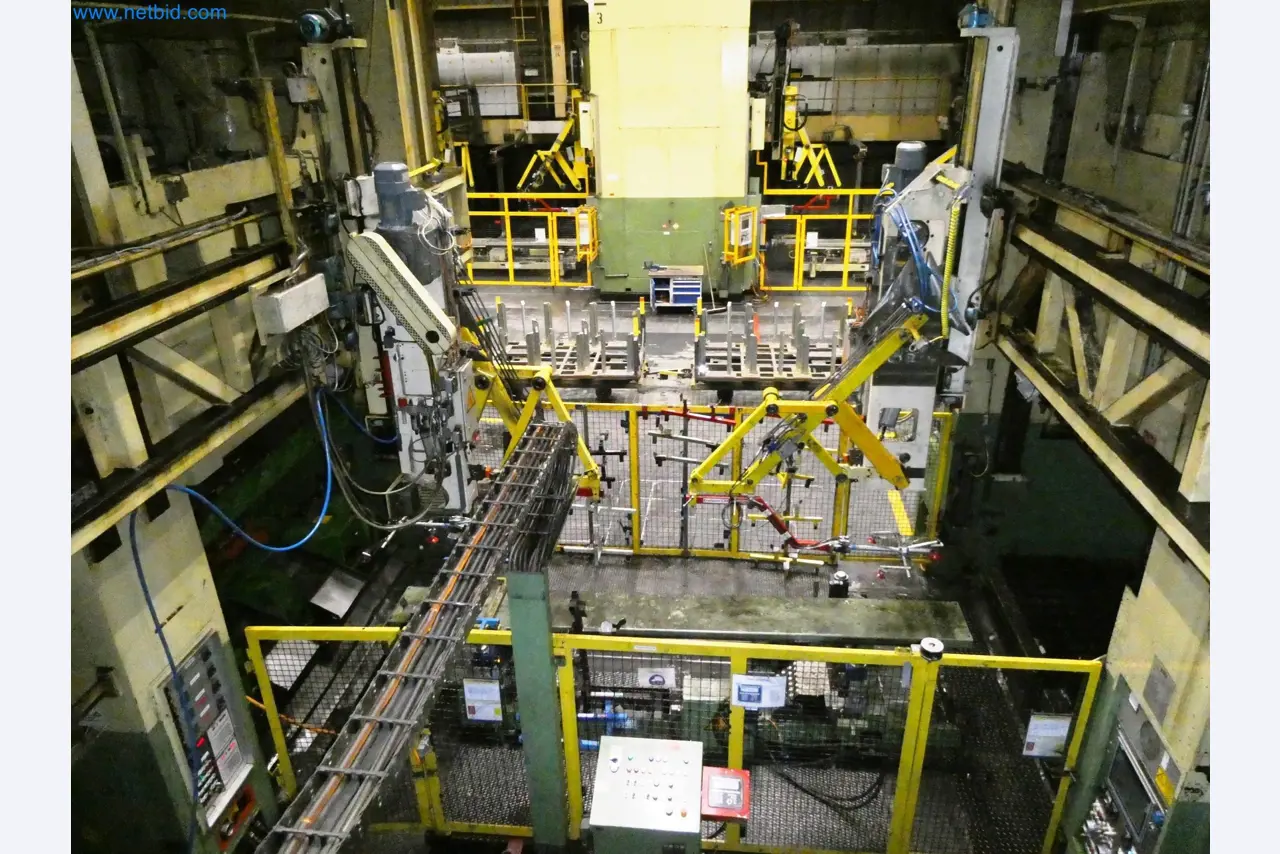

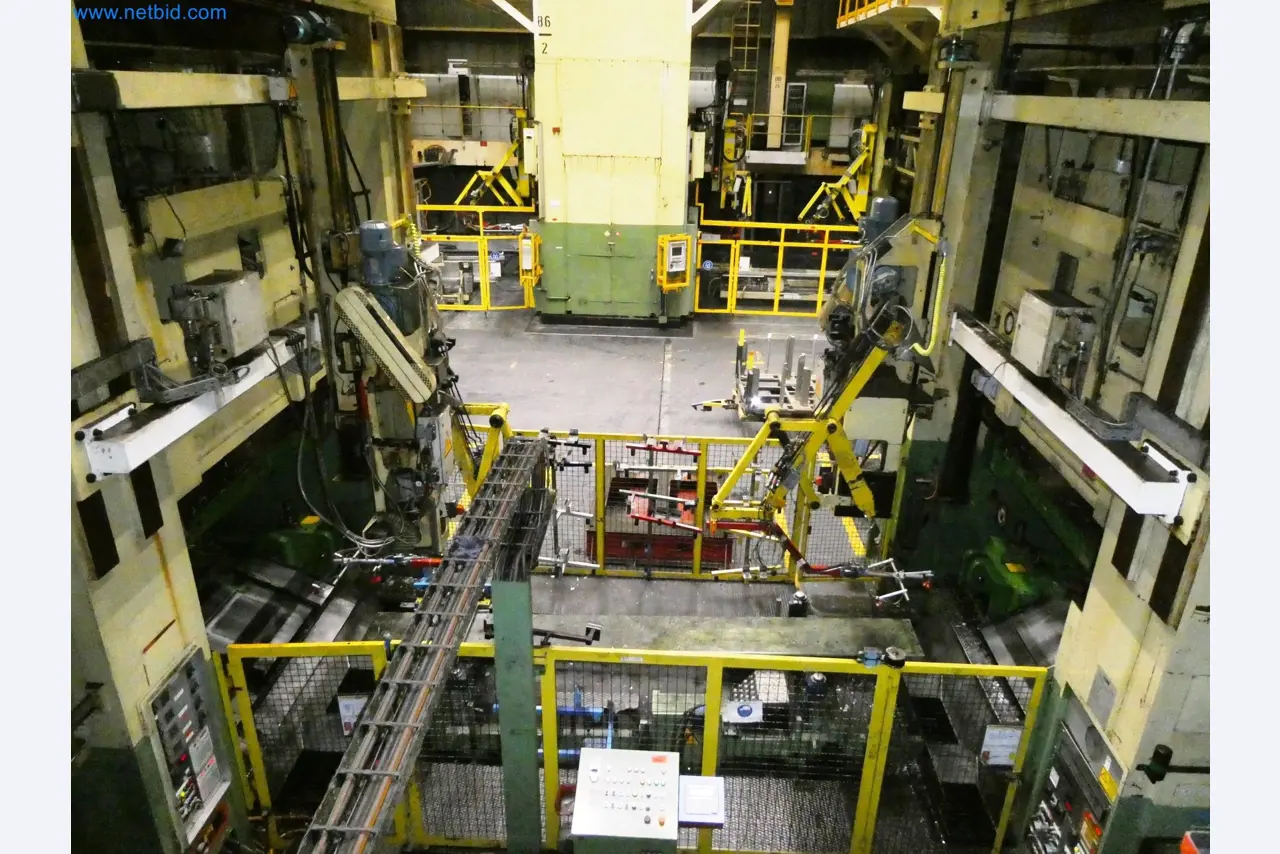

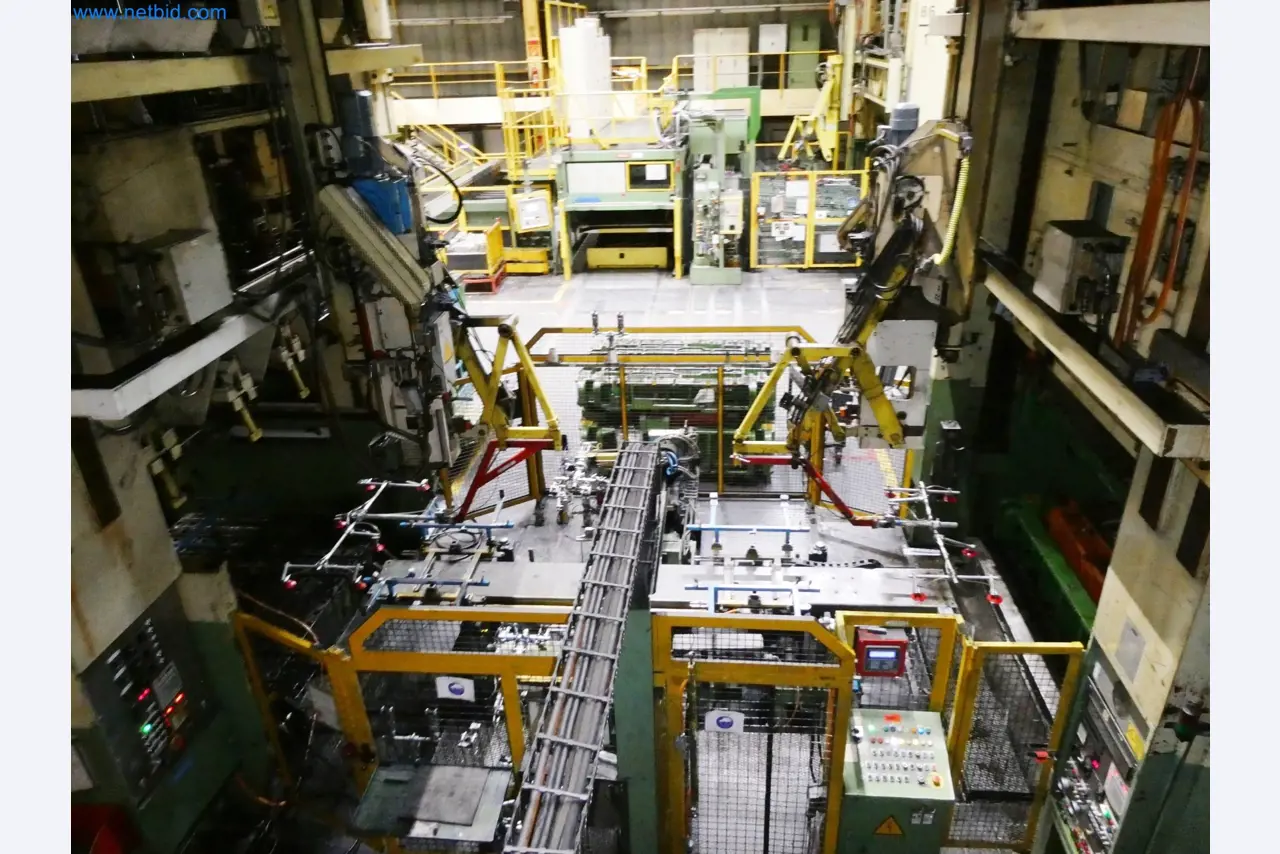

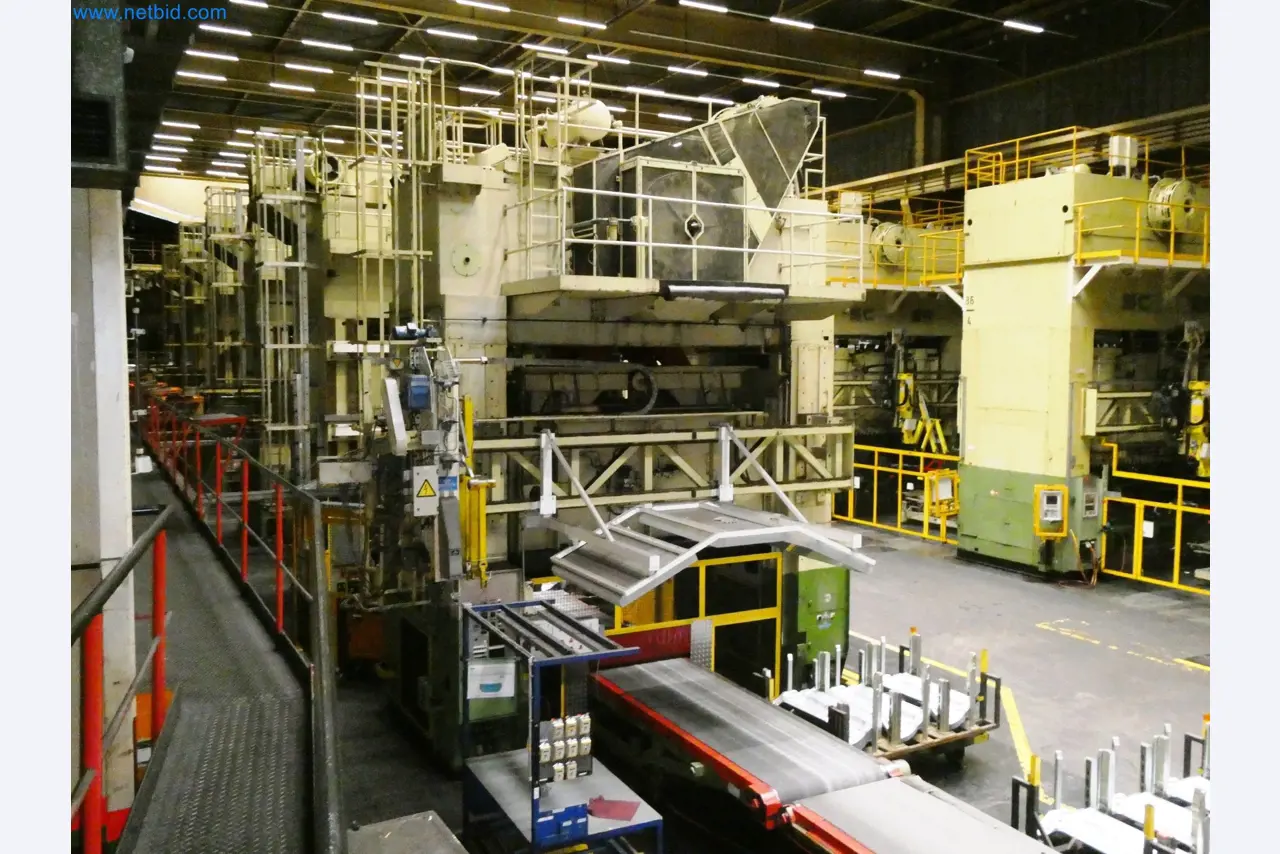

Part of the Auction Press lines from the automotive industry

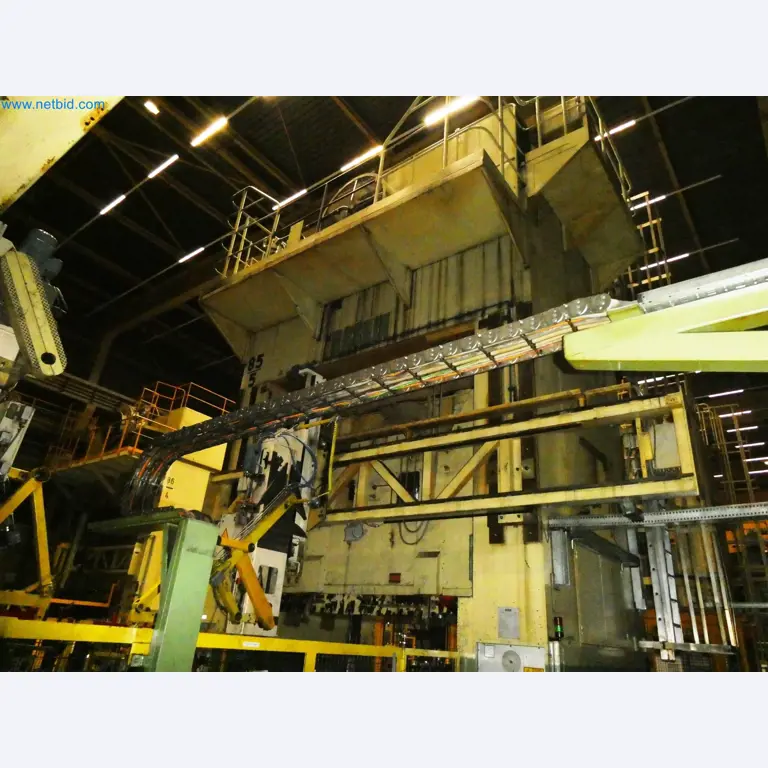

Press line (85) Weingarten/RaskinTRADING#18844-5005

Details

Product Type

Weingarten/Raskin

Description

Last overhaul 2010/2020, consisting of:

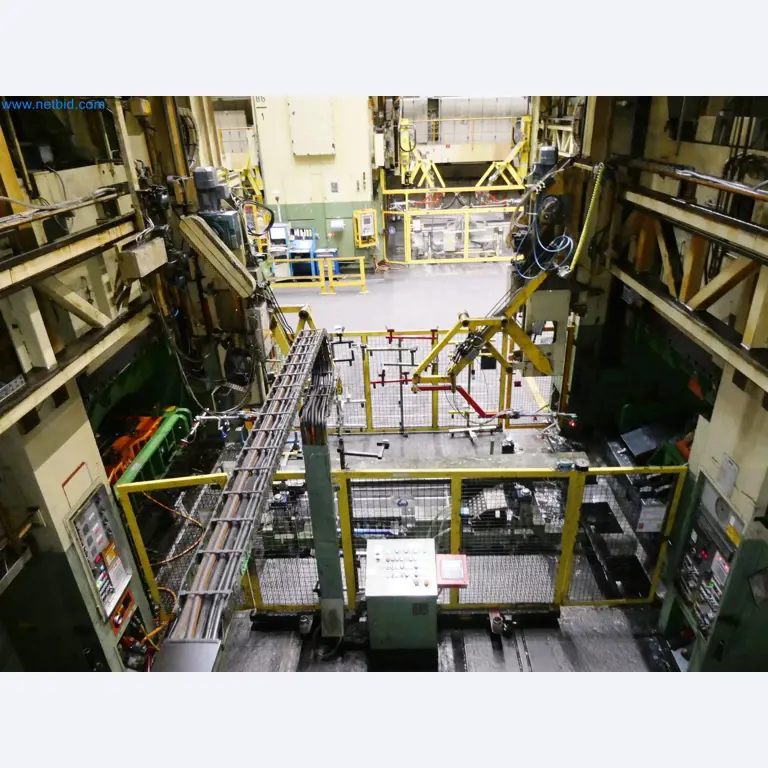

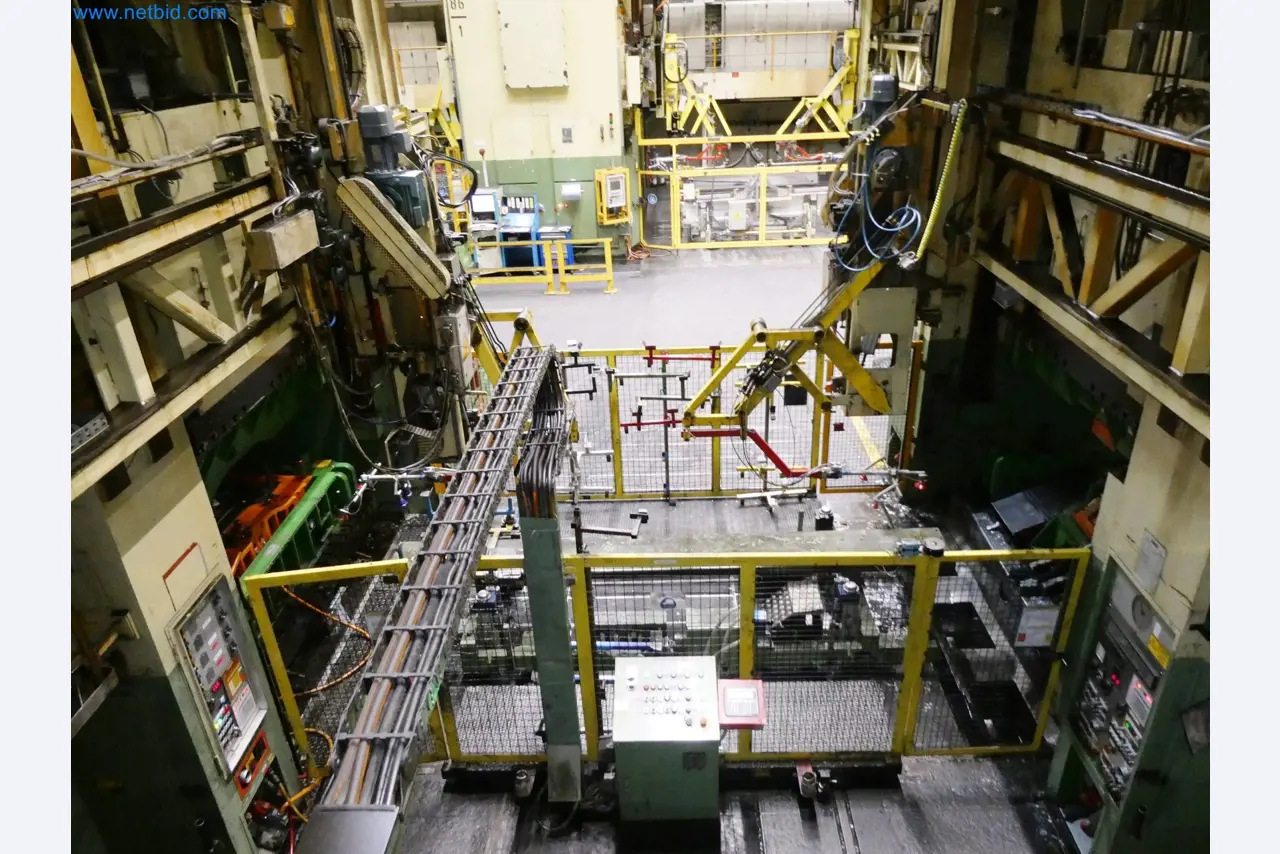

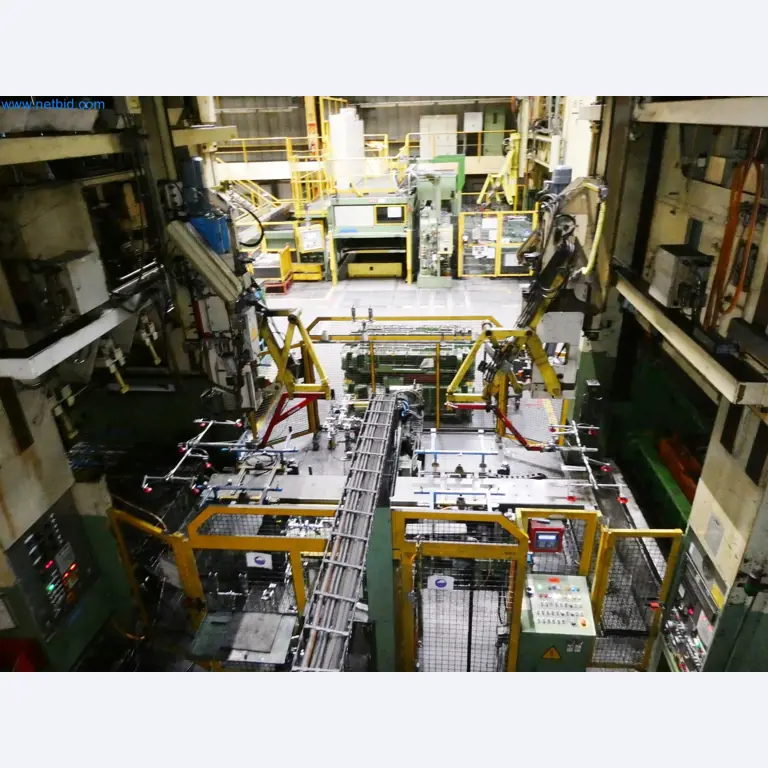

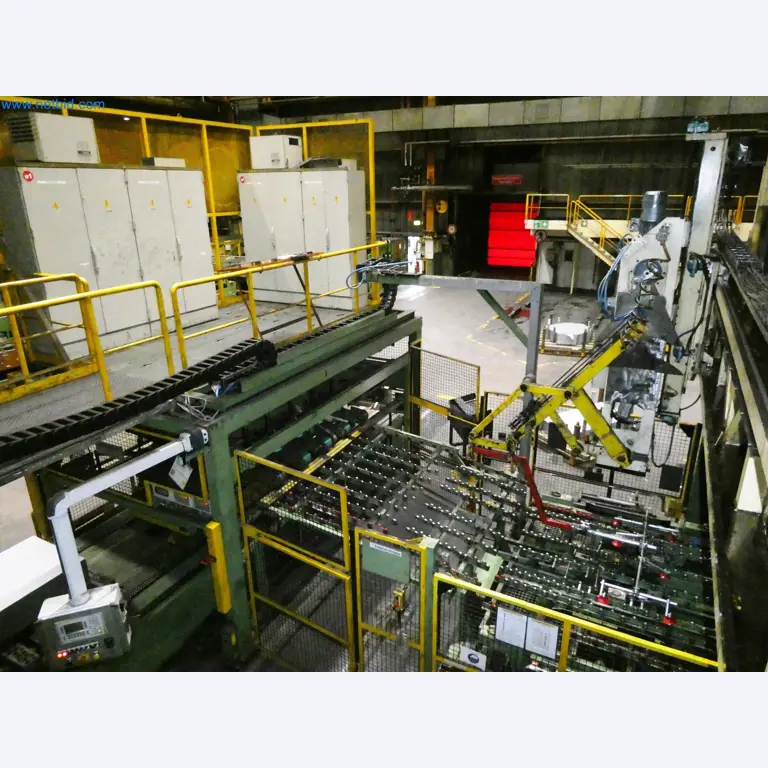

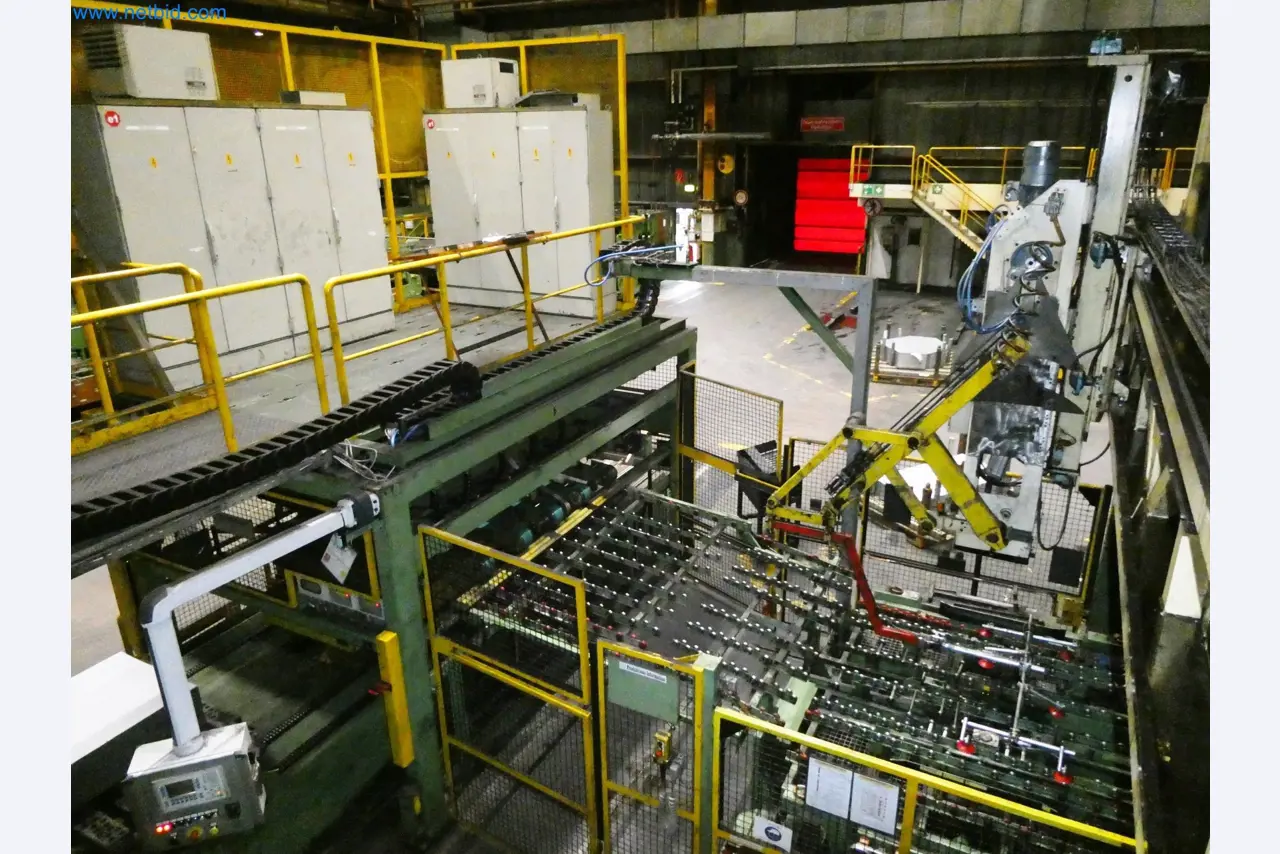

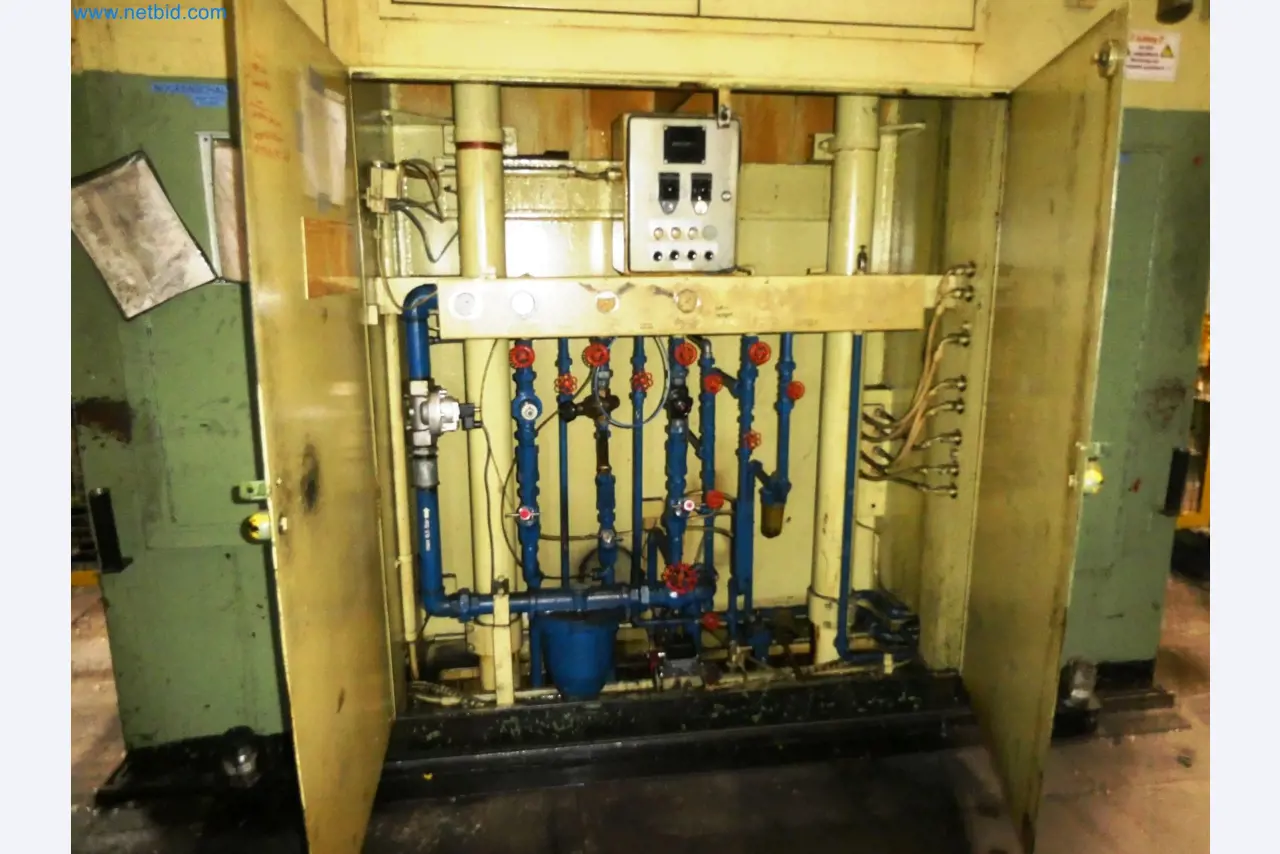

Board washing system, manufactured by Neuhäuser, with 6 cleaning rollers, system no. 0905200, control system, manufactured by Siemens

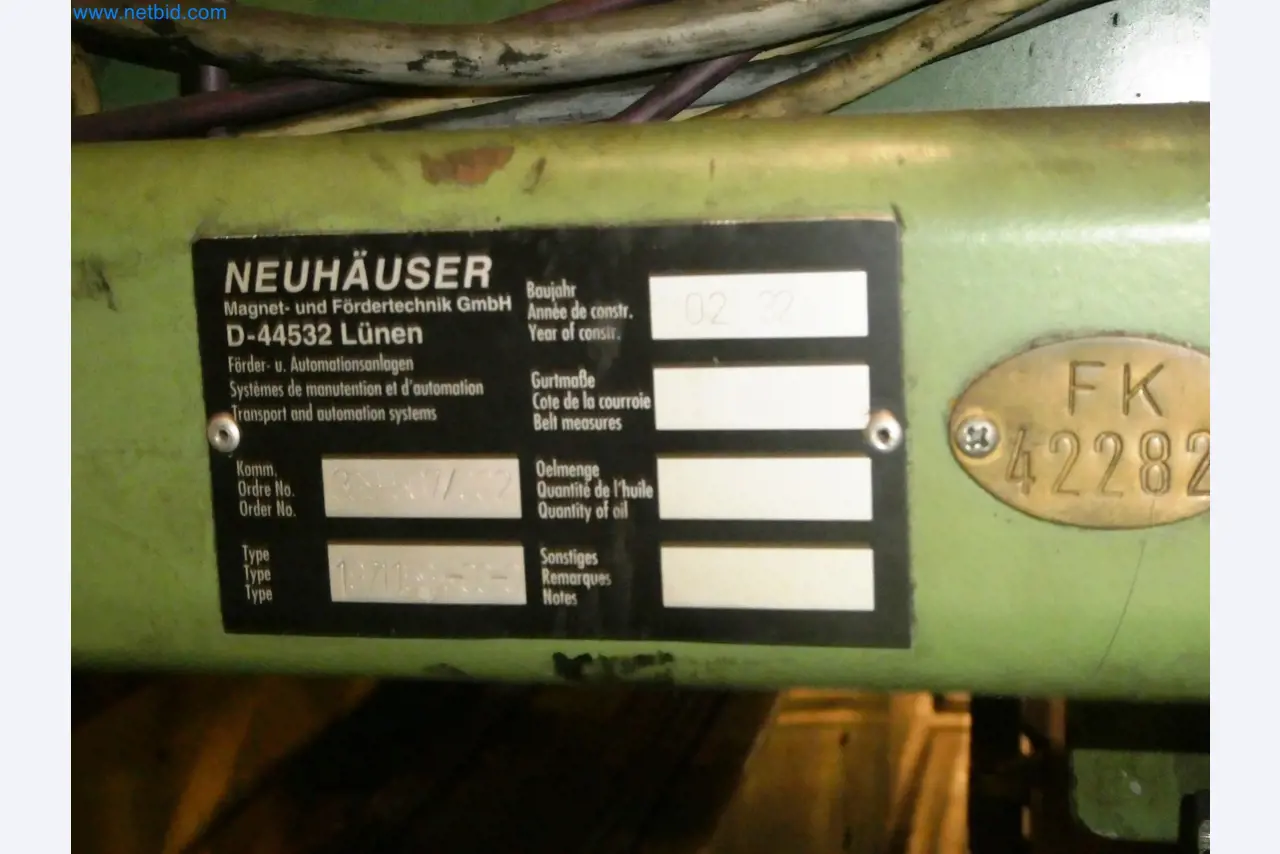

Board automation, Neuhäuser, type 19711594-00-0, year 2002, SN 369507/002, system no. FK42282, consisting of. Destacking device, oiler, pallet changer, empty pallet ejector

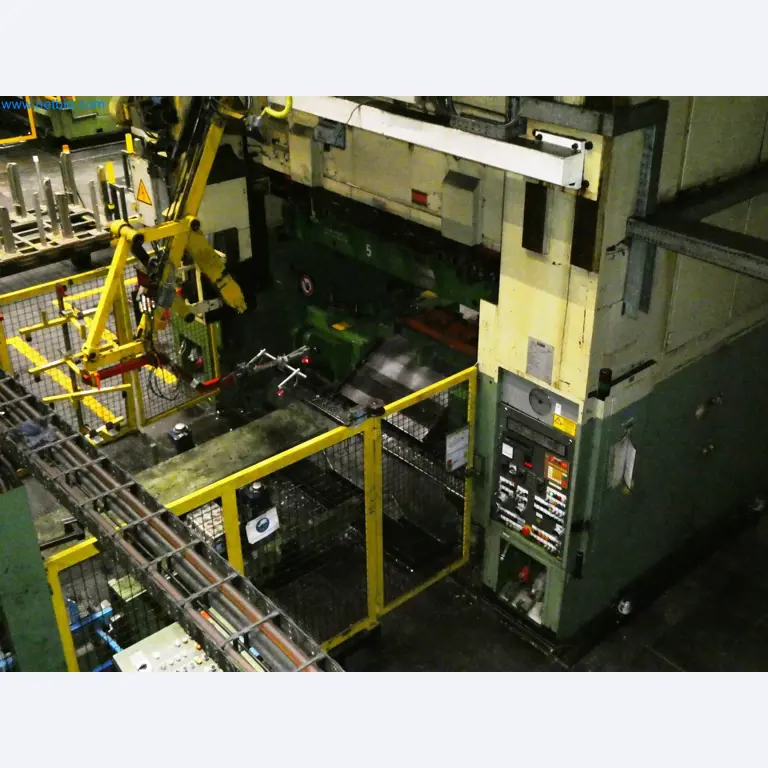

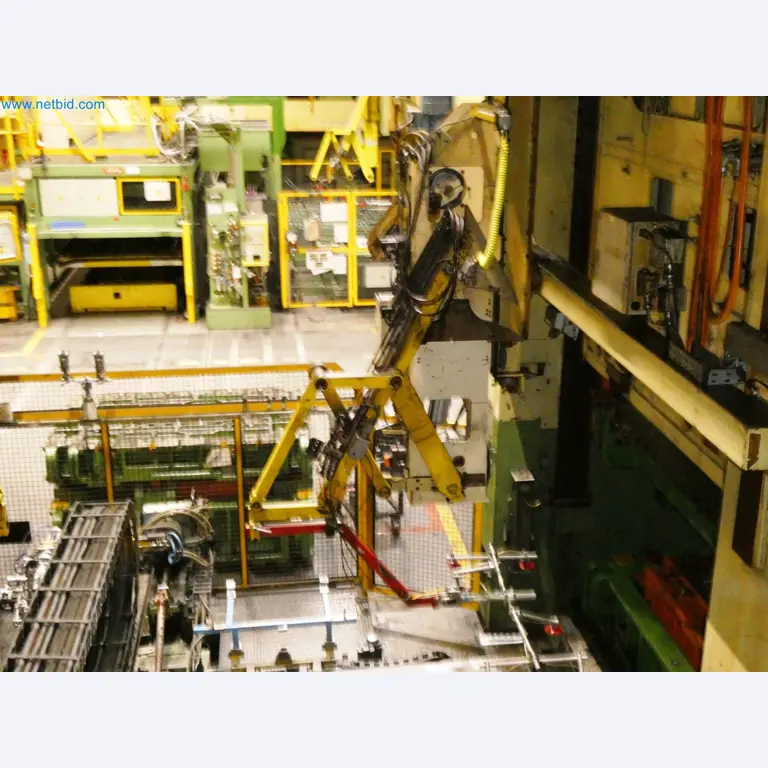

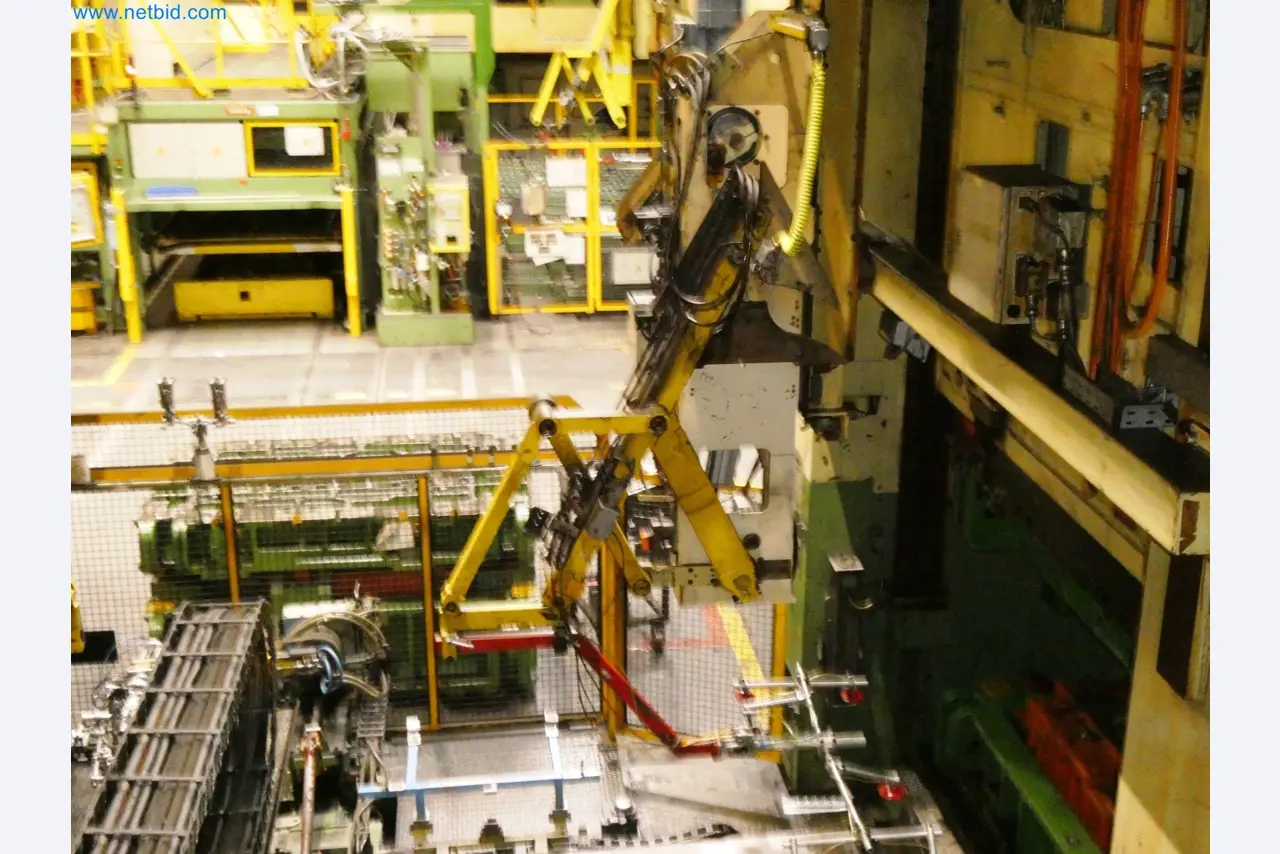

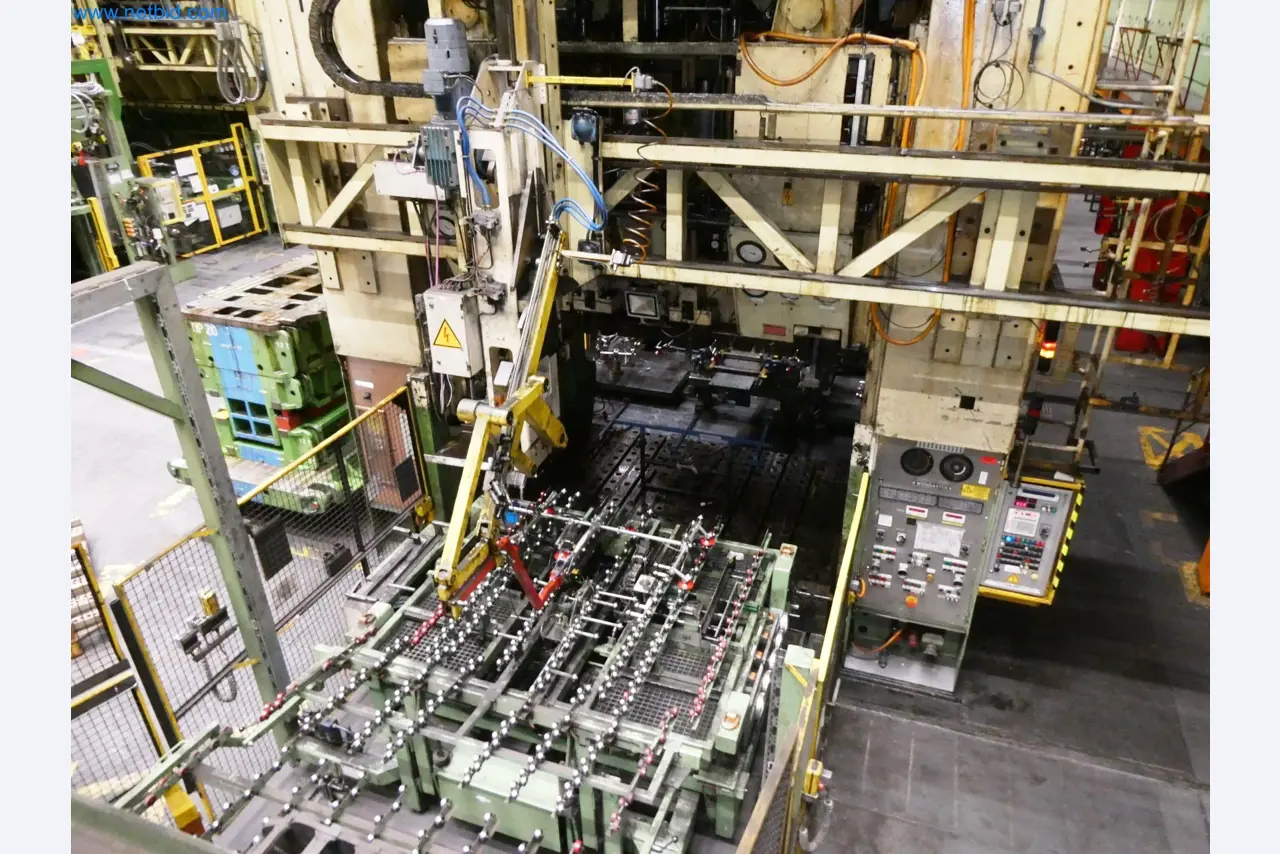

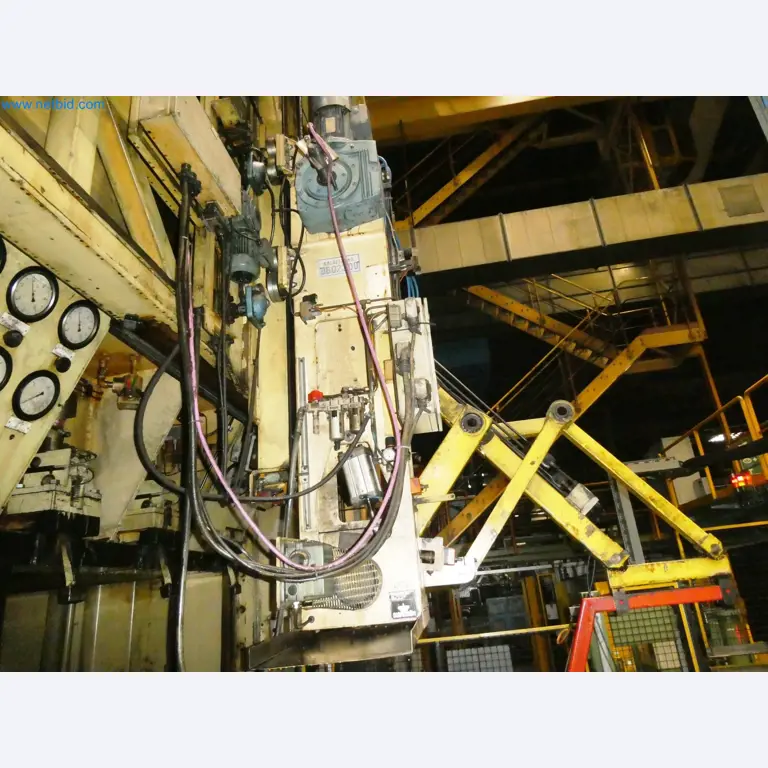

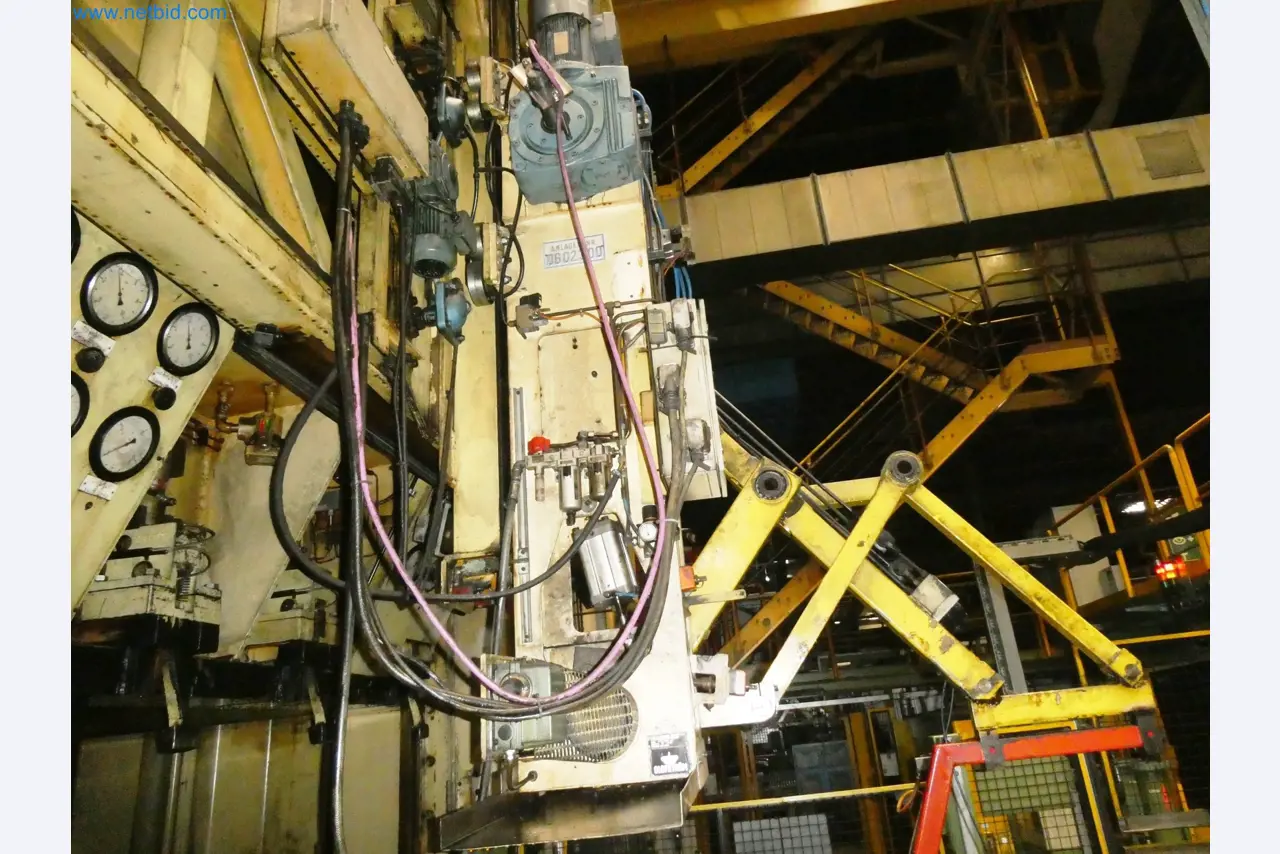

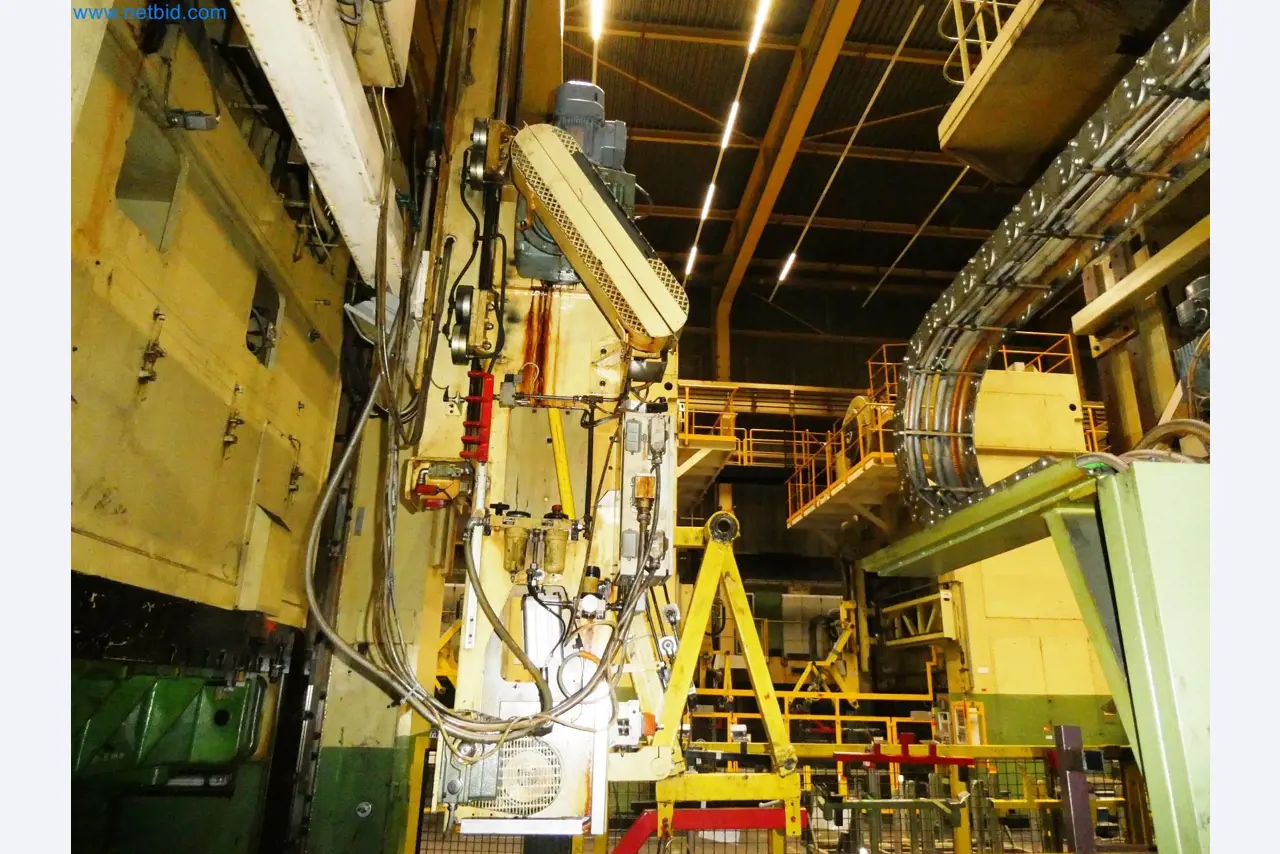

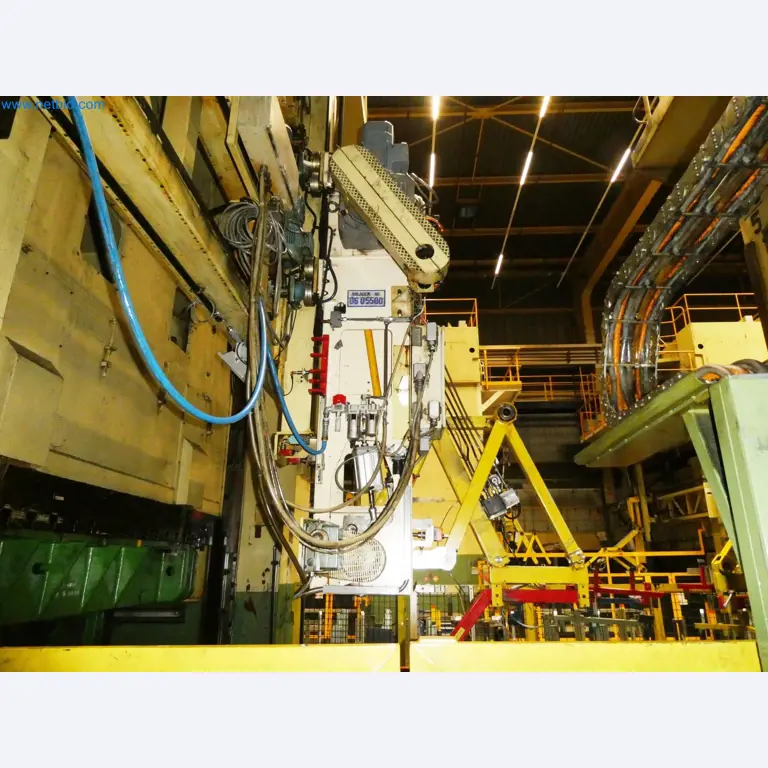

Gripper automation, manufactured by Olofström, type Doppin Loader 2000, SN 37719974886, system no. 0602300

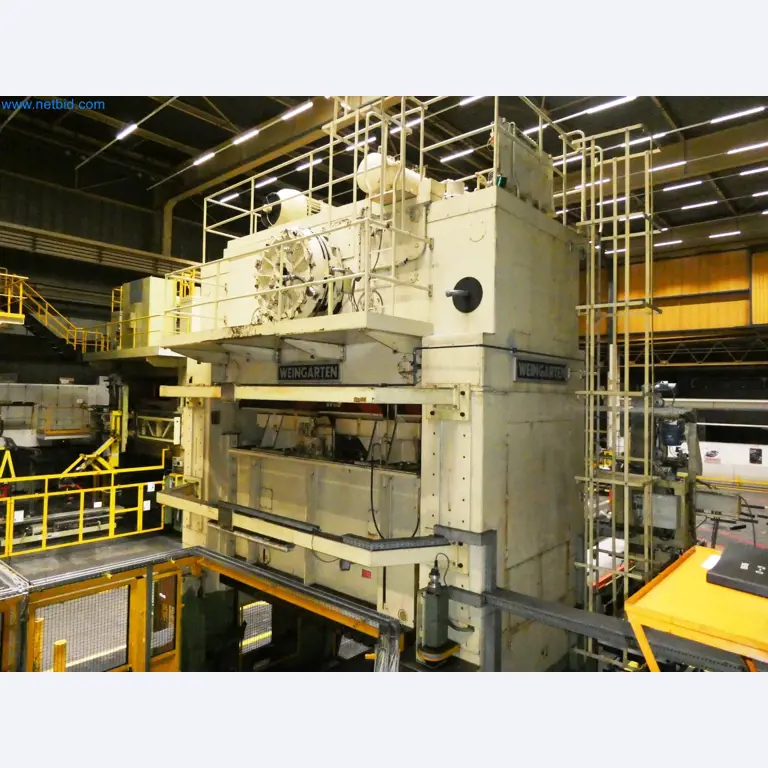

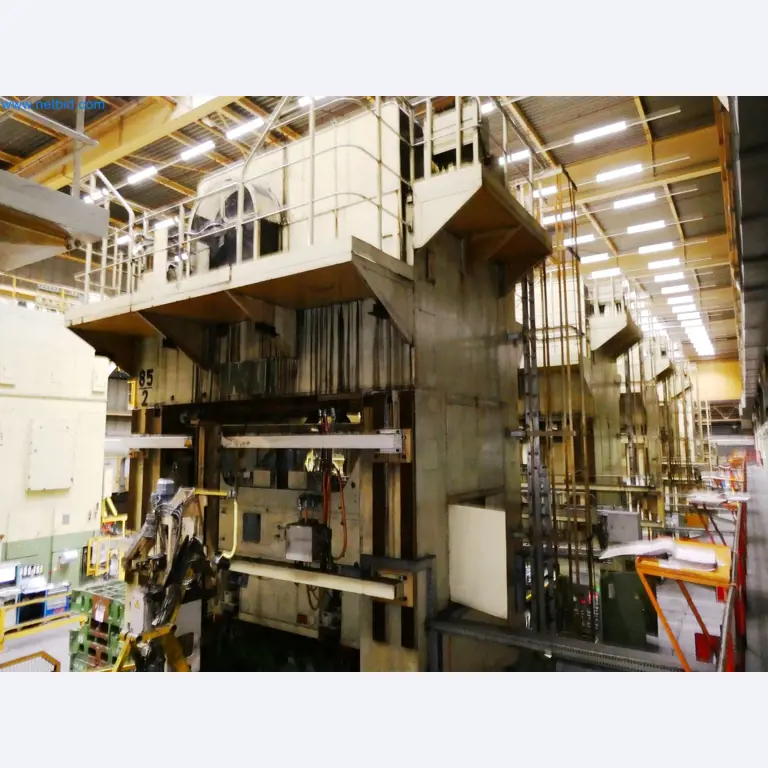

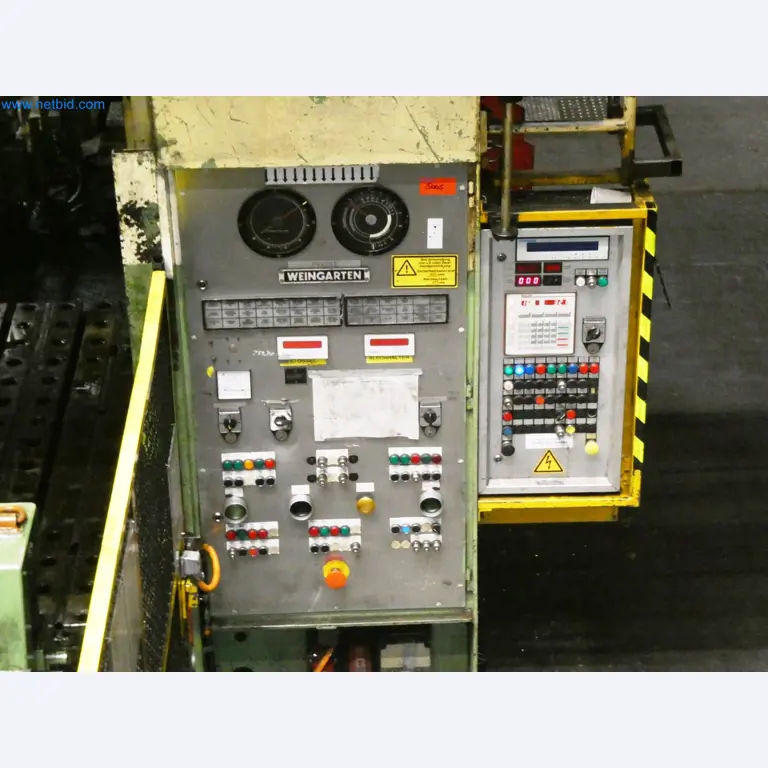

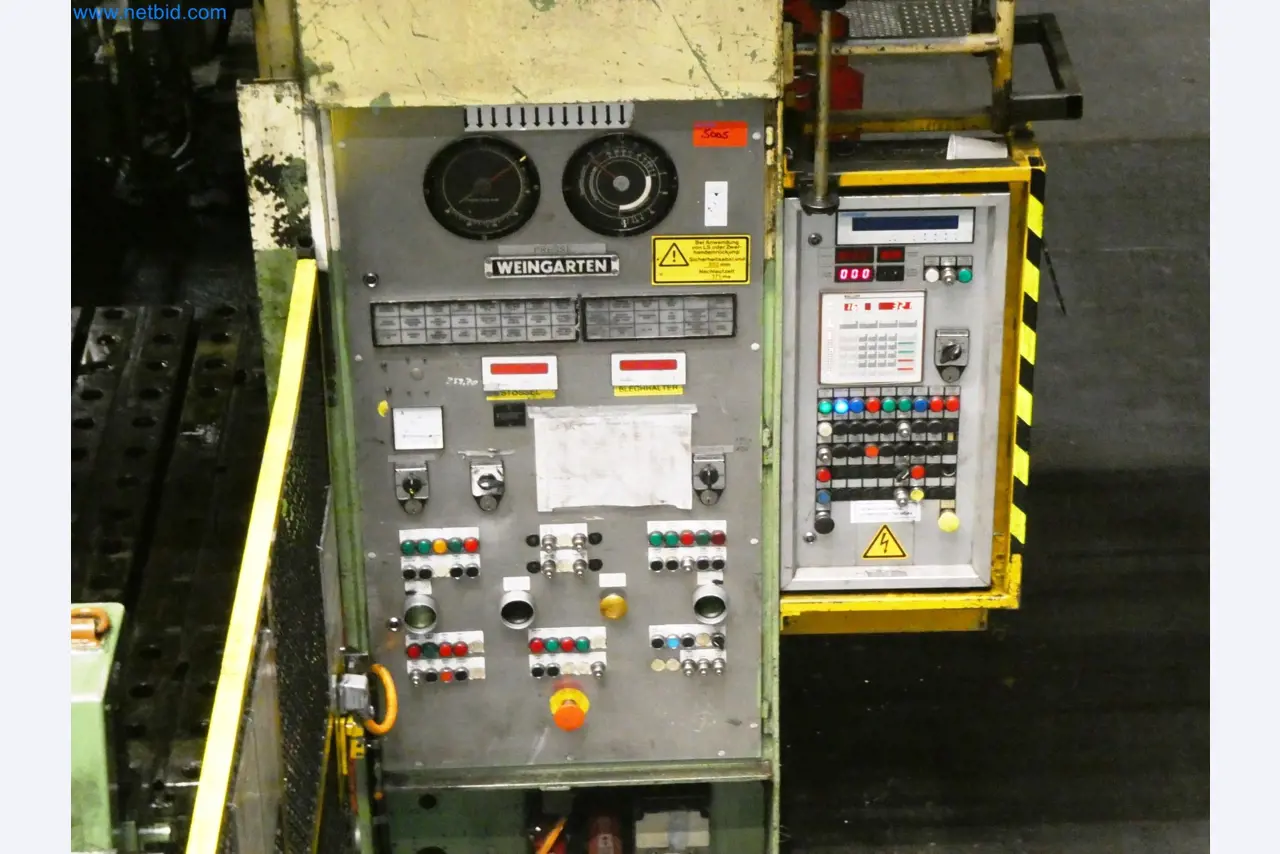

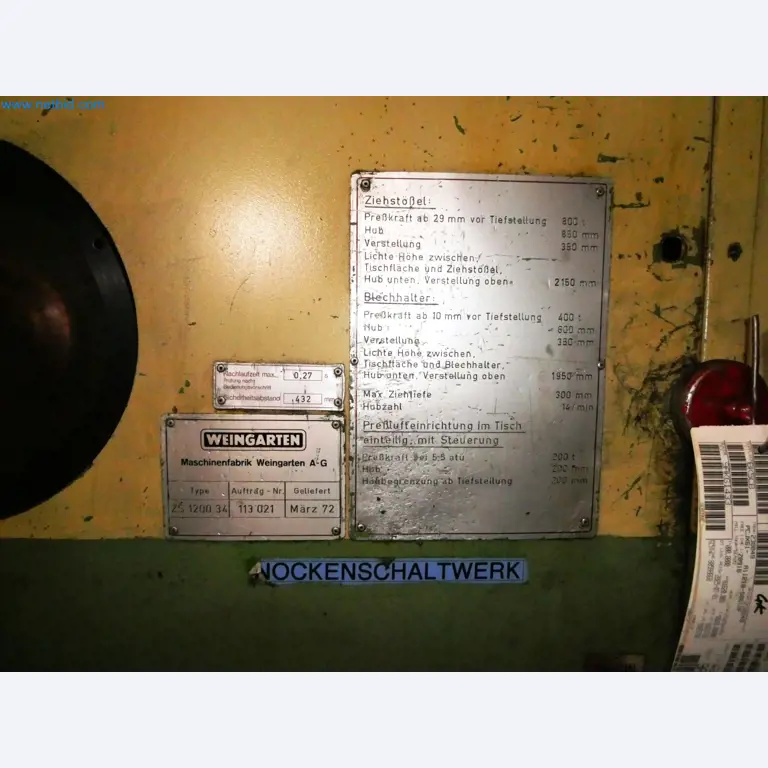

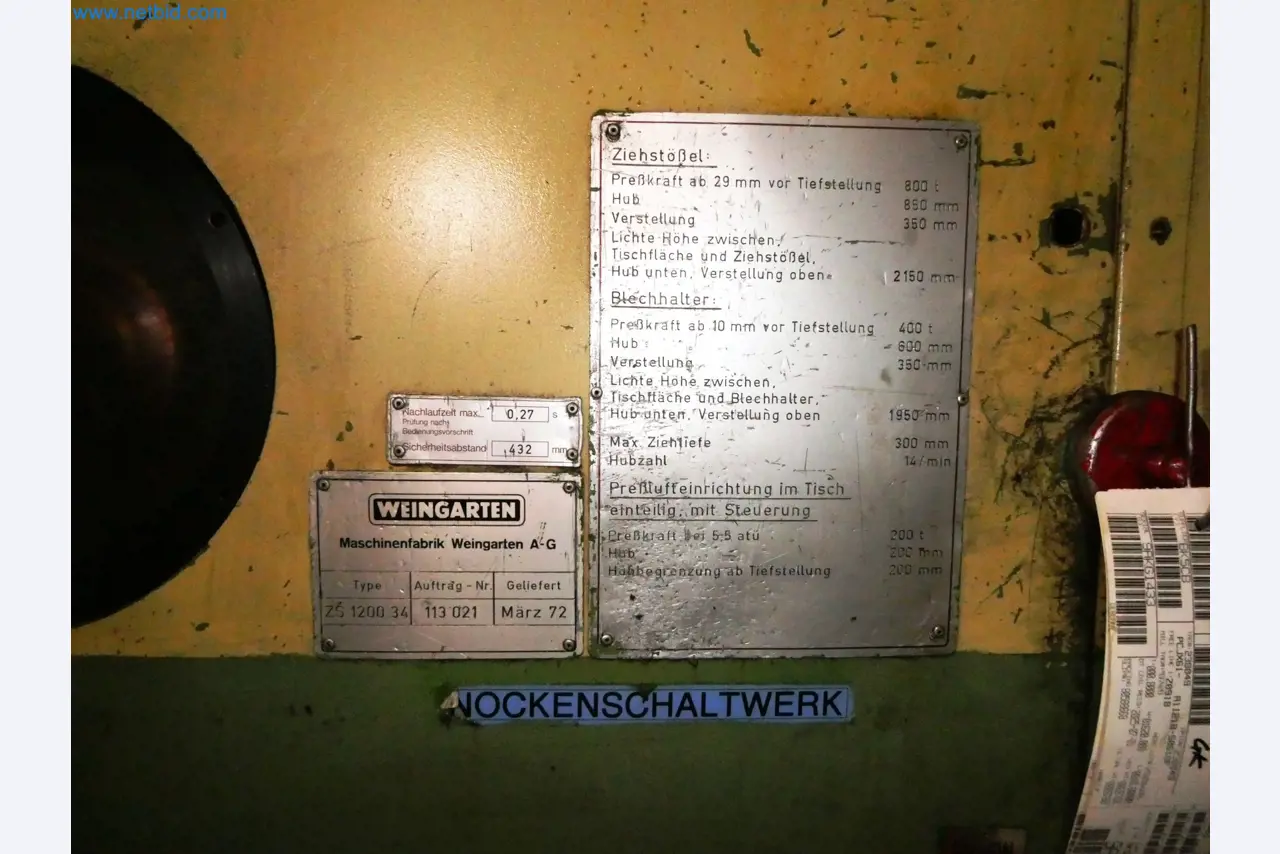

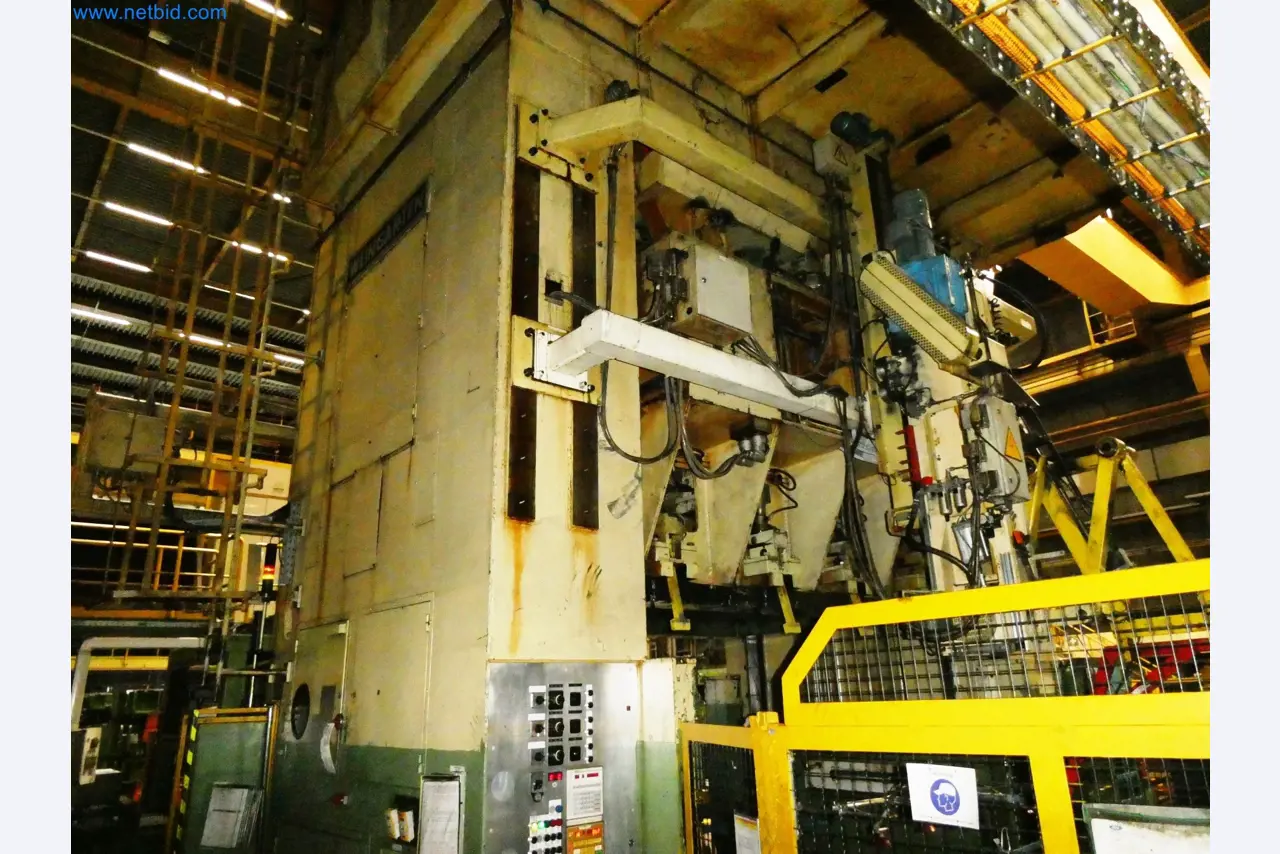

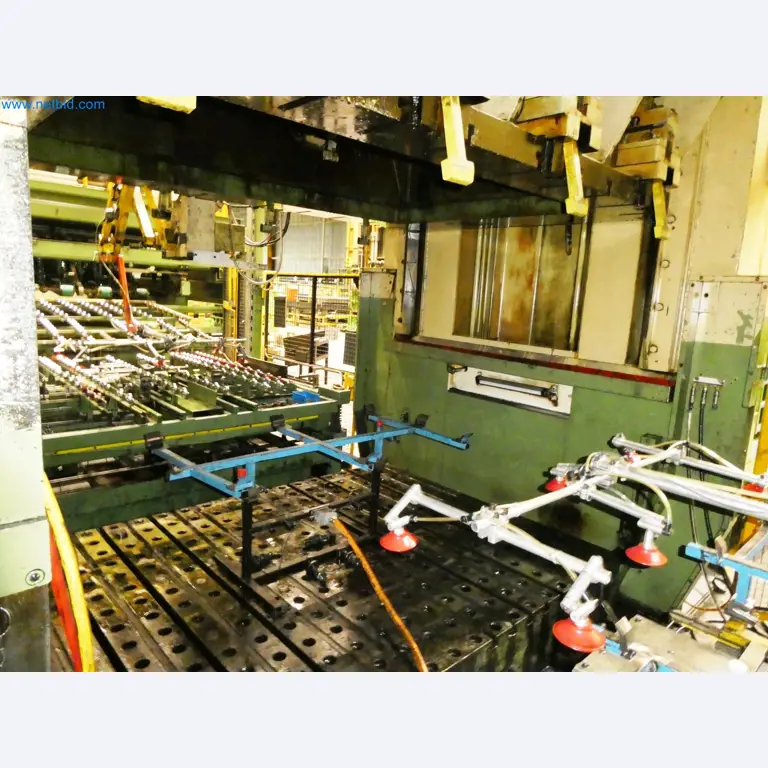

Double column press, Weingarten, type ZS 1200.34, built 1972, order no. 113 021, press force approx. 800 t, double action, stroke 850 mm, stroke adjustment 350 mm, height between table surface and ram 2.150 mm, sheet holder pressing force 400 t, stroke 600 mm, adjustment 350 mm, clearance height between table surface and sheet holder 1,950 mm, drawing depth max. 300 mm, stroke rate 14/min, control, Siemens, control panel Baluff, table size 3,200 x 2,200 mm, machine no. 0185100

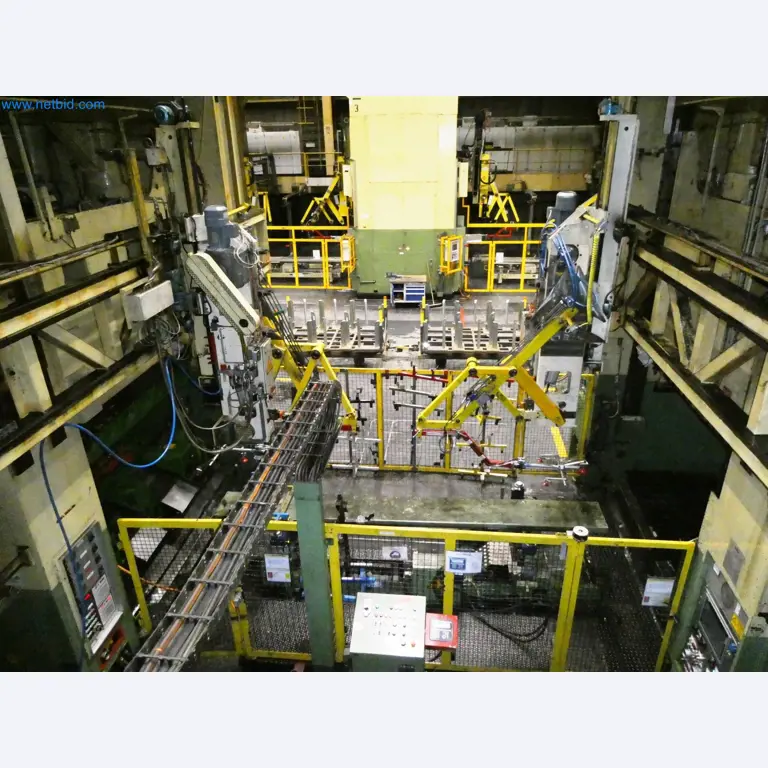

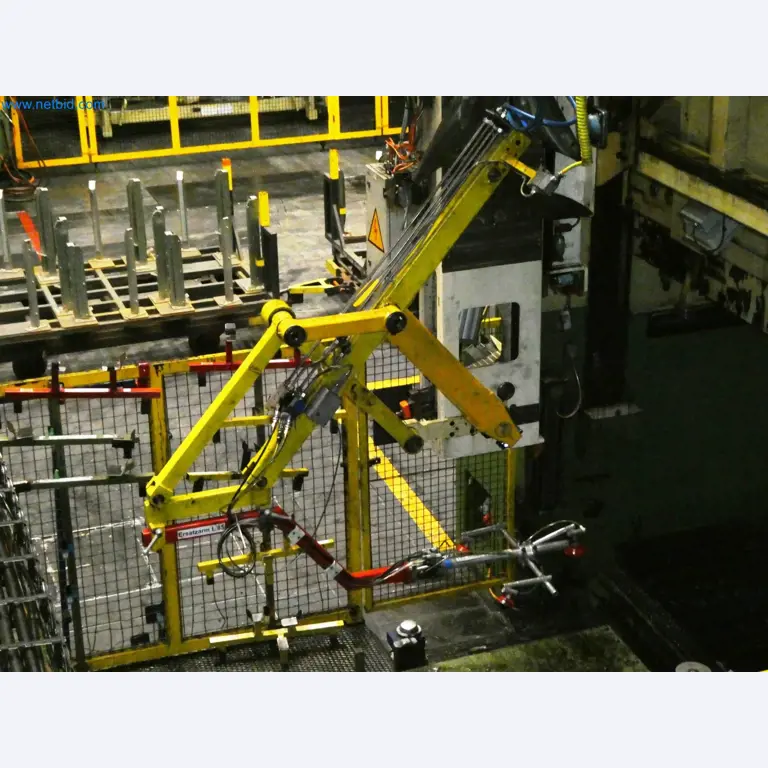

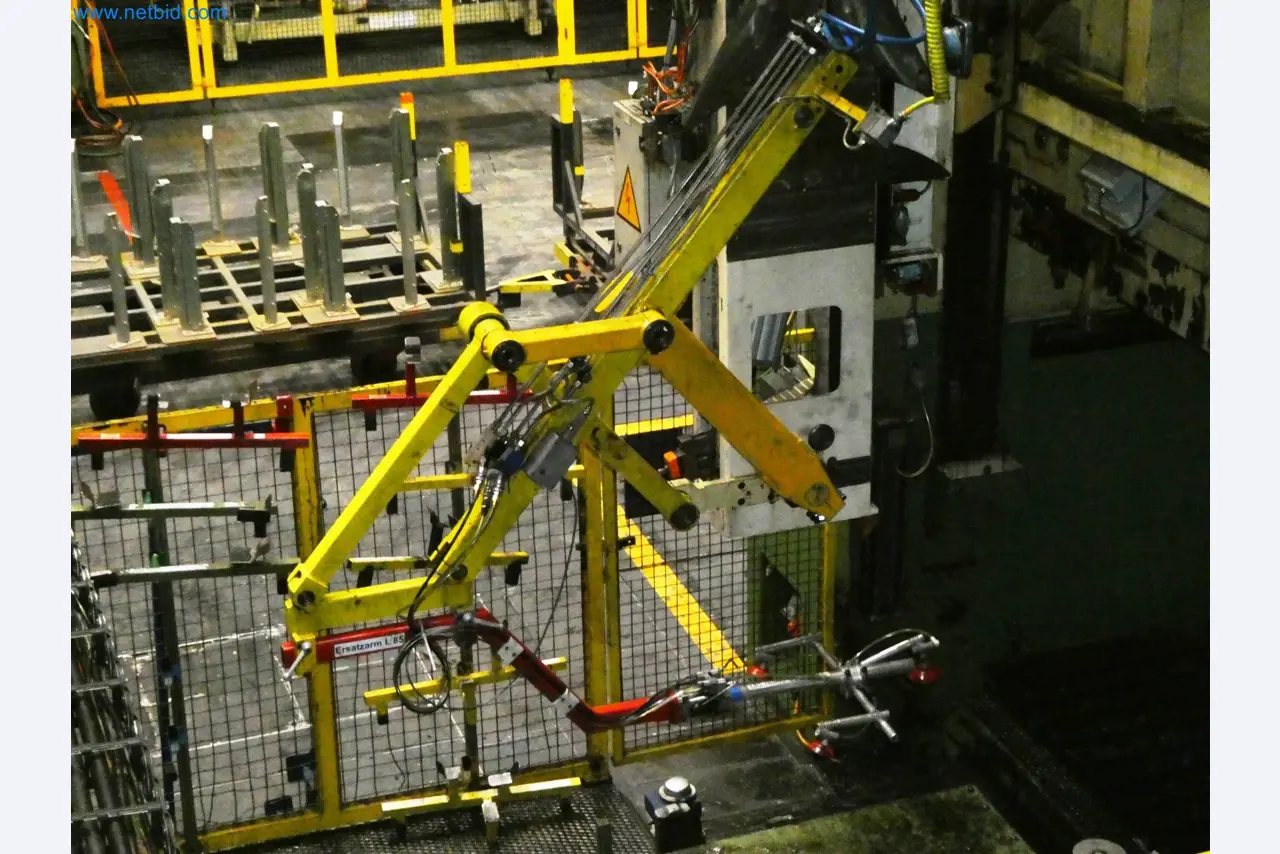

Gripper automation, consisting of: 2 blank grippers, press-mounted, system no. 0602400, 0602500, with turning table and turning device

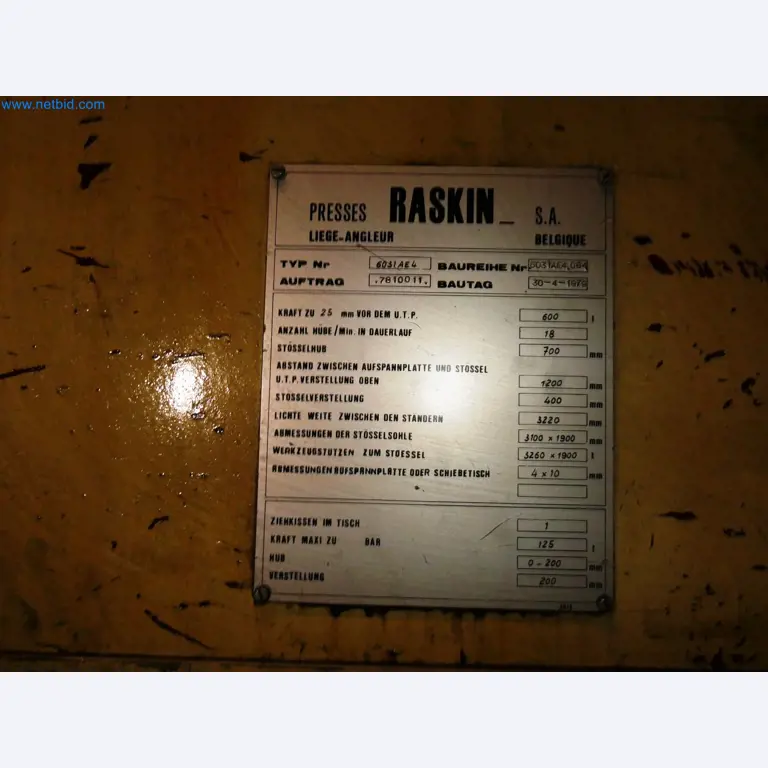

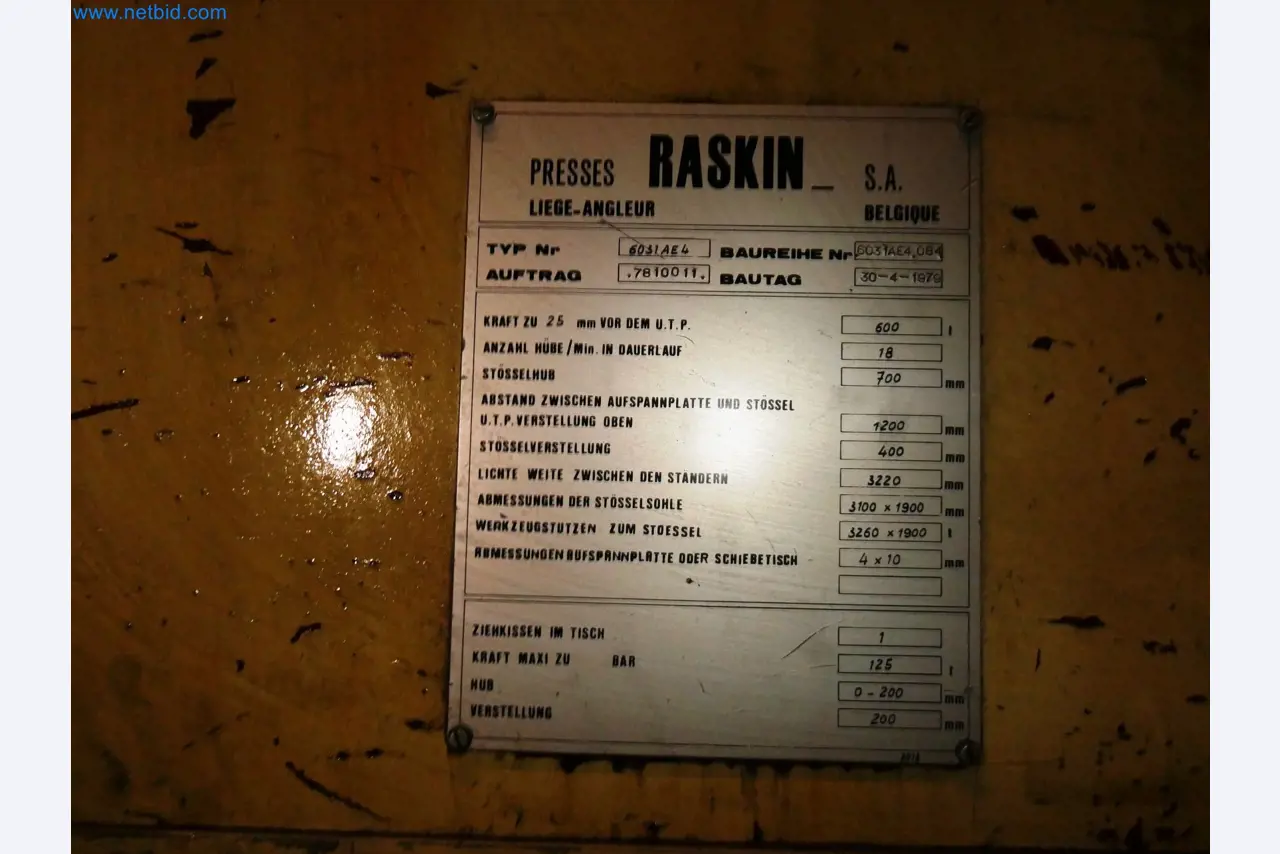

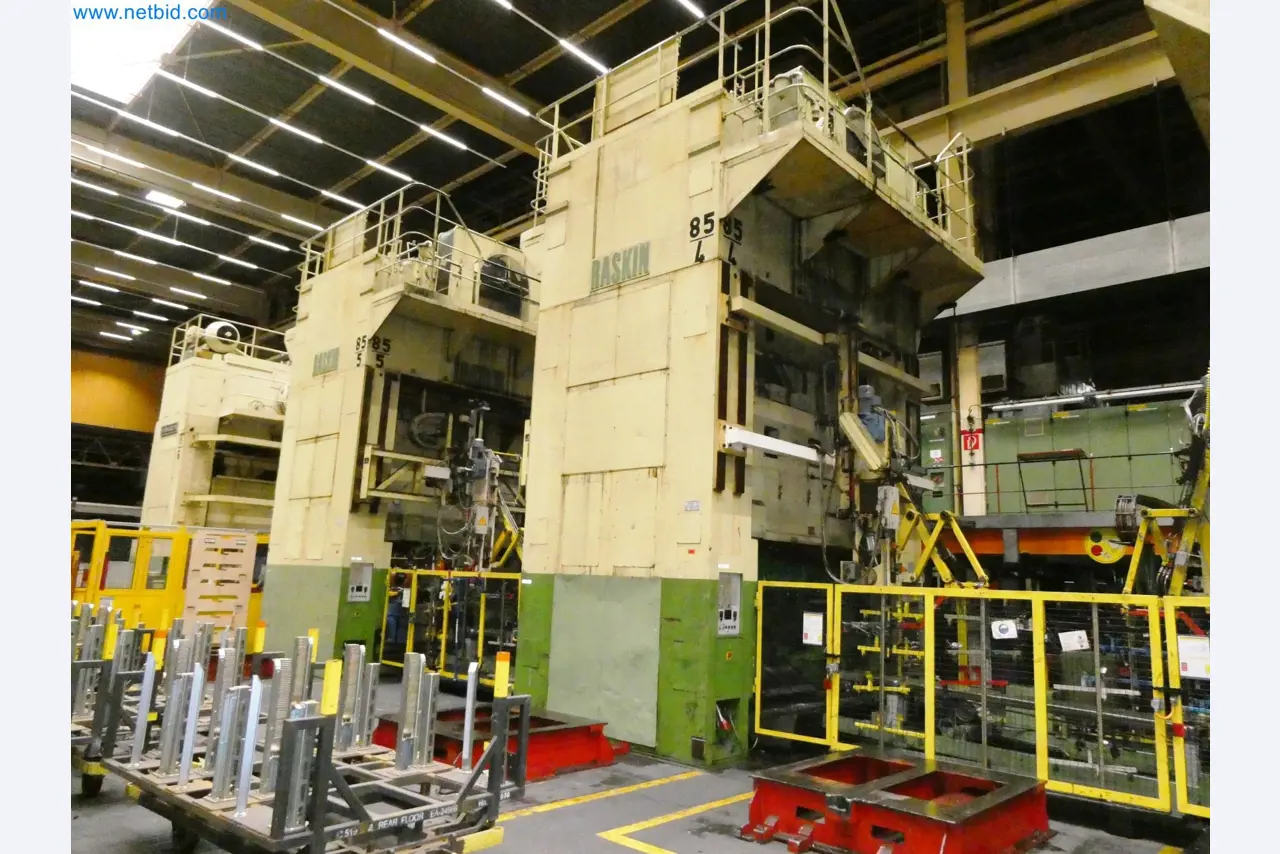

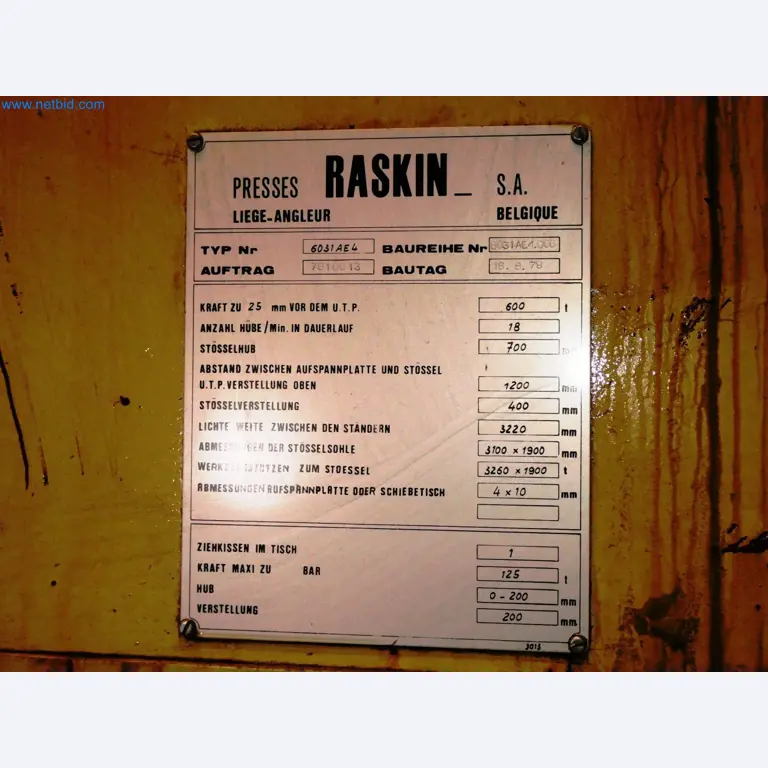

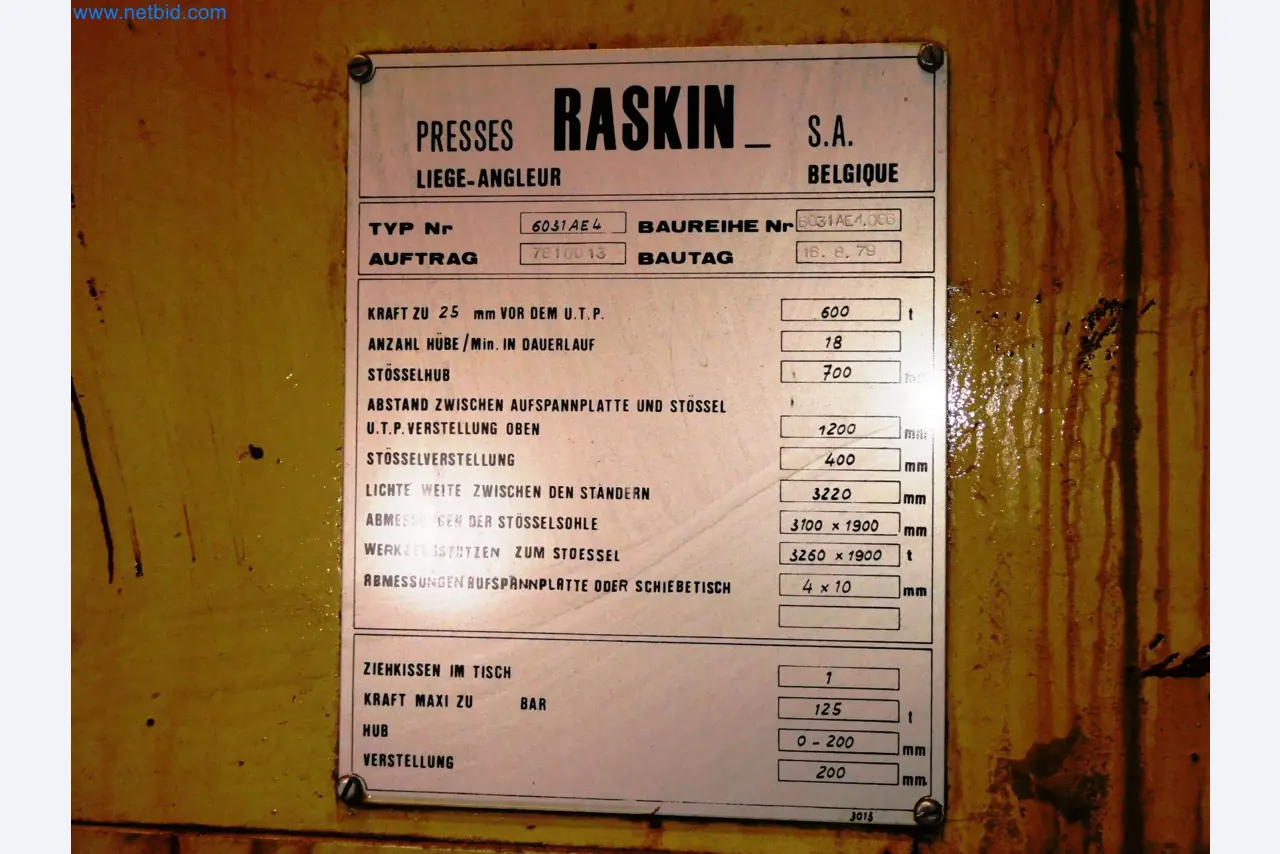

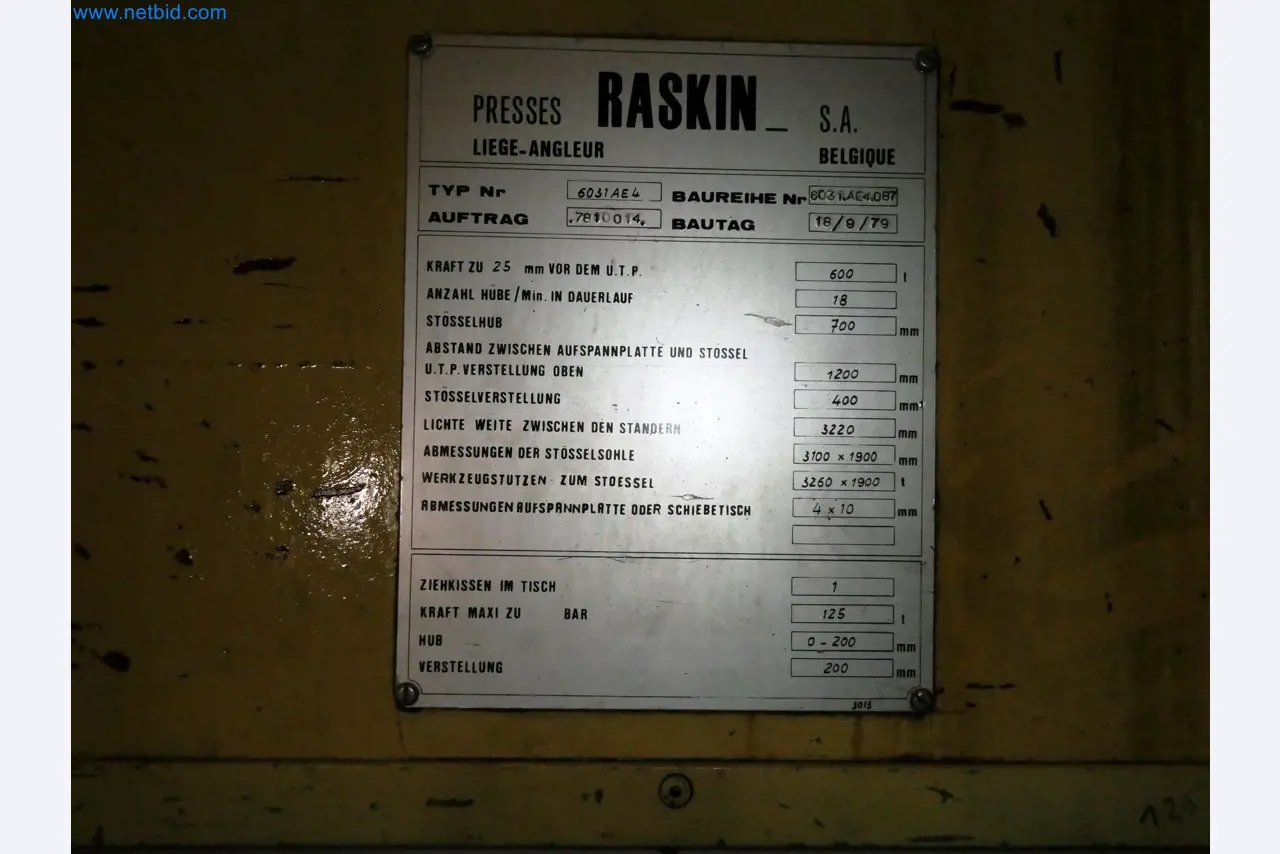

Double column press, Raskin, type 6031AE4, built 1979, SN 6031AE4.084, order no. 7810011, single action, press force approx. 600 t, stroke rate 18/min, ram stroke 700 mm, distance between clamping plate and ram 1.200 mm, ram adjustment 400 mm, clearance between uprights 3,220 mm, ram base 3,100 x 1,900 mm, die clamping area 3,260 x 1,900 mm, die cushion, pressure force 125 t, stroke 0-200 mm, Siemens control system

Press automation, consisting of: 2 blank grippers, press-mounted, turning and rotary table, system no. 0602600, 0602700

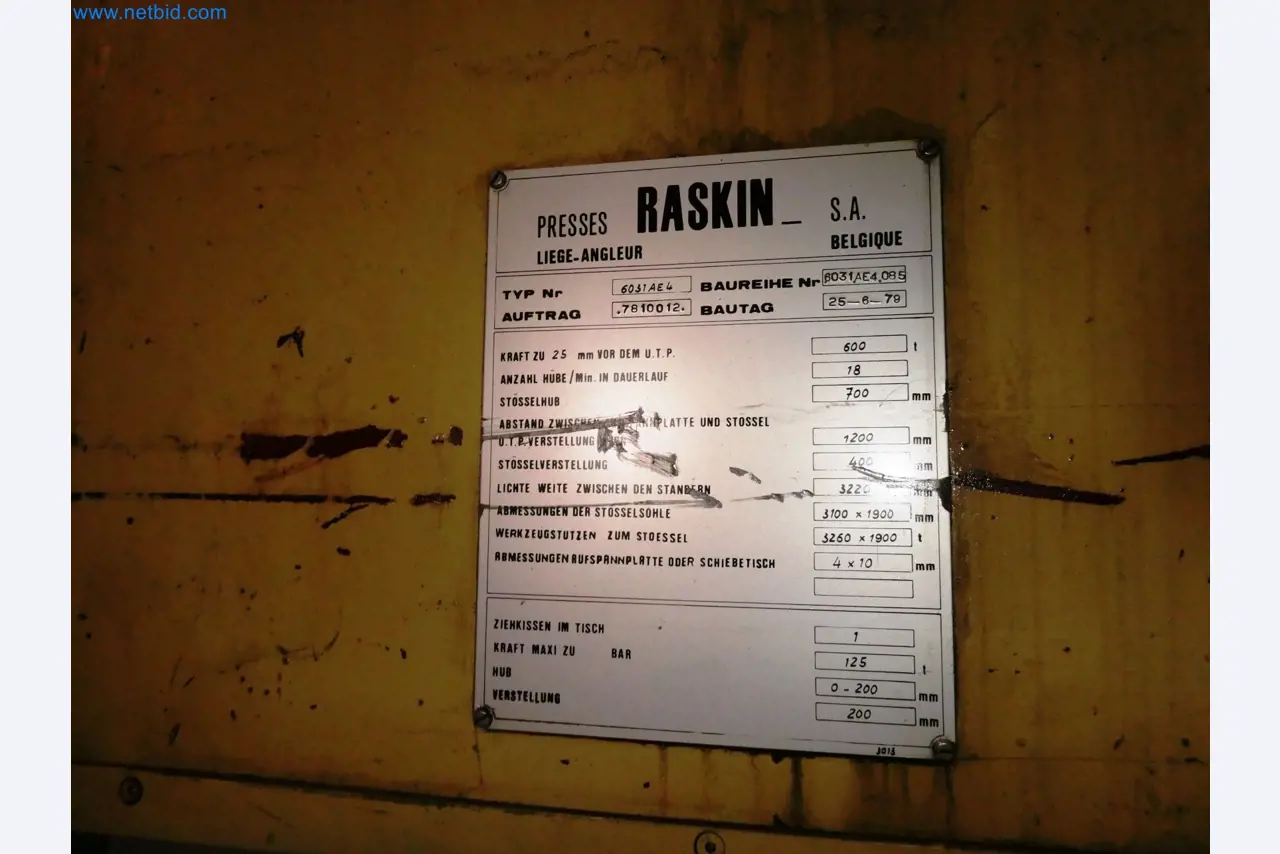

Double column press, Raskin, type 0631AE4, built 1979, SN 0631AE4085, order no. 7810012, single action, press force approx. 600 t, stroke rate 18/min, ram stroke 700 mm, distance between clamping plate and ram 1.200 mm, ram adjustment 400 mm, clearance between uprights 3,220 mm, ram base 3,100 x 1,900 mm, die clamping area 3,260 x 1,900 mm, die cushion, pressure force 125 t, stroke 0-200 mm, control system Siemens, machine no. 0185300

Board automation, consisting of: 2 grippers, system no. 0602800, 0602900, with tilting and turning table

Double column press, Raskin, type 6031AE4, built 1979, SN 06031AE4.086, order no. 7810013, single action, press force approx. 600 t, stroke rate 18/min, ram stroke 700 mm, distance between clamping plate and ram 1.200 mm, ram adjustment 400 mm, clearance between uprights 3,220 mm, ram base 3,100 x 1,900 mm, die clamping area 3,260 x 1,900 mm, die cushion, pressure force 125 t, stroke 0-200 mm, Siemens control system

Blank automation, consisting of: 2 blank grippers, press-mounted, turning and rotary table, system no. 0603000, 0603100

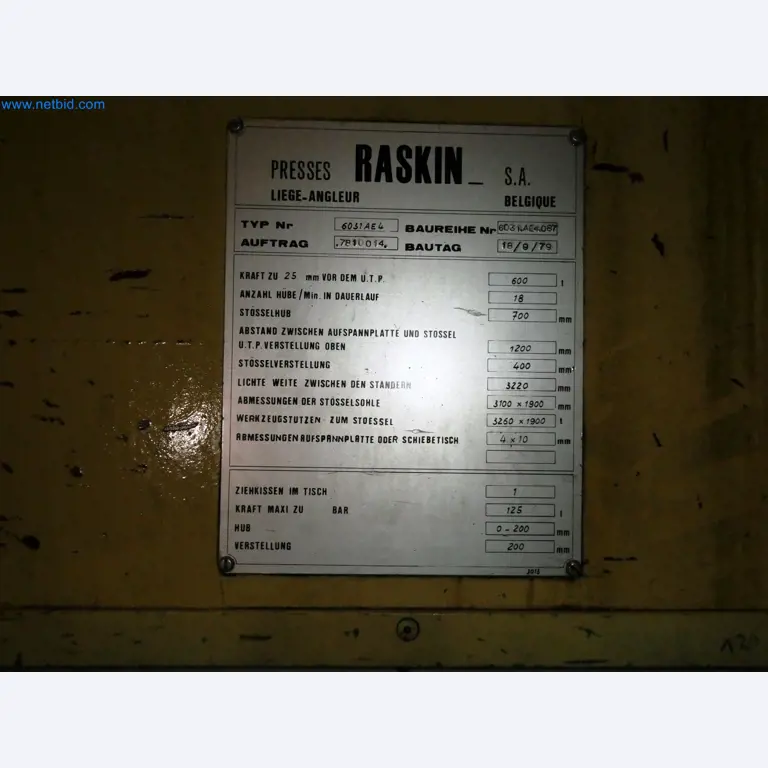

Double column press, Raskin, type 06031AE4, built 1979, SN 6031AE4.087, order no. 7810014, press force approx. 600 t, stroke rate 18/min, ram stroke 700 mm, distance between clamping plate and ram 1.200 mm, ram adjustment 400 mm, clearance between uprights 3,220 mm, ram base 3,100 x 1,900 mm, die clamping area 3,260 x 1,900 mm, die cushion, compressive force 125 t, stroke 0-200 mm, control system made by Siemens

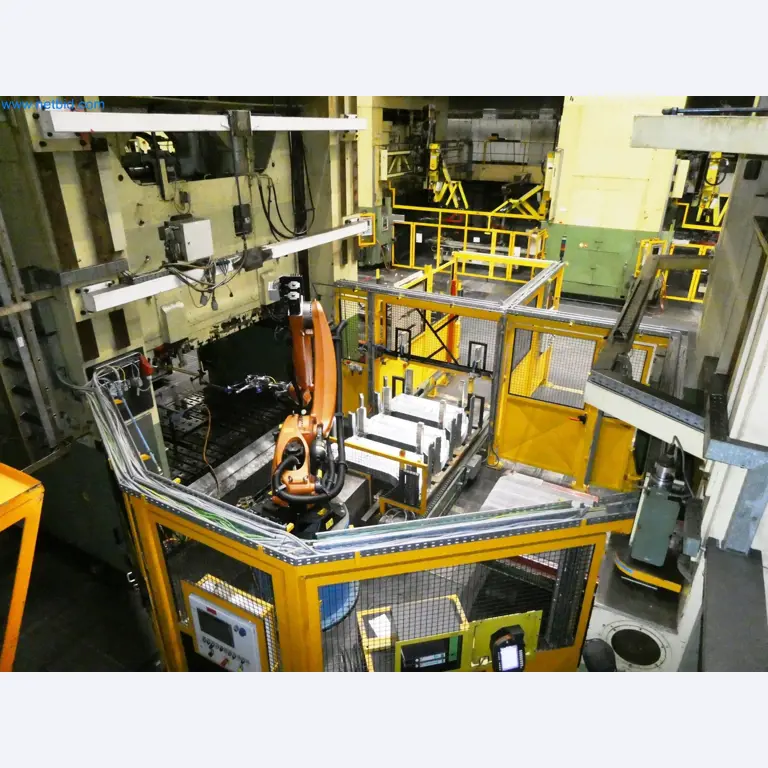

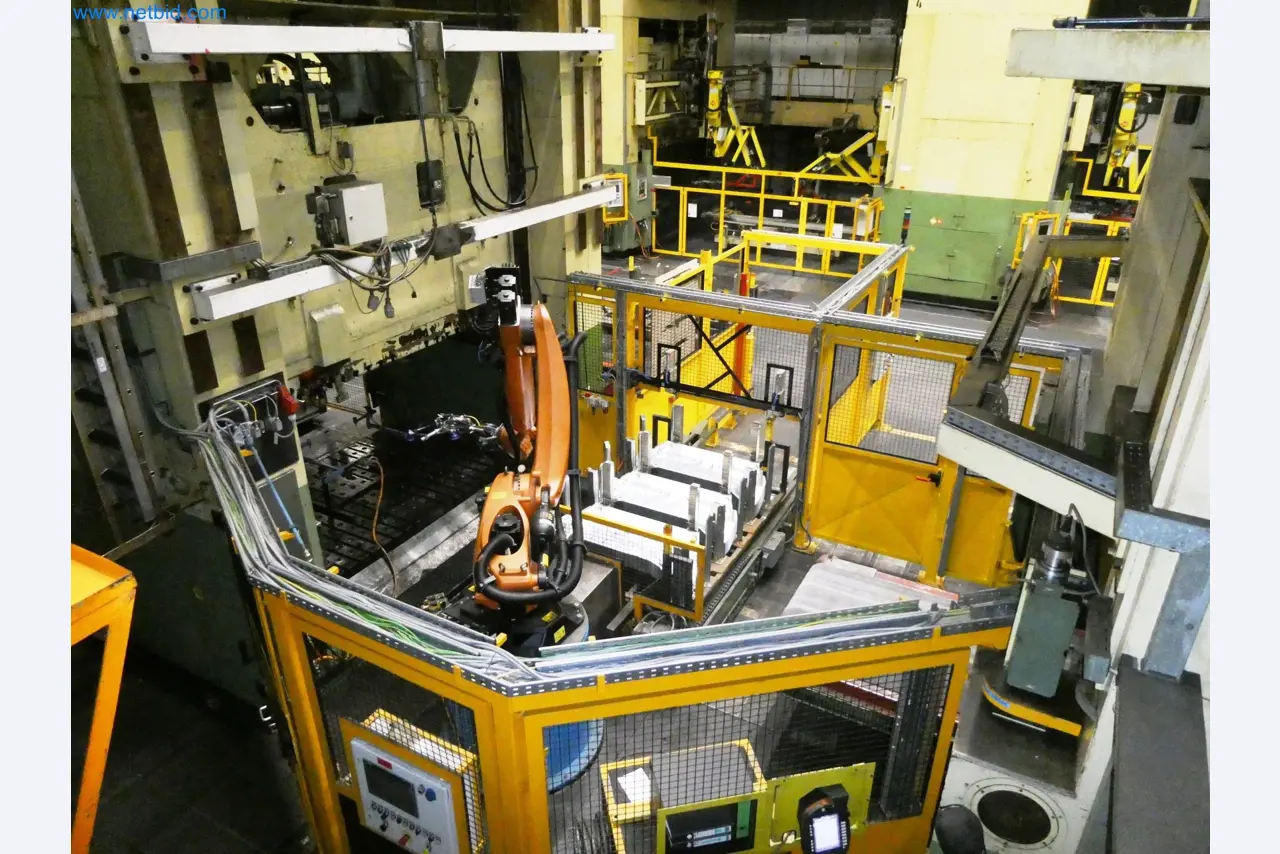

6-axis robot, Kuka, type KR 100 R3500 Press, year 2014, SN 674326, weight 1,240 kg, load capacity 100 kg, throat depth 3,500 mm, control, type KPC4, SN 604486, year 2020, with control cabinet and manual control unit

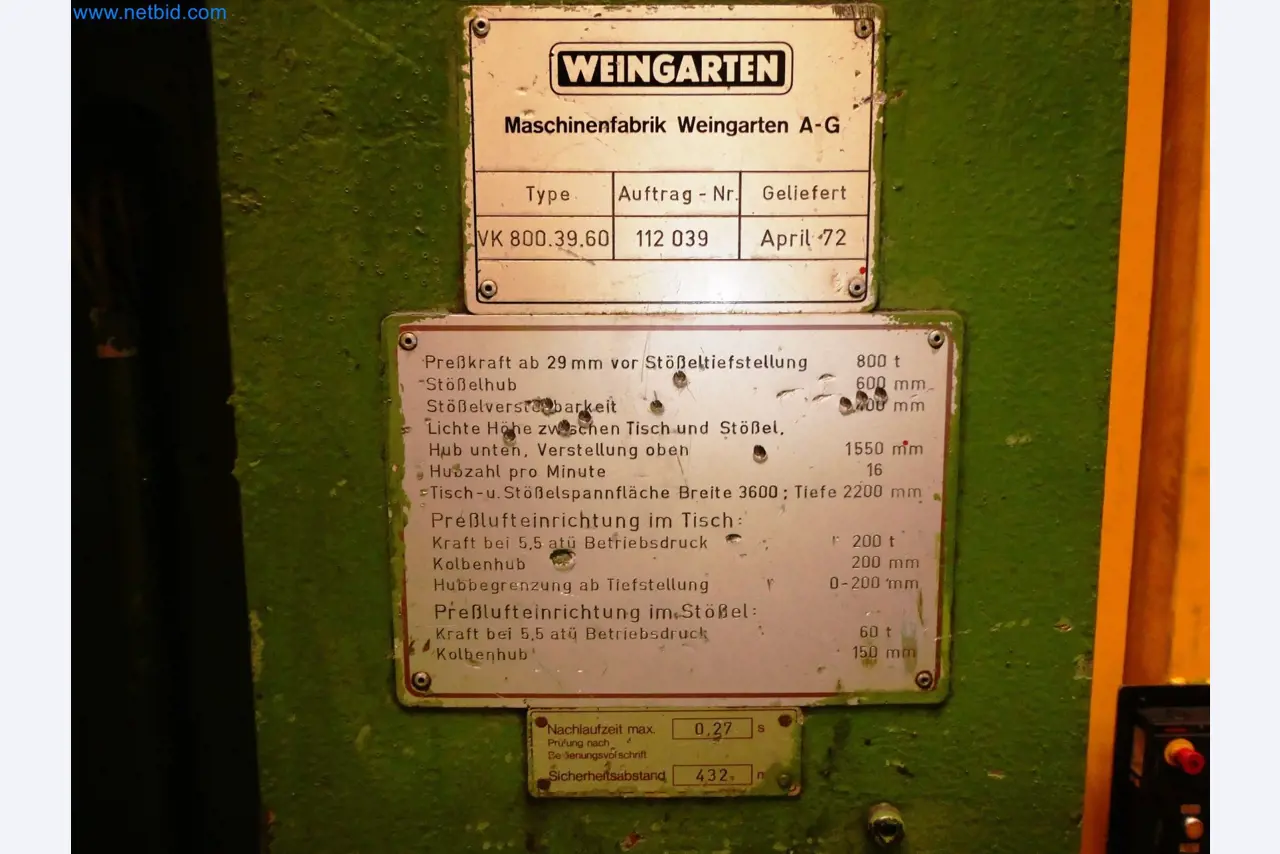

Double column press, Weingarten, type VK800.39.60, built 1972, SN 112039, single action, press force approx. 800 t, ram stroke 600 mm, ram adjustment 400 mm, clearance height between table and ram 1,550 mm, stroke rate 16/min, clamping area 3,600 x 2,200 mm, press out of operation

Board automation, manufactured by Olofström, out of operation

2 belt conveyors, system no. 1502400, belt size approx. 8,000 x 1,200 mm, mobile, on rollers

Safety fence system between the presses and to safeguard the robot cell, test light system, manufactured by Uwe Braun, switch cabinets on gallery

System available from February 2025

Disassembly can be offered as an option

Location

- 66740 Saarlouis, Henry-Ford-Str. 2/ Halle B/ Stamping/ Linie 85

Dates

Inspection

Only by prior written registration and appointment at weyand@netbid.com

Please note the access requirements, which can be found in the auction conditions.

Please note the access requirements, which can be found in the auction conditions.

Pickup

By arrangement.

Auction Terms

Due to the access requirements, we need the following information from you for a viewing appointment

Complete company name, name and contact details

Which production areas are of interest

Preferred date and time

Number of participants and names

Special conditions:

Special conditions:

- Access requirements

- HSE specifications

- Different auction conditions

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com