Este leilão terminou.

Detalhes

Tipo de Produto

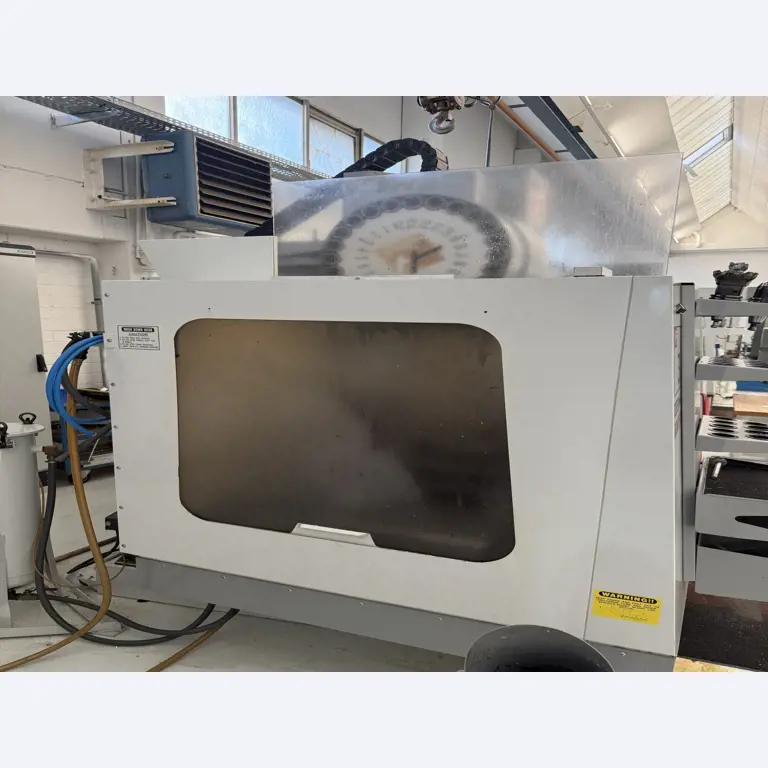

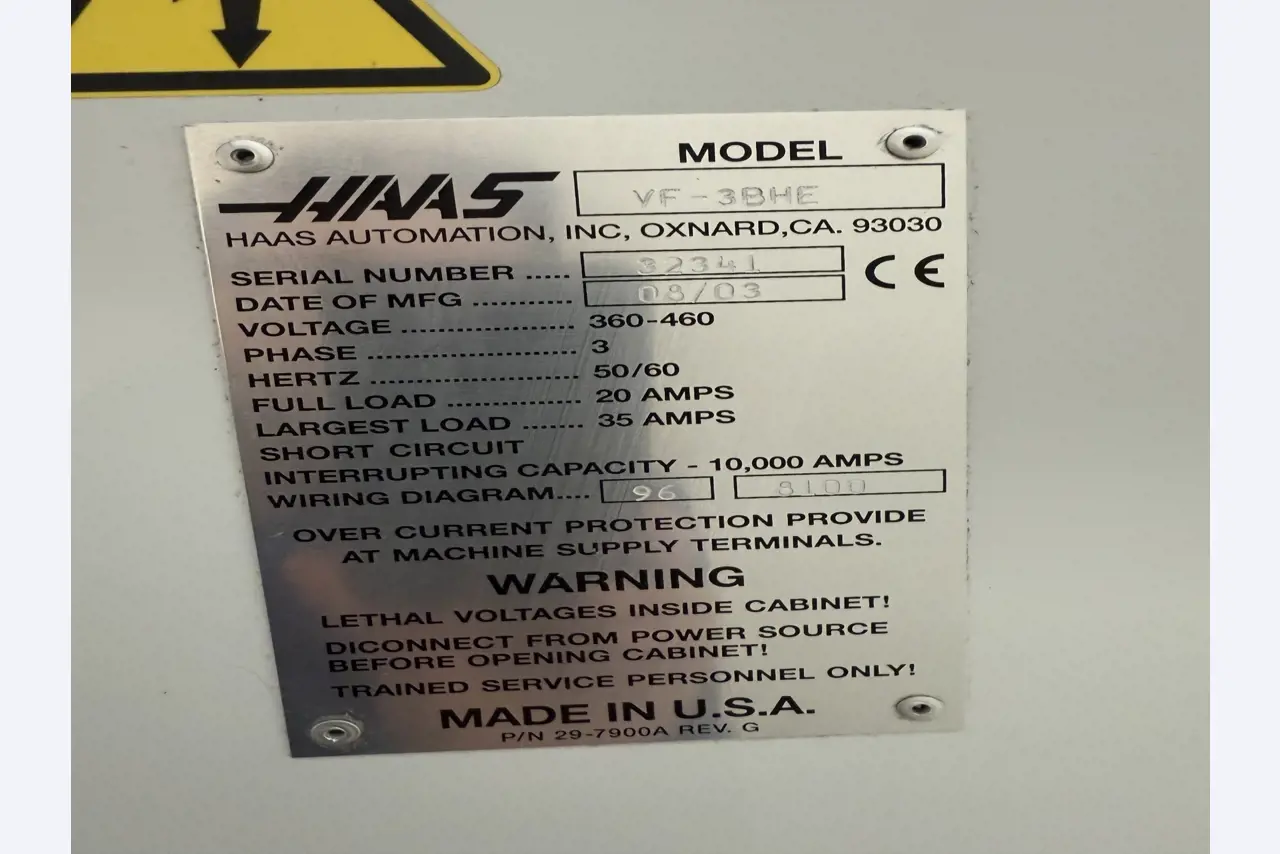

HAAS

Tipo

VF-3BHE

Ano de Construção

2003

Descrição

Maintenance report attached

Serial number: 32341

Tested in February 2025

Spindle running time: 2,765 h

Spindle speed 12,000 rpm

Switch-on time: 16,729 min

Number of tool changes: 144,267

Running time servo/motor: 15,870 min

Operating voltage: 360 - 460 V

Frequency: 50 - 60 Hz

Rated current: 35 A

Control unit: HAAS

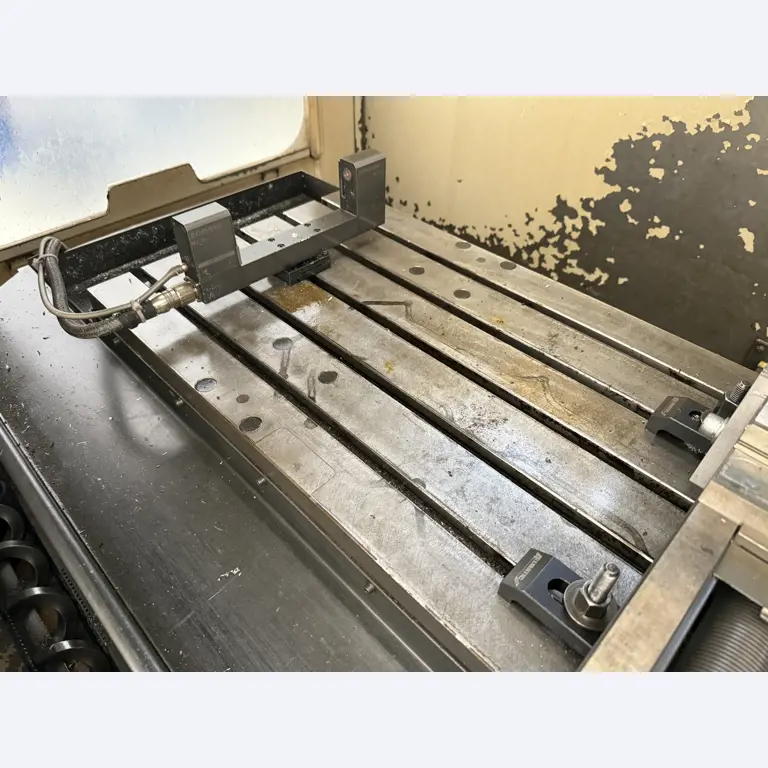

Table dimensions: 1200 x 460 mm

With 5 pcs. grooves

Attention: The machine vice located on the clamping surface is not included in the scope of delivery

Tool holder: SK 40

Travel distances: X: approx. 700 mm, Y: approx. 500 mm, Z: approx. 500 mm

Spindle speed: 10000 rpm

Incl. 24-position tool changer and 7 additional SK 40 tool holders equipped with cutting tools

Buffer battery from the kit at 3.09v is replaced

Machine can be switched on and started up without any problems

Error 118 gear stage 1 occurred during referencing

Gearbox was deselected in the parameter so that the machine can be referenced.

Reference run then OK.

The transmission shift valve was checked

Valve was cleaned

Transmission shifts back into 1st and 2nd gear i.O.

Gearbox selected again in the parameter i.O.

Spindle programmed with speeds OK

Tightening force of the spindle at 1900 lbs

Should be between 1600 - 2300 lbs.

Tool change carried out

Tools can be changed, but error 627 appears

Pocket does not start up fast enough, may be due to cylinder, pilot valve and valve

Cambox oil present and gear oil also present. Axle travel is OK

Slight running noises and backlash in all axles. axles.

Encoder belt, encoder pinion, gear/motor pinion and drive belt worn due to age.

Rubber buffer from gearbox worn out.

Lubrication pressure checked manually, pressure does not drop within the prescribed time

Non-return valves/dosing fittings blocked.

Coolant system cannot be checked as no coolant available. Wiper and waycover worn due to age

Slight running noises in all axles and backlash.

Worn belts, sprockets and rubber buffers.

Check valves/ metering fittings clogged from lubrication.

Cylinder, valve and pilot valuve hanging, probably defective due to long service life.

Cambox oil and transmission oil could be changed.

Waycover and wiper worn due to age.

Coolant system could not be tested as no coolant.

Backup created for the customer

Disassembly costs: 400,- €

These are incurred if dismantling/loading or the use of dismantling/loading aids is desired. Billing will take place between you and the service provider on site.

Serial number: 32341

Tested in February 2025

Spindle running time: 2,765 h

Spindle speed 12,000 rpm

Switch-on time: 16,729 min

Number of tool changes: 144,267

Running time servo/motor: 15,870 min

Operating voltage: 360 - 460 V

Frequency: 50 - 60 Hz

Rated current: 35 A

Control unit: HAAS

Table dimensions: 1200 x 460 mm

With 5 pcs. grooves

Attention: The machine vice located on the clamping surface is not included in the scope of delivery

Tool holder: SK 40

Travel distances: X: approx. 700 mm, Y: approx. 500 mm, Z: approx. 500 mm

Spindle speed: 10000 rpm

Incl. 24-position tool changer and 7 additional SK 40 tool holders equipped with cutting tools

Buffer battery from the kit at 3.09v is replaced

Machine can be switched on and started up without any problems

Error 118 gear stage 1 occurred during referencing

Gearbox was deselected in the parameter so that the machine can be referenced.

Reference run then OK.

The transmission shift valve was checked

Valve was cleaned

Transmission shifts back into 1st and 2nd gear i.O.

Gearbox selected again in the parameter i.O.

Spindle programmed with speeds OK

Tightening force of the spindle at 1900 lbs

Should be between 1600 - 2300 lbs.

Tool change carried out

Tools can be changed, but error 627 appears

Pocket does not start up fast enough, may be due to cylinder, pilot valve and valve

Cambox oil present and gear oil also present. Axle travel is OK

Slight running noises and backlash in all axles. axles.

Encoder belt, encoder pinion, gear/motor pinion and drive belt worn due to age.

Rubber buffer from gearbox worn out.

Lubrication pressure checked manually, pressure does not drop within the prescribed time

Non-return valves/dosing fittings blocked.

Coolant system cannot be checked as no coolant available. Wiper and waycover worn due to age

Slight running noises in all axles and backlash.

Worn belts, sprockets and rubber buffers.

Check valves/ metering fittings clogged from lubrication.

Cylinder, valve and pilot valuve hanging, probably defective due to long service life.

Cambox oil and transmission oil could be changed.

Waycover and wiper worn due to age.

Coolant system could not be tested as no coolant.

Backup created for the customer

Disassembly costs: 400,- €

These are incurred if dismantling/loading or the use of dismantling/loading aids is desired. Billing will take place between you and the service provider on site.

Localização

- 73642 Welzheim

Termos do Leilão

Sale only to traders/dealers!

Highest bidder/ auction winner is requested to submit a copy of the business registration within 3 working days, otherwise the knockdown is considered canceled.

Any warranty/regulation in relation to this offer is expressly excluded.

The seller is also not liable for claims for damages - regardless of the legal basis; however, this does not apply to claims for damages arising from grossly negligent or intentional breach of obligations by the seller or its vicarious agents or for injury to life, limb and health or essential contractual obligations.

Highest bidder/ auction winner is requested to submit a copy of the business registration within 3 working days, otherwise the knockdown is considered canceled.

Any warranty/regulation in relation to this offer is expressly excluded.

The seller is also not liable for claims for damages - regardless of the legal basis; however, this does not apply to claims for damages arising from grossly negligent or intentional breach of obligations by the seller or its vicarious agents or for injury to life, limb and health or essential contractual obligations.

Pessoa de Contato

Auction Coordination Assistant

Christopher Lau

Partes desta página foram traduzidas automaticamente. O texto original em alemão se aplica.

A sua plataforma líder para compra e venda de máquinas e equipamentos industriais usados. Descubra milhares de leilões online, e as melhores oportunidades do mercado. O seu parceiro de confiança na avaliação e comercialização de máquinas e bens móveis.

Os nossos especialistas estão ao seu dispor. Contacte-nos pelo +351 912 800 221 ou carrico@netbid.com.