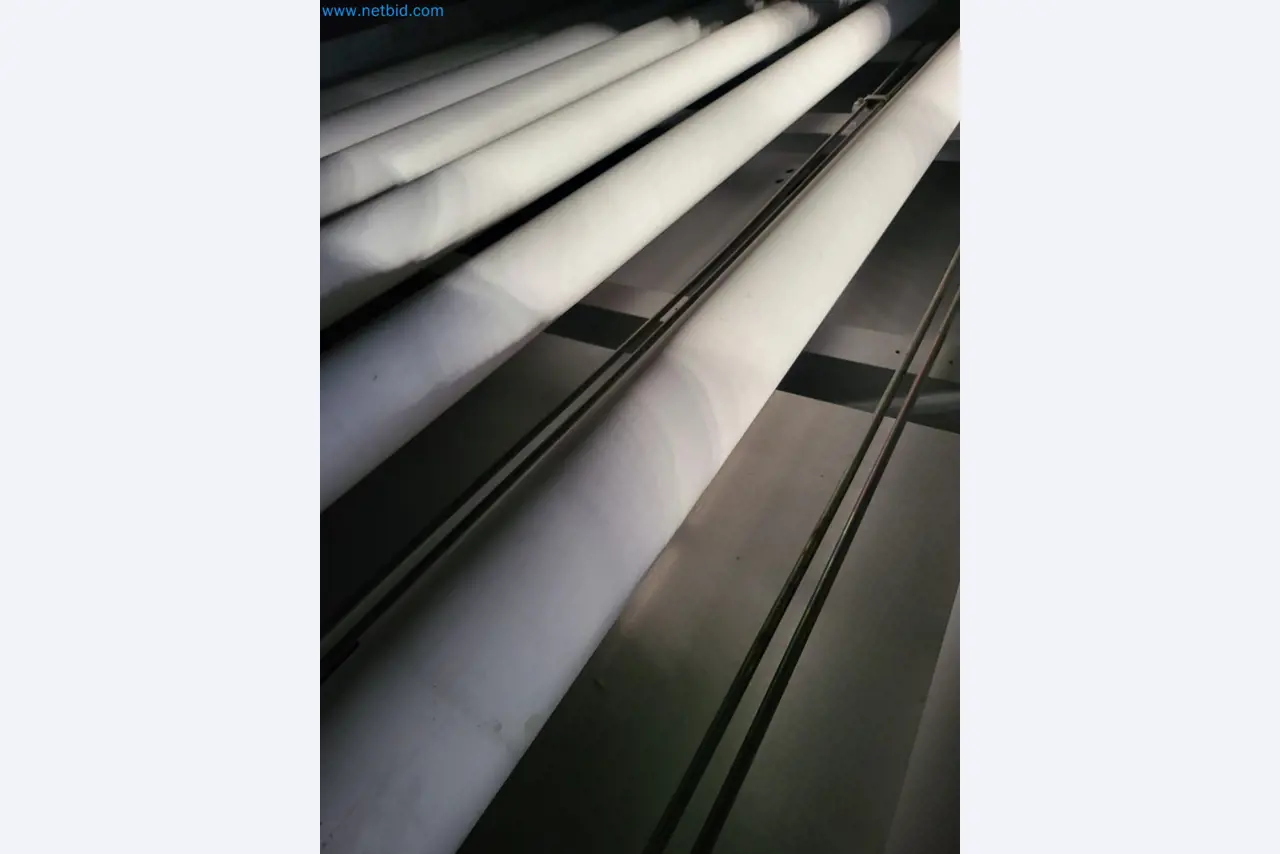

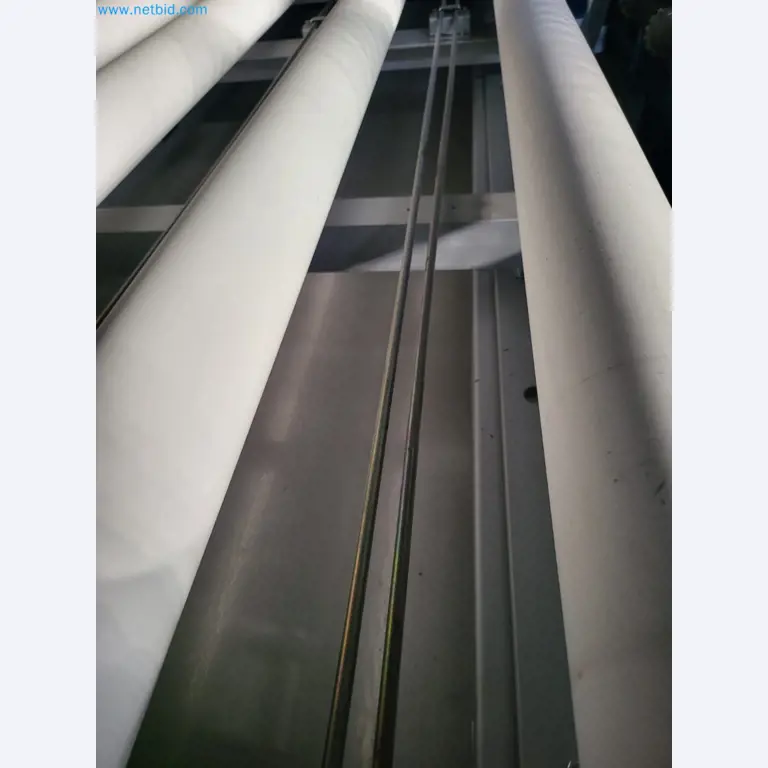

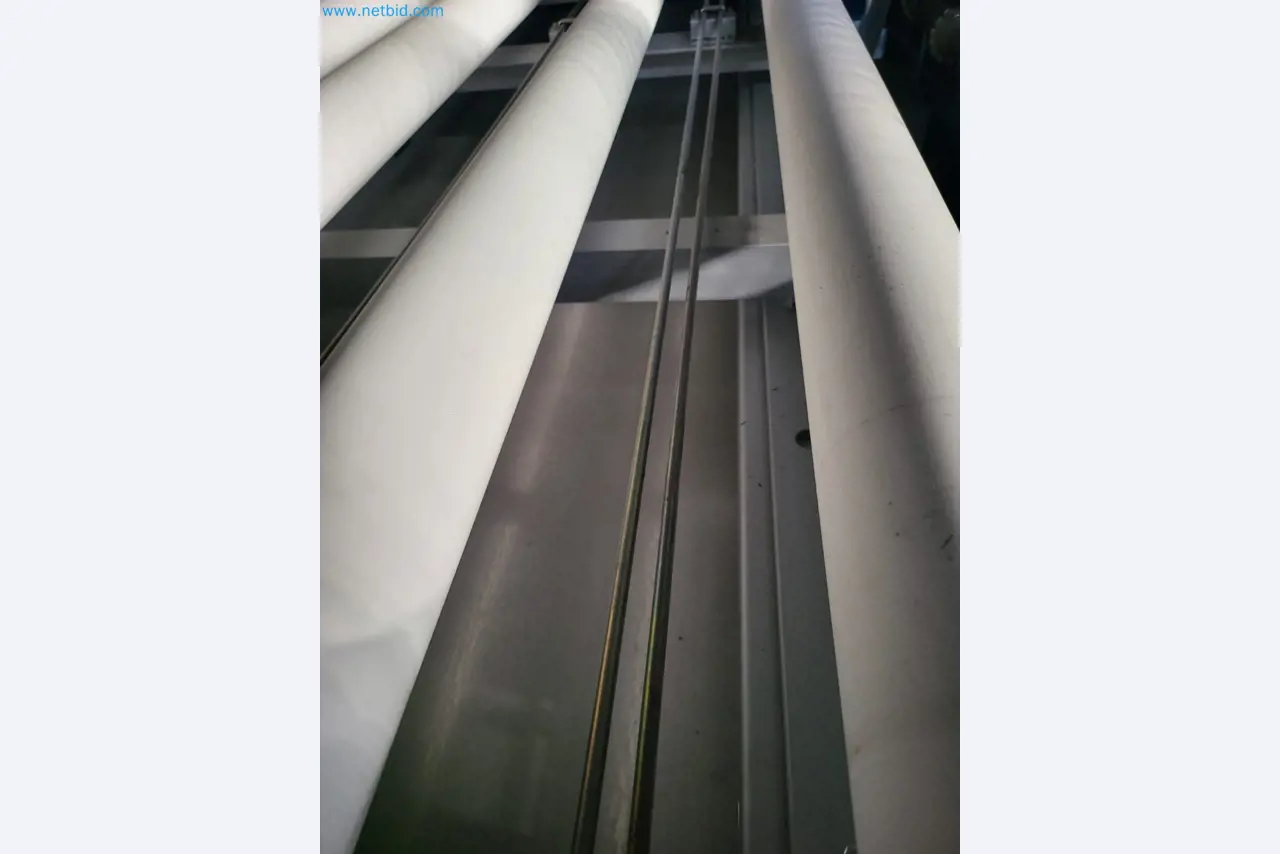

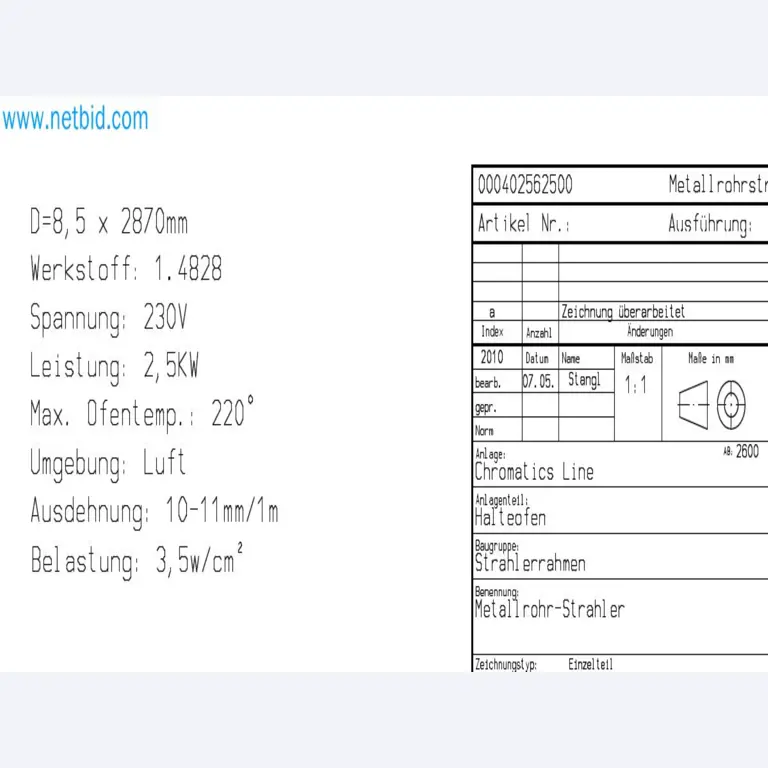

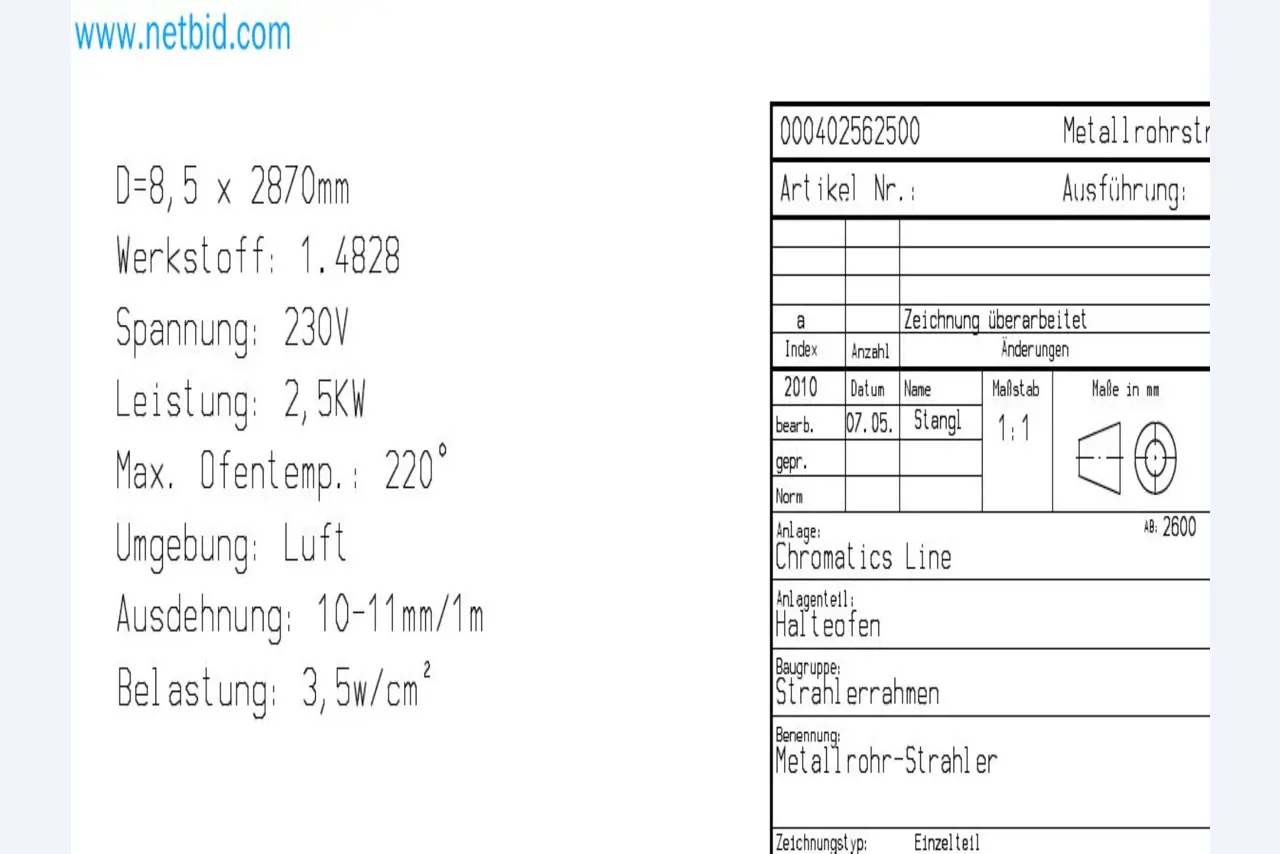

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings. The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature. Metal tube radiators are installed in the oven. The temperature control of the pre-heating section is an energy efficiency full-automatic loop temperature control with thyristor units. The temperature of the “material” panel will be measured by pyrometer inside the oven. The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “materials” temperature is measured and displayed.

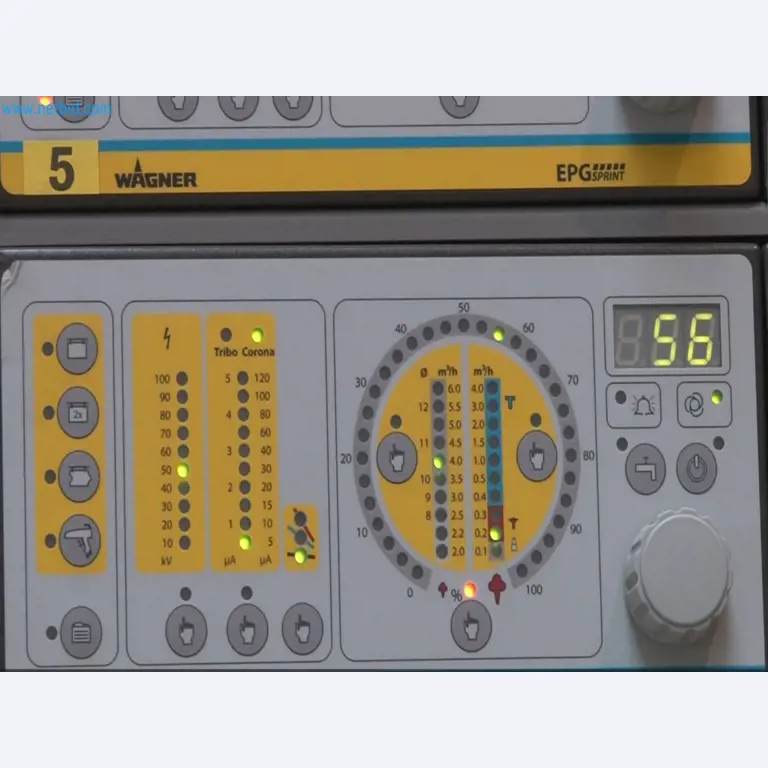

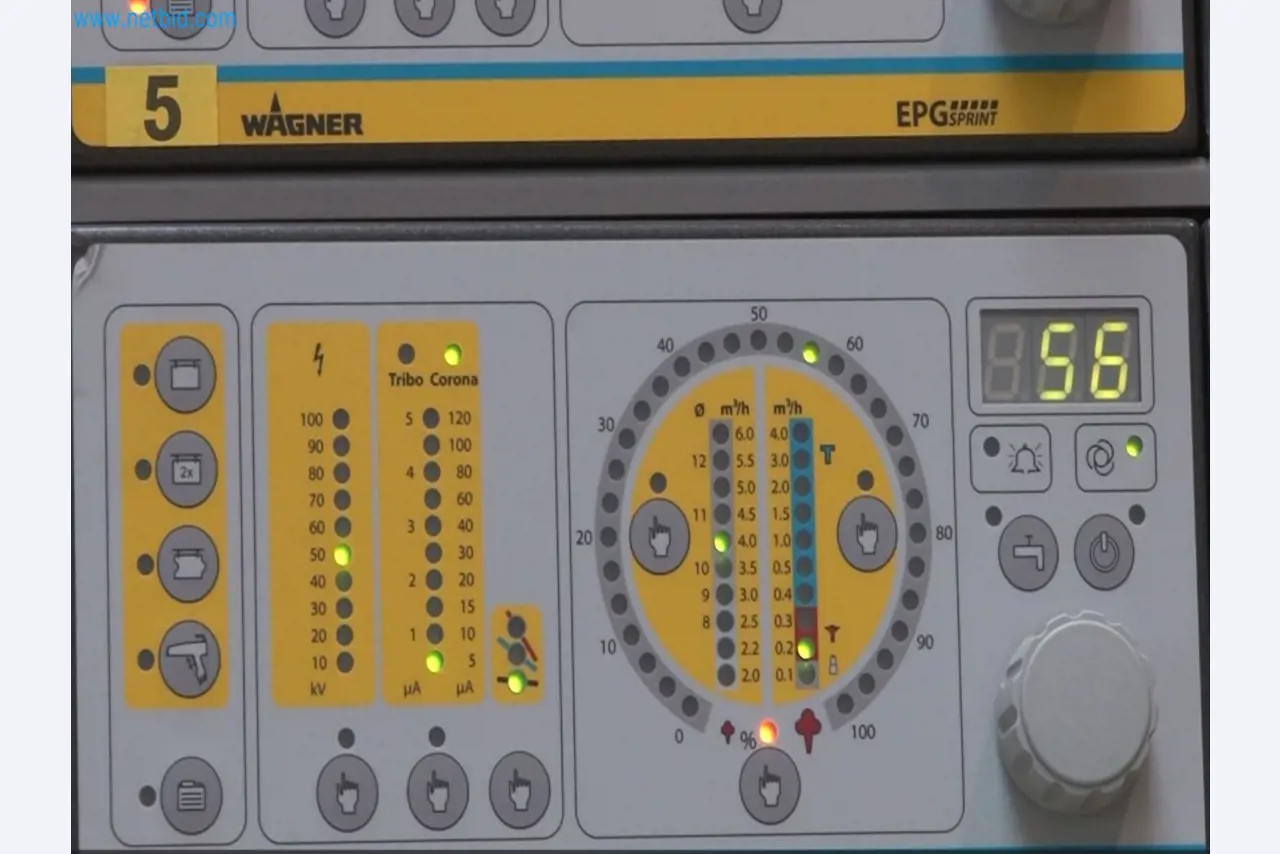

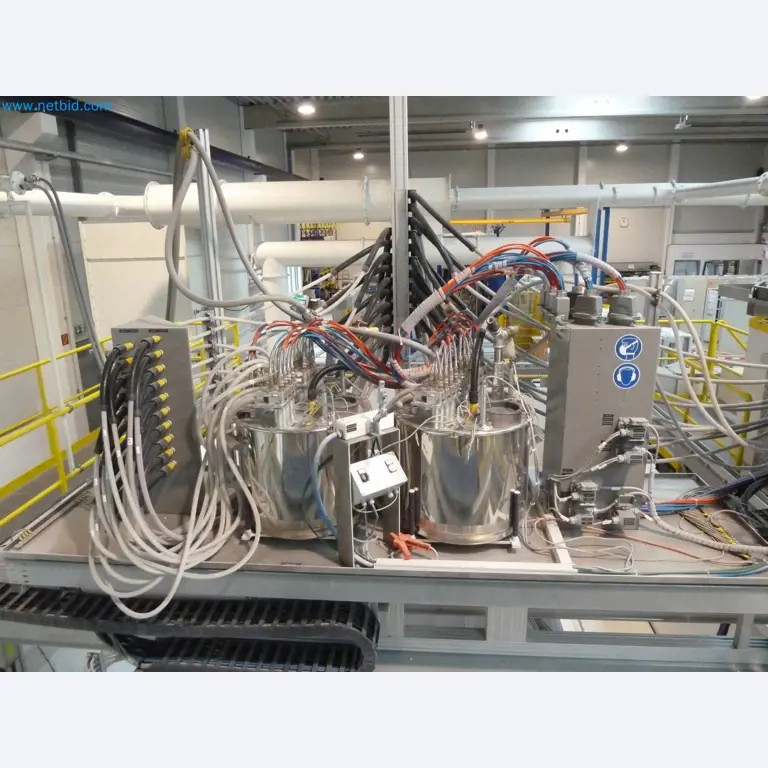

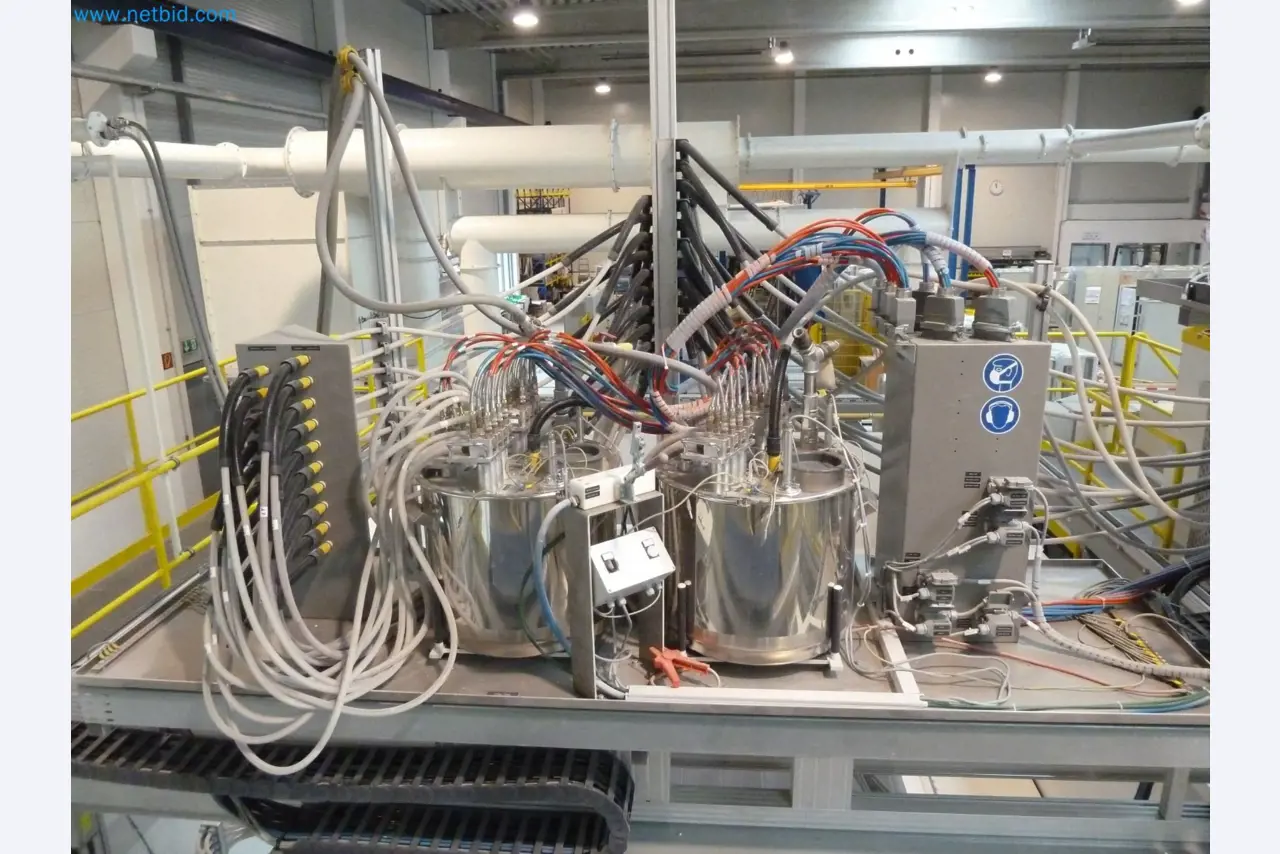

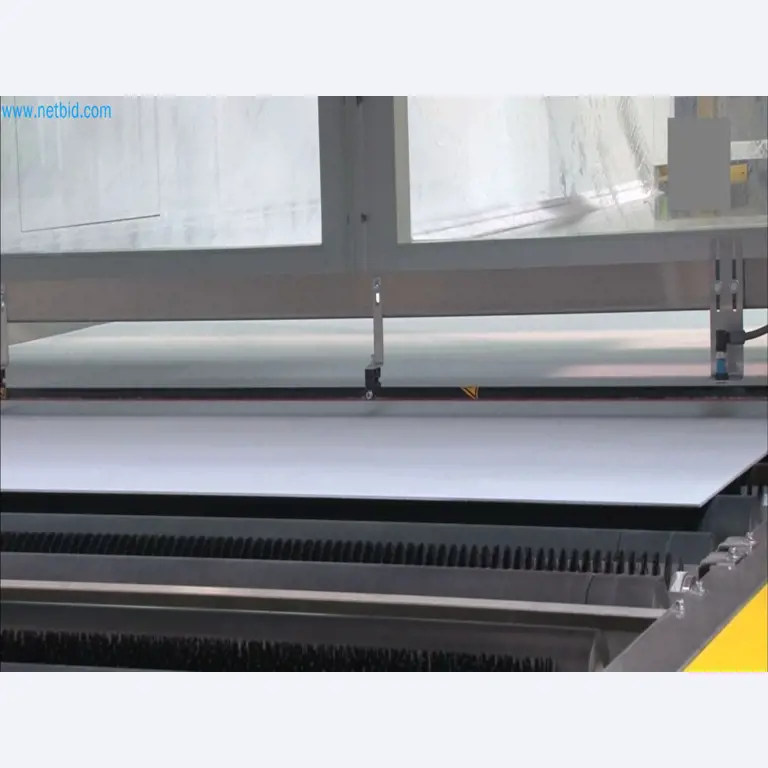

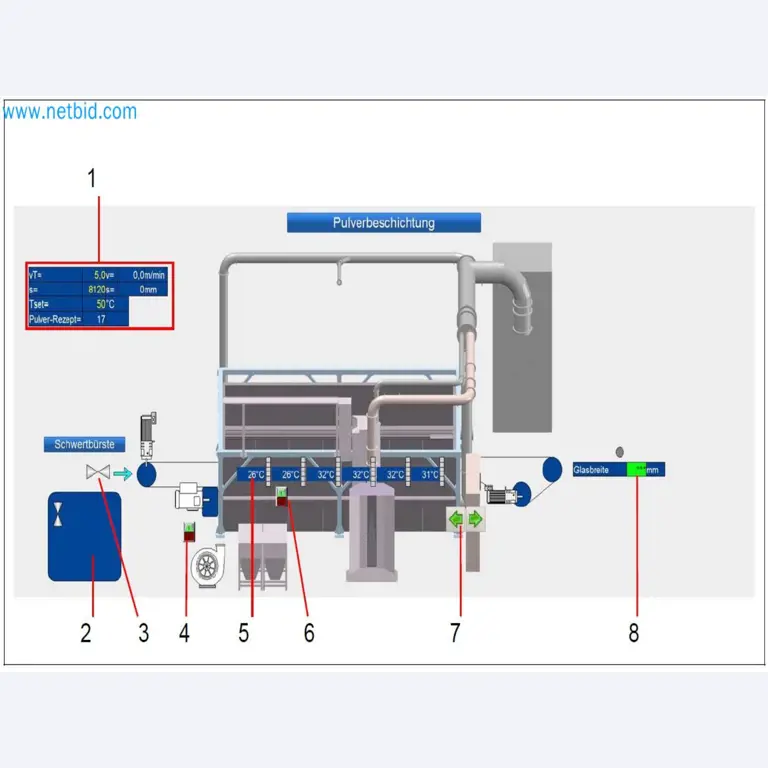

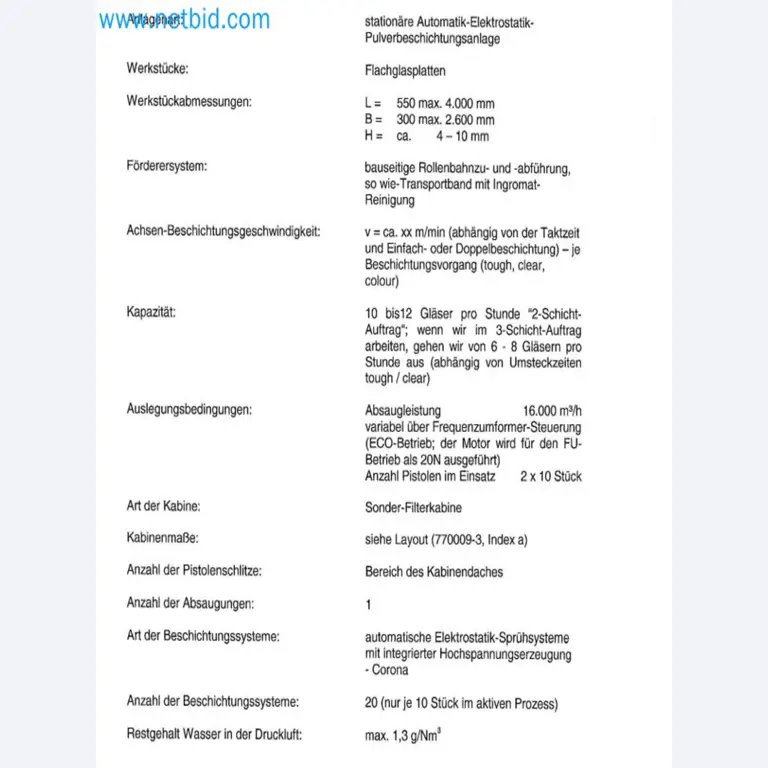

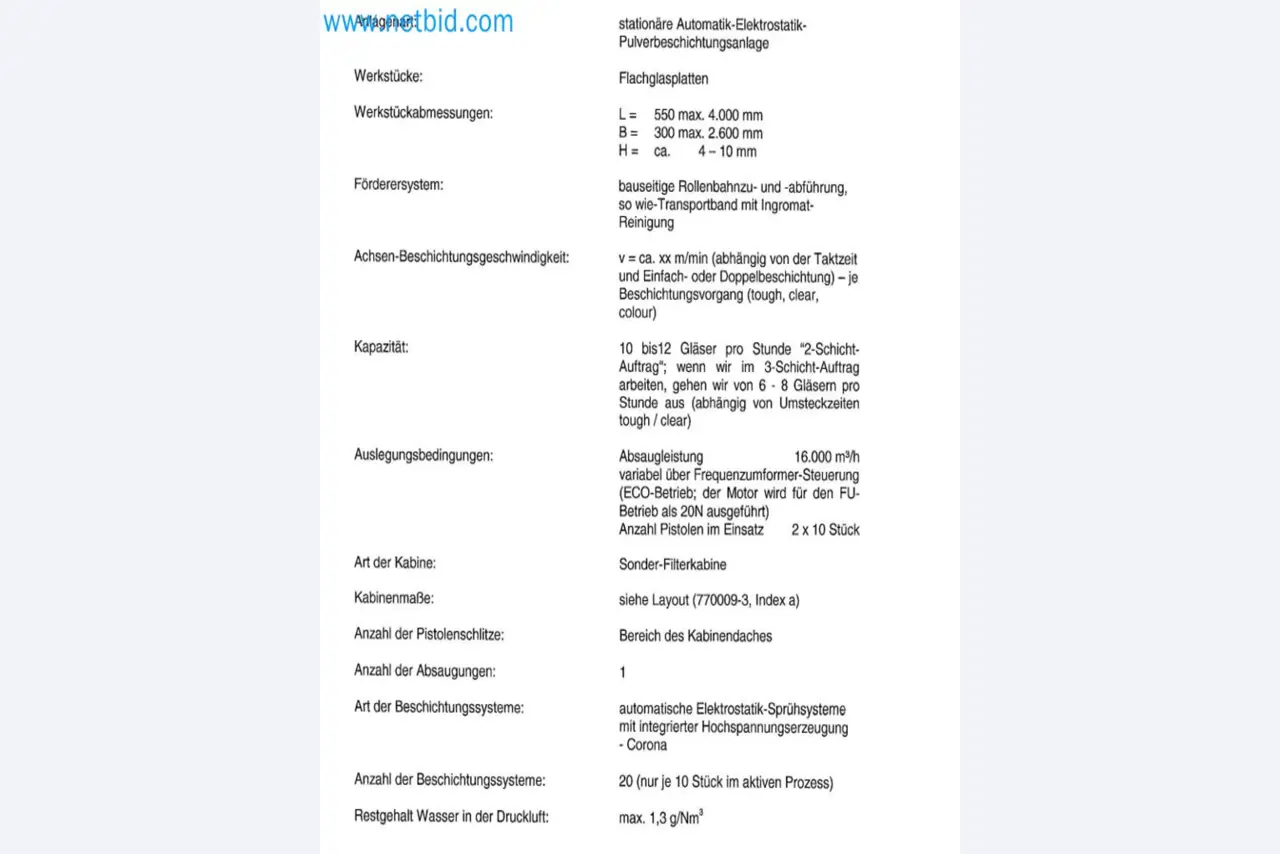

• Position 7 Automatic Powder Spray Booth 2600 x 4000 mm

• Position 8 Cleaning or only Conveyer

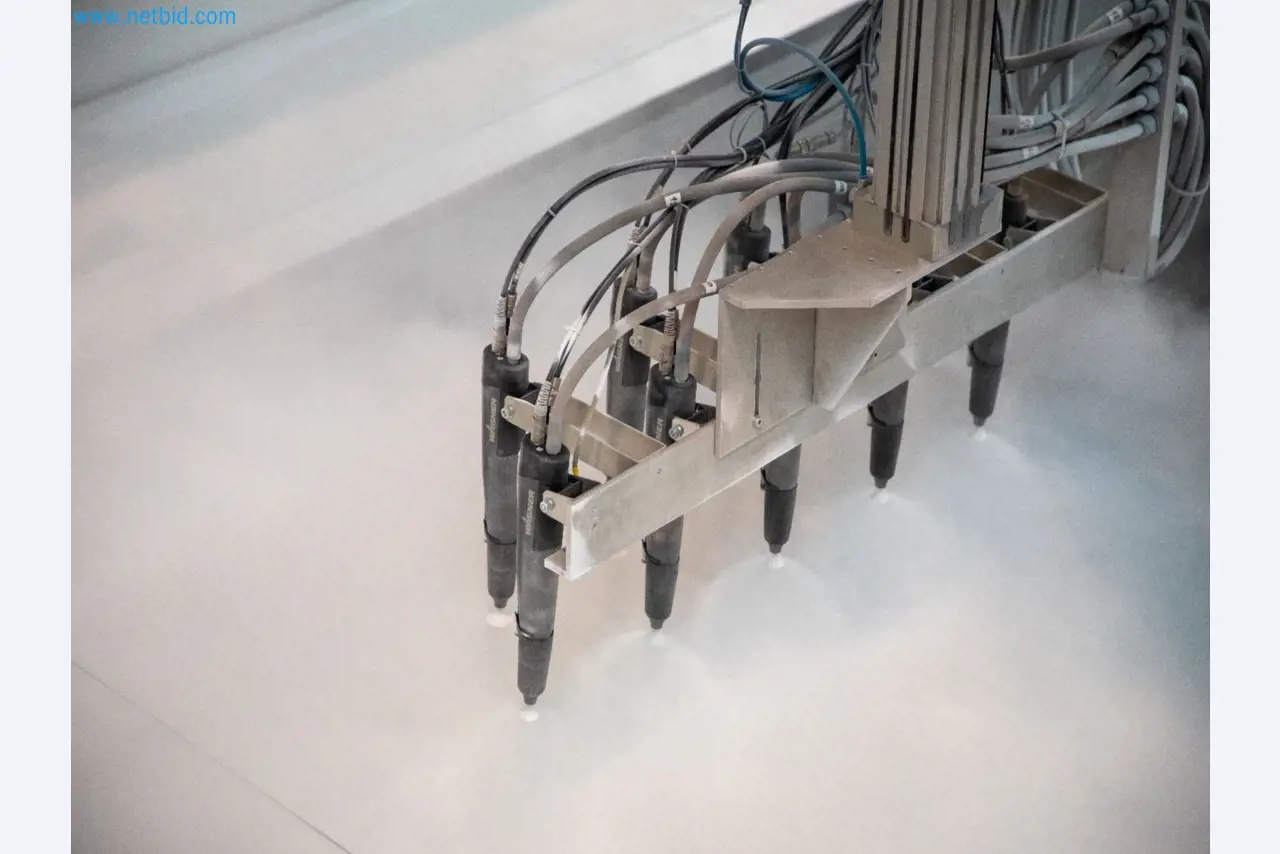

The powder booth is equipped with a sucking system. The two powder coatings, color and clear are sprayed in this section. “Material” transport is done by a special heated belt. Production parameters like the coating thickness, length and width of the “material” are stored in recipes and will be opened and controlled by the line recipes.

The belt is cleaned by vacuum section and a wet brush cleaning system. The fast color change is activated by a special cleaning system for the powder hoses and guns of the spraying system.

This roller transport is used as storage in front of the gel oven.

For Fiber Cement there’s no cleaning needed and no water contact!

The transport is equipped with cylindrical brushes and sponges to clean the material from the uncoated backside.

The cleaning is affected by filtered demi water. The full rubber coated transport rollers are individually driven by worm gear wheels and placed on a solid welded frame.

The transport rollers are arranged in drag bearings.

Active and not active ionization bars are installed to delete the static load from the “material”.

• Position 9 Gel furnace

To be controlled the difference in the GEL time for comparison with the product. The line parameters are based on the GEL time for float glass.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings. The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Special double tube infra red radiators are installed in the oven. The temperature control of the gel oven is a full automatic loop temperature control with thyristor units.

The temperature of the glass panel will be measured by pyrometer inside the oven. The temperature and gel time is set by recipe. The temperature and gel time is set by recipe. Thyristor are controlled by the set gel oven curves. In normal case there are 3 curves set by recipe for one process. Temperature and times are set and automatically controlled. The oven and the “material” temperature is measured and displayed.

This section melts the powder and prepares the surface for the laminator.

• Position 10 Aligment Furnace 1 zone before the lamination Station

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven.

The temperature control of the alignment oven is an energy efficiency, full-automatic loop, temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven. The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed. The “material” is aligned to an accurate position for later laminating the foil.

• Position 11 Laminator optional depending on your product application needs.

• Position 12 Curing furnace 1

The cure oven 1 serves to harden the melted powder coating.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven. The temperature control of the cure oven is an energy efficiency full automatic loop temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven.

The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed.

• Position 13 Curing furnace 2

The cure oven 2 idem to 1 serves to harden the melted powder coating.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven. The temperature control of the cure oven is an energy efficiency full automatic loop temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven.

The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed.

• Position 14 Cooling tunnel option with temperature and air controlling

The roller transport is used as a cooling section in front of the tilting table.

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame.

The transport rollers are arranged in drag bearings. The transport is covered on the top to reduce the cooling speed.

The second transport is open on the top.

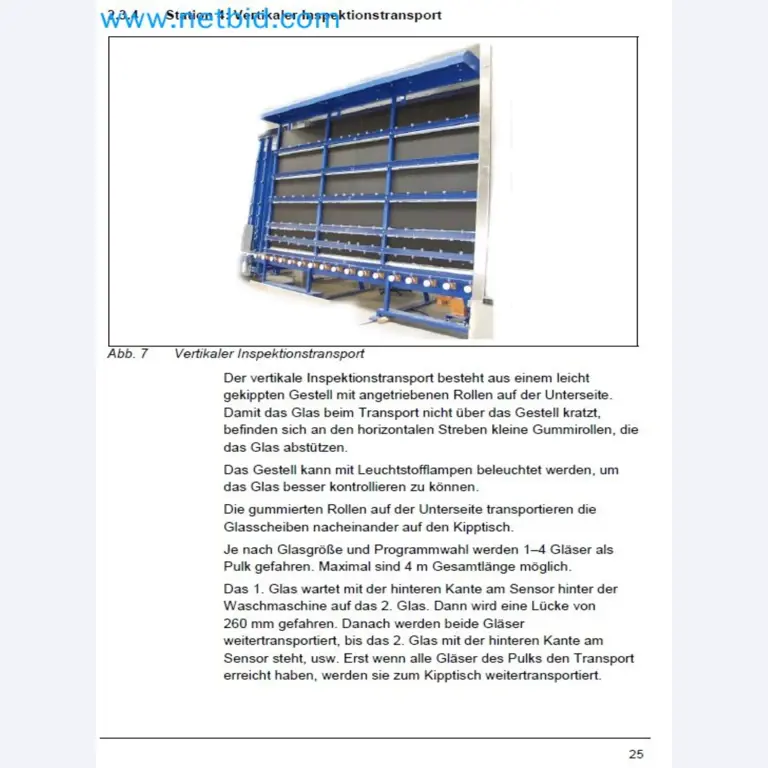

• Position 16 Tilting table Conveyers

Optional:

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame.

The transport rollers are arranged in drag bearings. Tilting arms are in horizontal position

The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°.

The tilting speed has its lowest speed at the beginning and at the end of the movement.

The material is tilted from horizontal to the vertical position. If no “material” happens to be on the vertical inspection transport the “material” runs onto the transport.

The tilting table is used also as storage while normal production.

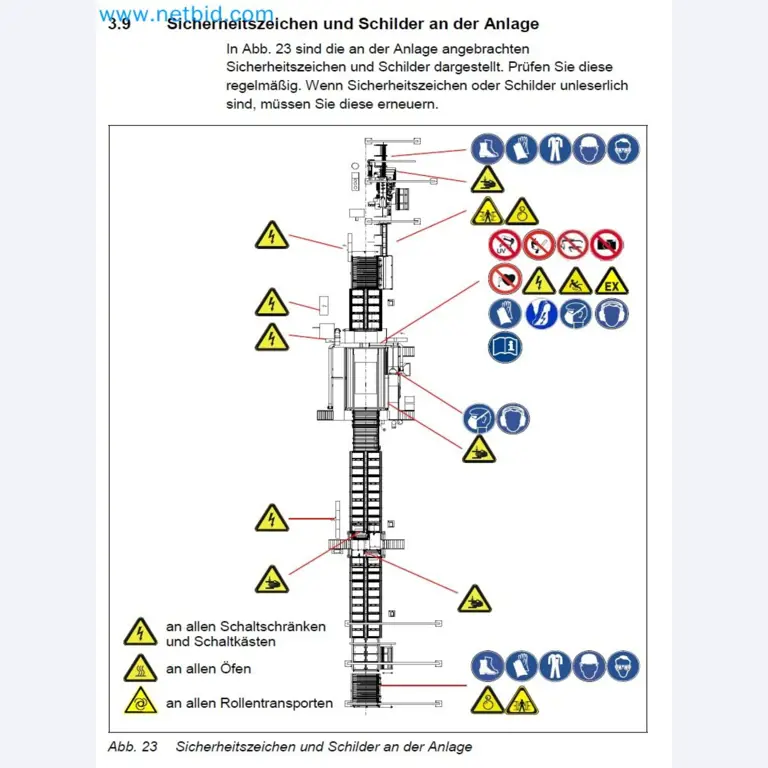

• Position 17 Electrical Distribution

For the above-described Powder Coating and Powder Coating Safety Glass Line:

Design: PLC controlled (Siemens S7 - 1500).

The supply comprises:

- Main control cabinets as well as local control boxes.

- Various terminal boxes

The electric switchboards belong to the production line and contain the corresponding switching devices as well as feeding and the processor PLC, fabrication Siemens with the corresponding construction groups.

Additionally, the switchboards have a preparation for UPS connection. All installed sensors designed to eliminate vibrations or wrong readings.

The control cabinets (Protection Class IP54) are complete wired to terminal strips and have been tested. Local terminal boxes are internal wired and partly pre-wired with the coordinated consumers.

All inputs and outputs applied to terminal strips. Spare terminal stripes with installed cable for future use should be there (no less than 10%).

All terminal boxes are with the necessary protection Class against their position on the line.

The PLC will be provided with spare memory as well as spare digital inputs and outputs (no less than 10% for each). In case of power failure all programs and data will be buffered.

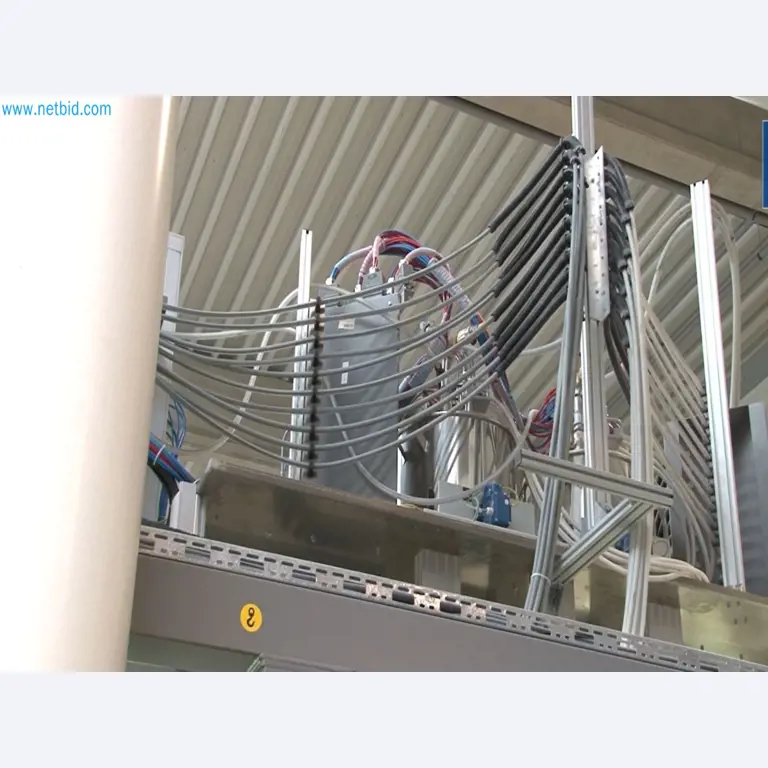

The complete line is controlled by a PLC. Input, creation, and storage of recipes for different process parameters and products via PC. Cable and Cable Trays

The electric includes all cables between the electric switchboards and the consumers and the complete installation material for the line like cable trays.

The cable trays from the electric switchboards to the line are part wise inside the floor against foundation drawing.

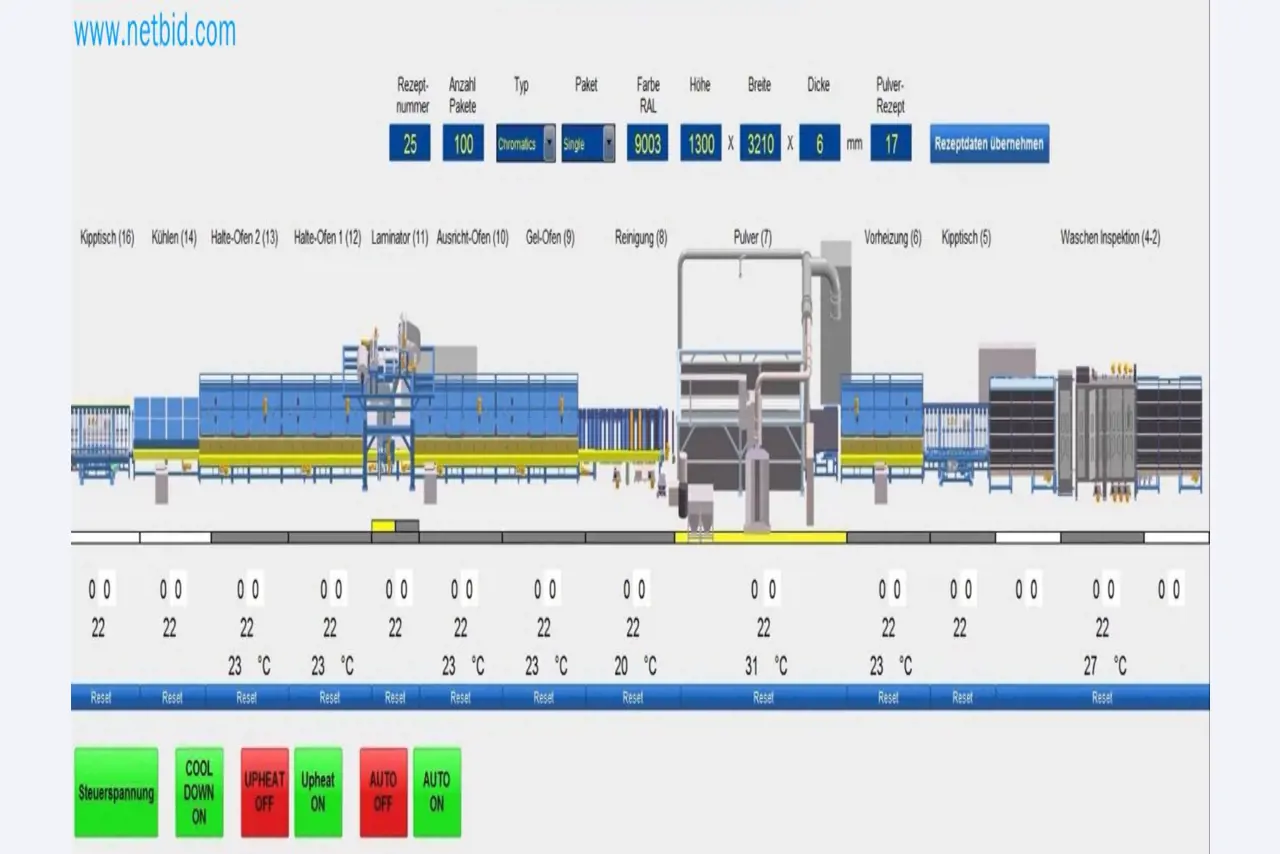

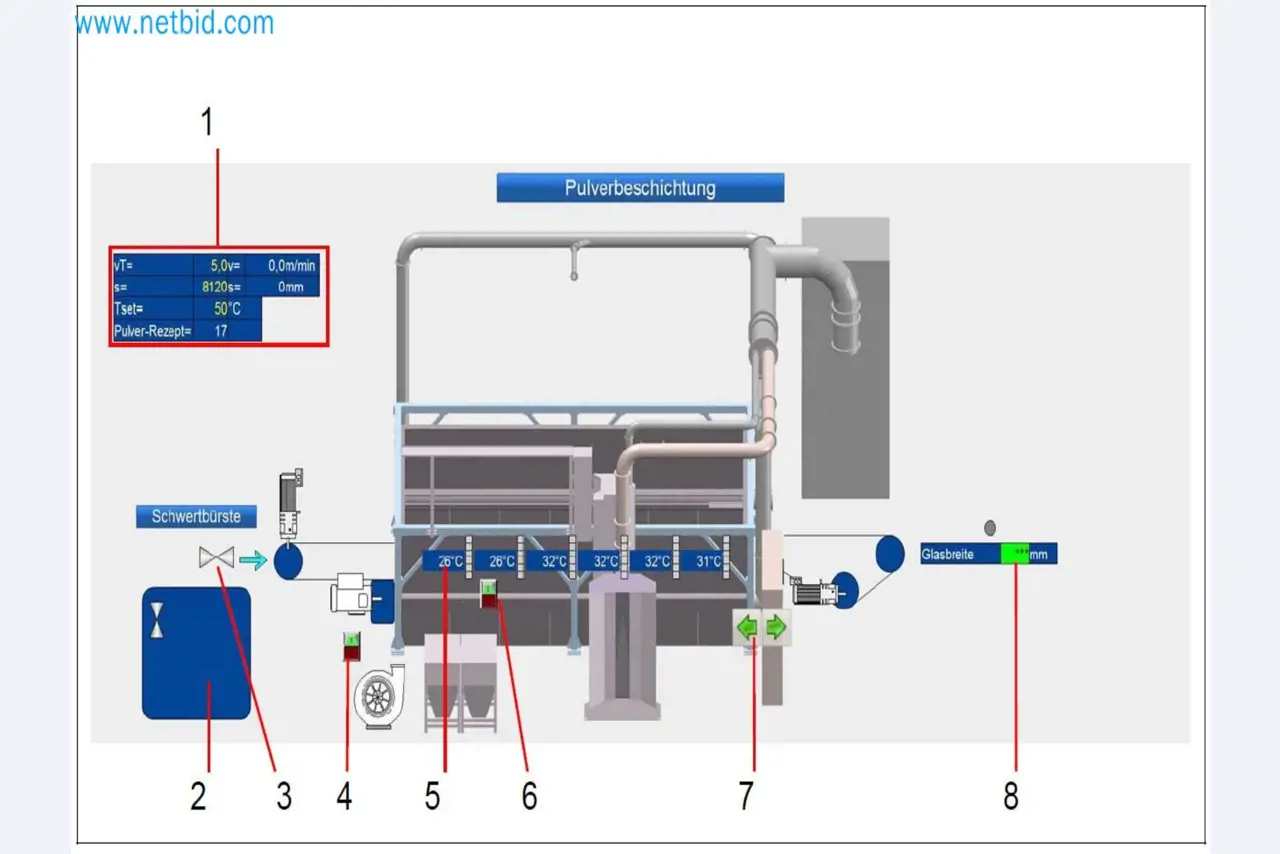

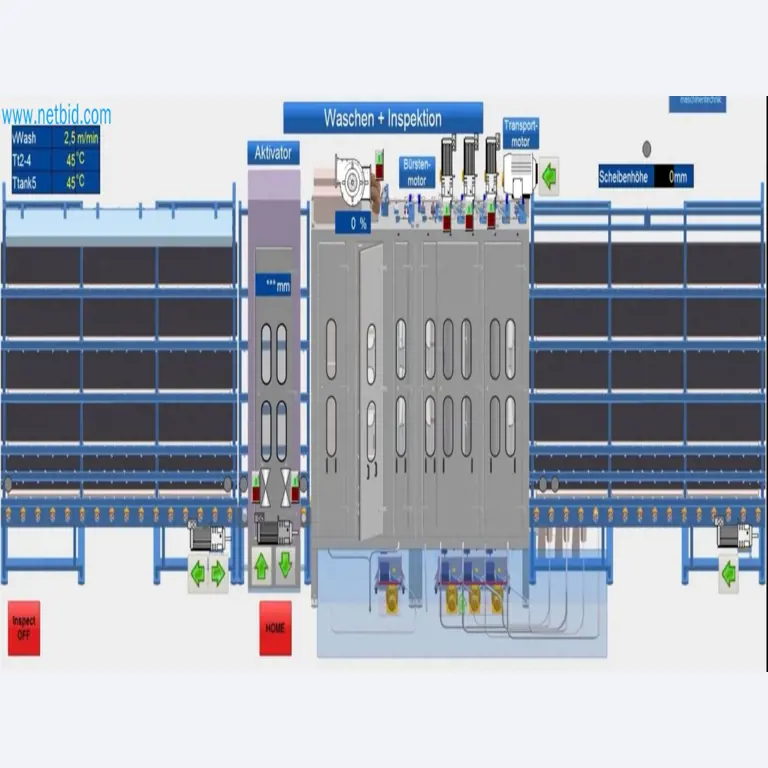

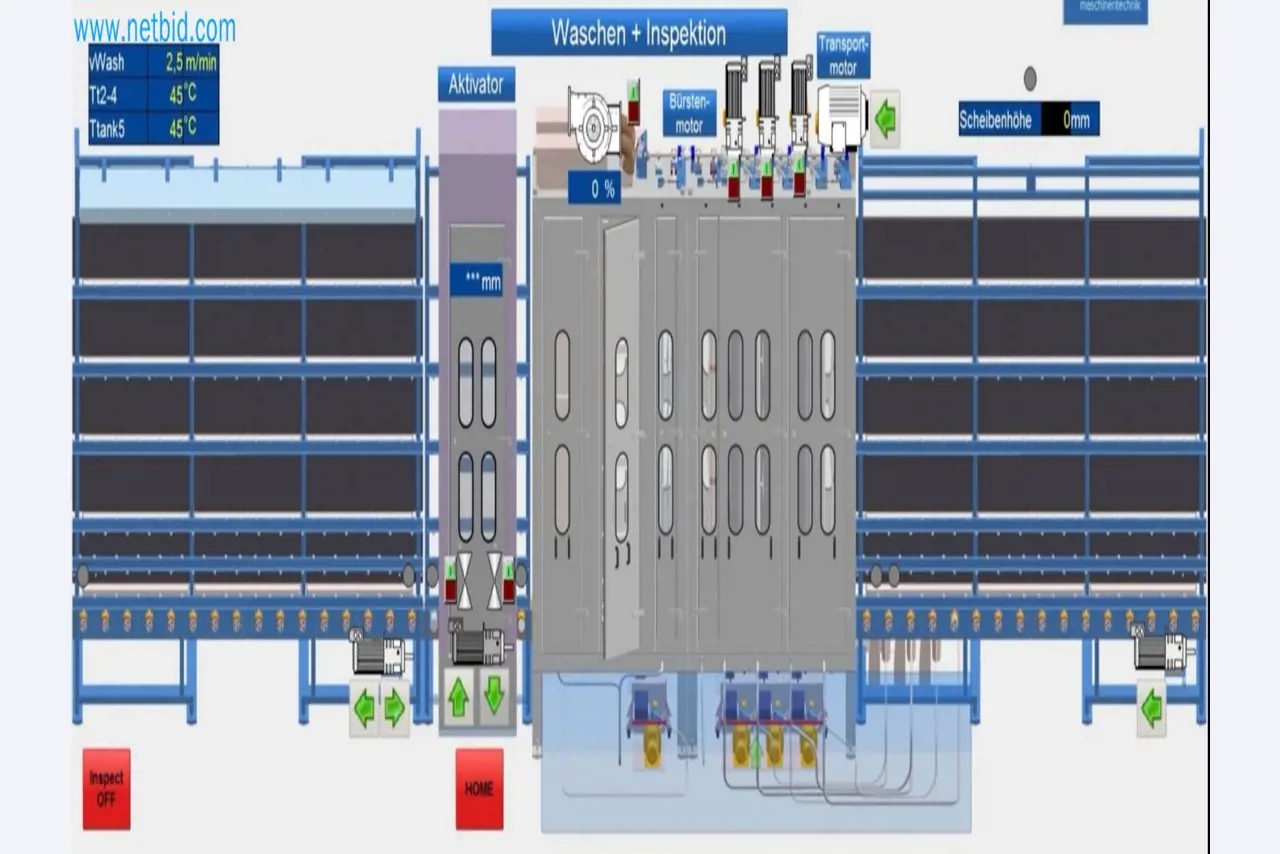

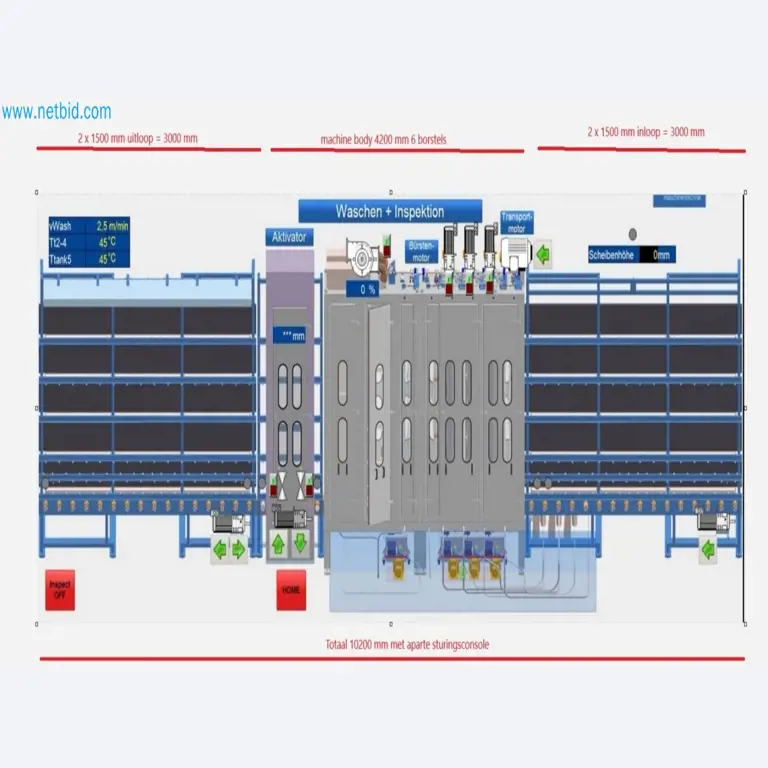

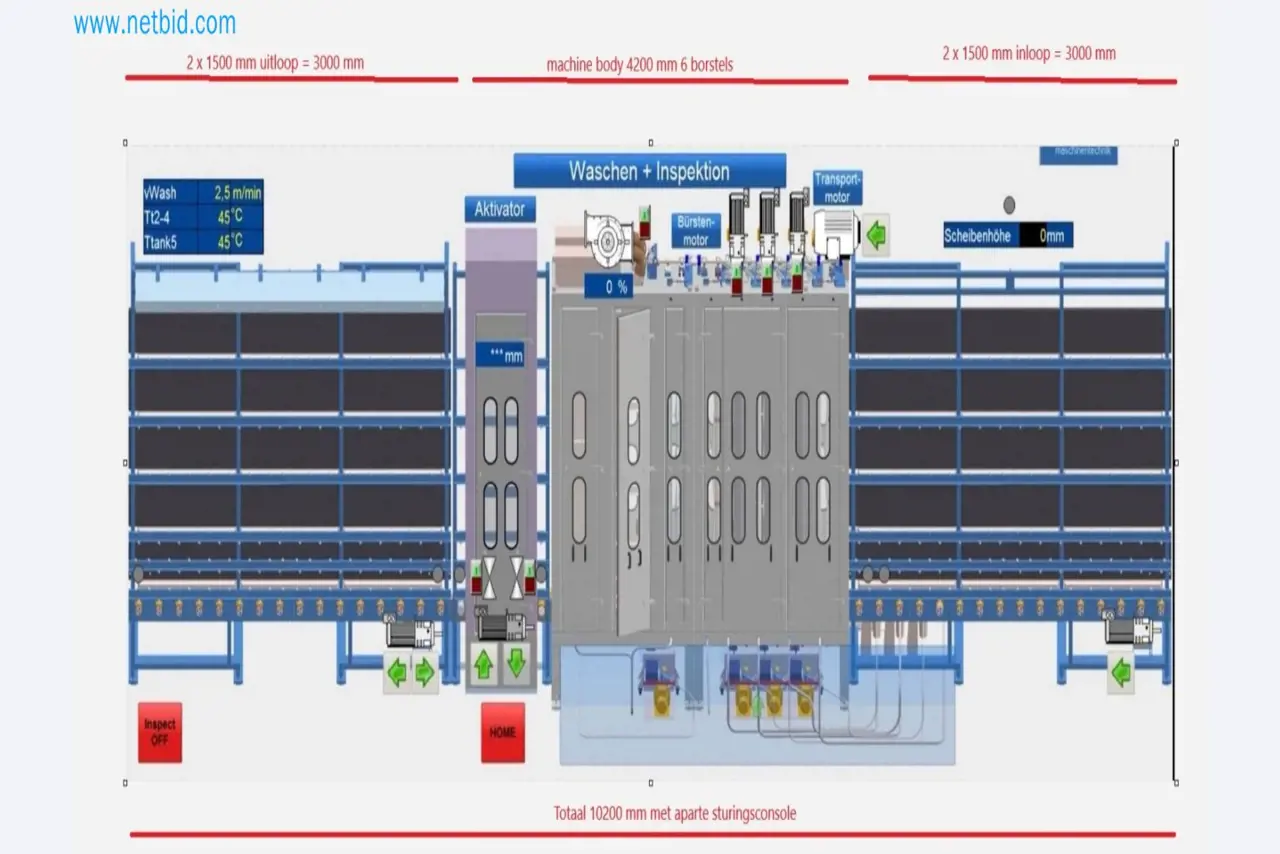

• PC-control:

The communication between the chromatics line and external line elements will be done via Profinet connection.

Visualization (SCADA Control system), PC-control including Monitor, Data Control, recipe administration and sheet tracking (Siemens Simatic)

WinCC Advanced (TIA Portal)) consisting of:

- 1 pcs. Standard PC

- 1 pcs. Monitor approx. 22” – 24”

- 1 pcs Keyboard and mouse

- 1 pcs. Simatic WinCC Advanced (TIA Portal)Software

Function control of motors, radiators, and the complete line via PC. Integrated failure indication with supervision of systems.

Visualization of all construction groups. Parameters for the quality control can be saved and archived.

Screen display of the machine with motors, etc. and all operation parameter such as speed, Thyristor settings, temperatures, etc. The PC can be used for supervision and adjustment of the line components.

Storage of recipes for different process parameters, like glass dimensions, glass thickness or different set points for different products.

• Quality Control

Measured production parameter along the line are stored corresponding to the produced “Material”. The “Material” can be signed by hand or as option marked by digital printer on the backside of the foil.

Other functionality: Alarm logging, Tag logging, Visualization of the plate tracking, Archiving of the various process Parameters

• Operation and Monitoring

- 2 pcs. Simatic Comfort Panel

One Panel located at the Laminator, one Panel located at the end of the line.

The panels are used to operate and run the line in Automatic and Manual Mode

- Operation Modes:

Automatic Mode:

Automatic Mode to run the line full automatically by recipe.

Recall of recipes for the running production in case of need. After selection of a recipe the new set points will be automatic transferred.

The line adjusts automatically to the new production parameter.

All the valves, motors are supervised and in case of failure a signal is given.

Manual Mode:

The manual mode allows activation of all motors for maintenance of the line.

Manual mode with end position monitoring but without interlocking.

General Design Data:

Input: 3 x 400 V, +50 Hz, PEN

Control Voltage : 24 V DC / 230 V DC

Voltage variations : + 5% / - 5%

Installation height: < 1.000 m M.S.L.

Ambient temperature: min. +5°C max. +40°C

Relative air humidity: max. 95%

Cabinets with air condition: If necessary, after final design of the line inside the Workshop

Switching devices: acc. to IEC, EN, VDE

Cable outlet cabinets: below

Documentation: acc. to DIN on ELCAD

Doc. language: English

Complete line disassembled !!!

18 Standard trucks needed to load the complete line (approx.)

Important! The line has already been professionally dismantled and will be loaded onto the buyer's transport. The mandatory costs for dismantling and loading, which are to be borne by the buyer, amount to €16,000 (plus VAT, if applicable). The seller will issue an invoice for these costs, which must be paid in full before collection. NetBid ESP SLU does not receive any commission for the dismantling and loading and is therefore not responsible for these actions of the seller. The dismantled line can be viewed and is purchased “as is.”

The below sizes and types can be processed on the line:

Material width: 2.600mm, 2550mm or 1300 mm, (from to: different sizes are possible, but the dimensions need to be fixed)

Material length max./min.: 3.660 mm / 2000 mm

Material thickness single unit max./min.: 12 mm / 4 mm

Production capacity of Powder Coating and Powder Coating Safety Line:

Cycle time: 10 Batch / hour for an average size of 2600 x 4000 x 4 mm

Capacity of Powder Coating Safety ”Material” approx. 740 m² in 8 hrs product with a batch sizes of 2.600 x 4.000 x 4mm (without changing colour) at theoretical operation of 90 %:

Regular powdered painted “material” product

“Material” width, max./min.: 2.600 mm / 360 mm

“Material” length max./min.: 3.660 mm / 765 mm

“Material” thickness single unit max./min.: 12 mm / 4 mm

Regular powdered painted “material” (without “lamination” foil) depends on the size up to 4 pieces can be driven as Batch

• Optional Single station ( not in lay-out drawing) in front of the line - Primer station Pyrosil HE500

• Position 5 Line input Inspection lighting-zone vertical and tilting table conveyer ( can be an optional position for quality control).

• Position 6 Pre-heating furnace 50-65°C for better painting result

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings. The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature. Metal tube radiators are installed in the oven. The temperature control of the pre-heating section is an energy efficiency full-automatic loop temperature control with thyristor units. The temperature of the “material” panel will be measured by pyrometer inside the oven. The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “materials” temperature is measured and displayed.

• Position 7 Automatic Powder Spray Booth 2600 x 4000 mm

• Position 8 Cleaning or only Conveyer

The powder booth is equipped with a sucking system. The two powder coatings, color and clear are sprayed in this section. “Material” transport is done by a special heated belt. Production parameters like the coating thickness, length and width of the “material” are stored in recipes and will be opened and controlled by the line recipes.

The belt is cleaned by vacuum section and a wet brush cleaning system. The fast color change is activated by a special cleaning system for the powder hoses and guns of the spraying system.

This roller transport is used as storage in front of the gel oven.

For Fiber Cement there’s no cleaning needed and no water contact!

The transport is equipped with cylindrical brushes and sponges to clean the material from the uncoated backside.

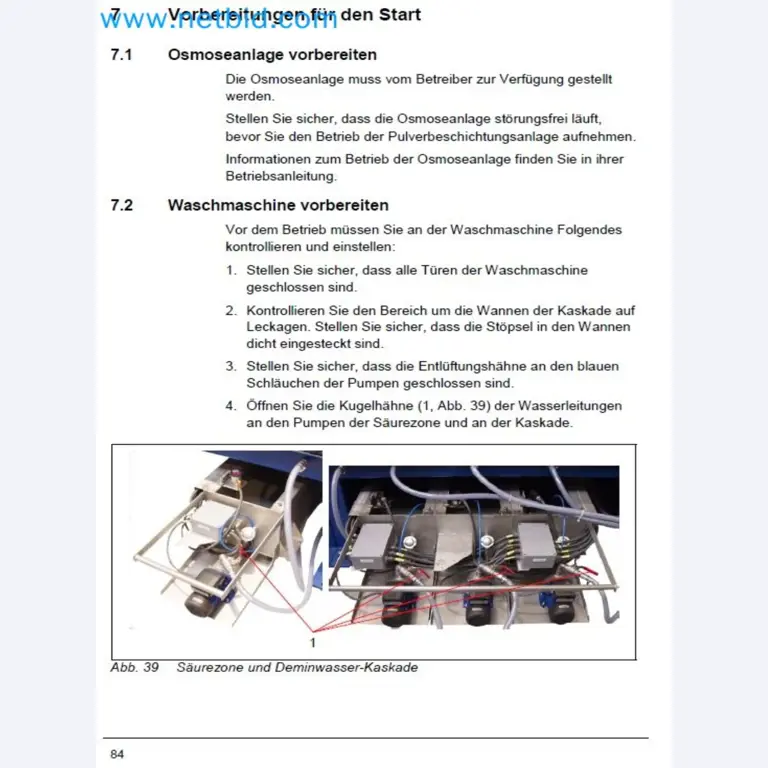

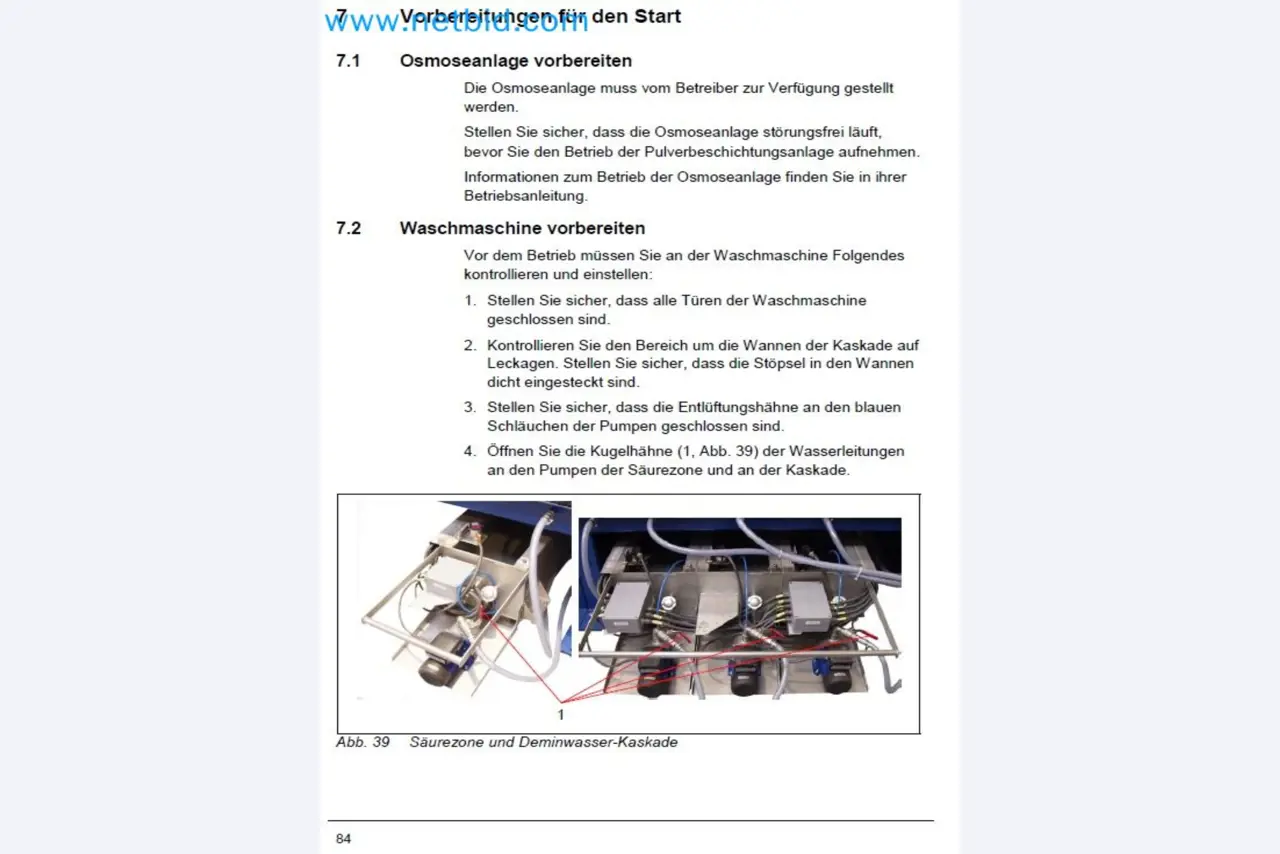

The cleaning is affected by filtered demi water. The full rubber coated transport rollers are individually driven by worm gear wheels and placed on a solid welded frame.

The transport rollers are arranged in drag bearings.

Active and not active ionization bars are installed to delete the static load from the “material”.

• Position 9 Gel furnace

To be controlled the difference in the GEL time for comparison with the product. The line parameters are based on the GEL time for float glass.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings. The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Special double tube infra red radiators are installed in the oven. The temperature control of the gel oven is a full automatic loop temperature control with thyristor units.

The temperature of the glass panel will be measured by pyrometer inside the oven. The temperature and gel time is set by recipe. The temperature and gel time is set by recipe. Thyristor are controlled by the set gel oven curves. In normal case there are 3 curves set by recipe for one process. Temperature and times are set and automatically controlled. The oven and the “material” temperature is measured and displayed.

This section melts the powder and prepares the surface for the laminator.

• Position 10 Aligment Furnace 1 zone before the lamination Station

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven.

The temperature control of the alignment oven is an energy efficiency, full-automatic loop, temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven. The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed. The “material” is aligned to an accurate position for later laminating the foil.

• Position 11 Laminator optional depending on your product application needs.

• Position 12 Curing furnace 1

The cure oven 1 serves to harden the melted powder coating.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven. The temperature control of the cure oven is an energy efficiency full automatic loop temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven.

The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed.

• Position 13 Curing furnace 2

The cure oven 2 idem to 1 serves to harden the melted powder coating.

The roller transport is equipped with ceramic rollers. Transport rollers inside the ovens with special hot bearings.

The upper and lower heating hoods are furnished with insulated plates. The isolation material for the ovens is designed for a high oven temperature.

Metal tube radiators are installed in the oven. The temperature control of the cure oven is an energy efficiency full automatic loop temperature control with thyristor units.

The temperature of the “material” panel will be measured by pyrometer inside the oven.

The average temperature in comparison with the set temperature calculates the Thyristor setpoints for the radiators to control the necessary electrical power to maintain the target temperature.

The oven and the “material” temperature is measured and displayed.

• Position 14 Cooling tunnel option with temperature and air controlling

The roller transport is used as a cooling section in front of the tilting table.

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame.

The transport rollers are arranged in drag bearings. The transport is covered on the top to reduce the cooling speed.

The second transport is open on the top.

• Position 16 Tilting table Conveyers

Optional:

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame.

The transport rollers are arranged in drag bearings. Tilting arms are in horizontal position

The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°.

The tilting speed has its lowest speed at the beginning and at the end of the movement.

The material is tilted from horizontal to the vertical position. If no “material” happens to be on the vertical inspection transport the “material” runs onto the transport.

The tilting table is used also as storage while normal production.

• Position 17 Electrical Distribution

For the above-described Powder Coating and Powder Coating Safety Glass Line:

Design: PLC controlled (Siemens S7 - 1500).

The supply comprises:

- Main control cabinets as well as local control boxes.

- Various terminal boxes

The electric switchboards belong to the production line and contain the corresponding switching devices as well as feeding and the processor PLC, fabrication Siemens with the corresponding construction groups.

Additionally, the switchboards have a preparation for UPS connection. All installed sensors designed to eliminate vibrations or wrong readings.

The control cabinets (Protection Class IP54) are complete wired to terminal strips and have been tested. Local terminal boxes are internal wired and partly pre-wired with the coordinated consumers.

All inputs and outputs applied to terminal strips. Spare terminal stripes with installed cable for future use should be there (no less than 10%).

All terminal boxes are with the necessary protection Class against their position on the line.

The PLC will be provided with spare memory as well as spare digital inputs and outputs (no less than 10% for each). In case of power failure all programs and data will be buffered.

The complete line is controlled by a PLC. Input, creation, and storage of recipes for different process parameters and products via PC. Cable and Cable Trays

The electric includes all cables between the electric switchboards and the consumers and the complete installation material for the line like cable trays.

The cable trays from the electric switchboards to the line are part wise inside the floor against foundation drawing.

• PC-control:

The communication between the chromatics line and external line elements will be done via Profinet connection.

Visualization (SCADA Control system), PC-control including Monitor, Data Control, recipe administration and sheet tracking (Siemens Simatic)

WinCC Advanced (TIA Portal)) consisting of:

- 1 pcs. Standard PC

- 1 pcs. Monitor approx. 22” – 24”

- 1 pcs Keyboard and mouse

- 1 pcs. Simatic WinCC Advanced (TIA Portal)Software

Function control of motors, radiators, and the complete line via PC. Integrated failure indication with supervision of systems.

Visualization of all construction groups. Parameters for the quality control can be saved and archived.

Screen display of the machine with motors, etc. and all operation parameter such as speed, Thyristor settings, temperatures, etc. The PC can be used for supervision and adjustment of the line components.

Storage of recipes for different process parameters, like glass dimensions, glass thickness or different set points for different products.

• Quality Control

Measured production parameter along the line are stored corresponding to the produced “Material”. The “Material” can be signed by hand or as option marked by digital printer on the backside of the foil.

Other functionality: Alarm logging, Tag logging, Visualization of the plate tracking, Archiving of the various process Parameters

• Operation and Monitoring

- 2 pcs. Simatic Comfort Panel

One Panel located at the Laminator, one Panel located at the end of the line.

The panels are used to operate and run the line in Automatic and Manual Mode

- Operation Modes:

Automatic Mode:

Automatic Mode to run the line full automatically by recipe.

Recall of recipes for the running production in case of need. After selection of a recipe the new set points will be automatic transferred.

The line adjusts automatically to the new production parameter.

All the valves, motors are supervised and in case of failure a signal is given.

Manual Mode:

The manual mode allows activation of all motors for maintenance of the line.

Manual mode with end position monitoring but without interlocking.

General Design Data:

Input: 3 x 400 V, +50 Hz, PEN

Control Voltage : 24 V DC / 230 V DC

Voltage variations : + 5% / - 5%

Installation height: < 1.000 m M.S.L.

Ambient temperature: min. +5°C max. +40°C

Relative air humidity: max. 95%

Cabinets with air condition: If necessary, after final design of the line inside the Workshop

Switching devices: acc. to IEC, EN, VDE

Cable outlet cabinets: below

Documentation: acc. to DIN on ELCAD

Doc. language: English

Complete line disassembled !!!

18 Standard trucks needed to load the complete line (approx.)

Important! The line has already been professionally dismantled and will be loaded onto the buyer's transport. The mandatory costs for dismantling and loading, which are to be borne by the buyer, amount to €16,000 (plus VAT, if applicable). The seller will issue an invoice for these costs, which must be paid in full before collection. NetBid ESP SLU does not receive any commission for the dismantling and loading and is therefore not responsible for these actions of the seller. The dismantled line can be viewed and is purchased “as is.”

Location

- 25440 Vinaixa (Spain)

Dates

Inspection

Visits are only possible after prior registration at fernandez@netbid.com.

Pickup

Collection is only possible after prior registration at fernandez@netbid.com.

Auction Terms

Special conditions:

- Important! The line has already been professionally dismantled and will be loaded onto the buyer's transport. The mandatory costs for dismantling and loading, which are to be borne by the buyer, amount to €16,000 (plus VAT, if applicable). The seller will issue an invoice for these costs, which must be paid in full before collection. NetBid ESP SLU does not receive any commission for the dismantling and loading and is therefore not responsible for these actions of the seller. The dismantled line can be viewed and is purchased “as is.”

- Available loading facilities on-site: Forklift (loading capacity 4800 kg), crane, loading ramp. Please contact our collague on the location site for more details, if needed.

- Protection shoes and reflective vest are mandatory for the visit.

- Important! The line has already been professionally dismantled and will be loaded onto the buyer's transport. The mandatory costs for dismantling and loading, which are to be borne by the buyer, amount to €16,000 (plus VAT, if applicable). The seller will issue an invoice for these costs, which must be paid in full before collection. NetBid ESP SLU does not receive any commission for the dismantling and loading and is therefore not responsible for these actions of the seller. The dismantled line can be viewed and is purchased “as is.”

- Available loading facilities on-site: Forklift (loading capacity 4800 kg), crane, loading ramp. Please contact our collague on the location site for more details, if needed.

- Protection shoes and reflective vest are mandatory for the visit.

Contact Person

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com