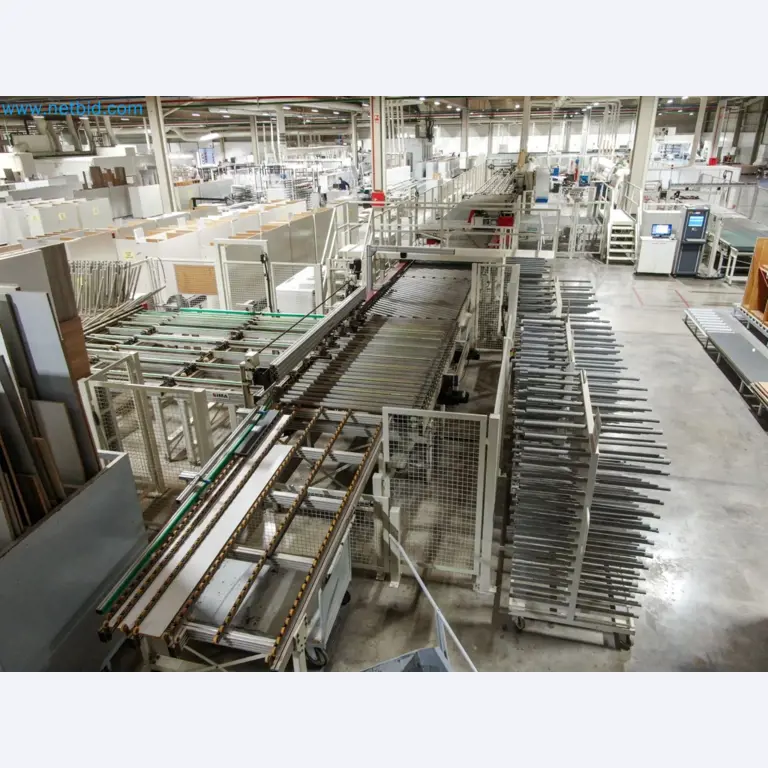

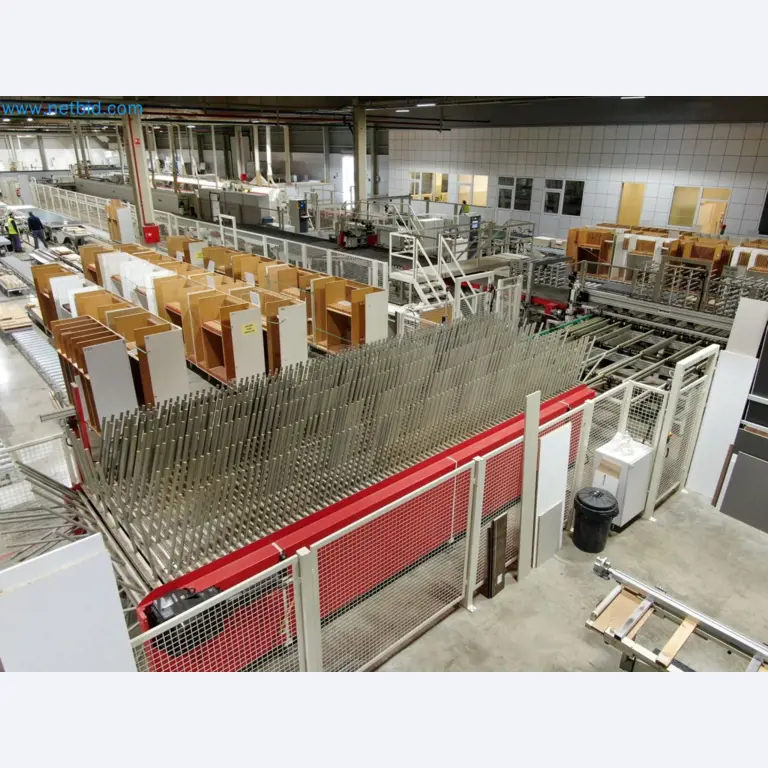

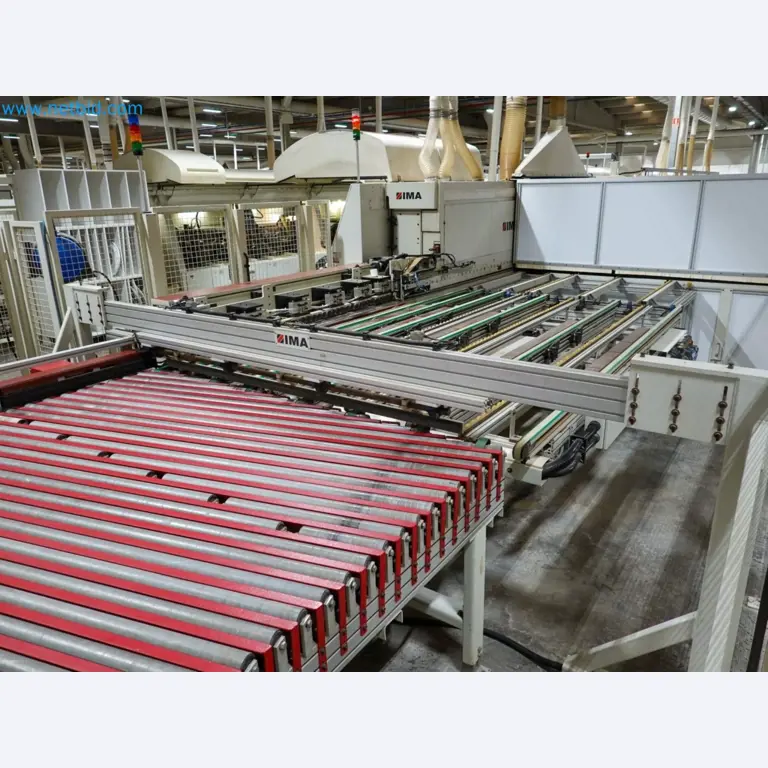

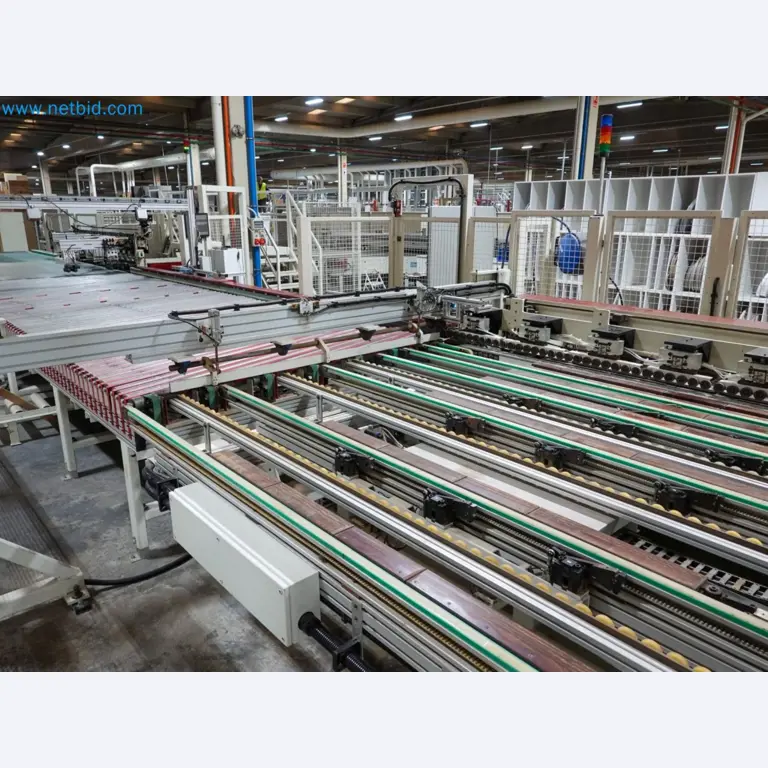

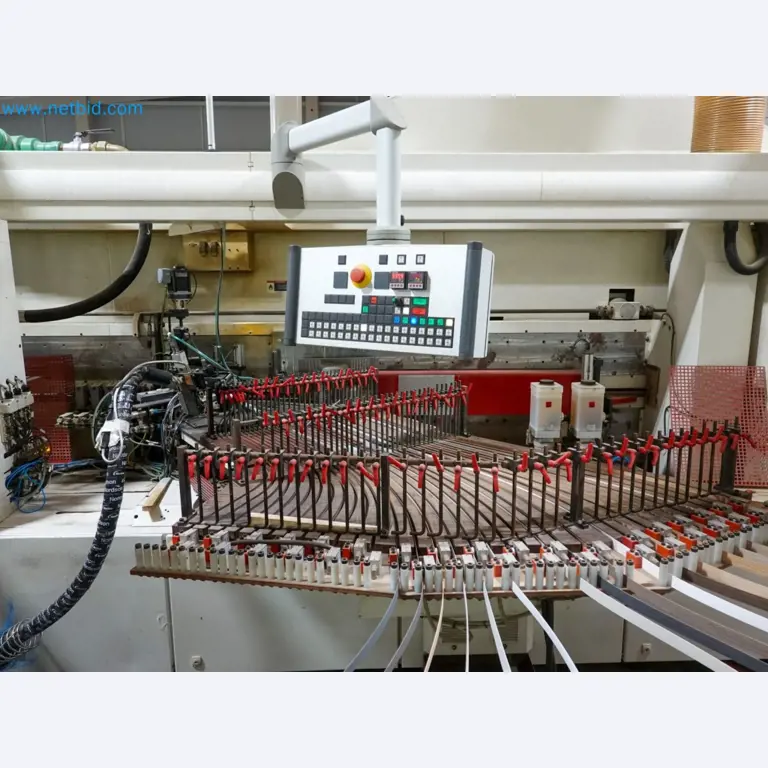

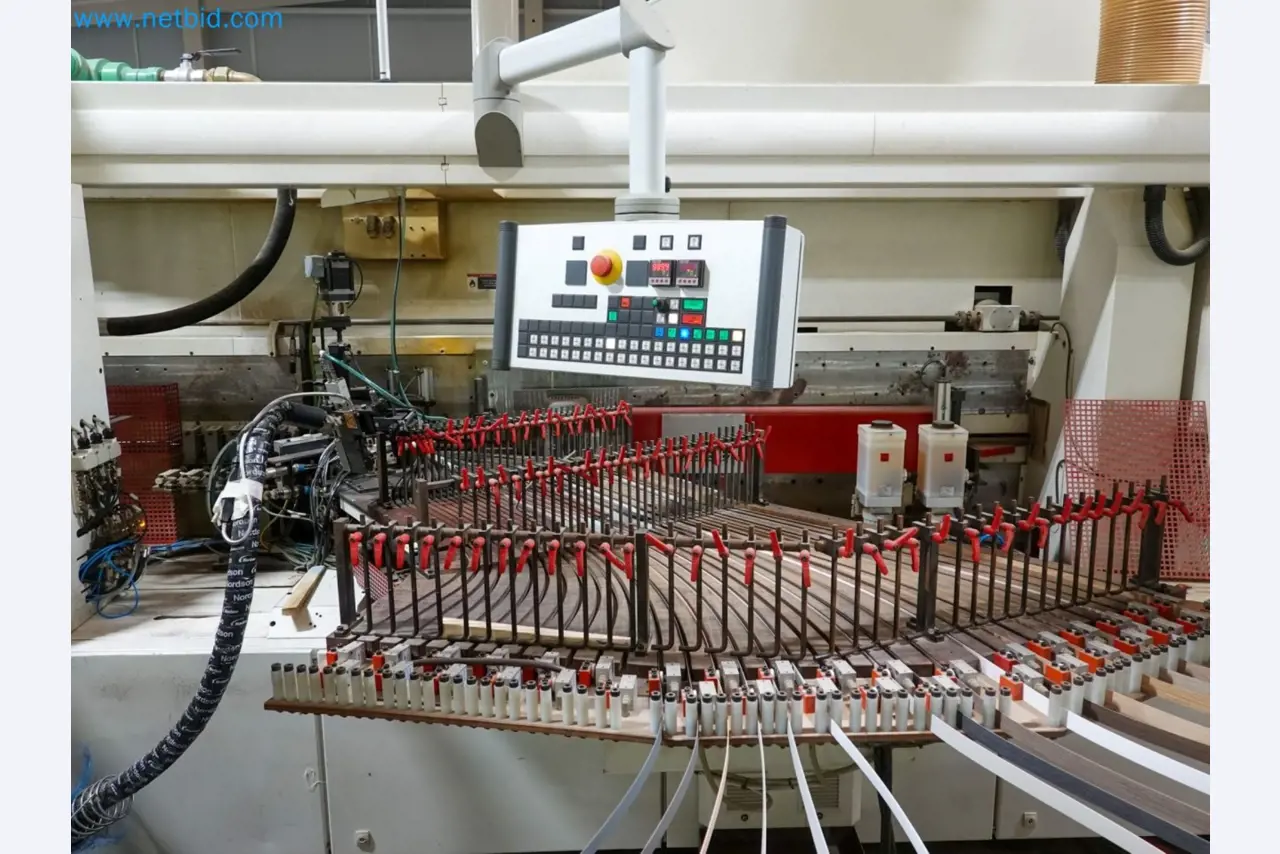

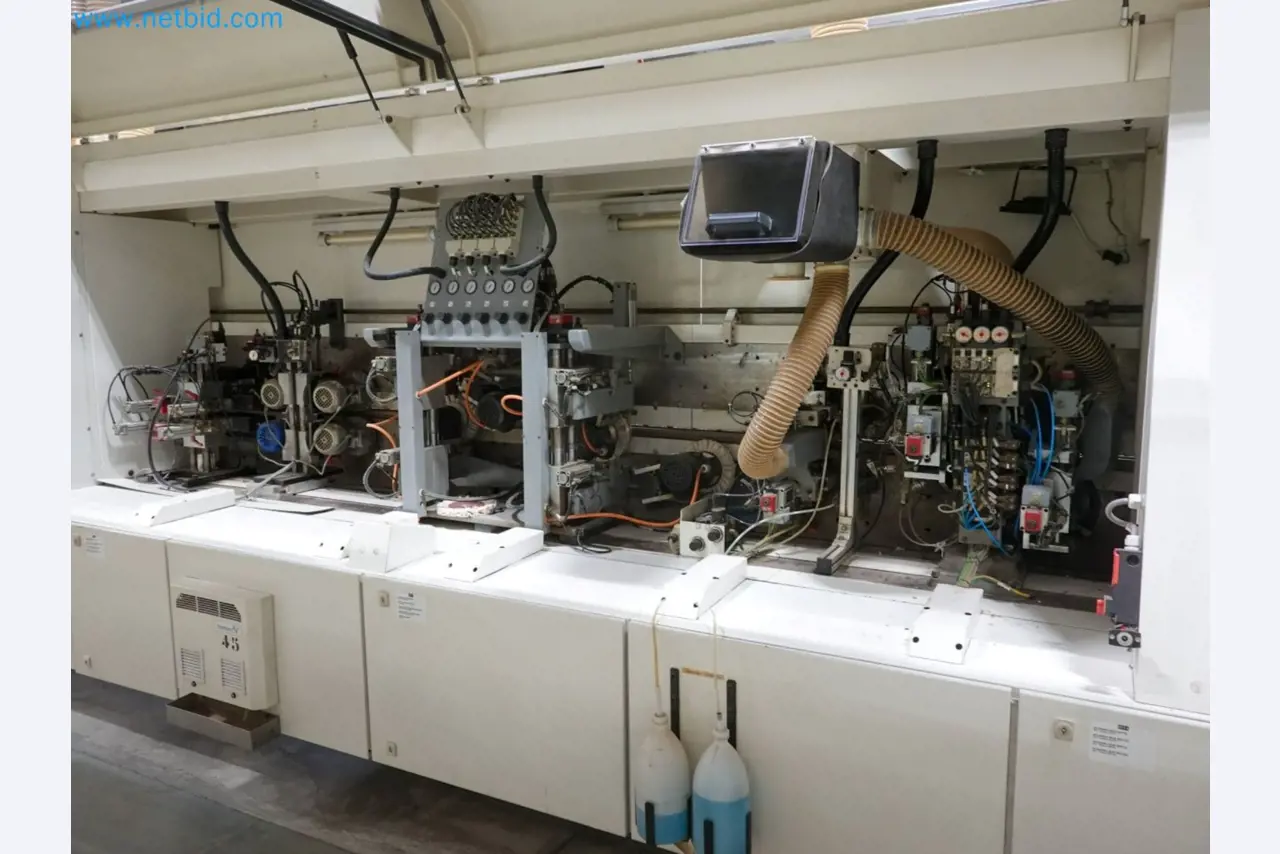

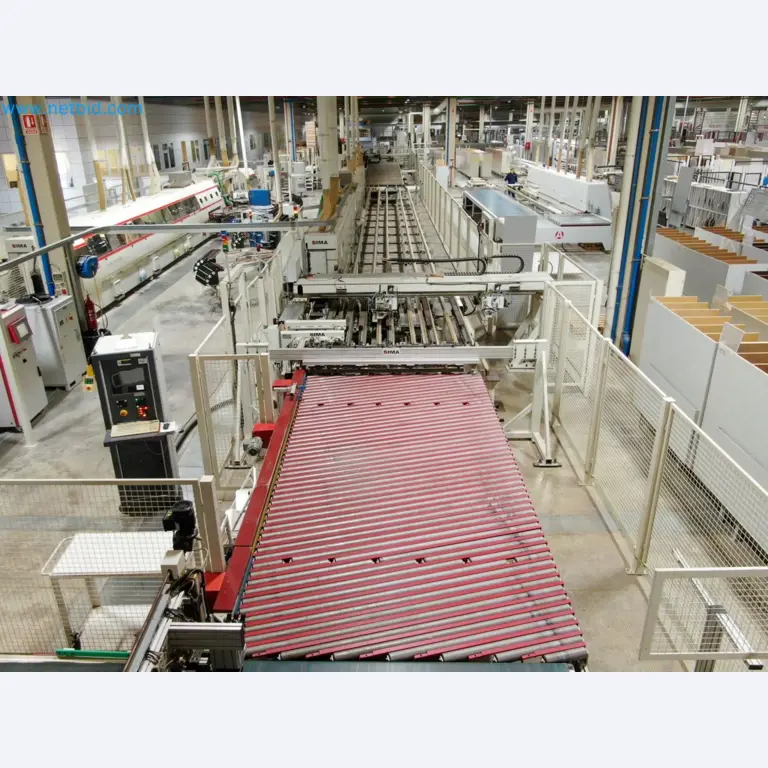

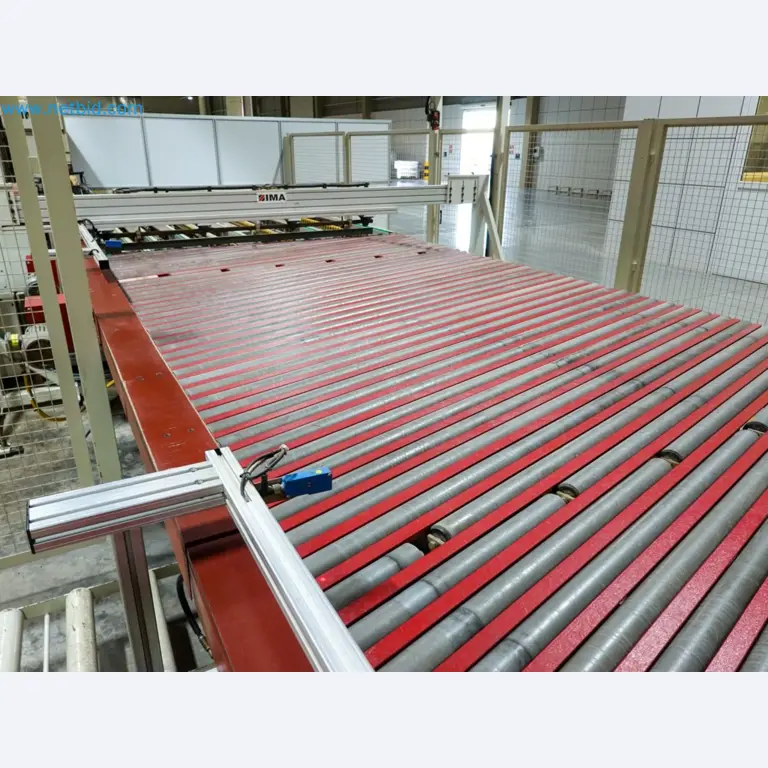

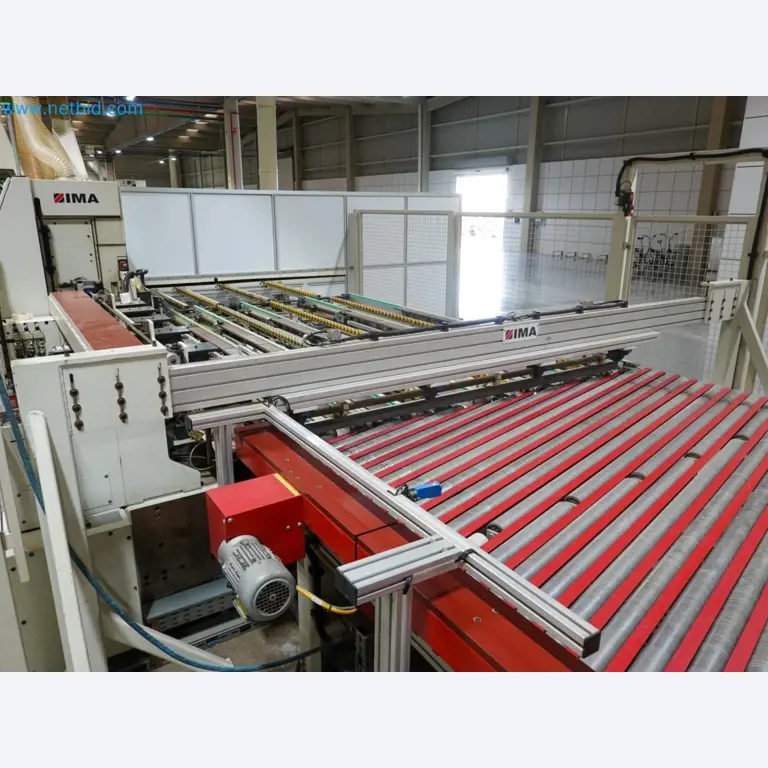

Part of the Auction Great opportunity: IMA Edgebanding Line on sale

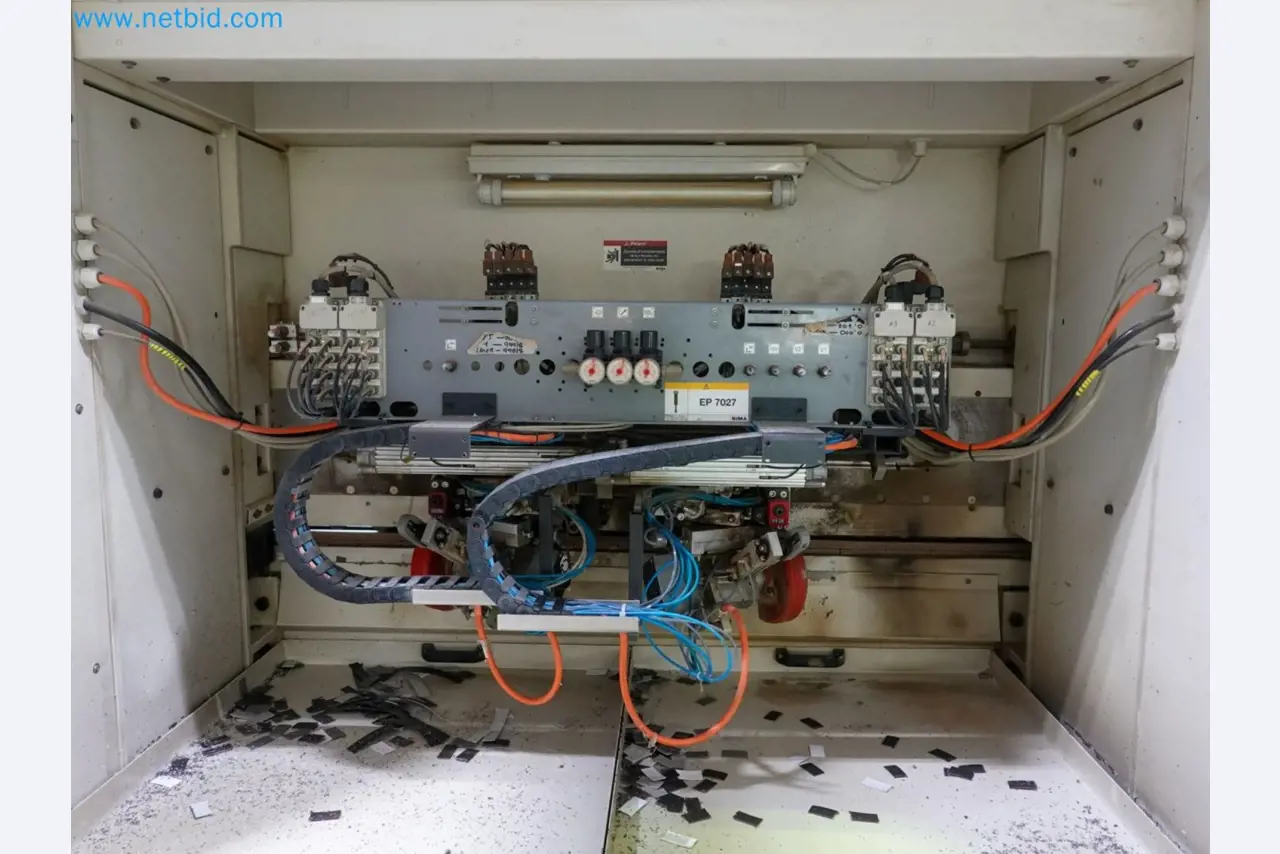

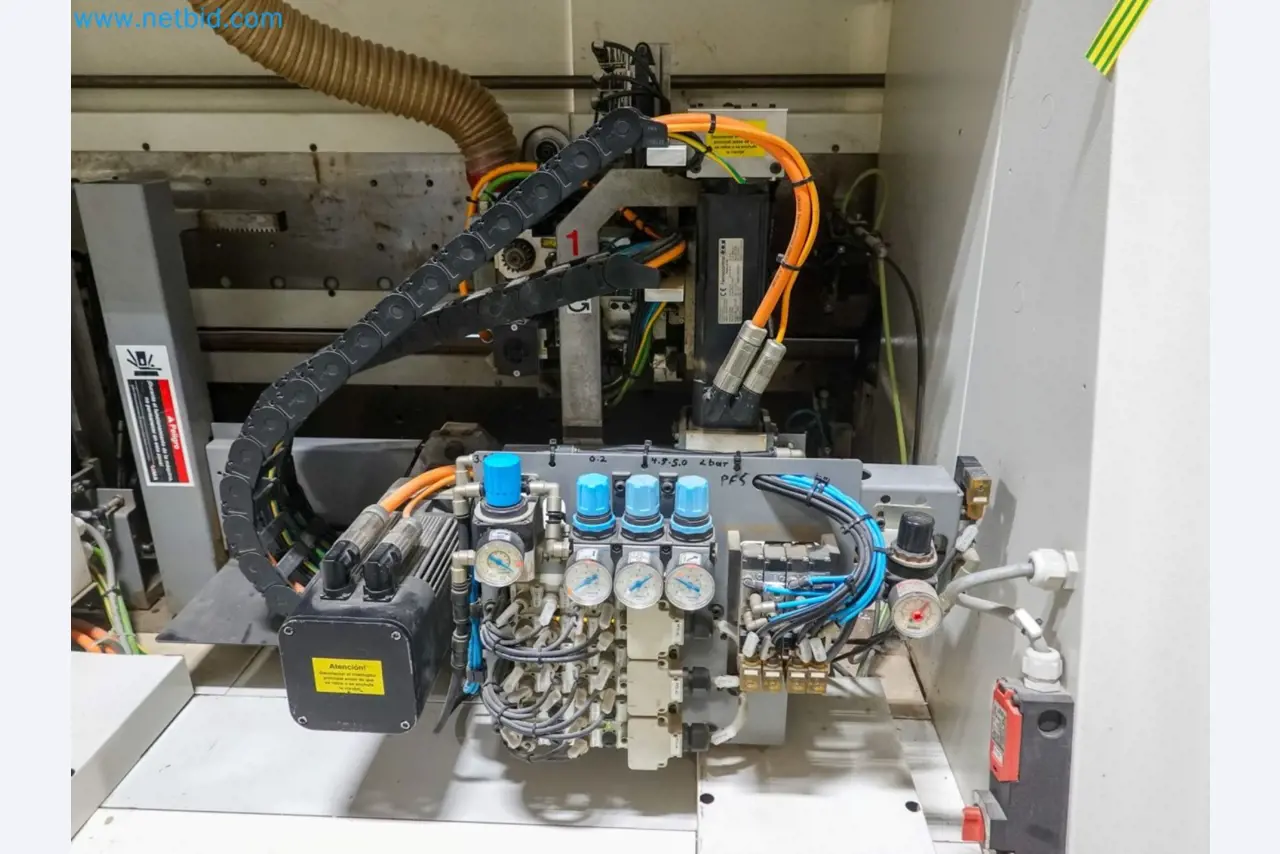

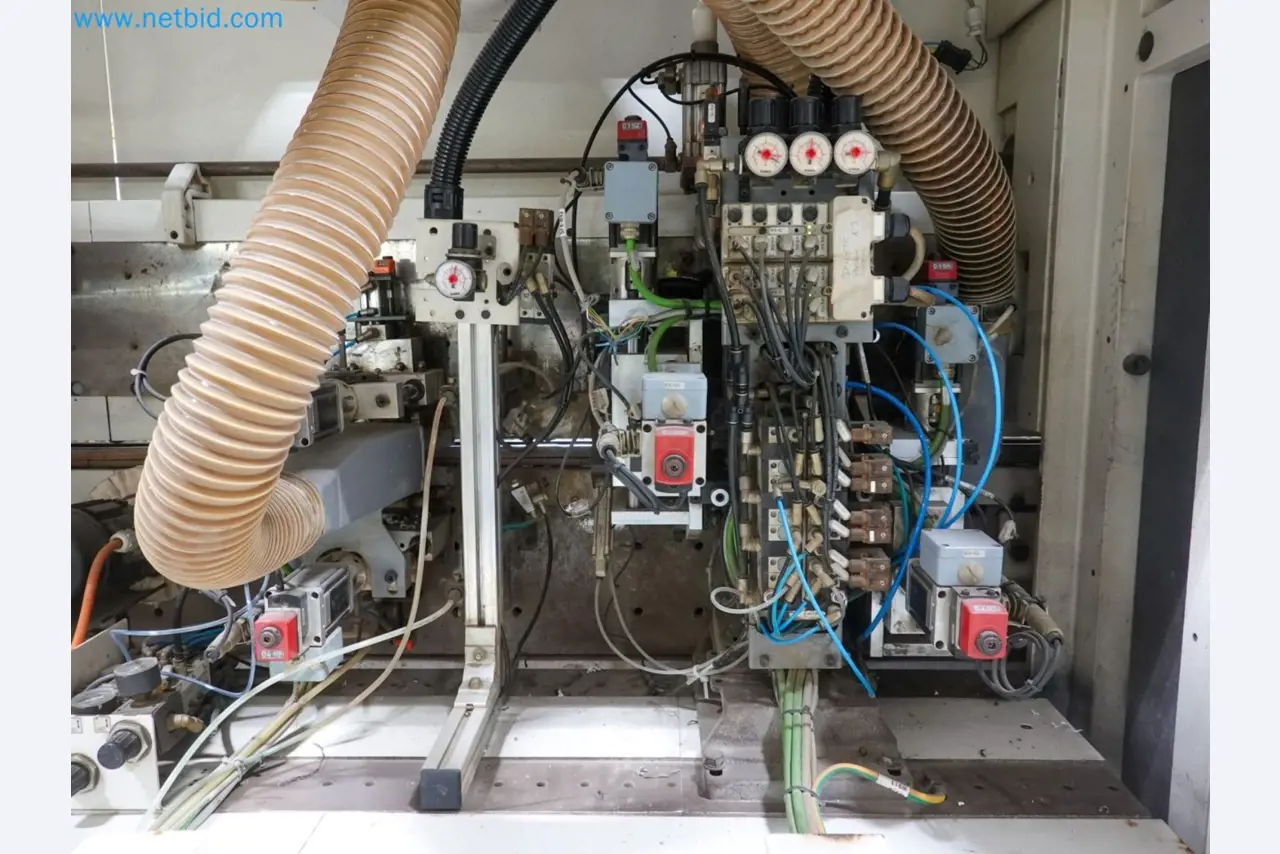

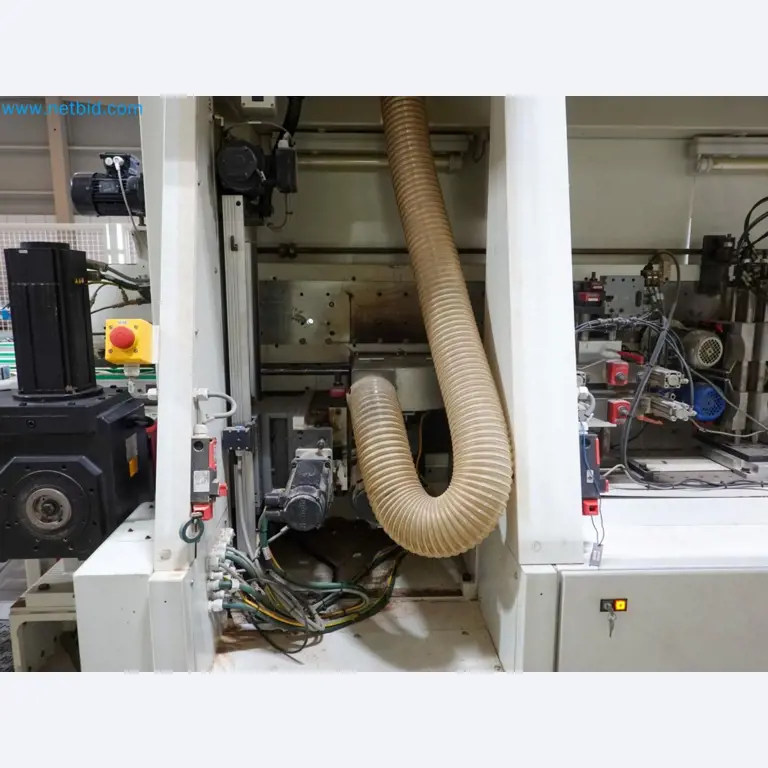

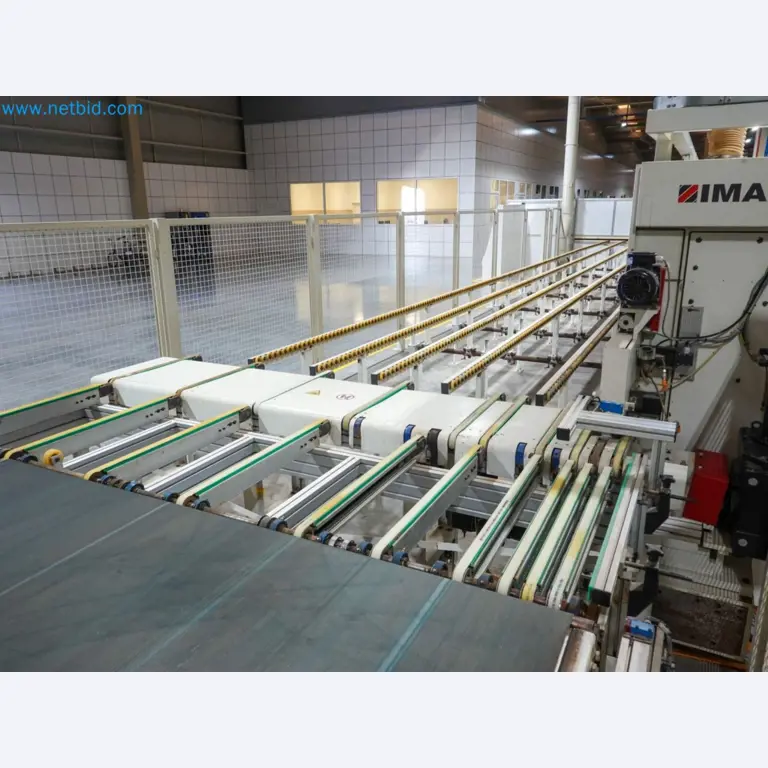

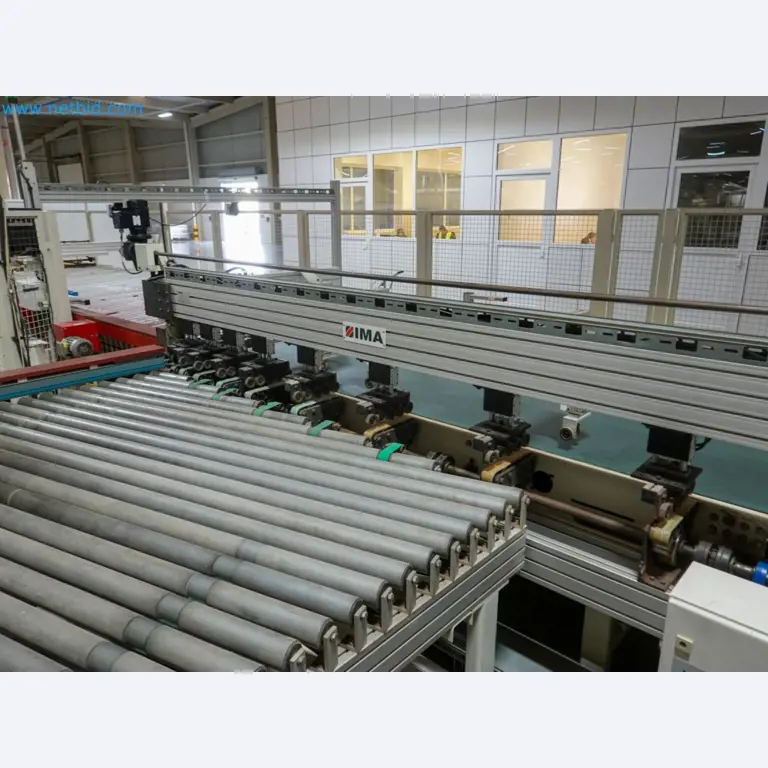

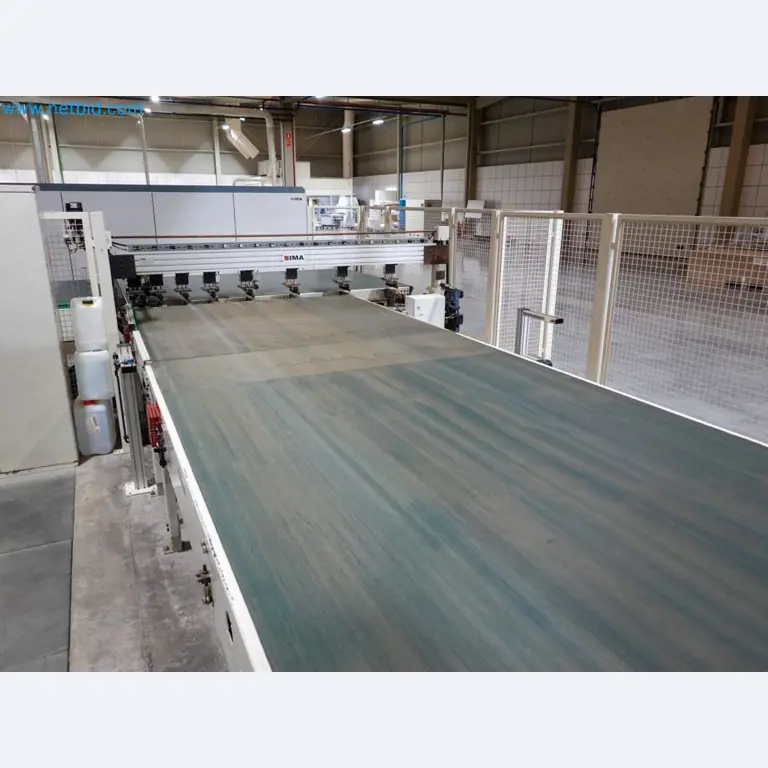

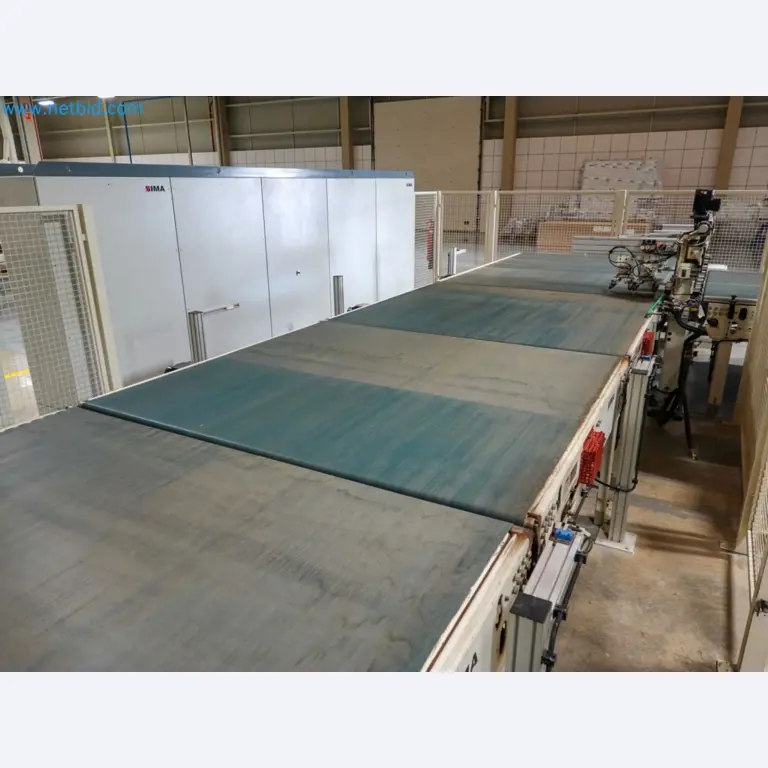

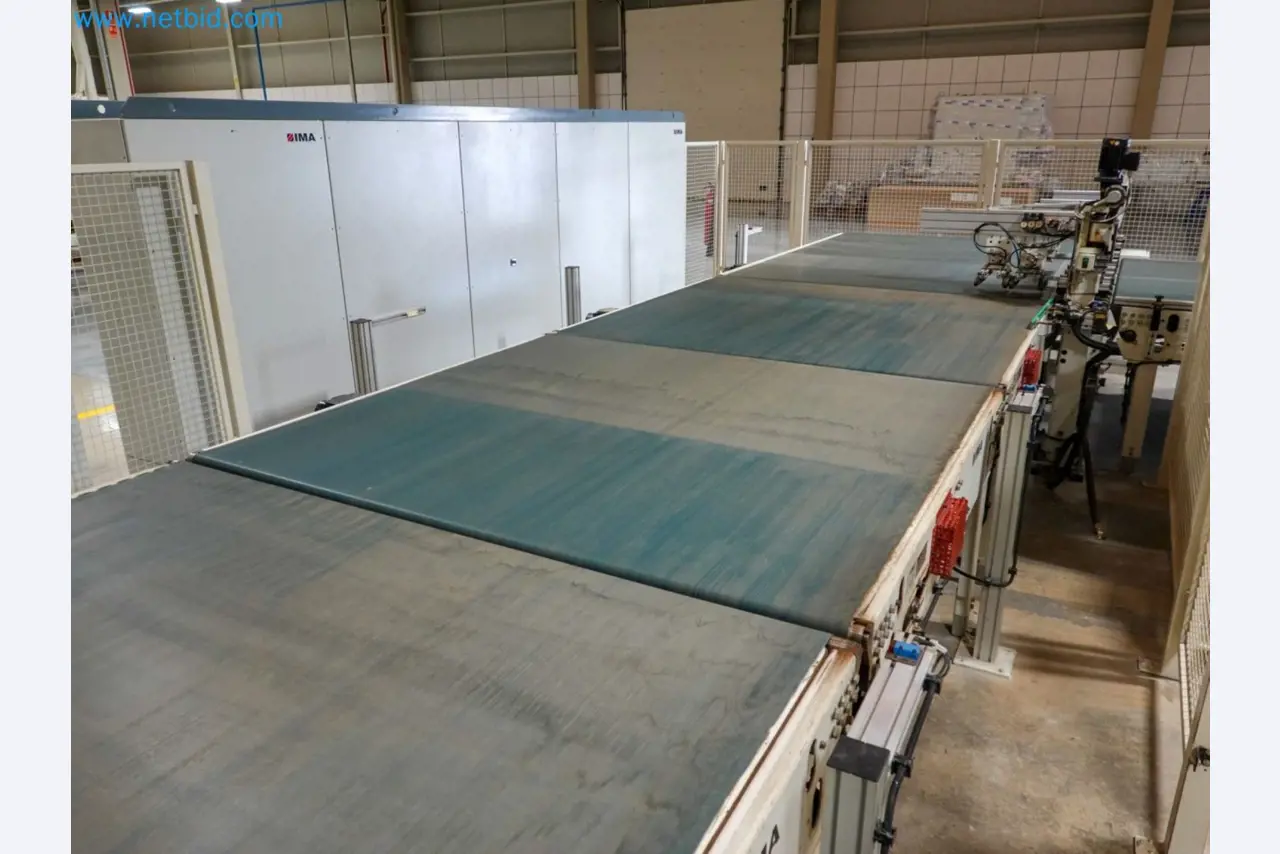

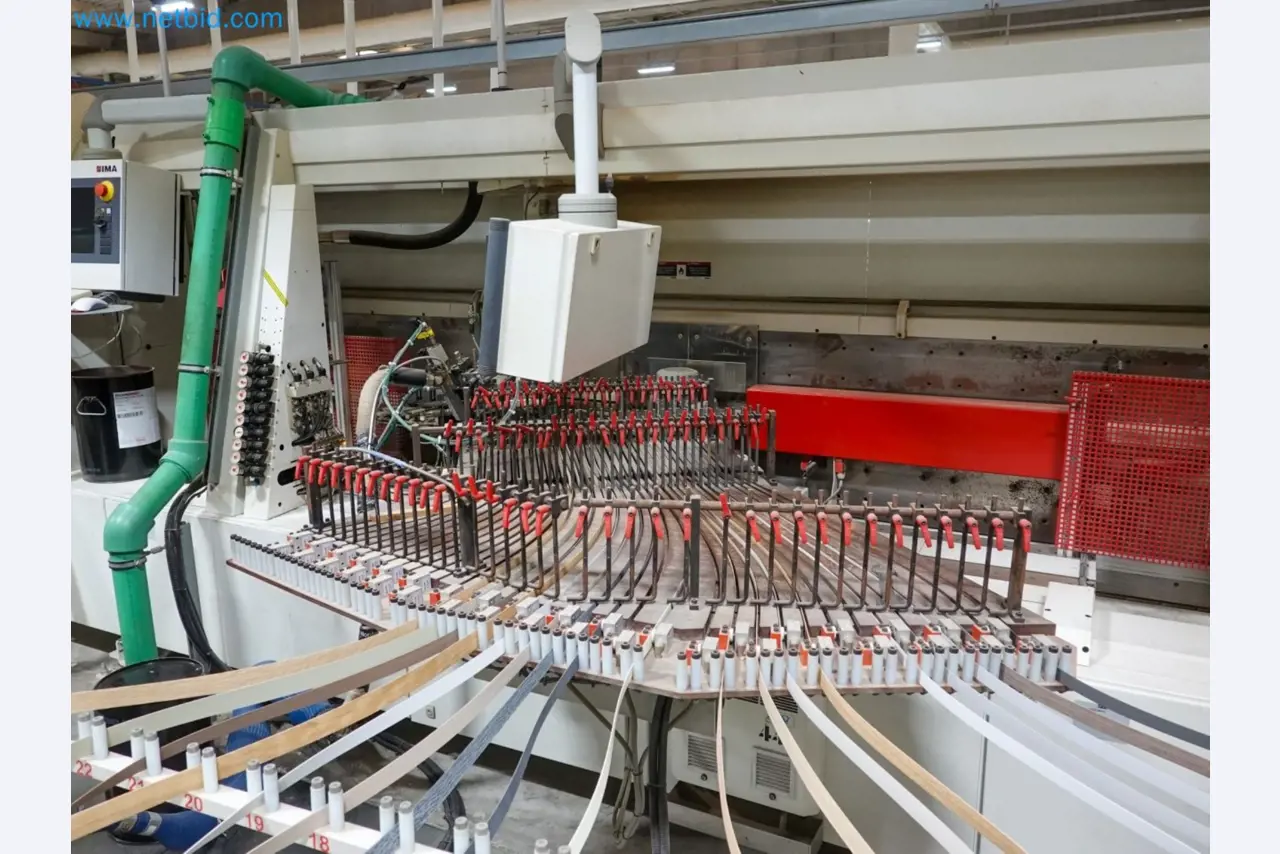

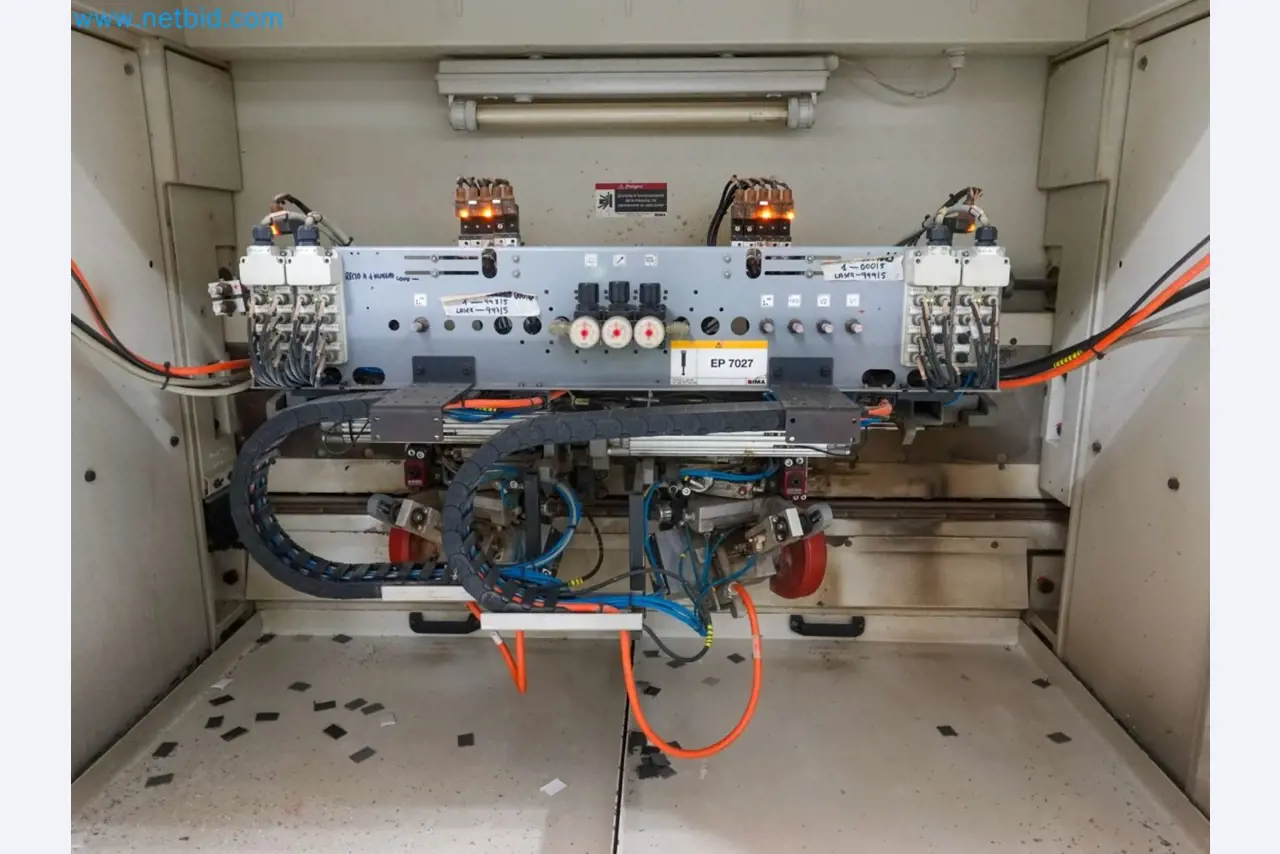

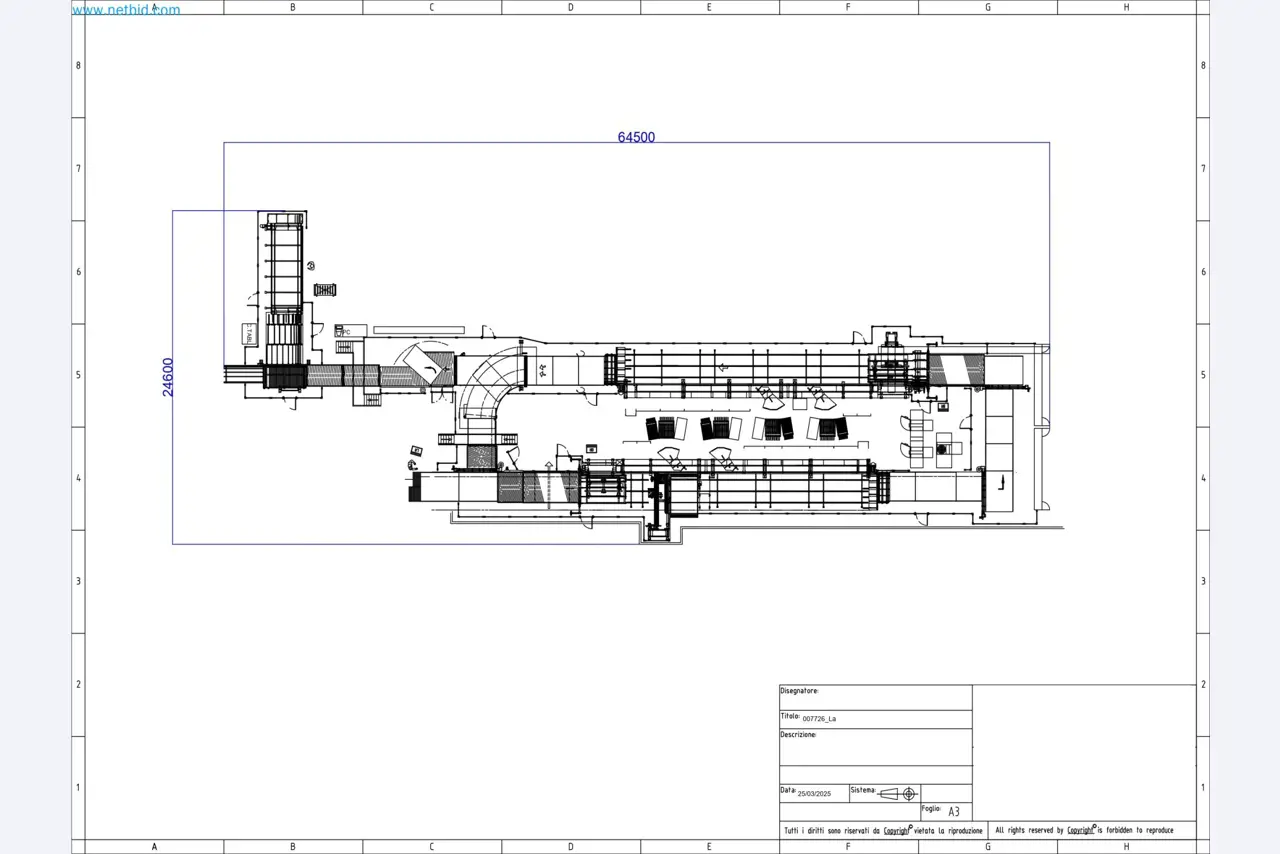

Edgebanding Line IMA Combima Systems I/R75/1840TRADING#19129-1

Details

Product Type

IMA

Type

Combima Systems I/R75/1840

Construction Year

2008

Description

Serial Number: 14259

Year of Manufacture: 2008

IMA-COMBIMA SYSTEM/I/R75/1840

Type of edge applied: thin edge, thick edge

Gluing system: PUR, laser

Trimming group: yes

Corner rounding group: yes

Maximum panel thickness: 60 mm

Operator groups: 10 nr

Minimum panel height: 8 mm

Maximum panel height: 60 mm

Minimum panel length: 300 mm

Maximum panel length: 5000 mm

Minimum panel width: 115 mm

Maximum panel width: 1300 mm

Minimum edge thickness: 0.3 mm

Maximum feed speed: 40 m/min

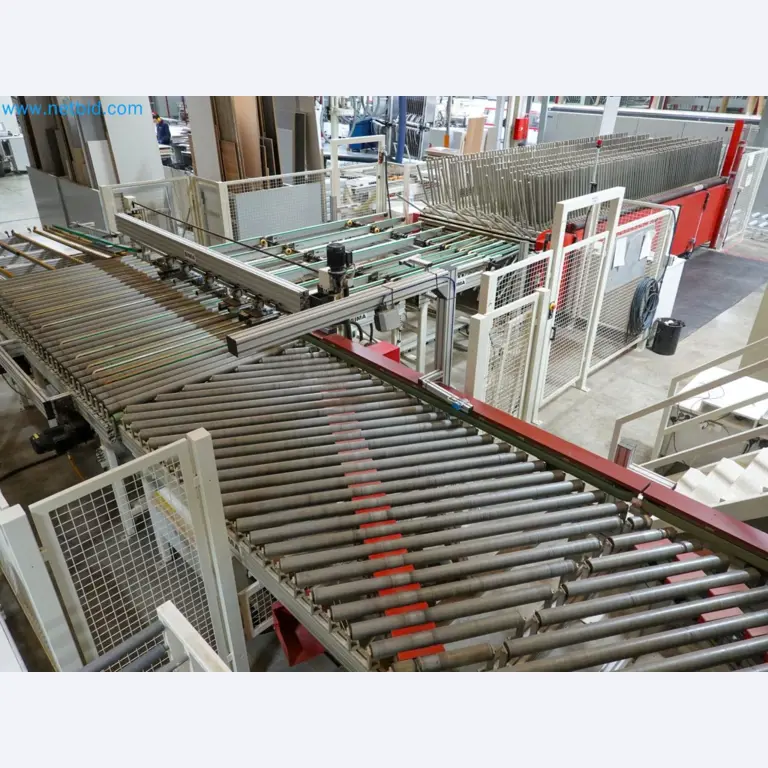

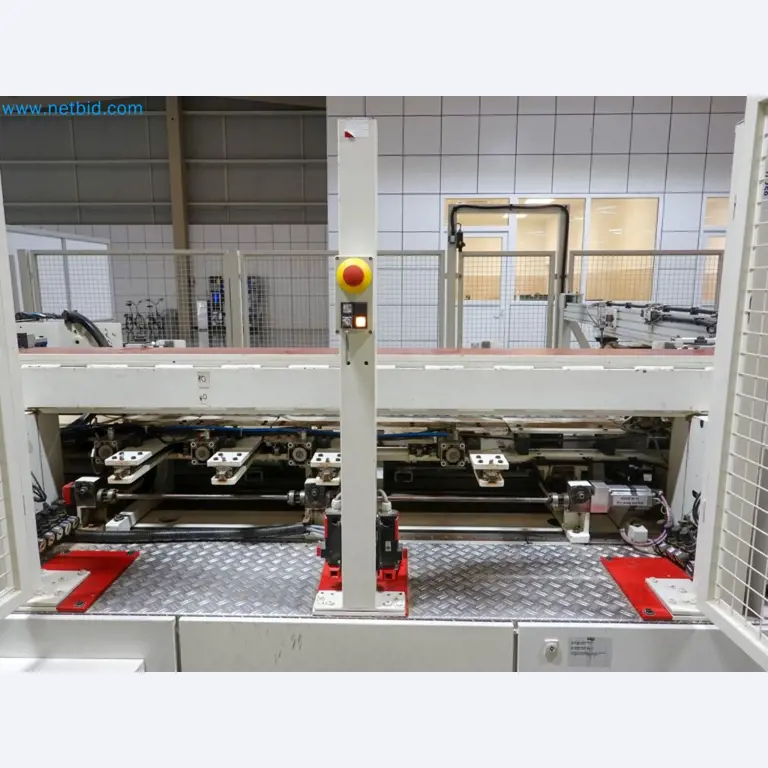

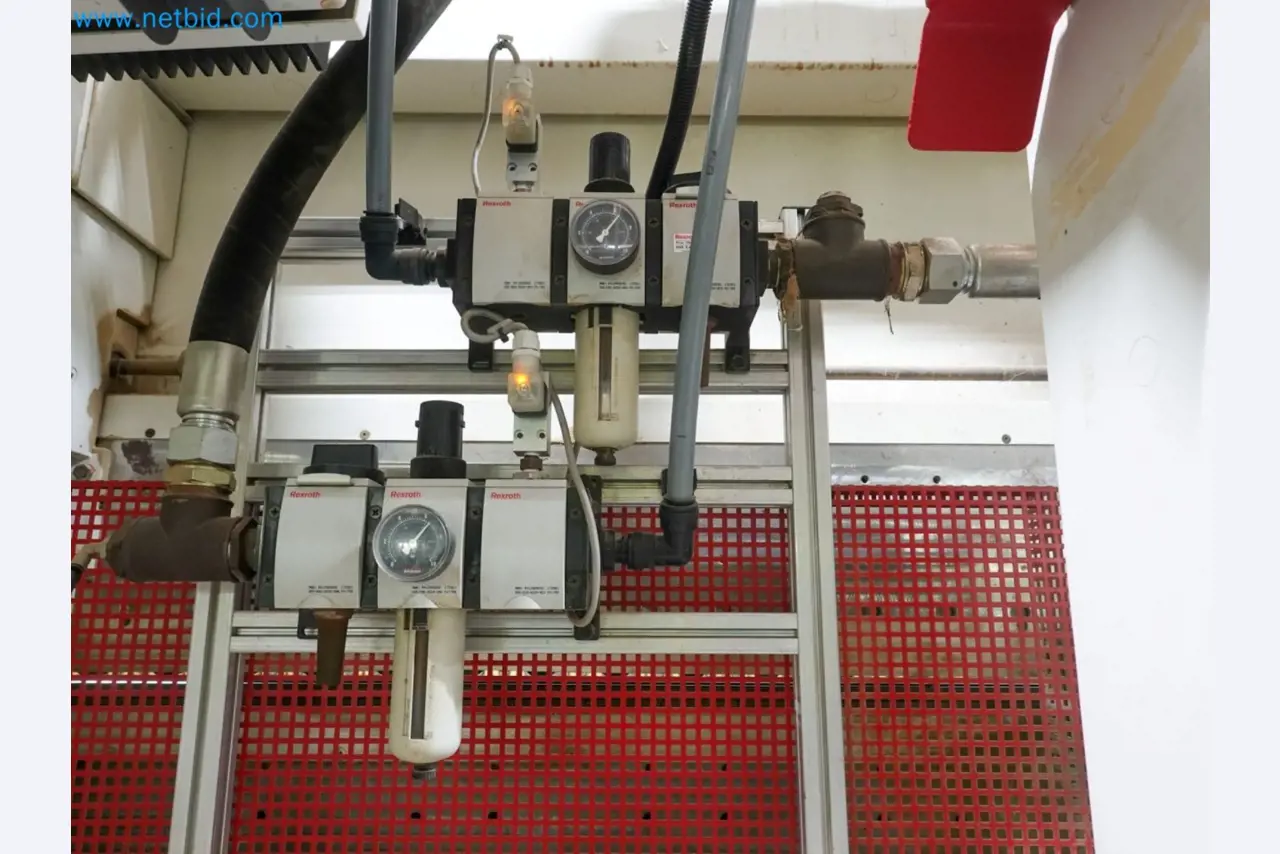

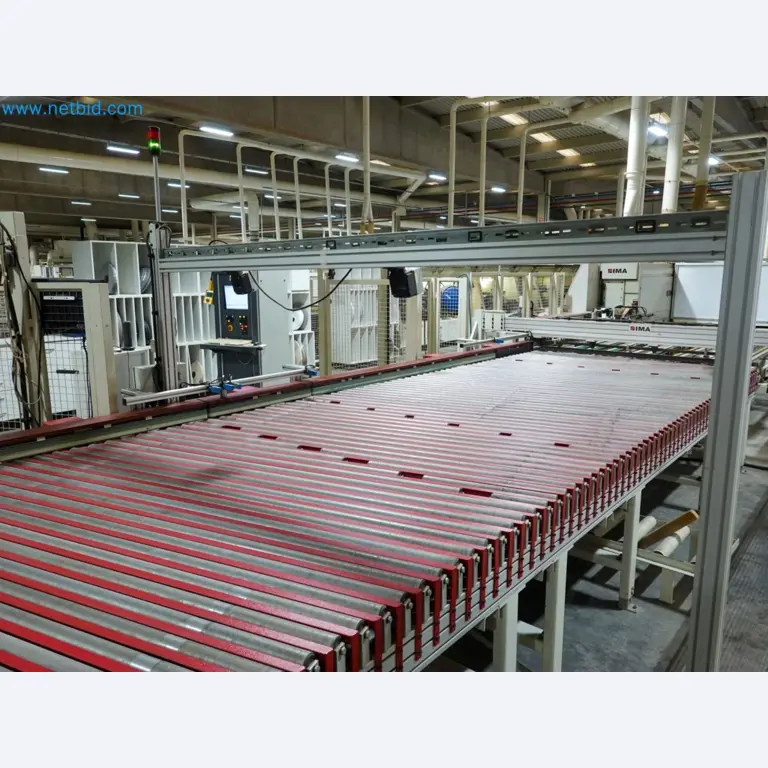

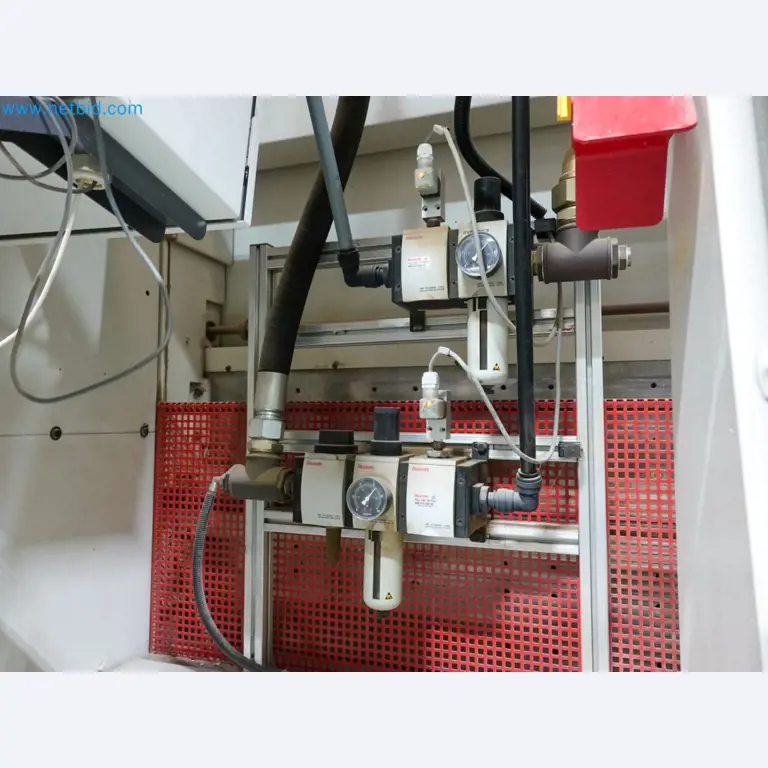

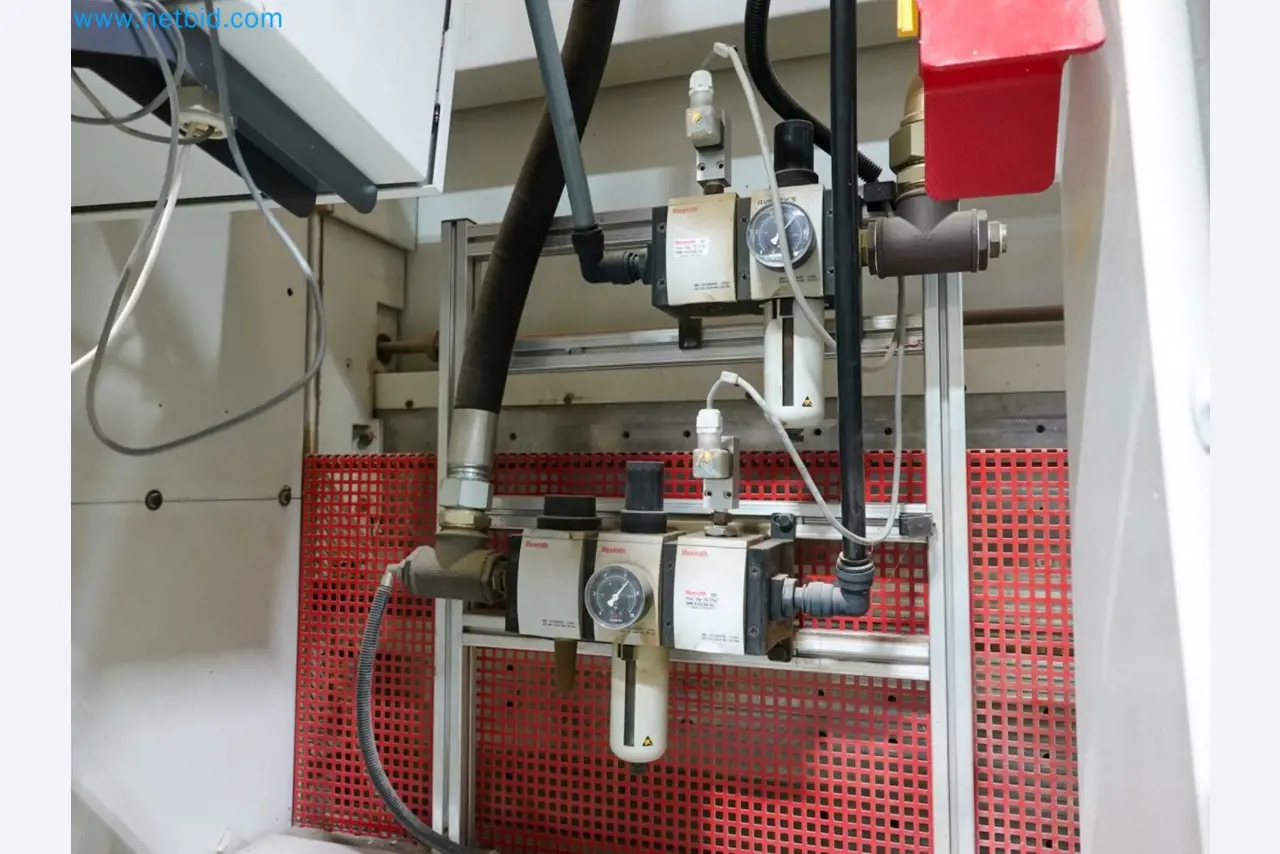

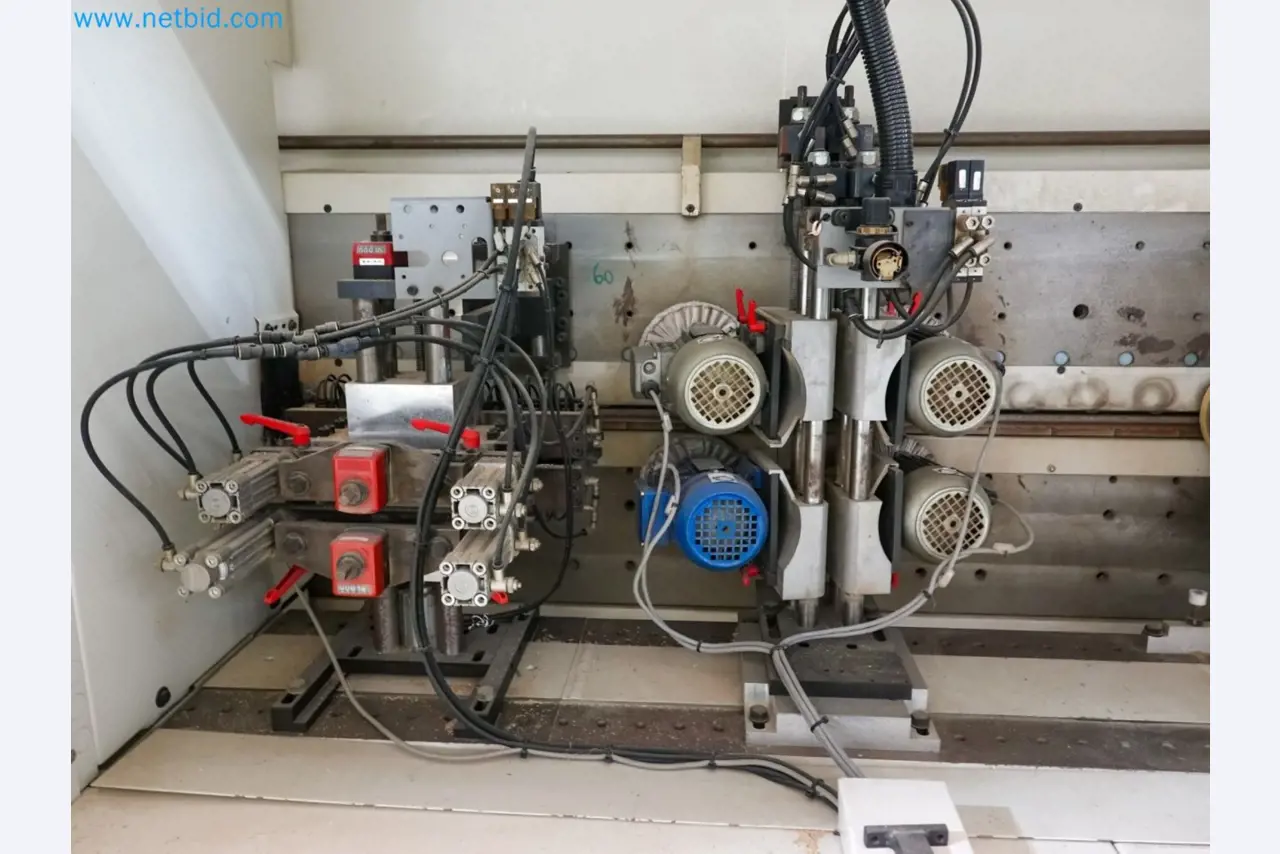

Top pressure: yes

Pressure with rubber belt

Panel support guide: yes

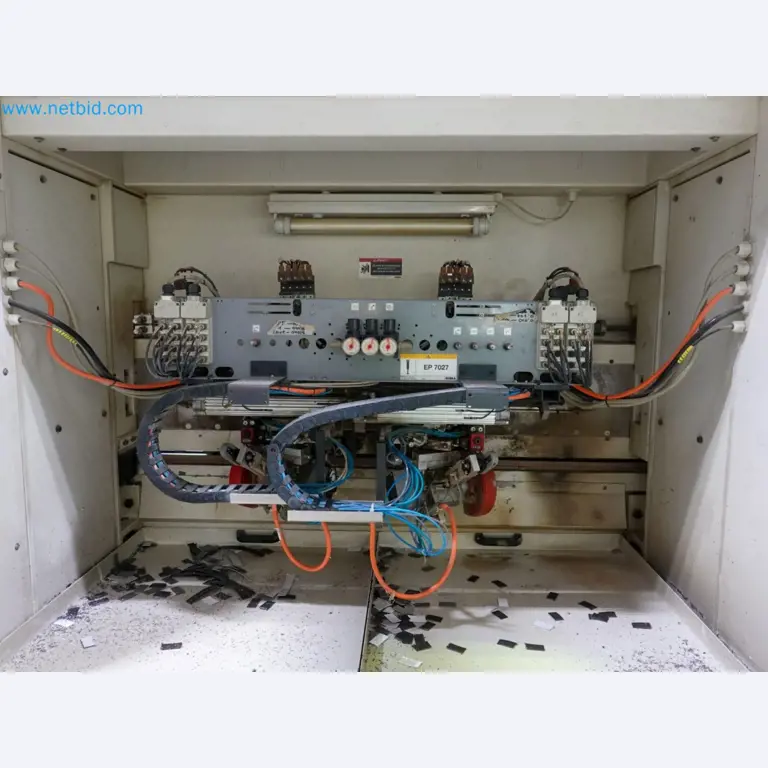

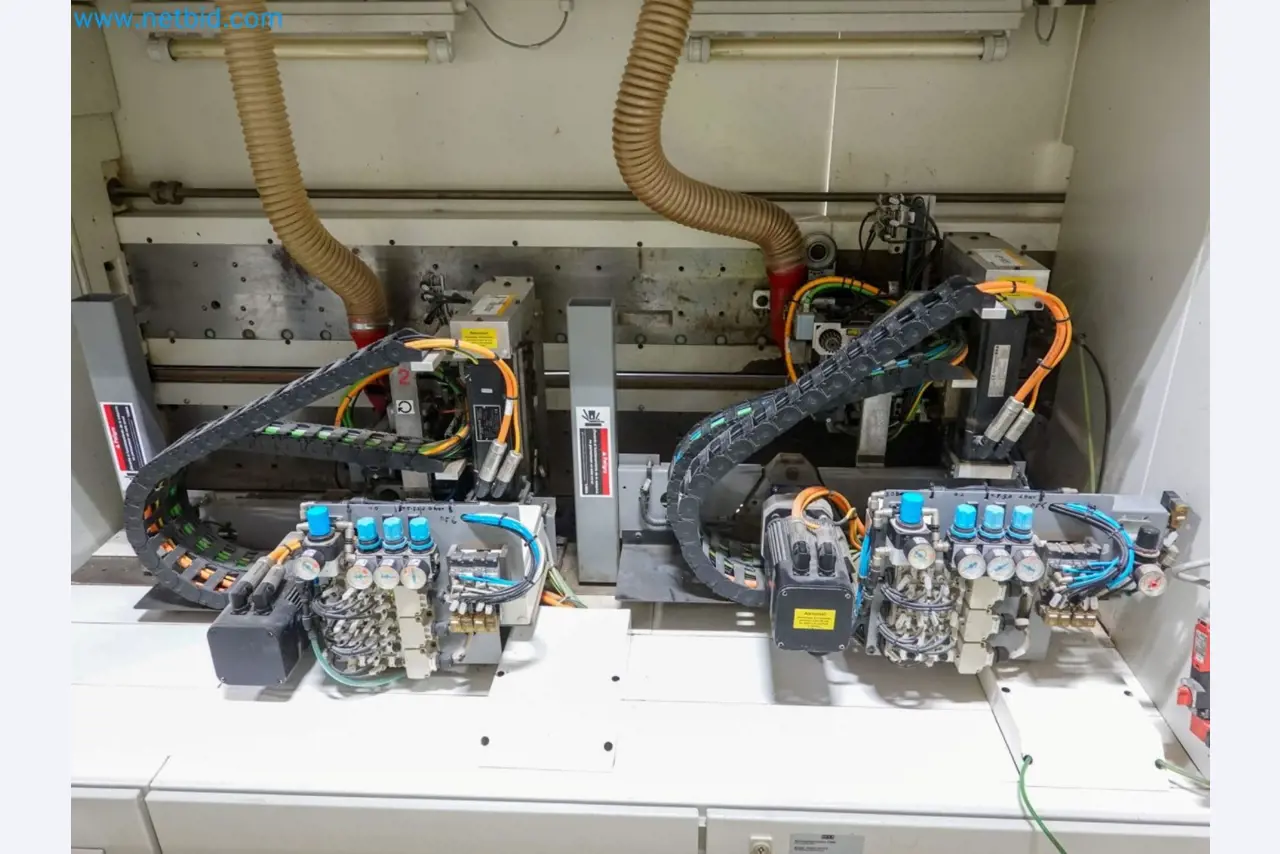

With CNC positioning: yes

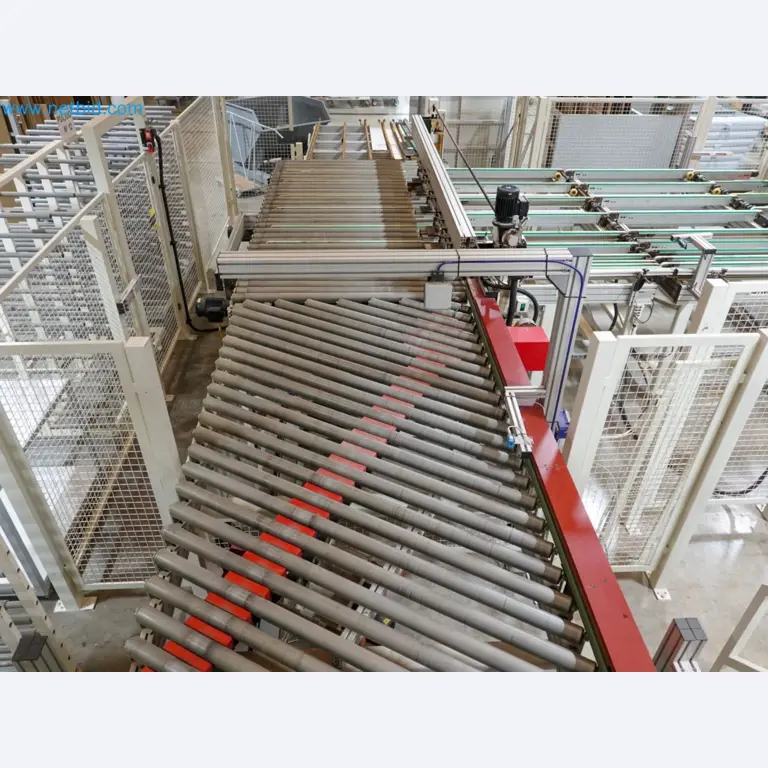

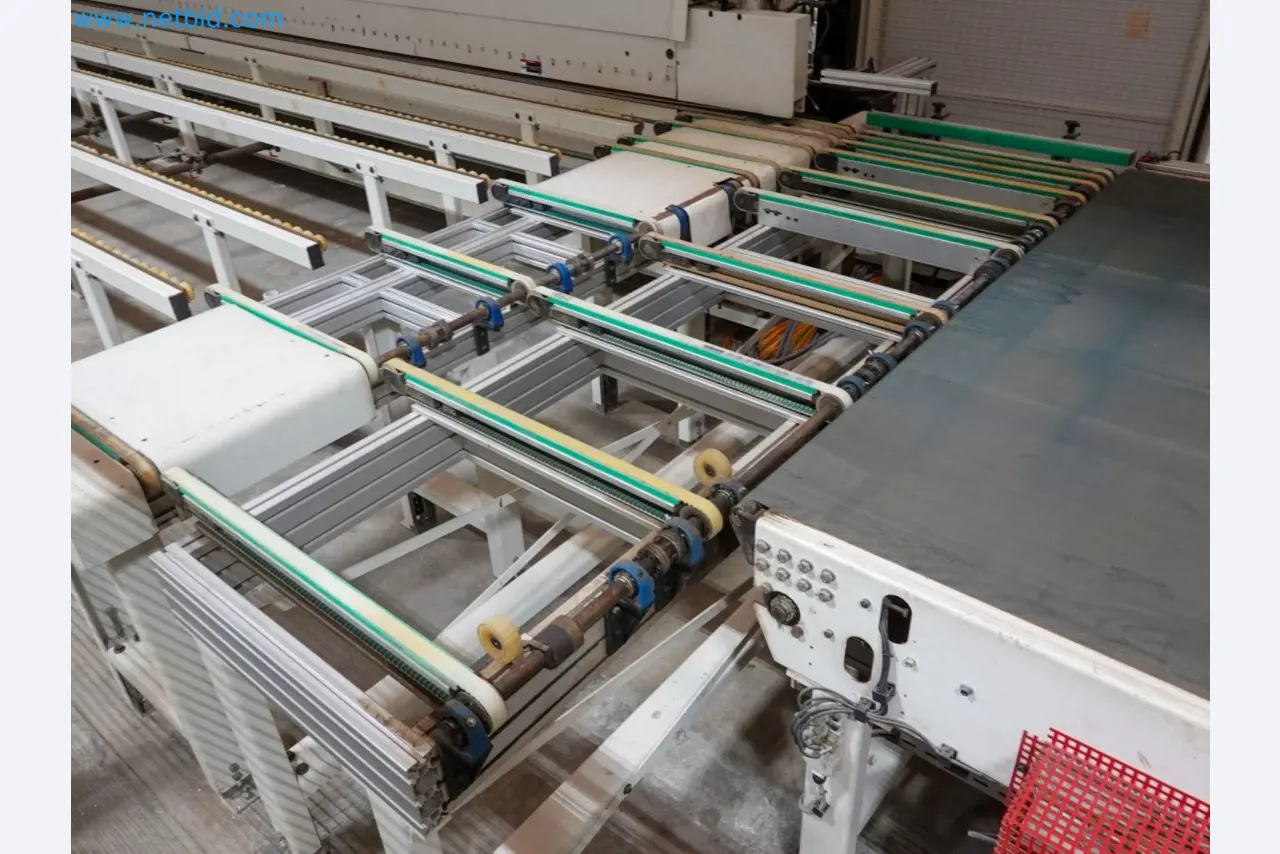

Panel squaring-in feed system: yes

Operator groups in squaring section: 1

Group 1: trimming

Manufacturer model: 08.38B

Automatic time intervention: yes

With CNC positioning: yes

Motor power: 4.5 kW

Revolutions/min: 9000 RPM

Edge-heating lamps: yes

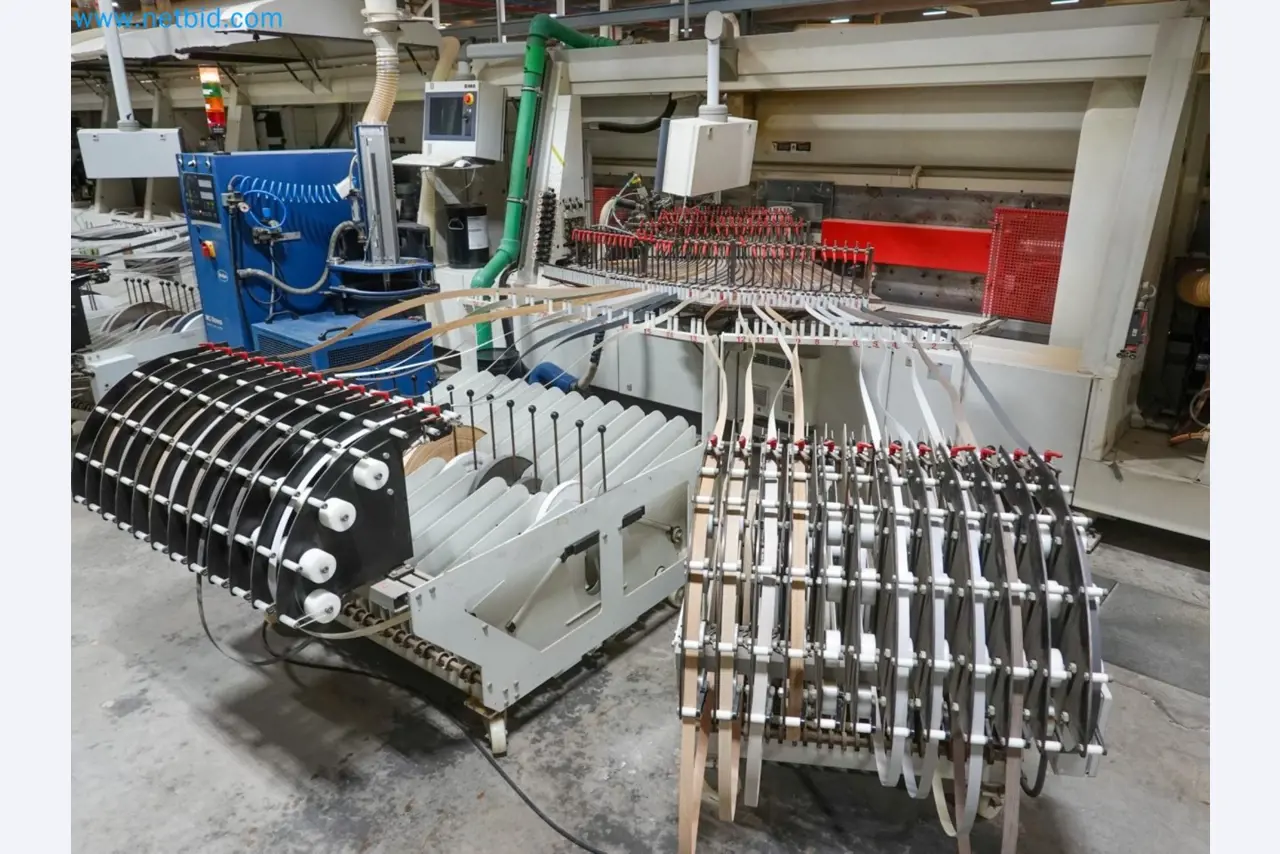

Edge-tape magazine: yes

Number of positions: 36

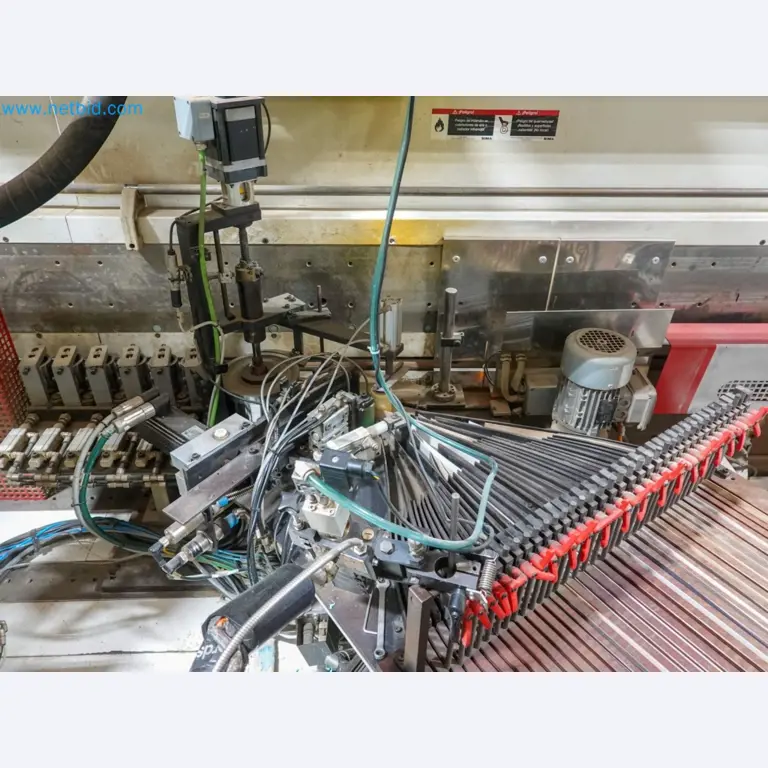

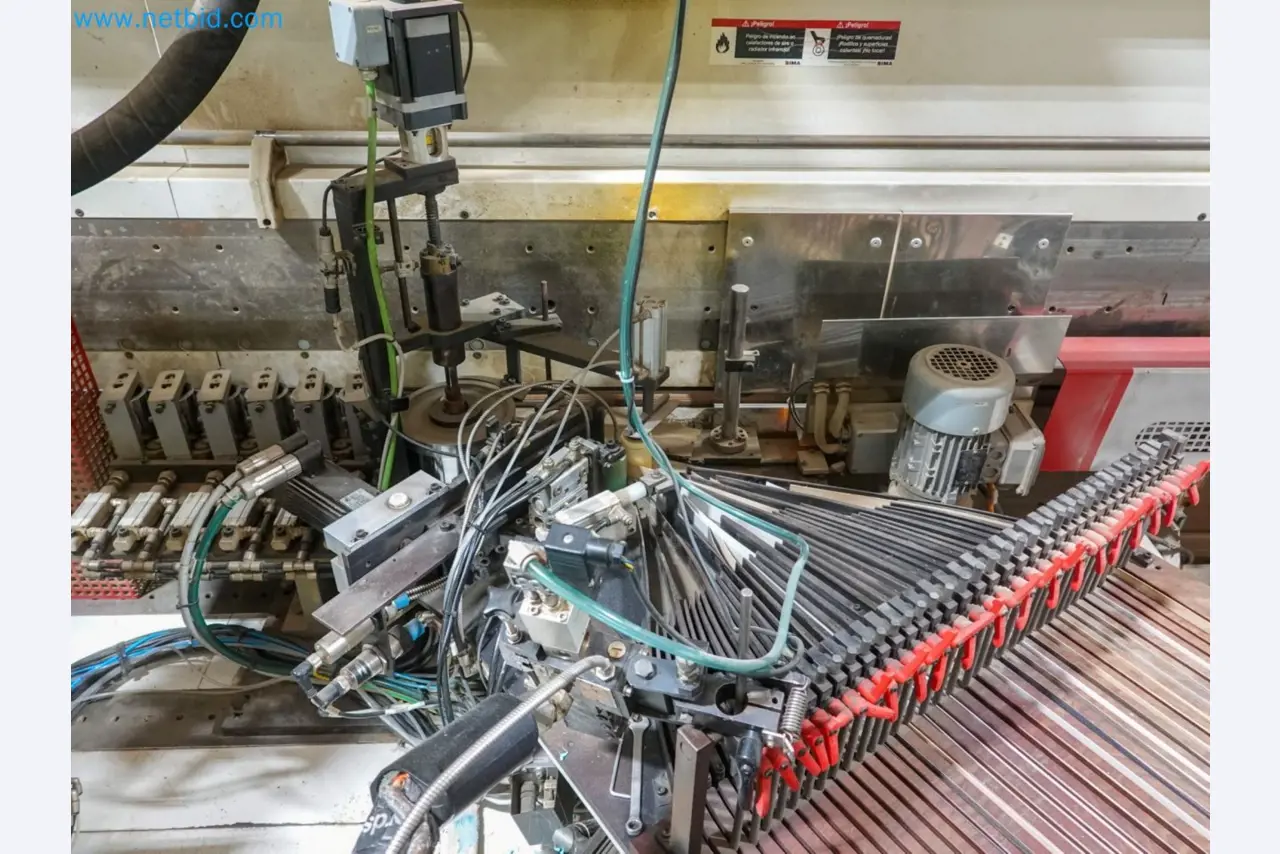

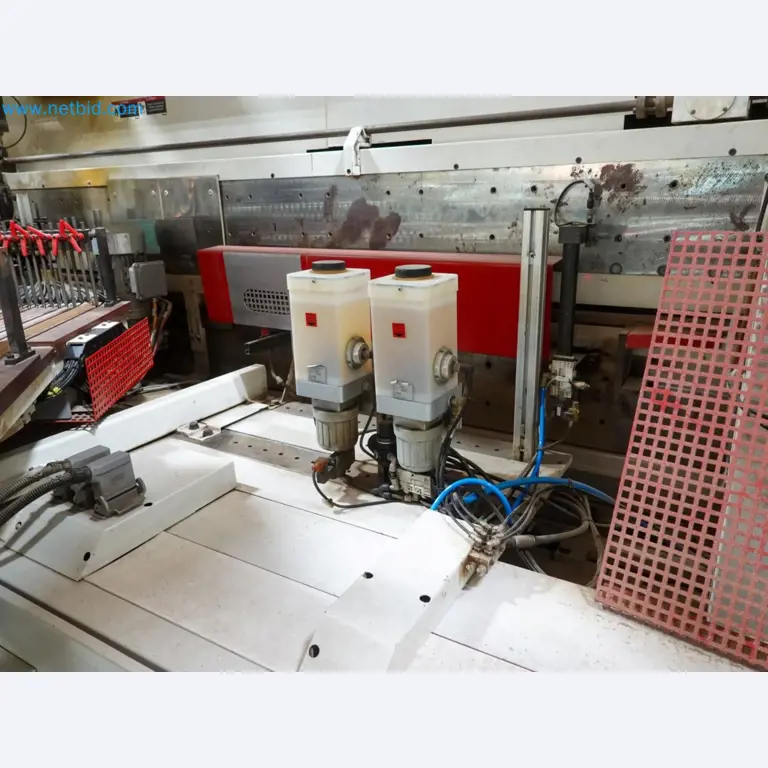

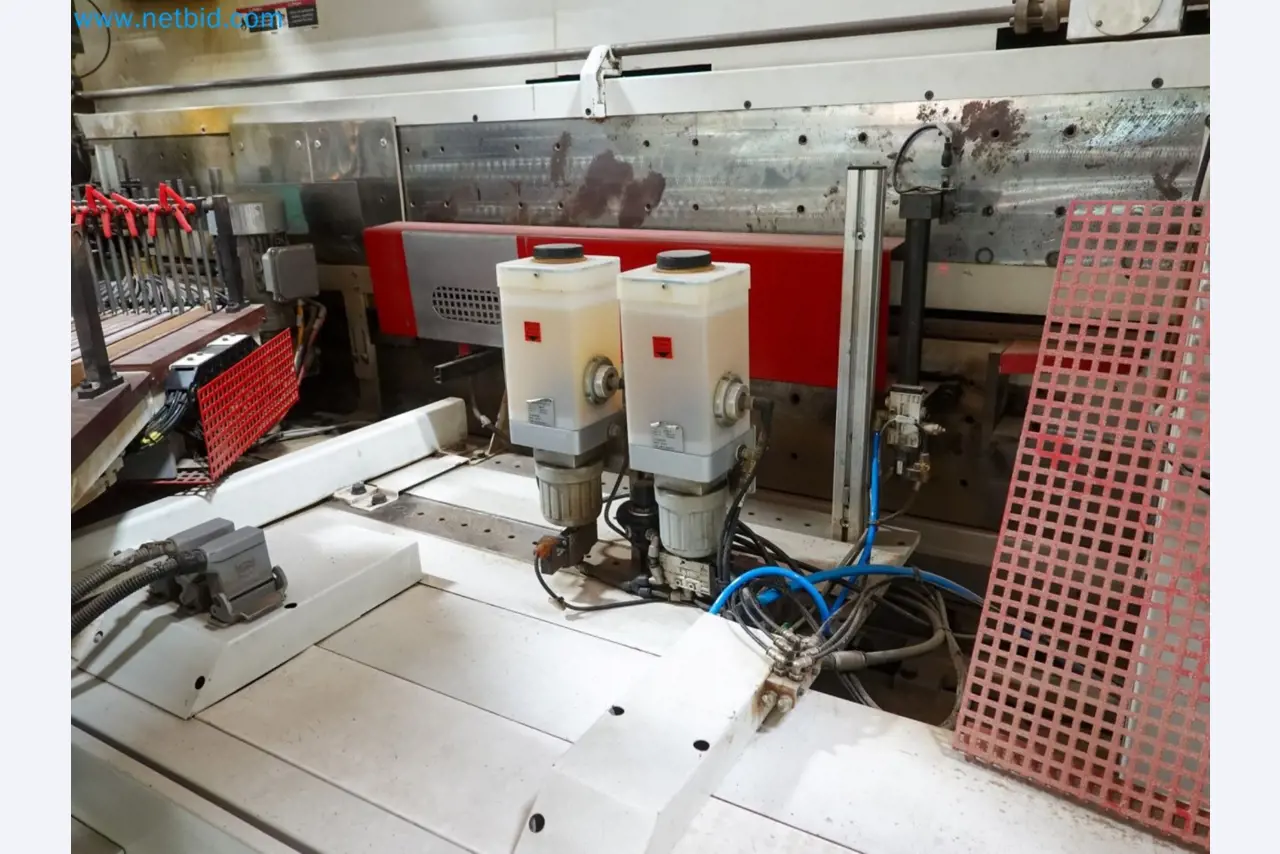

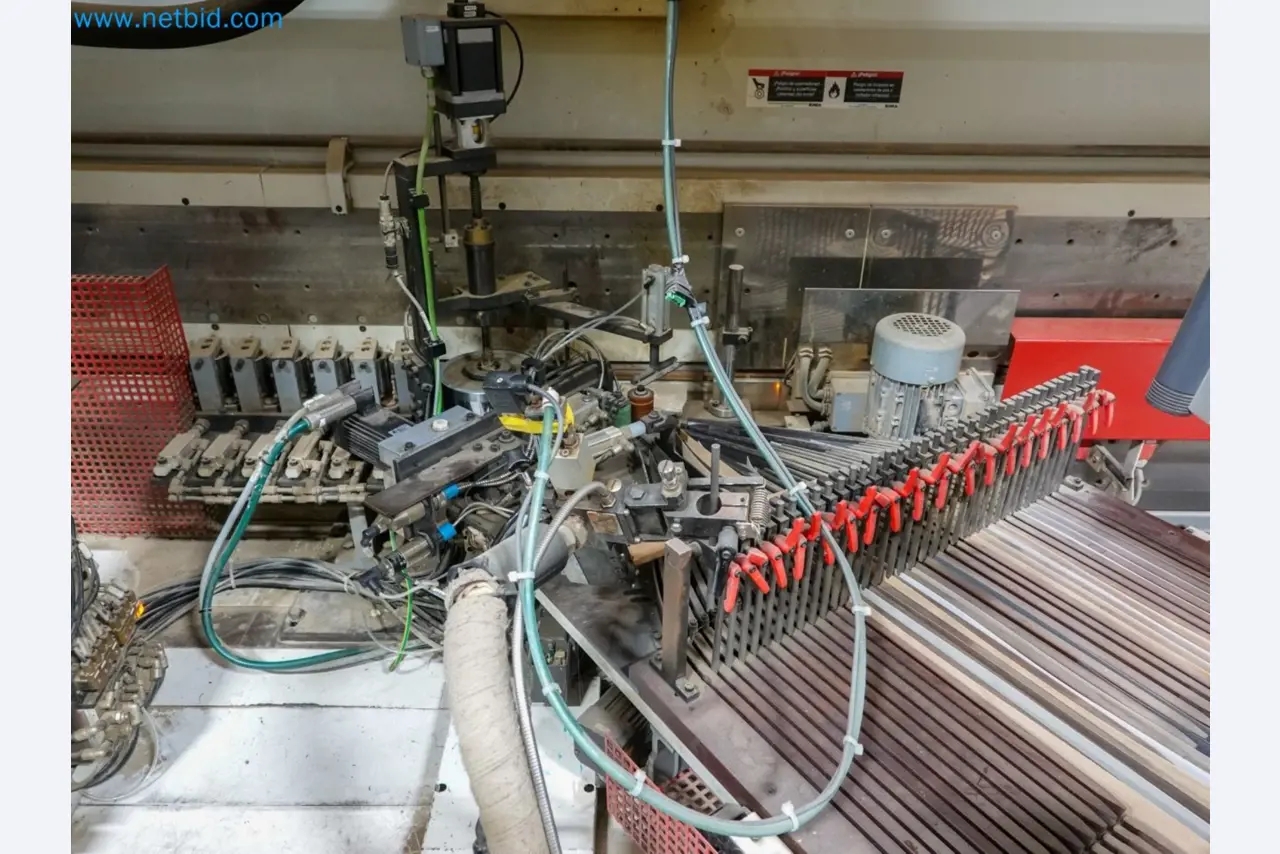

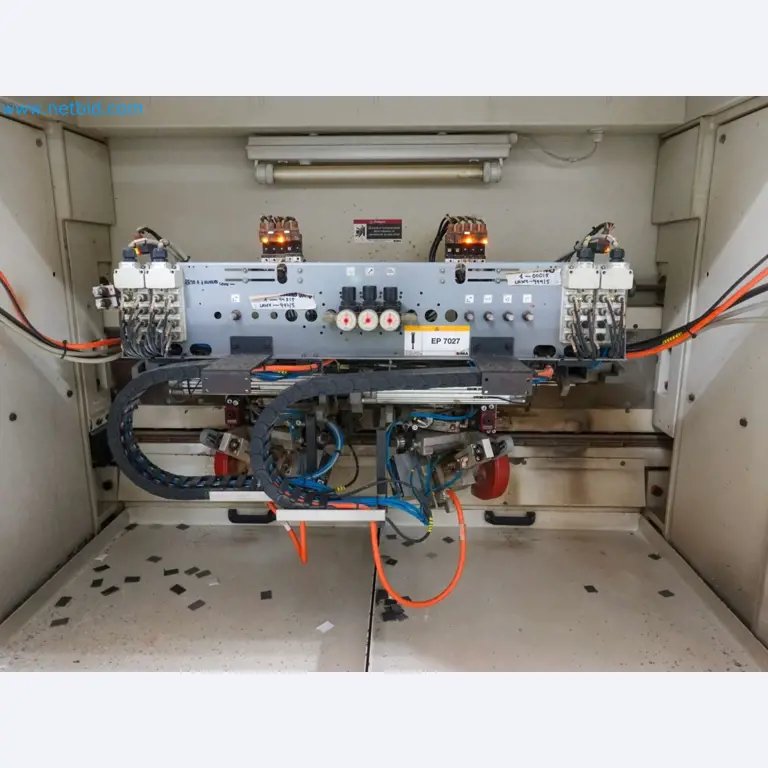

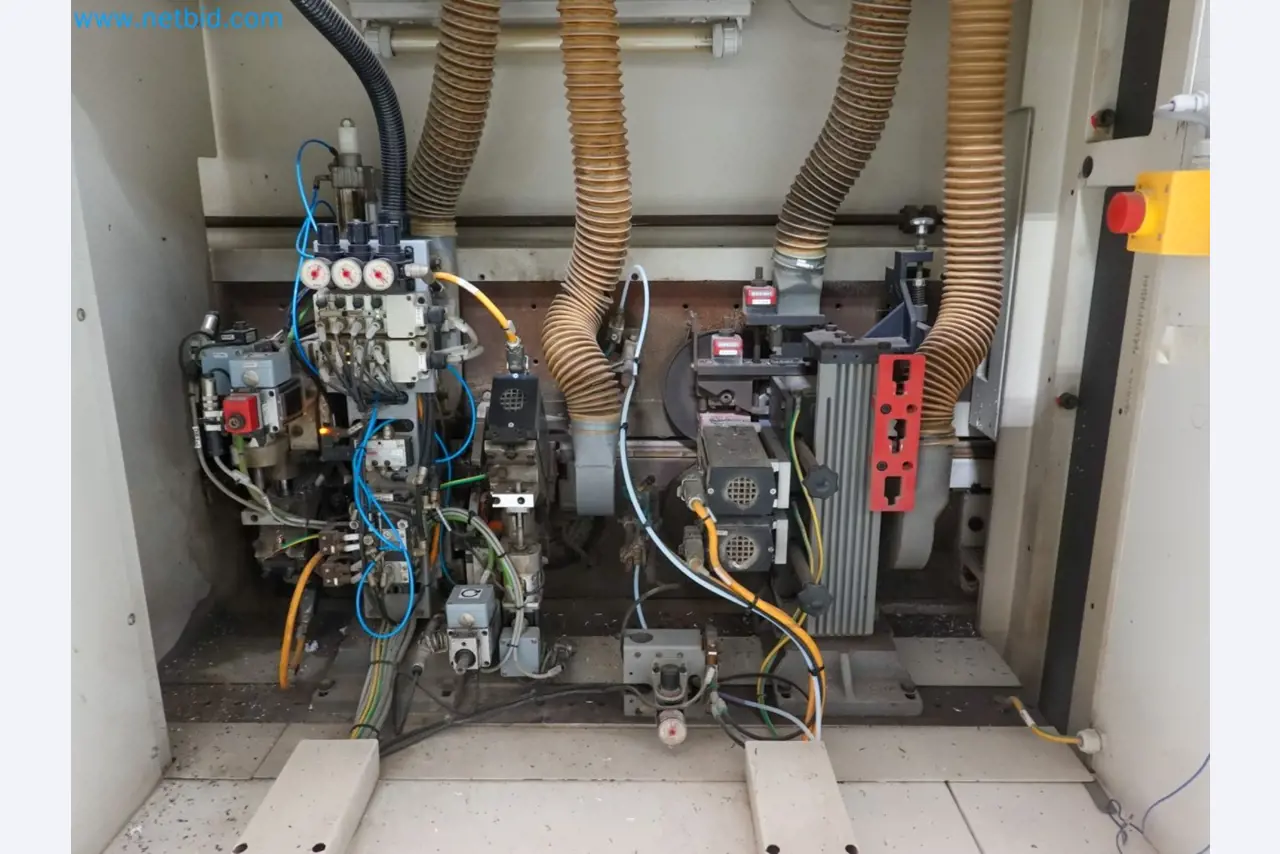

Gluing system: yes

Glue pot for polyurethane glue: yes

Pre-melter for polyurethane glue: yes

Laser: yes

Edge-pressure roller group: yes

Number of pressure rollers: 5

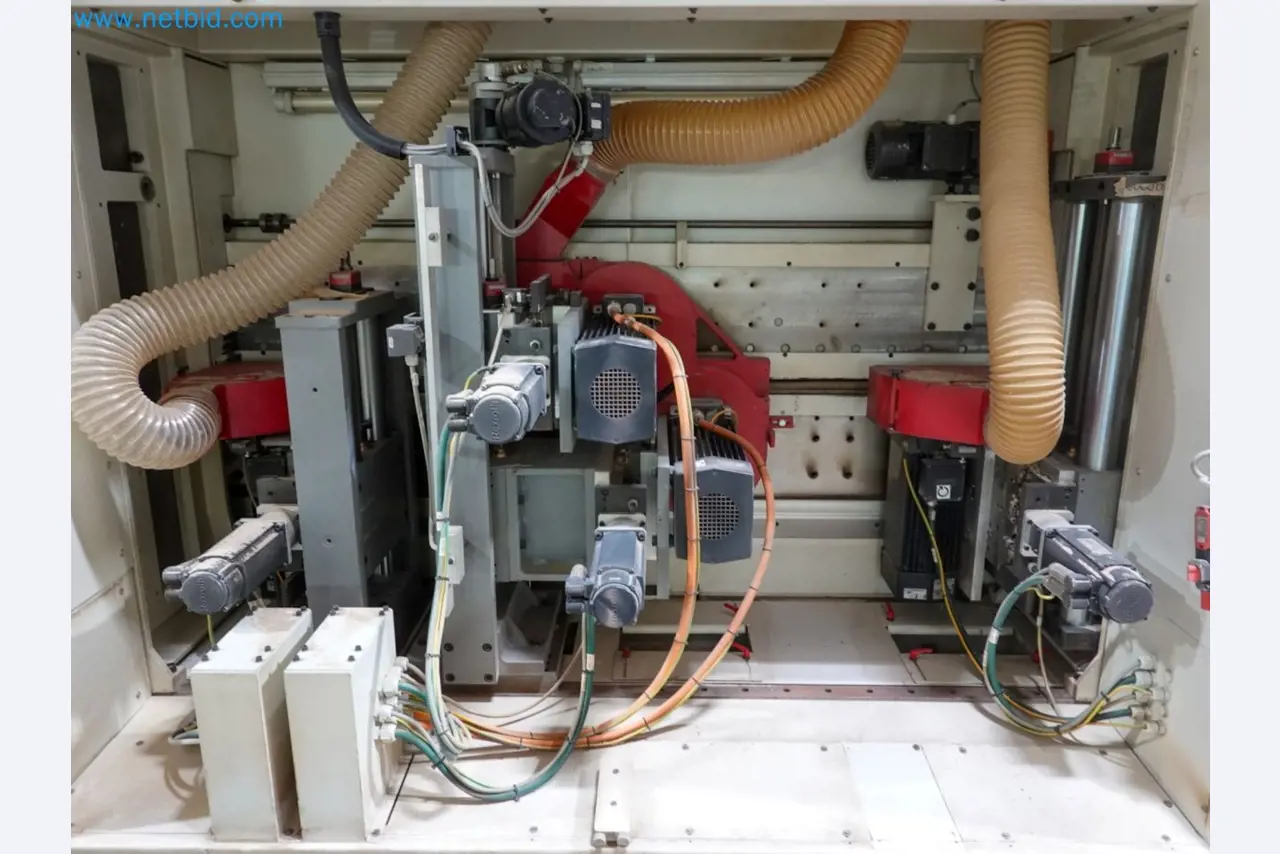

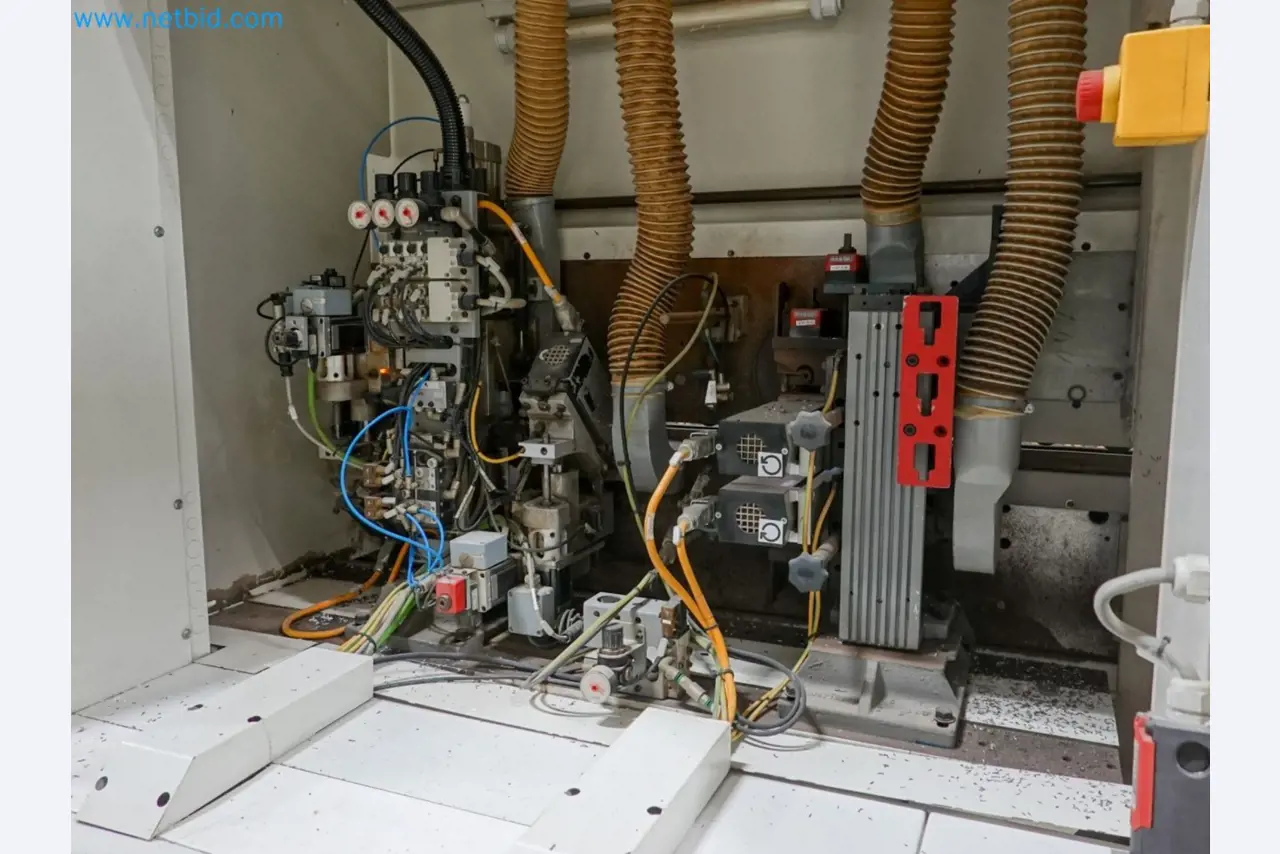

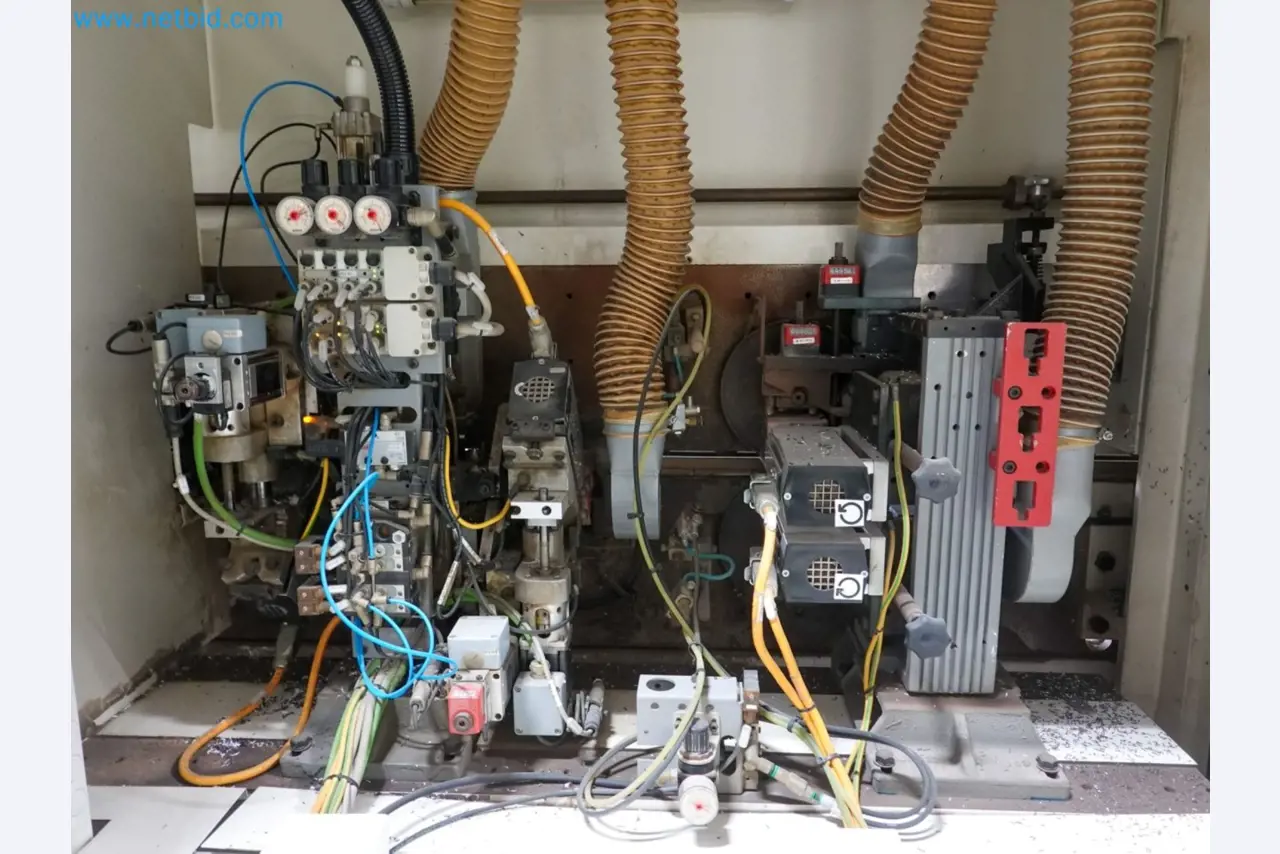

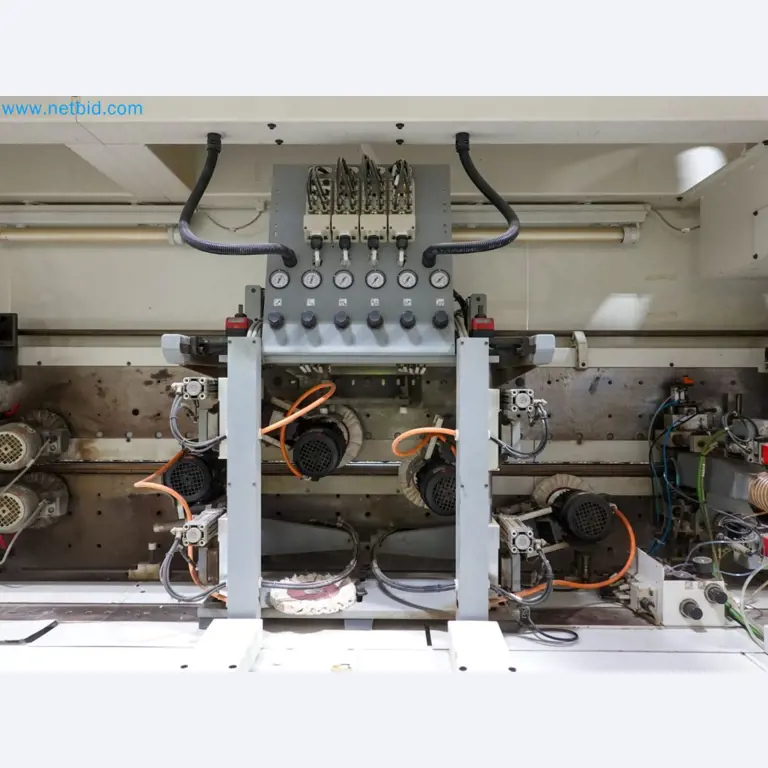

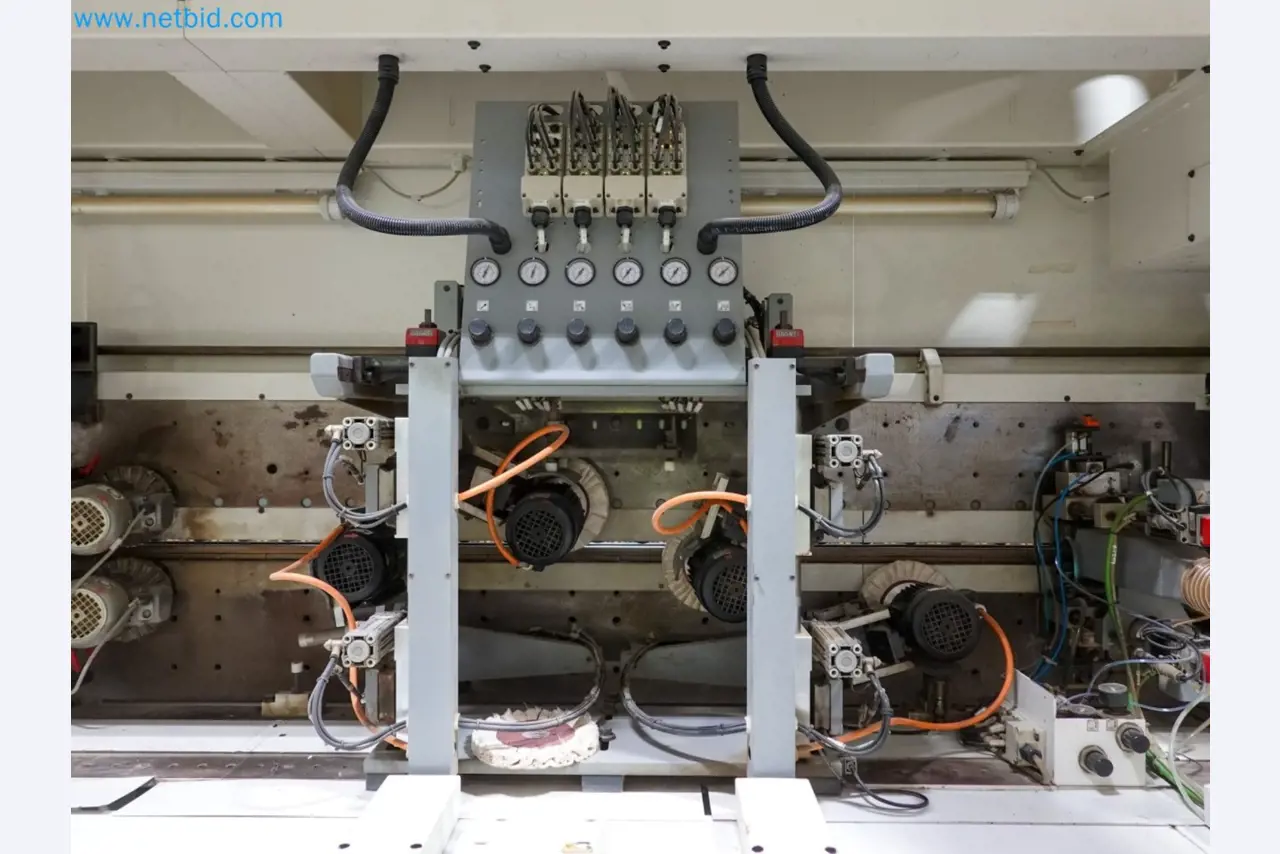

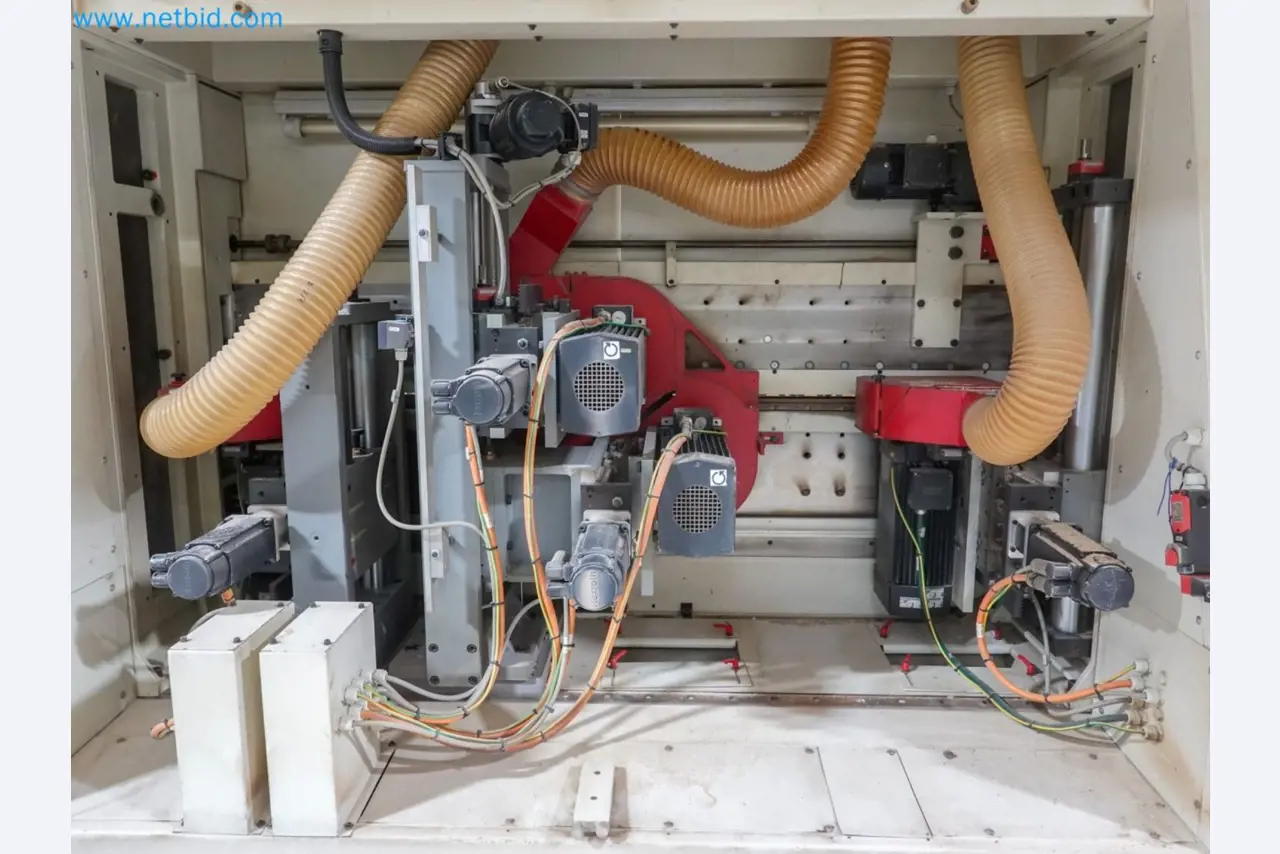

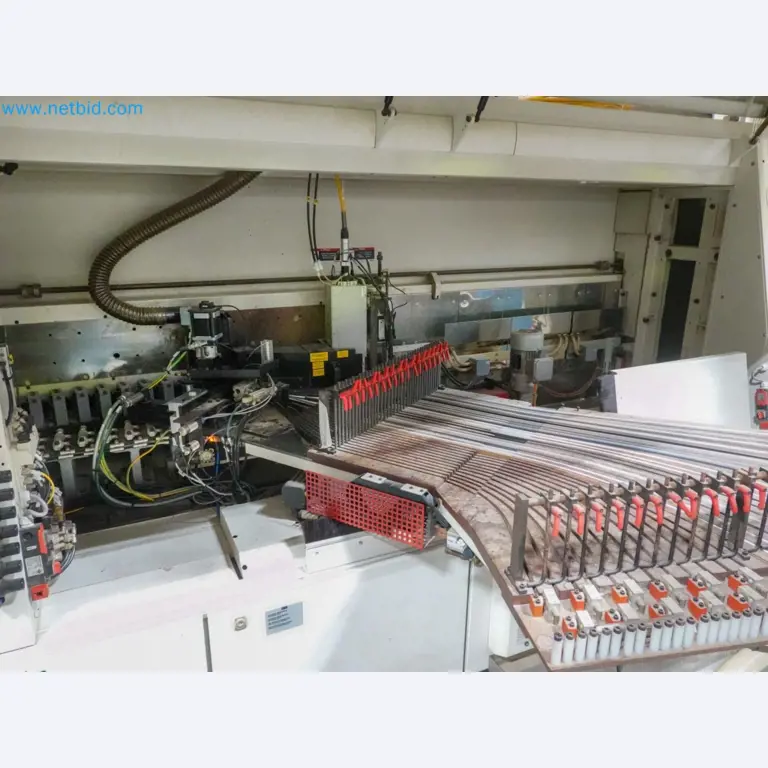

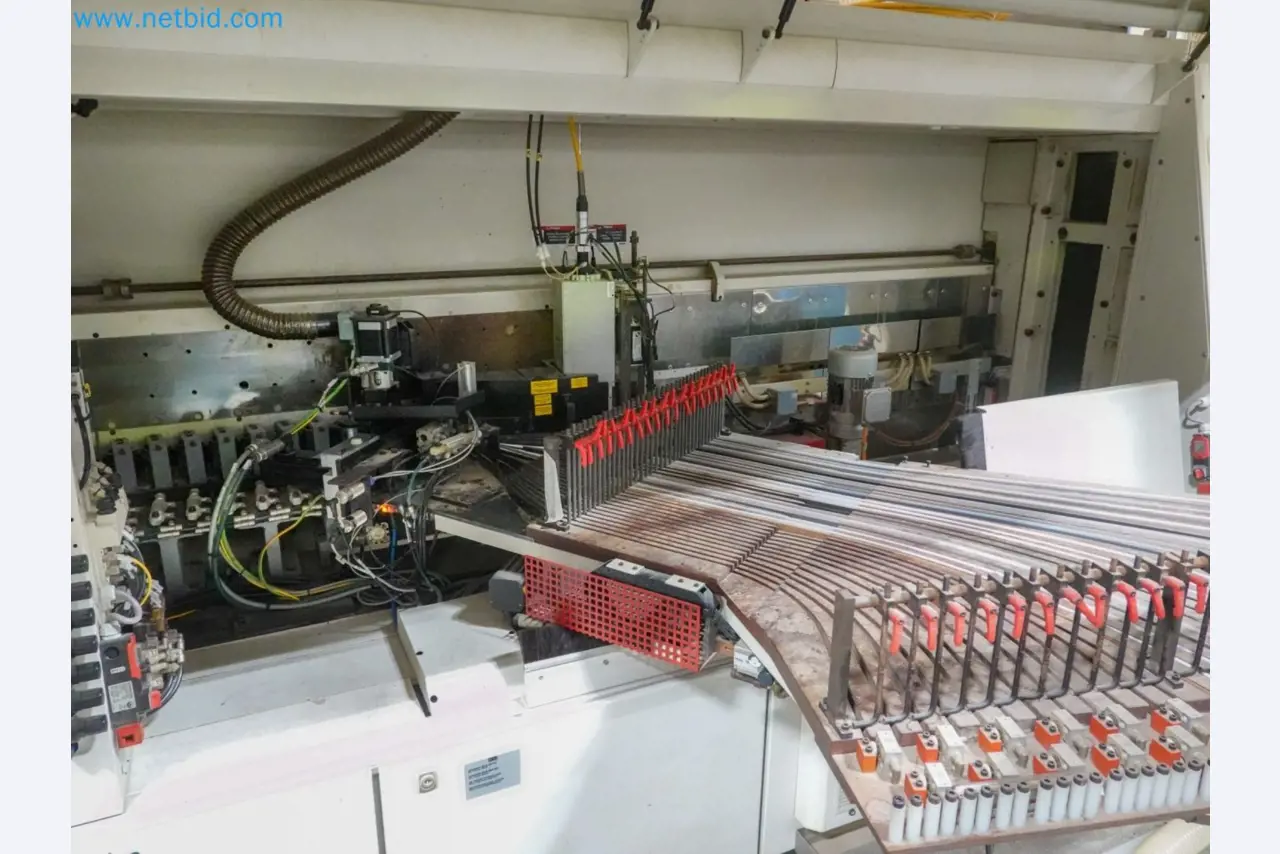

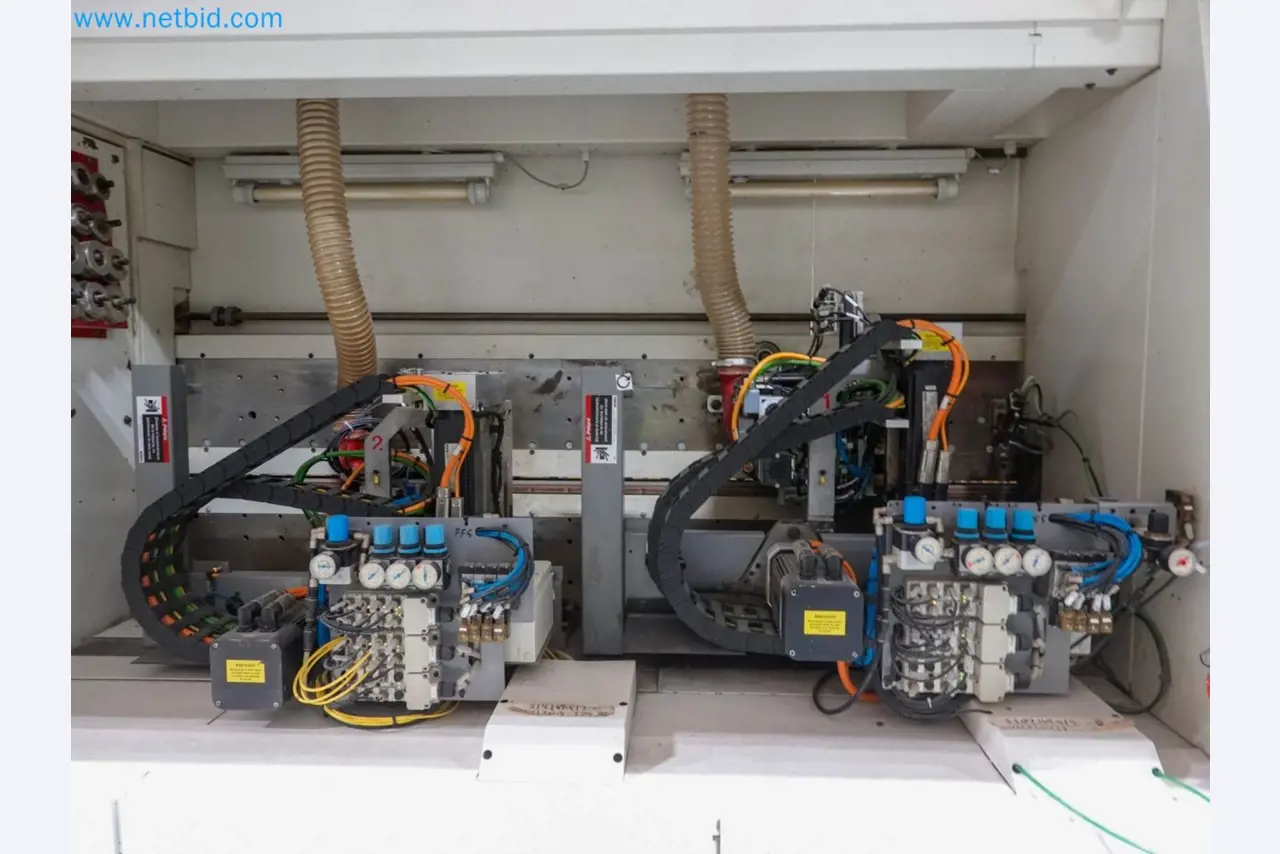

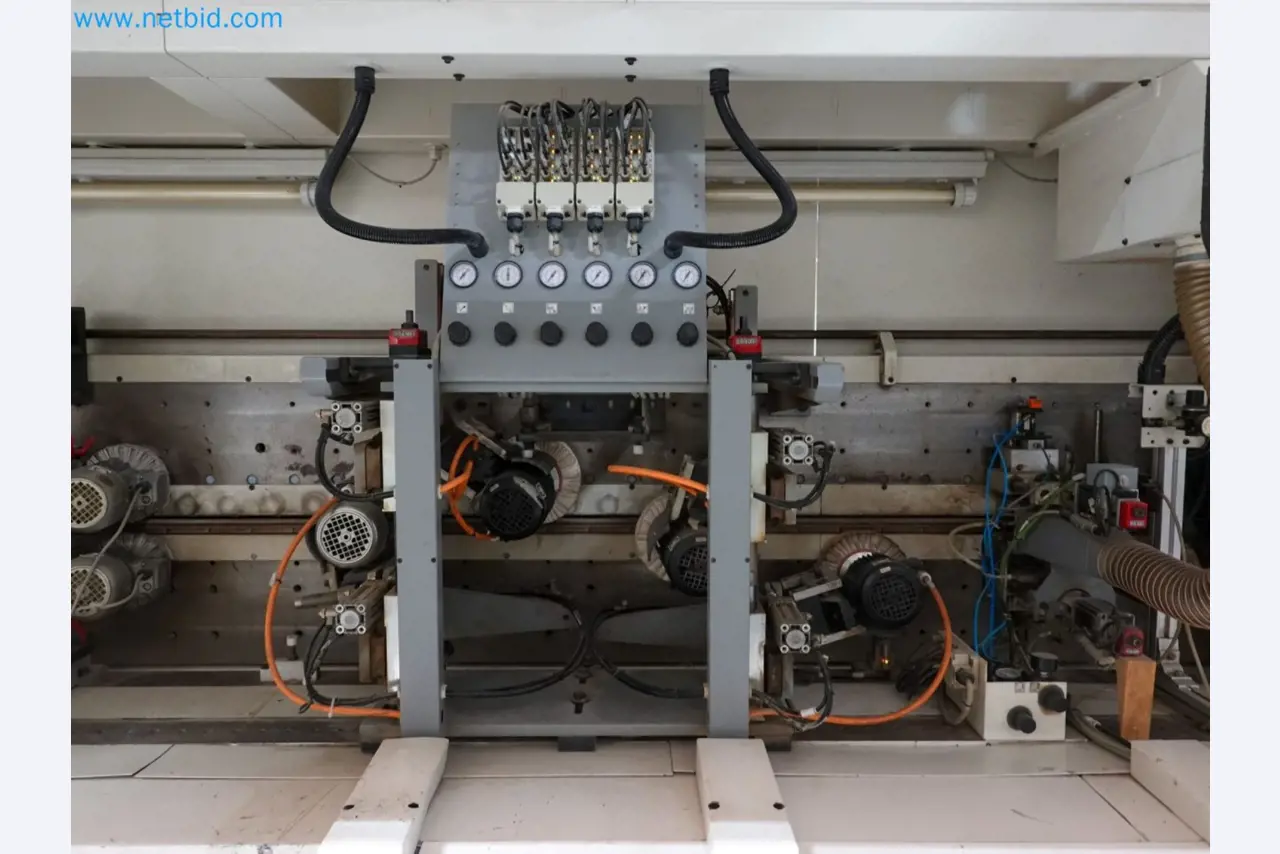

Operator groups in edging section: 8 Units

1 Belt sanding group

Number of motors: 1

2 Belt sanding group

Number of motors: 1

Motor power: 1.85 kW

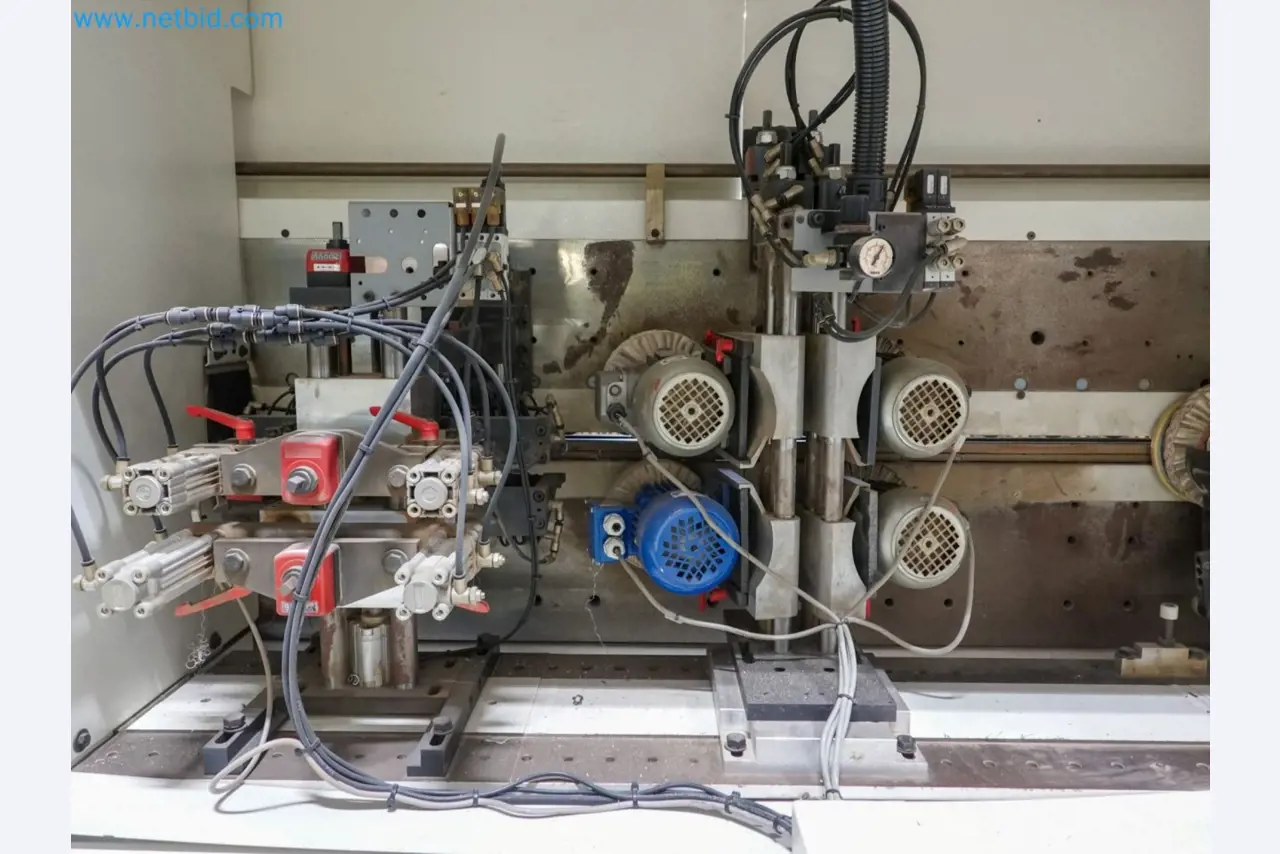

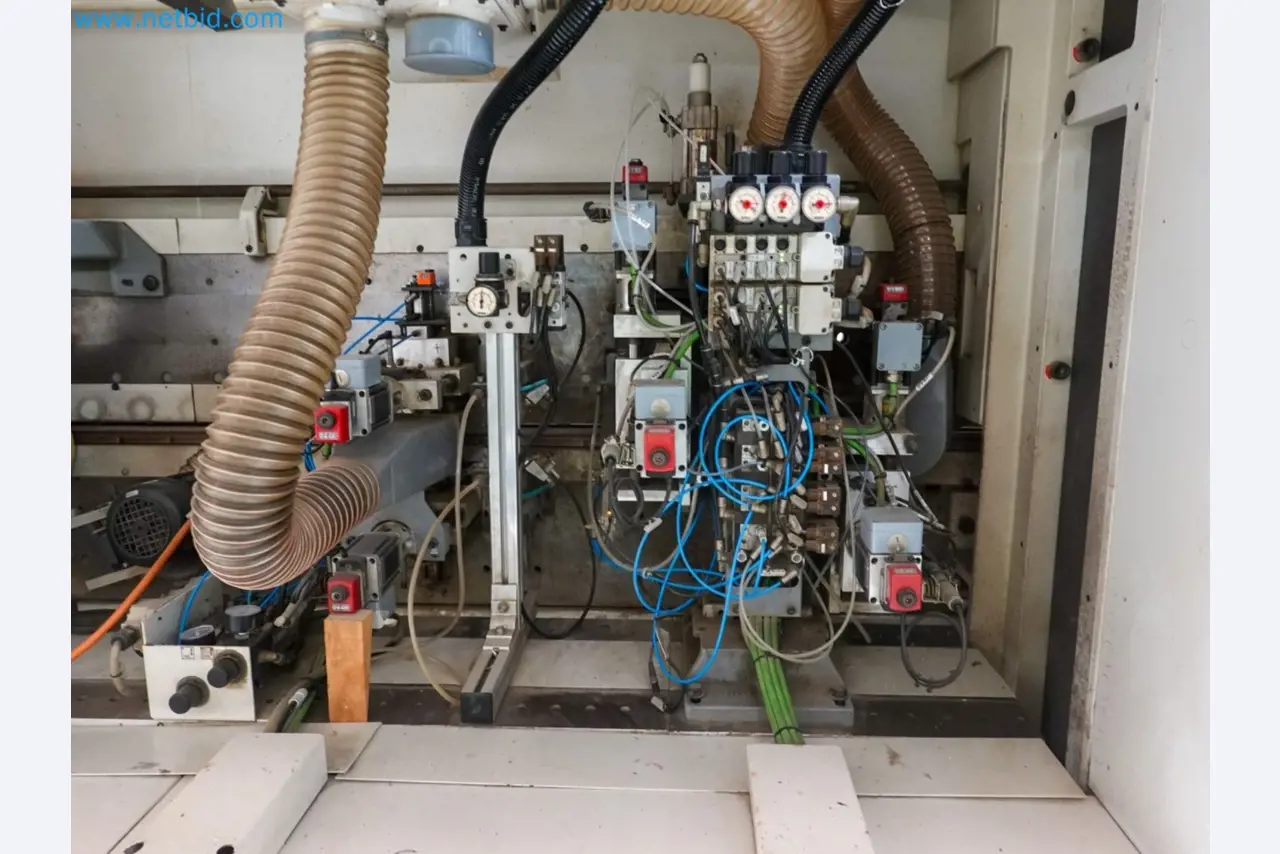

3 End trimming group

Number of motors: 2

Motor power: 0.66 kW

4 Edge profiling group

Number of motors: 2

With CNC positioning: yes

Motor power: 0.66 kW

5 Corner rounding group

Manufacturer model: MFA

Number of motors: 1

With CNC positioning: yes

6 Edge scraper group

With CNC positioning: yes

7 Glue scraper group

With CNC positioning: yes

8 Brush group

Number of motors: 2

Spray group: yes

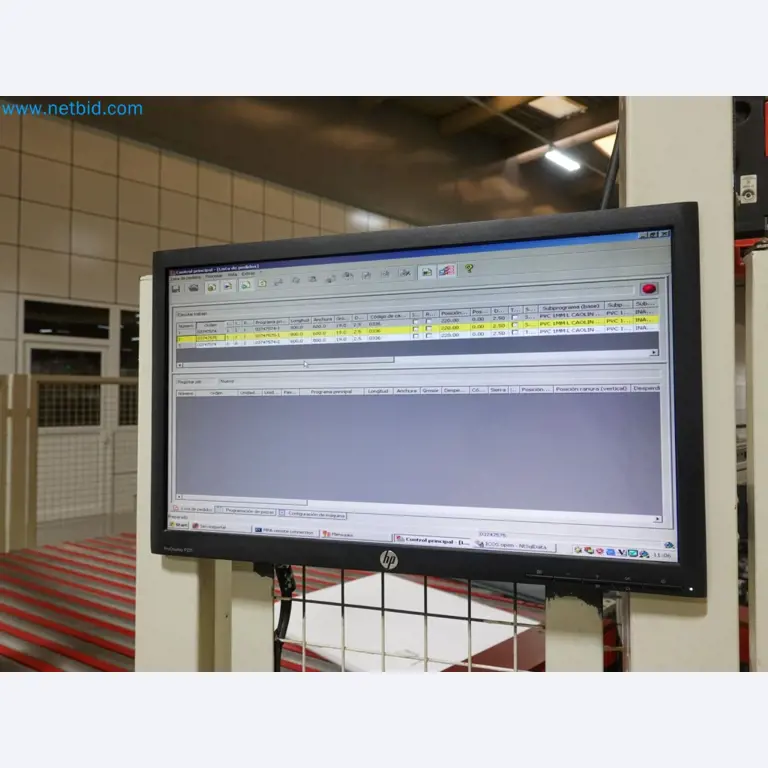

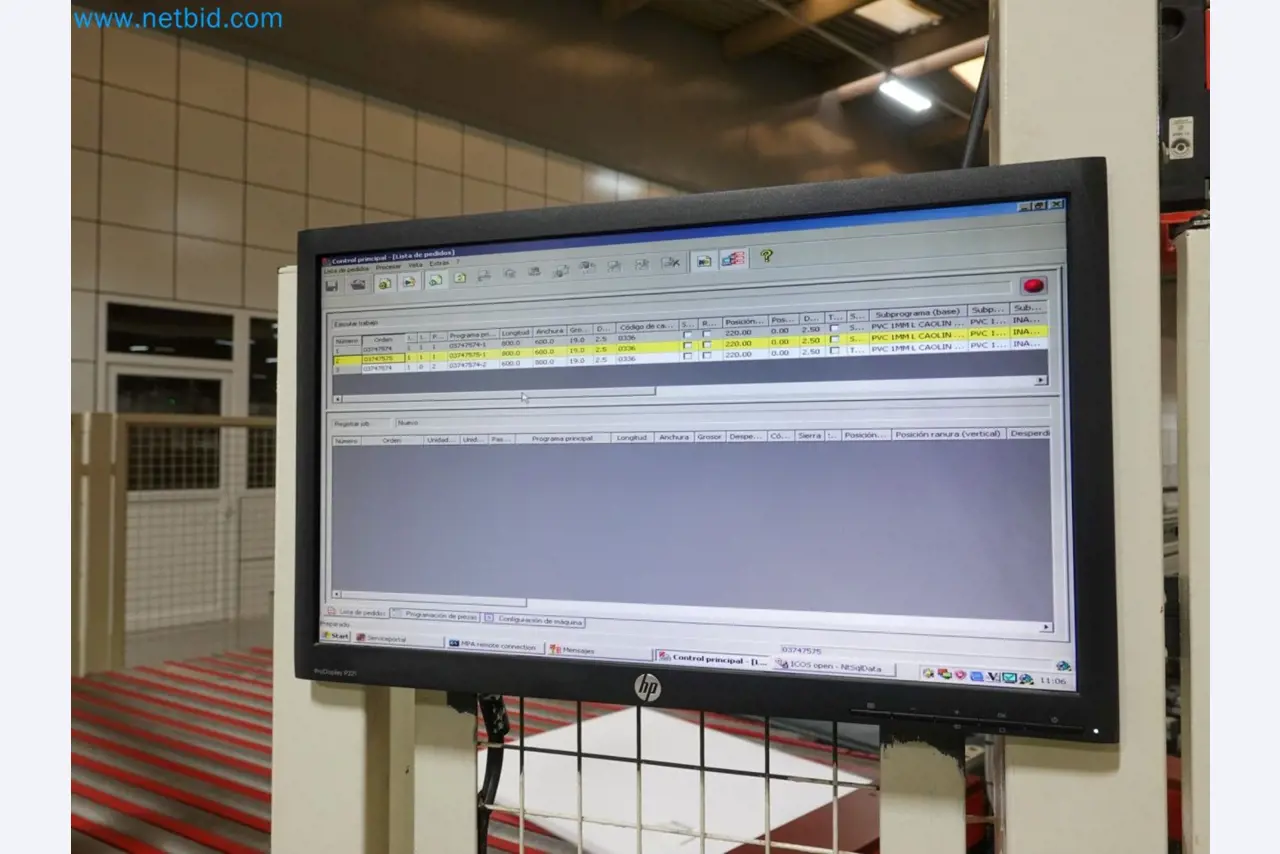

Control system: WINDOWS EMBEDDED POS READY 2009

Machine programming software: ICOS OPEN + IMAWOOP KFA 7.0

Safety standards with CE mark: yes

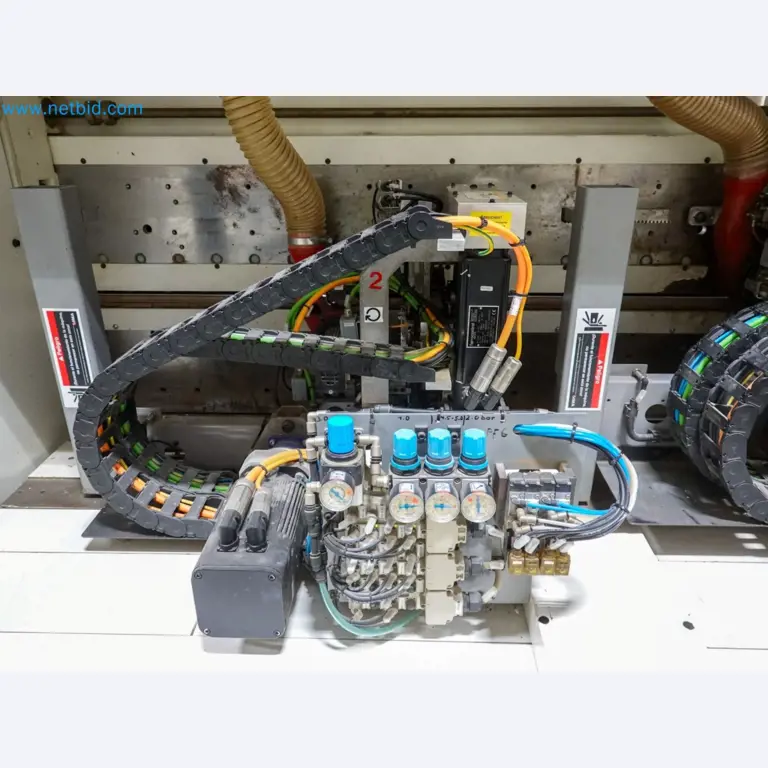

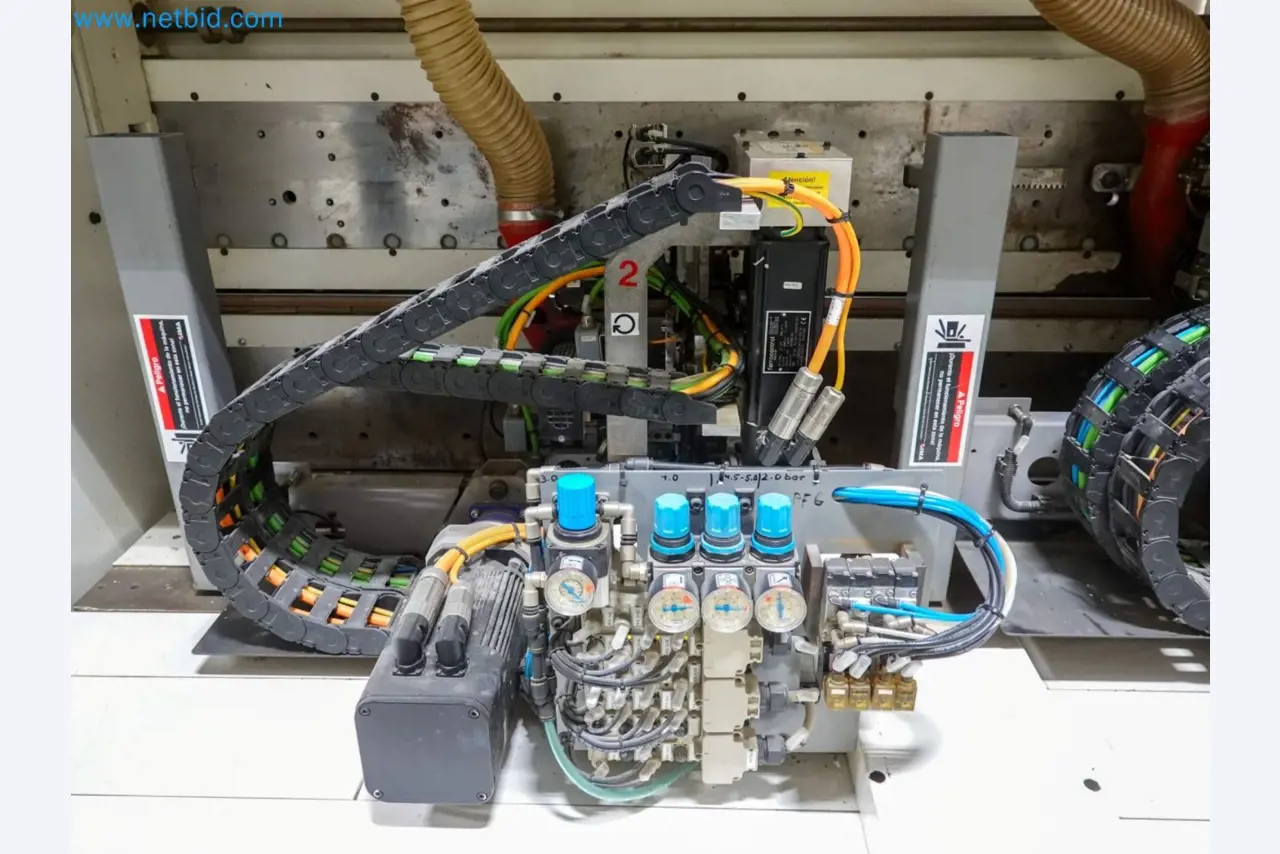

Position 2:

Edgebander Lot 1

Serial Number: 14260

Year of Manufacture: 2008

IMA-COMBIMA SYSTEM/I/R75/1840

Type of edge applied: thin edge, thick edge

Gluing system: PUR, laser

Trimming group: yes

Corner rounding group: yes

Maximum panel thickness: 60 mm

Operator groups: 10 nr

Minimum panel height: 8 mm

Maximum panel height: 60 mm

Minimum panel length: 300 mm

Maximum panel length: 5000 mm

Minimum panel width: 115 mm

Maximum panel width: 1300 mm

Minimum edge thickness: 0.3 mm

Maximum feed speed: 40 m/min

Top pressure: yes

Pressure with rubber belt

Panel support guide: yes

With CNC positioning: yes

Panel squaring-in feed system: yes

Operator groups in squaring section: 1

Trimming group manufacturer model: 08.38B

Automatic time intervention: yes

With CNC positioning: yes

Motor power: 4.5 kW

Revolutions/min: 9000 RPM

Edge-heating lamps: yes

Edge-tape magazine: yes

Number of positions: 36

Gluing system: yes

Glue pot for polyurethane glue: yes

Pre-melter for polyurethane glue: yes

Laser: yes

Edge-pressure roller group: yes

Number of pressure rollers: 5

Operator groups in edging section: 8 units

1 Belt sanding group

Number of motors: 1

2 Belt sanding group

Number of motors: 1

Motor power: 1.85 kW

3 End trimming group

Number of motors: 2

Motor power: 0.66 kW

4 Edge profiling group

Number of motors: 2

With CNC positioning: yes

Motor power: 0.66 kW

5 Corner rounding group

Manufacturer model: MFA

Number of motors: 1

With CNC positioning: yes

6 Edge scraper group

With CNC positioning: yes

7 Glue scraper group

With CNC positioning: yes

8 Brush group

Number of motors: 2

Spray group: yes

Control system: WINDOWS EMBEDDED POS READY 2009

Machine programming software: ICOS OPEN + IMAWOOP KFA 7.0

Safety standards with CE mark: yes

Year of Manufacture: 2008

IMA-COMBIMA SYSTEM/I/R75/1840

Type of edge applied: thin edge, thick edge

Gluing system: PUR, laser

Trimming group: yes

Corner rounding group: yes

Maximum panel thickness: 60 mm

Operator groups: 10 nr

Minimum panel height: 8 mm

Maximum panel height: 60 mm

Minimum panel length: 300 mm

Maximum panel length: 5000 mm

Minimum panel width: 115 mm

Maximum panel width: 1300 mm

Minimum edge thickness: 0.3 mm

Maximum feed speed: 40 m/min

Top pressure: yes

Pressure with rubber belt

Panel support guide: yes

With CNC positioning: yes

Panel squaring-in feed system: yes

Operator groups in squaring section: 1

Group 1: trimming

Manufacturer model: 08.38B

Automatic time intervention: yes

With CNC positioning: yes

Motor power: 4.5 kW

Revolutions/min: 9000 RPM

Edge-heating lamps: yes

Edge-tape magazine: yes

Number of positions: 36

Gluing system: yes

Glue pot for polyurethane glue: yes

Pre-melter for polyurethane glue: yes

Laser: yes

Edge-pressure roller group: yes

Number of pressure rollers: 5

Operator groups in edging section: 8 Units

1 Belt sanding group

Number of motors: 1

2 Belt sanding group

Number of motors: 1

Motor power: 1.85 kW

3 End trimming group

Number of motors: 2

Motor power: 0.66 kW

4 Edge profiling group

Number of motors: 2

With CNC positioning: yes

Motor power: 0.66 kW

5 Corner rounding group

Manufacturer model: MFA

Number of motors: 1

With CNC positioning: yes

6 Edge scraper group

With CNC positioning: yes

7 Glue scraper group

With CNC positioning: yes

8 Brush group

Number of motors: 2

Spray group: yes

Control system: WINDOWS EMBEDDED POS READY 2009

Machine programming software: ICOS OPEN + IMAWOOP KFA 7.0

Safety standards with CE mark: yes

Position 2:

Edgebander Lot 1

Serial Number: 14260

Year of Manufacture: 2008

IMA-COMBIMA SYSTEM/I/R75/1840

Type of edge applied: thin edge, thick edge

Gluing system: PUR, laser

Trimming group: yes

Corner rounding group: yes

Maximum panel thickness: 60 mm

Operator groups: 10 nr

Minimum panel height: 8 mm

Maximum panel height: 60 mm

Minimum panel length: 300 mm

Maximum panel length: 5000 mm

Minimum panel width: 115 mm

Maximum panel width: 1300 mm

Minimum edge thickness: 0.3 mm

Maximum feed speed: 40 m/min

Top pressure: yes

Pressure with rubber belt

Panel support guide: yes

With CNC positioning: yes

Panel squaring-in feed system: yes

Operator groups in squaring section: 1

Trimming group manufacturer model: 08.38B

Automatic time intervention: yes

With CNC positioning: yes

Motor power: 4.5 kW

Revolutions/min: 9000 RPM

Edge-heating lamps: yes

Edge-tape magazine: yes

Number of positions: 36

Gluing system: yes

Glue pot for polyurethane glue: yes

Pre-melter for polyurethane glue: yes

Laser: yes

Edge-pressure roller group: yes

Number of pressure rollers: 5

Operator groups in edging section: 8 units

1 Belt sanding group

Number of motors: 1

2 Belt sanding group

Number of motors: 1

Motor power: 1.85 kW

3 End trimming group

Number of motors: 2

Motor power: 0.66 kW

4 Edge profiling group

Number of motors: 2

With CNC positioning: yes

Motor power: 0.66 kW

5 Corner rounding group

Manufacturer model: MFA

Number of motors: 1

With CNC positioning: yes

6 Edge scraper group

With CNC positioning: yes

7 Glue scraper group

With CNC positioning: yes

8 Brush group

Number of motors: 2

Spray group: yes

Control system: WINDOWS EMBEDDED POS READY 2009

Machine programming software: ICOS OPEN + IMAWOOP KFA 7.0

Safety standards with CE mark: yes

Location

- 12540 Vila-Real

Dates

Inspection

Viewing by appointment via fernandez@netbid.com possible.

Pickup

Collection possible by arrangement via fernandez@netbid.com.

Auction Terms

Special conditions:

- For buyers’ convenience, dismantling can be organized upon request with an external company; costs (36.000 € plus applicable VAT) to be borne by the buyer. The loading, however, should be organized by the buyer.

Important: NetBid ESP SLU is in no way affiliated with the dismantling and loading company, receives no commission and is therefore not responsible for its actions. Customers are free to find and choose another service provider who can carry out the required work on site in a professional way.

- Protection shoes and reflective vest are mandatory for the visit.

- All items have to be collected no later than 30.01.2026!

- For buyers’ convenience, dismantling can be organized upon request with an external company; costs (36.000 € plus applicable VAT) to be borne by the buyer. The loading, however, should be organized by the buyer.

Important: NetBid ESP SLU is in no way affiliated with the dismantling and loading company, receives no commission and is therefore not responsible for its actions. Customers are free to find and choose another service provider who can carry out the required work on site in a professional way.

- Protection shoes and reflective vest are mandatory for the visit.

- All items have to be collected no later than 30.01.2026!

Contact Person

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com