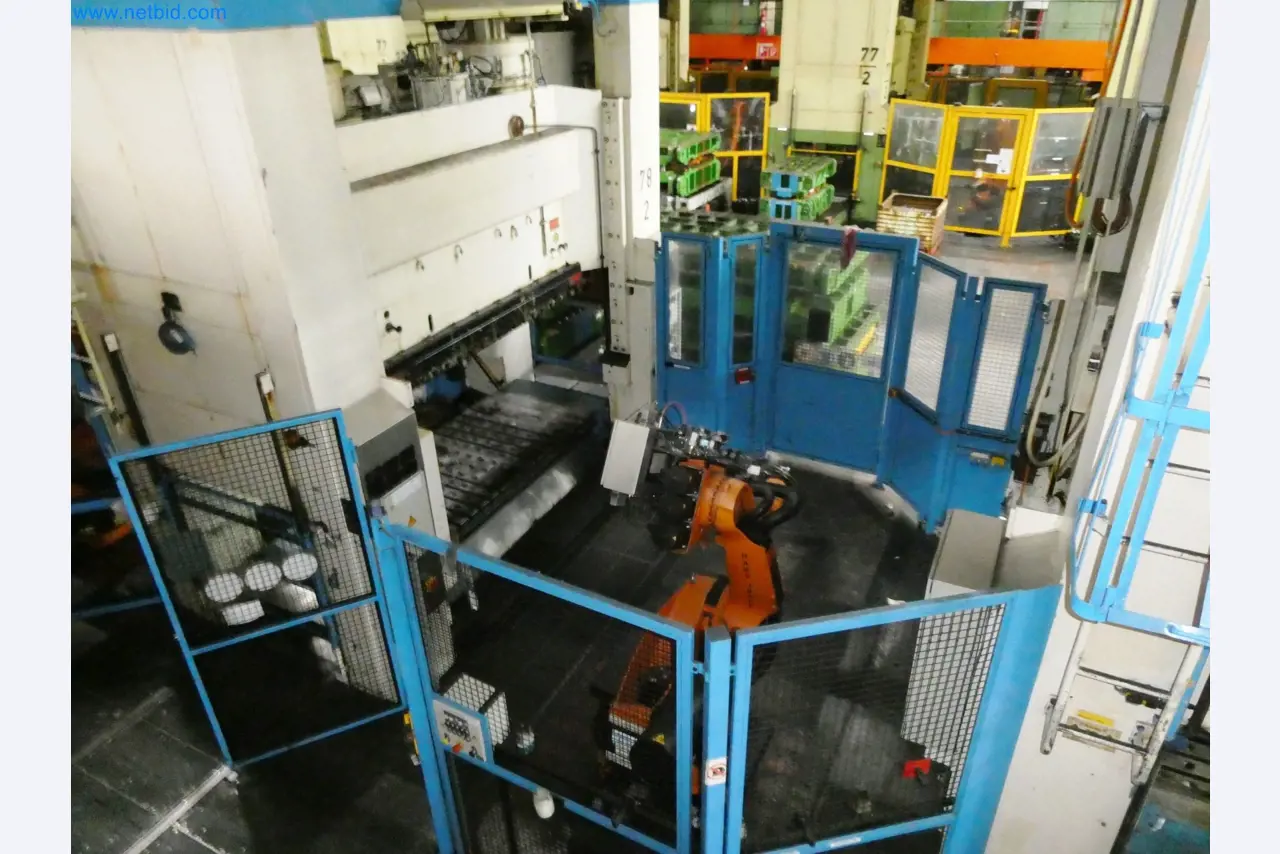

Part of the Auction Press lines from the automotive industry

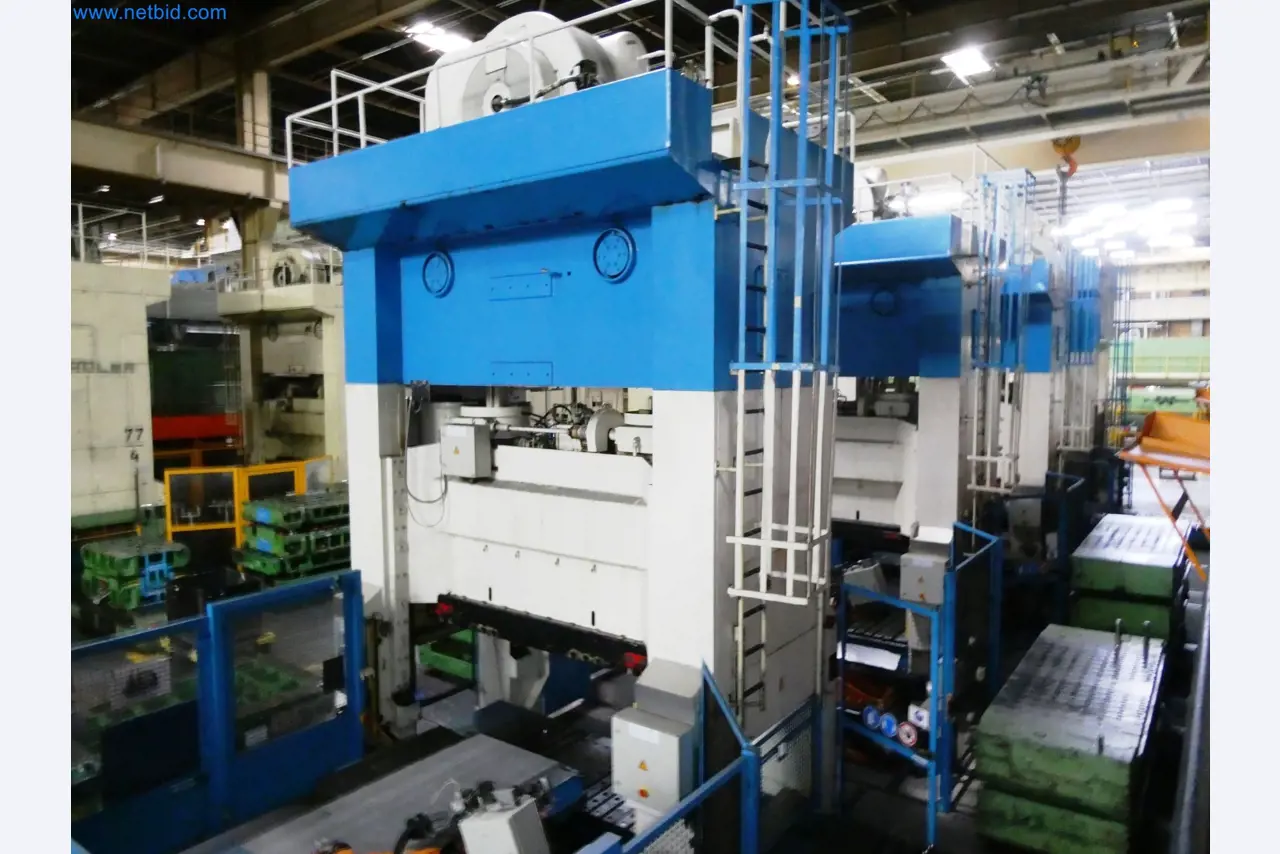

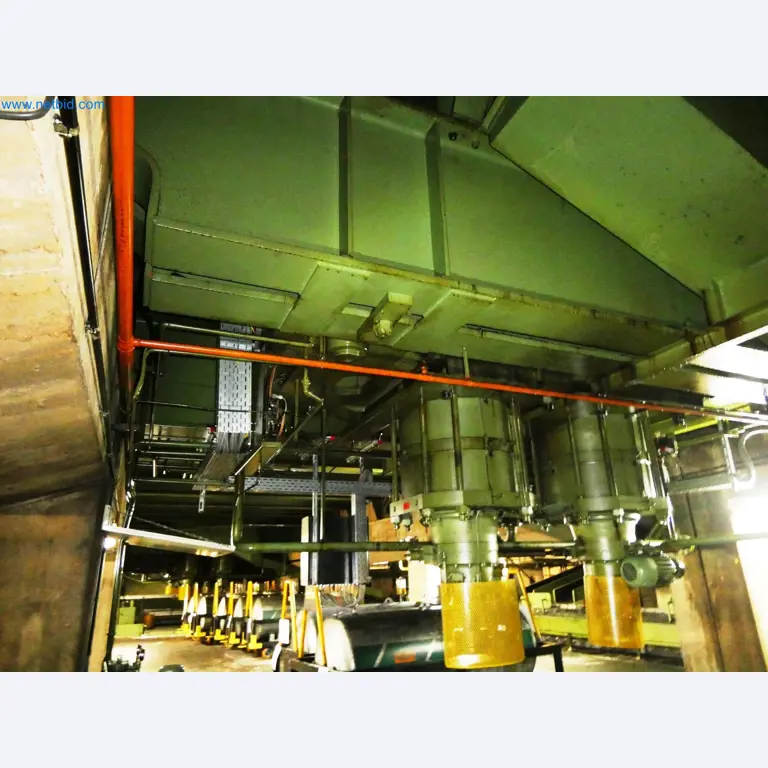

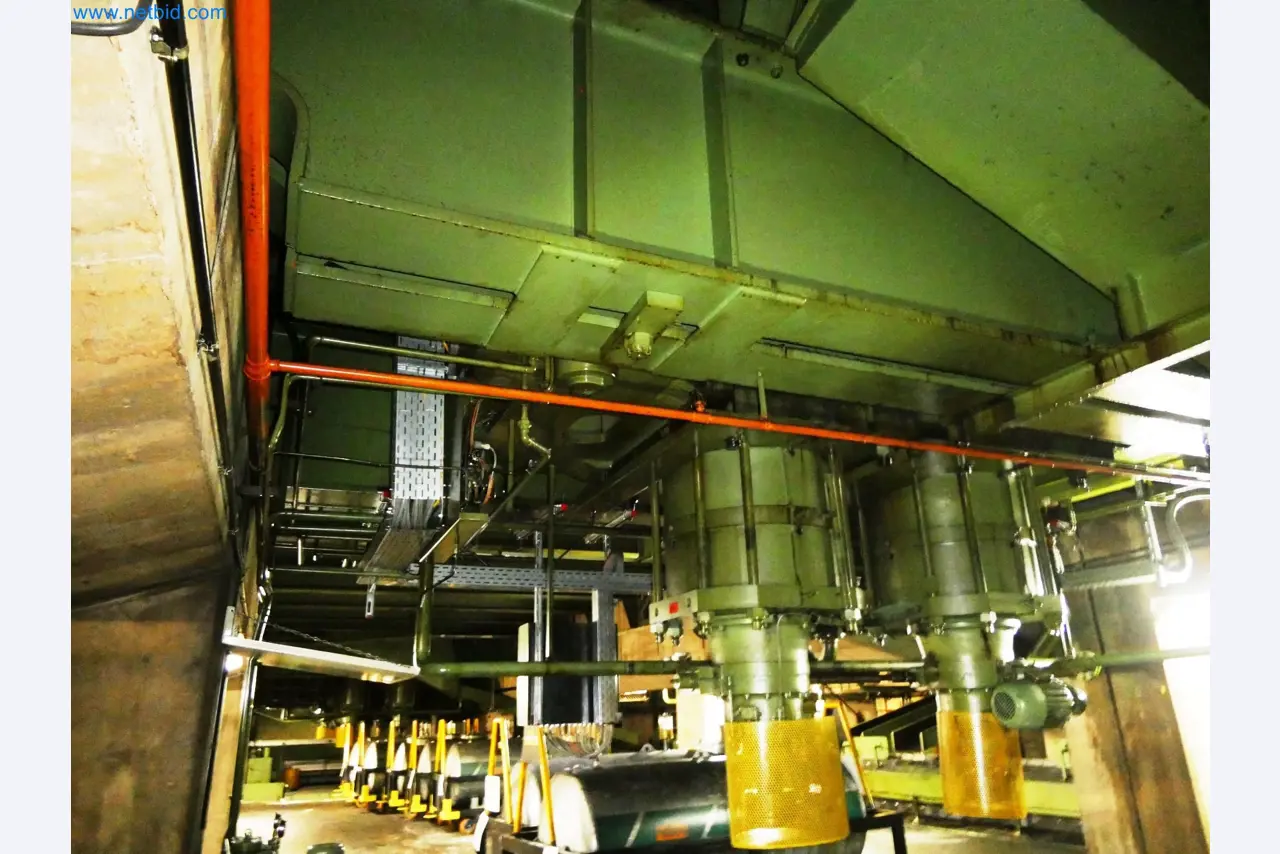

Press line (78A) SchulerLIVE#18844-5002

This auction has ended.

Details

Product Type

Schuler

Description

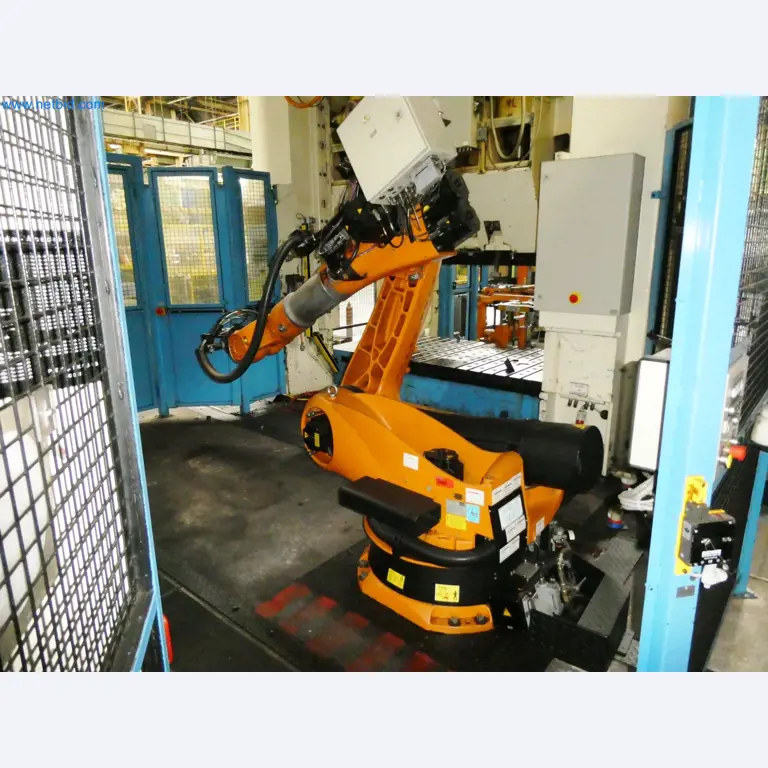

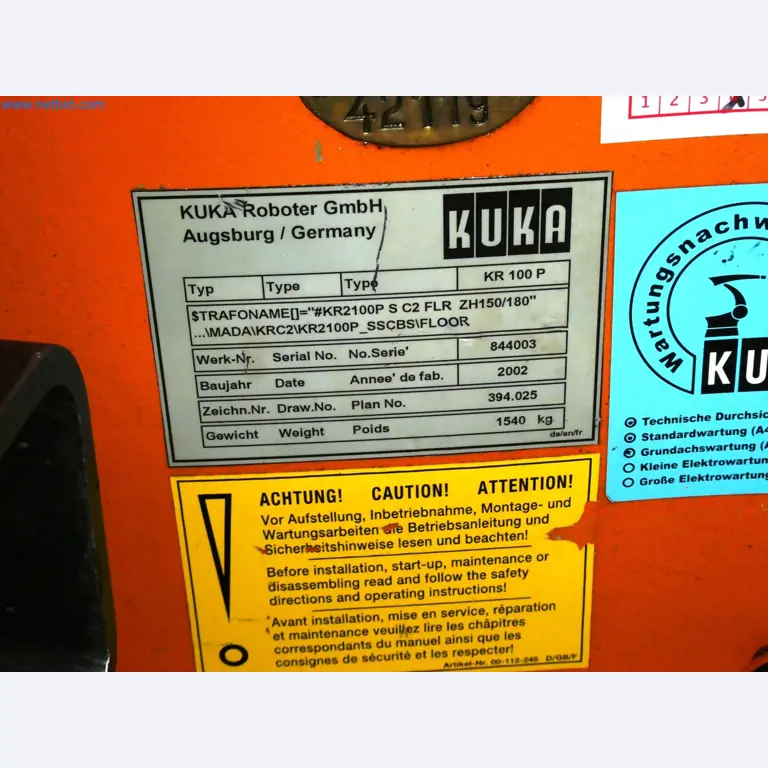

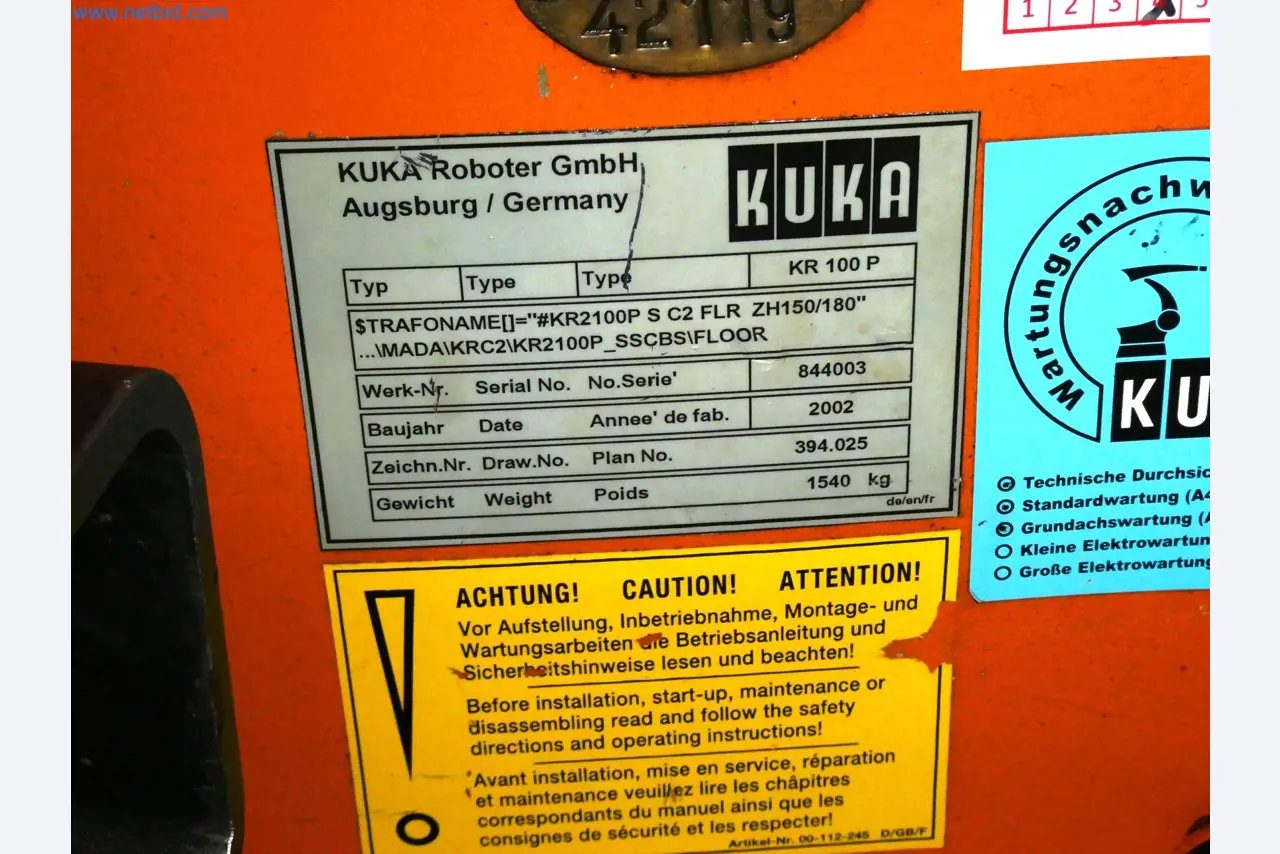

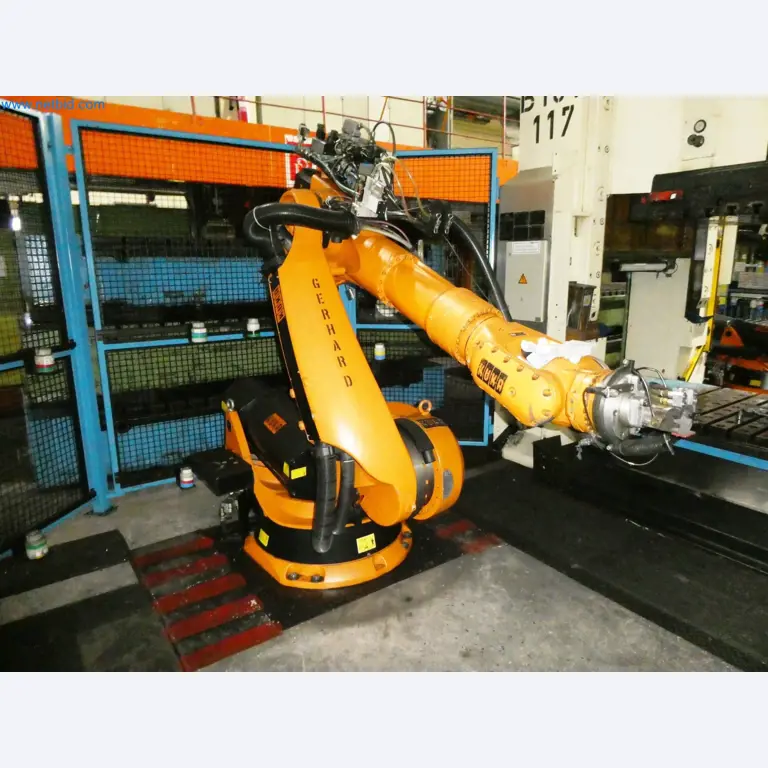

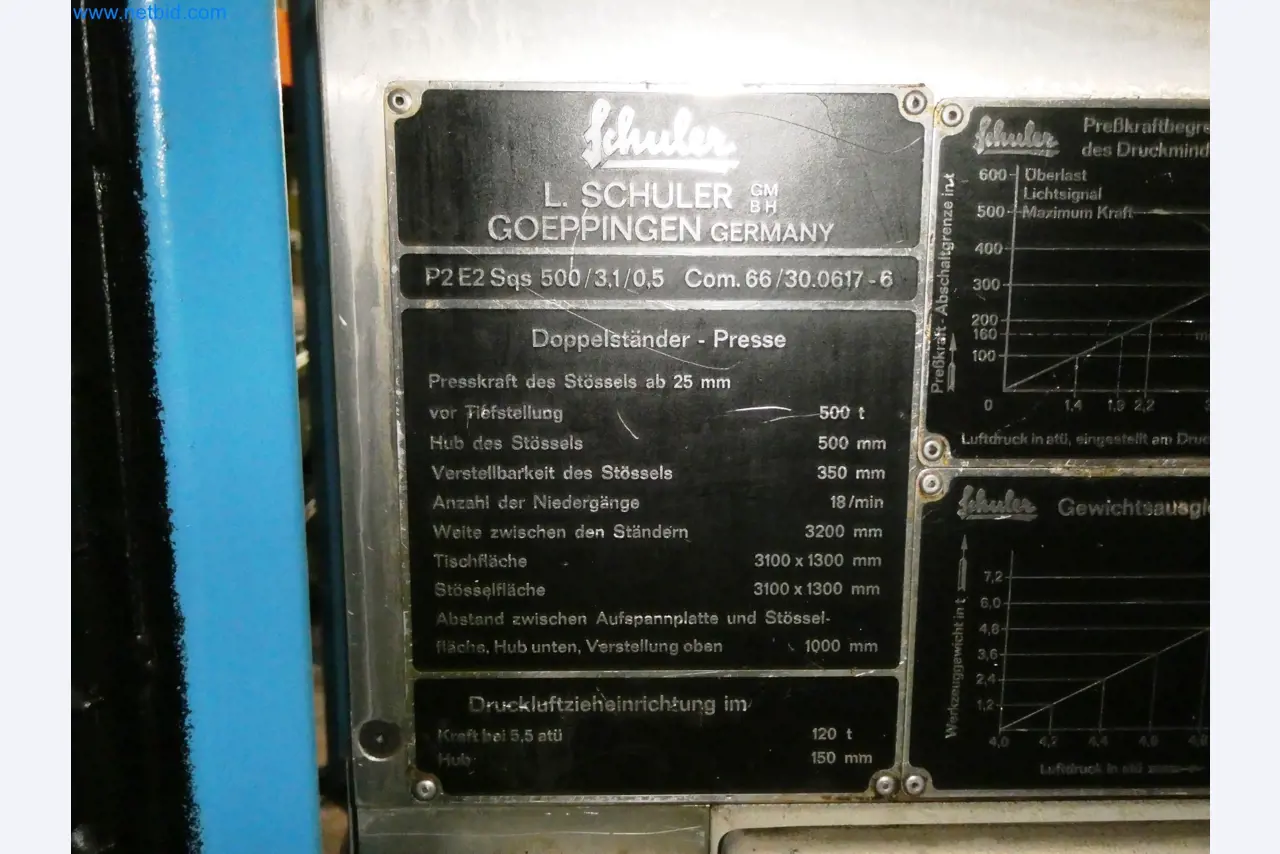

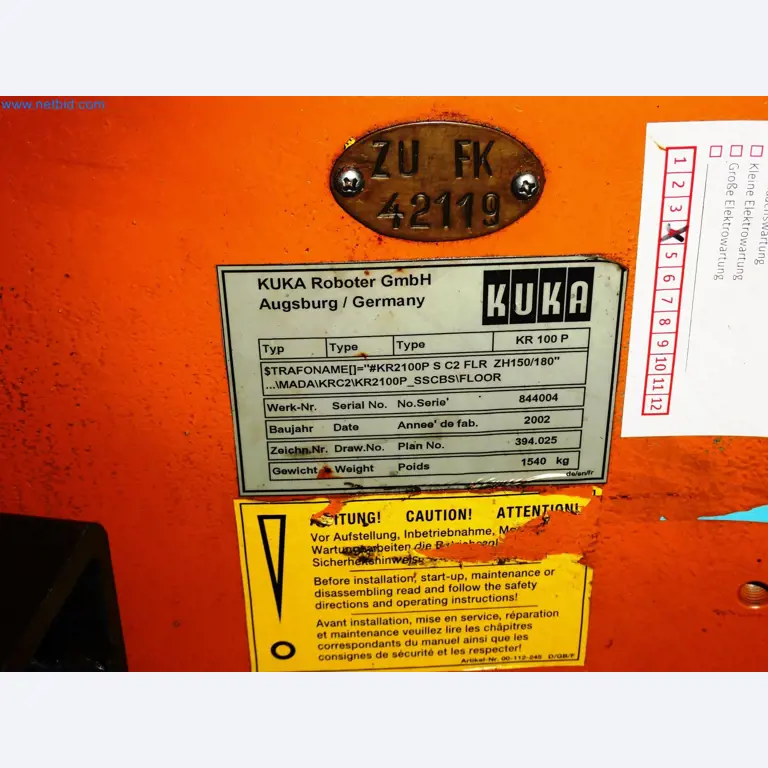

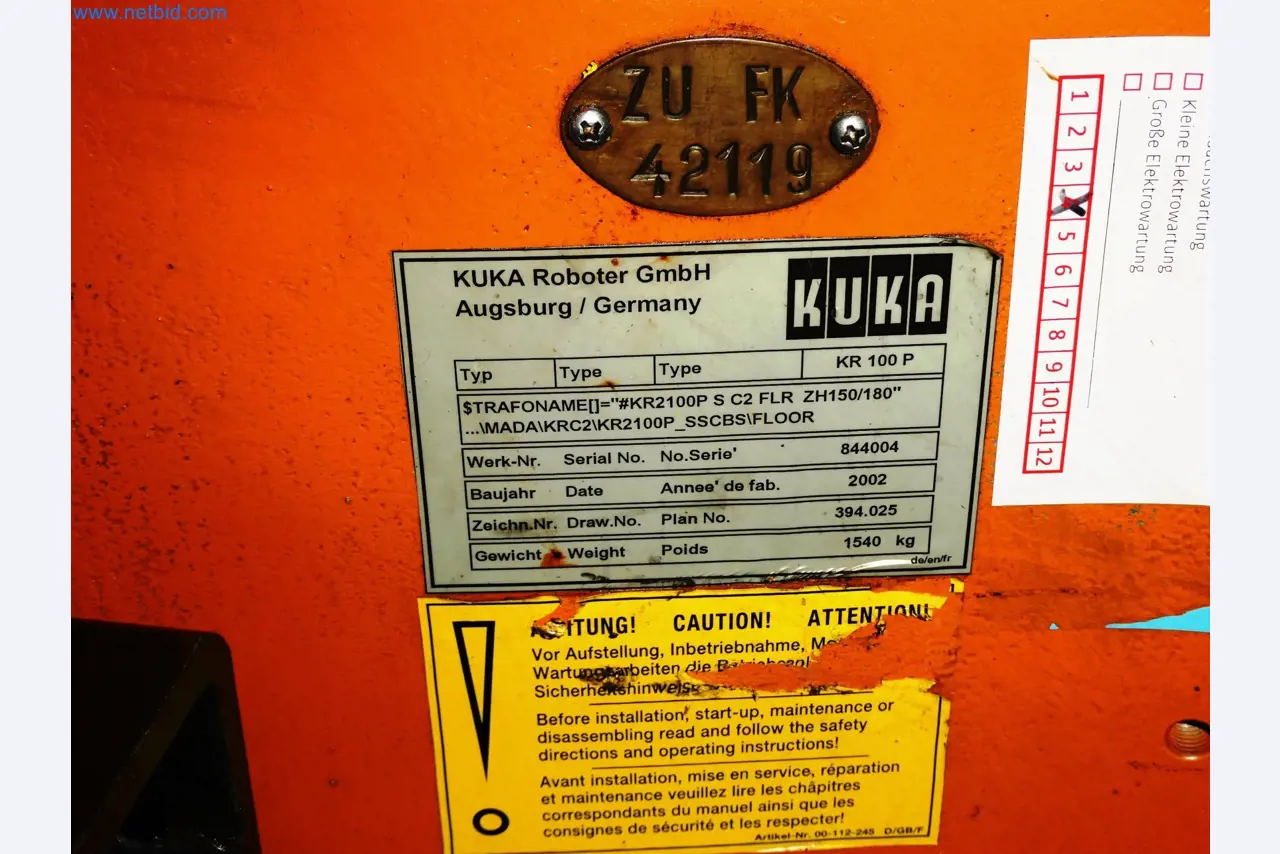

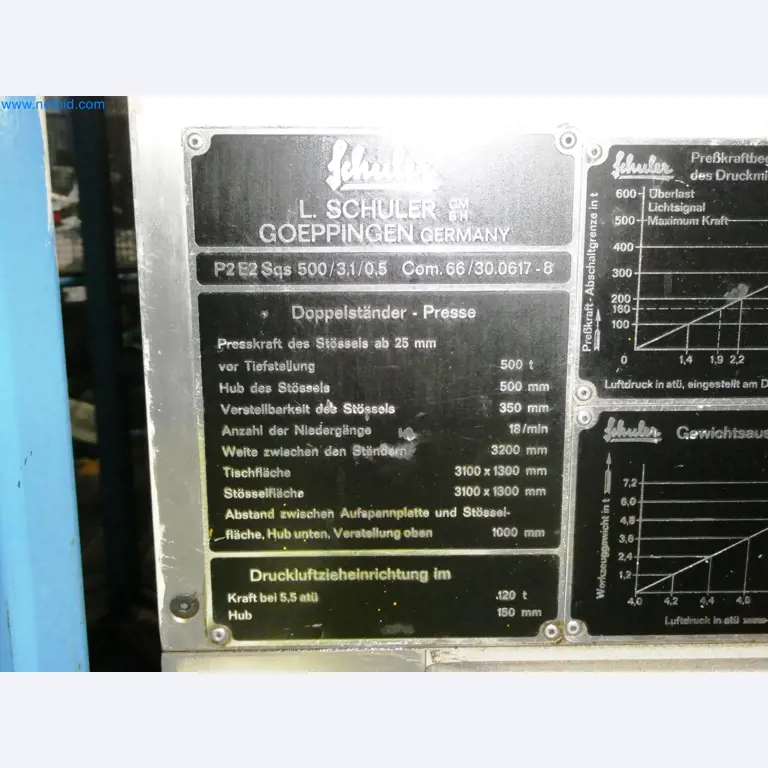

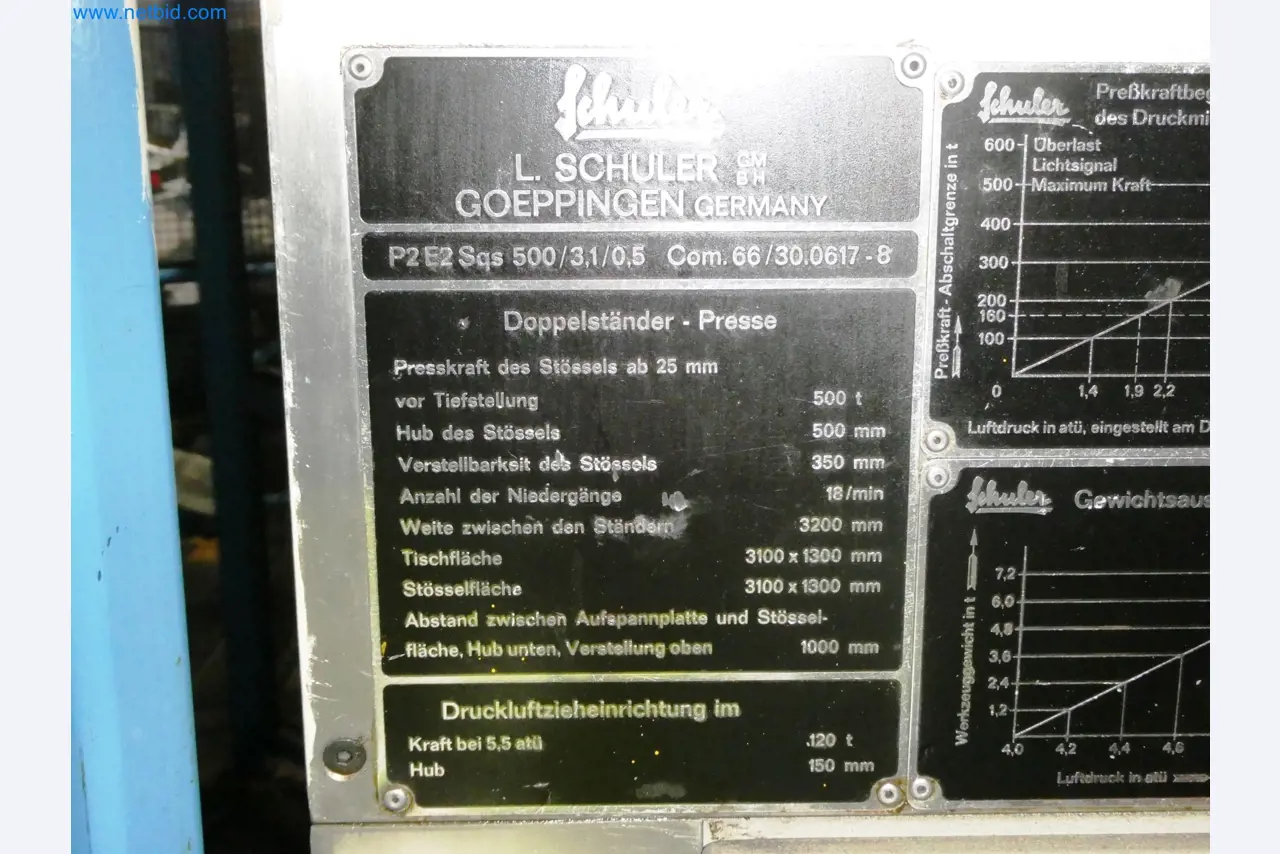

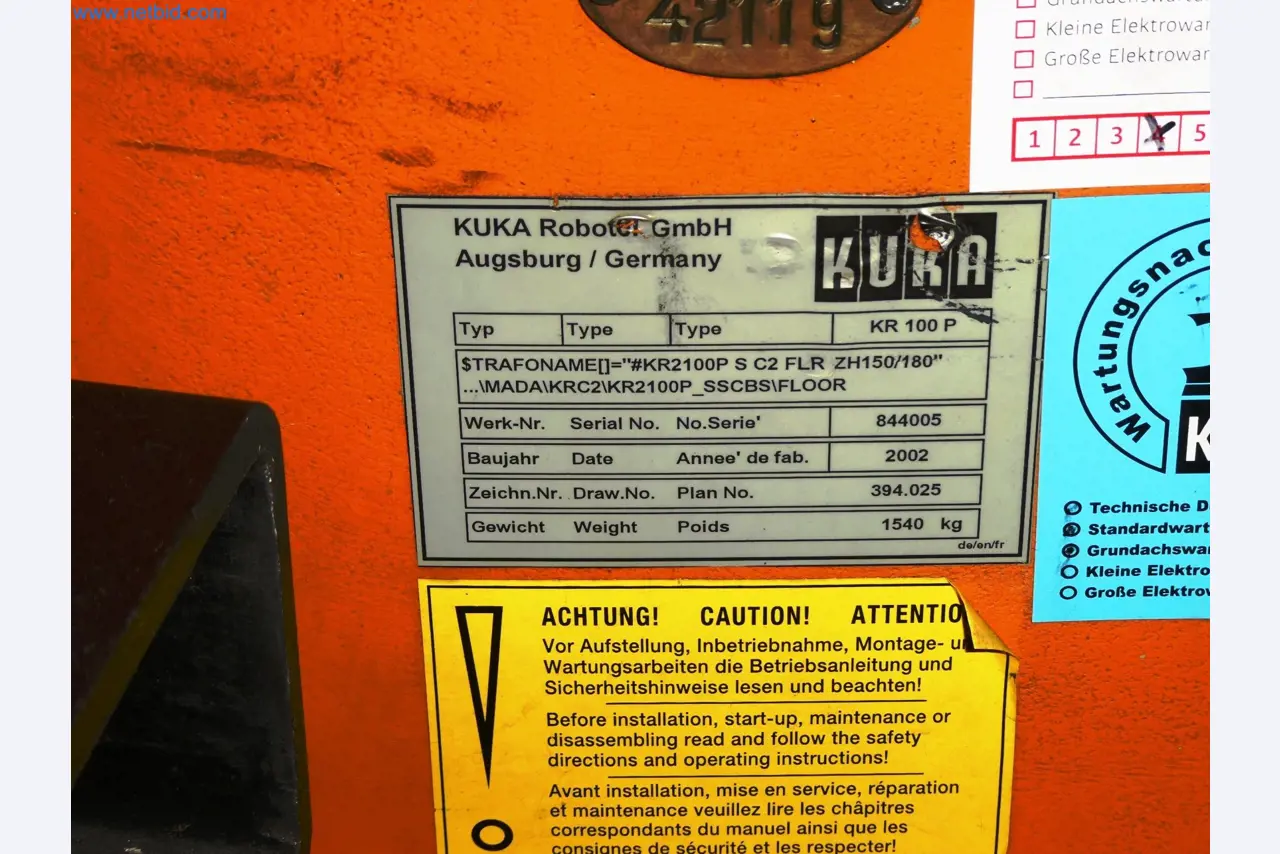

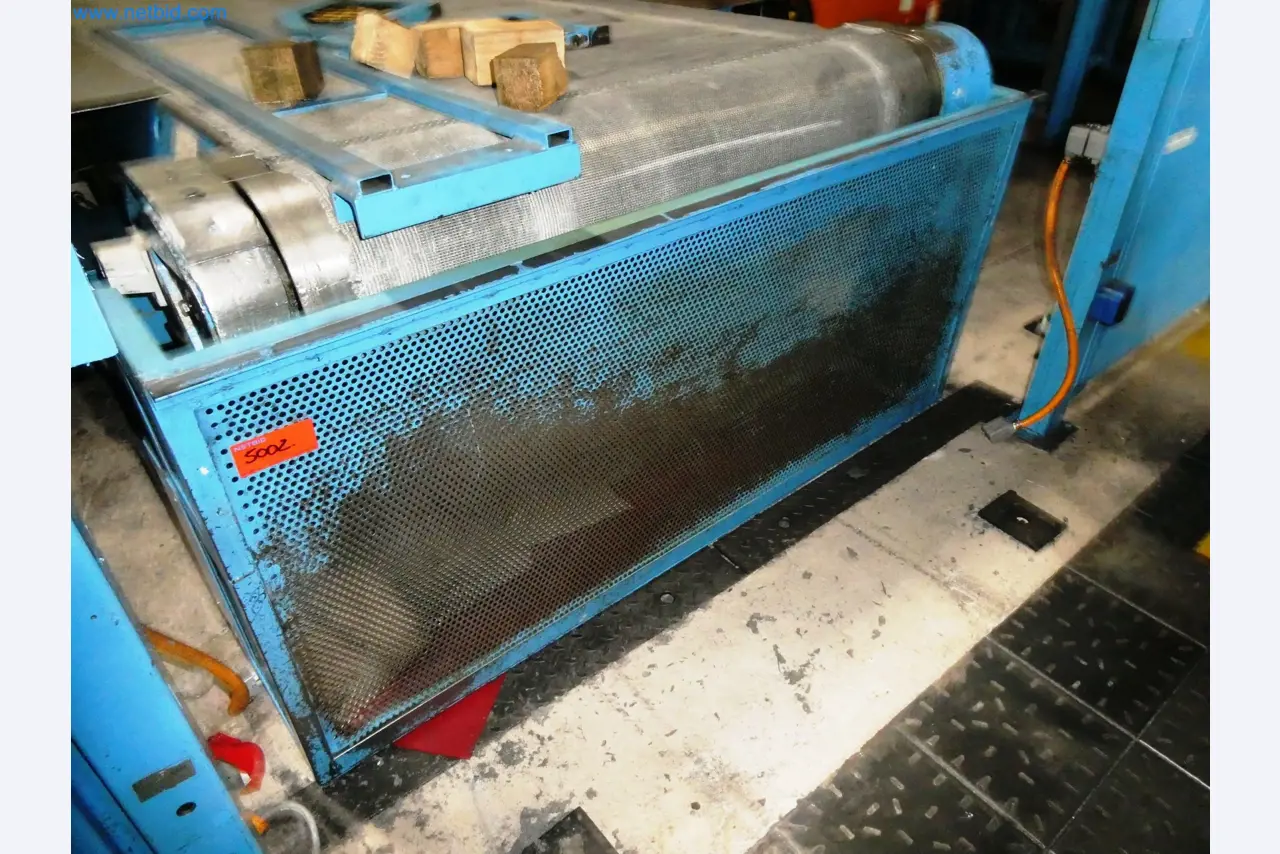

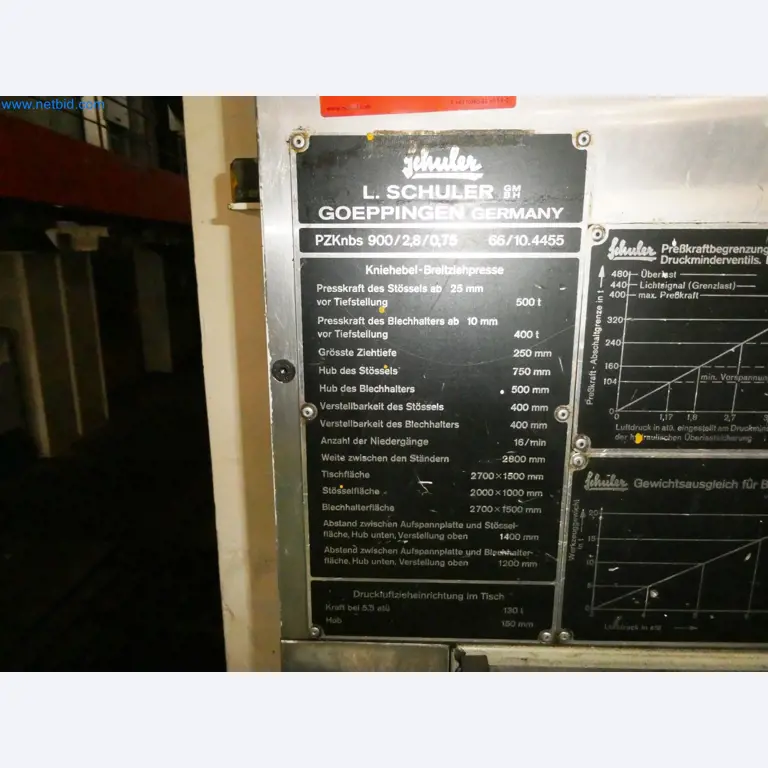

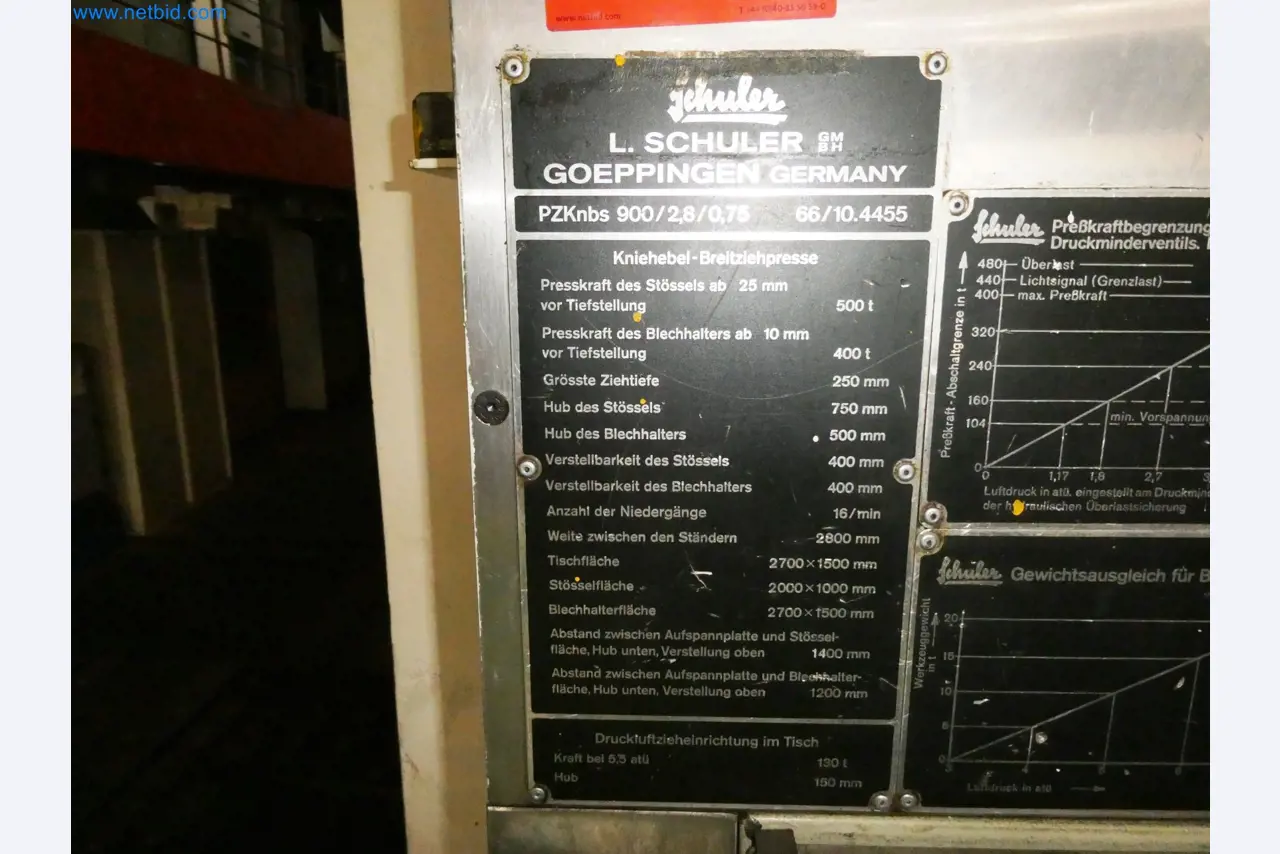

3 pcs. double Column Presses 78/2, 78/3, 78/4, make Schuler, type P2E2 SQS 500/3.1/0.5, SN 66/30.617-7, 66/30.0617-6, 66/30.0617-8, Pressforce 500 t, table 3.100 x 1.300 mm, moving bolsters, incl. spare parts (subject to availability), excl. Cables, electrical cabinets robots, destacker and automation

Location

- Deutschland/ Halle B/ Stamping/ Linie 78A

Dates

Inspection

Only by prior written registration and appointment at weyand@netbid.com

Please note the access requirements, which can be found in the auction conditions.

Please note the access requirements, which can be found in the auction conditions.

Pickup

By arrangement.

Auction Terms

Due to the access requirements, we need the following information from you for a viewing appointment

Complete company name, name and contact details

Which production areas are of interest

Preferred date and time

Number of participants and names

Special conditions:

Special conditions:

- Access requirements

- HSE specifications

- Different auction conditions

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com