Part of the Auction various vehicles

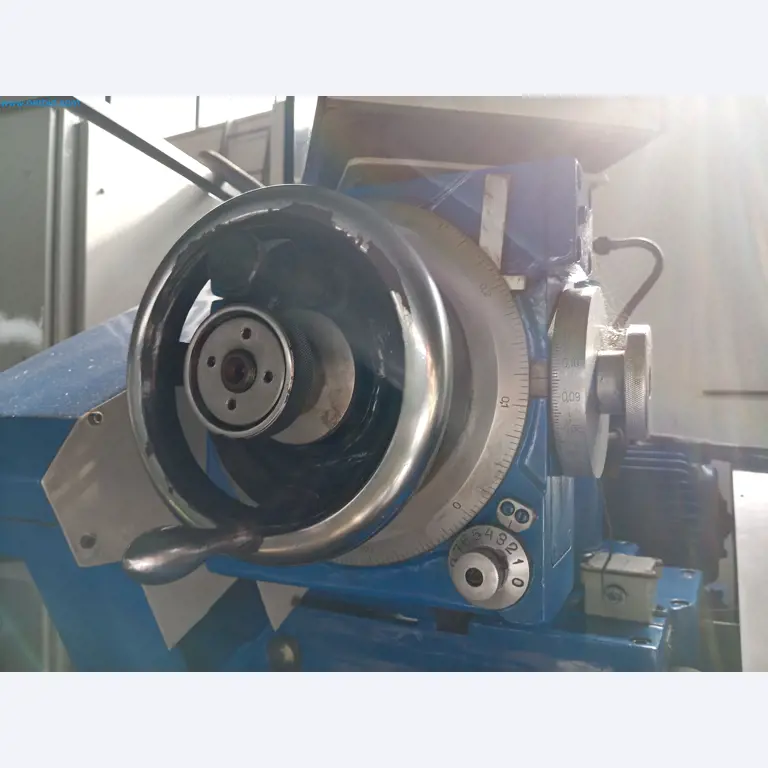

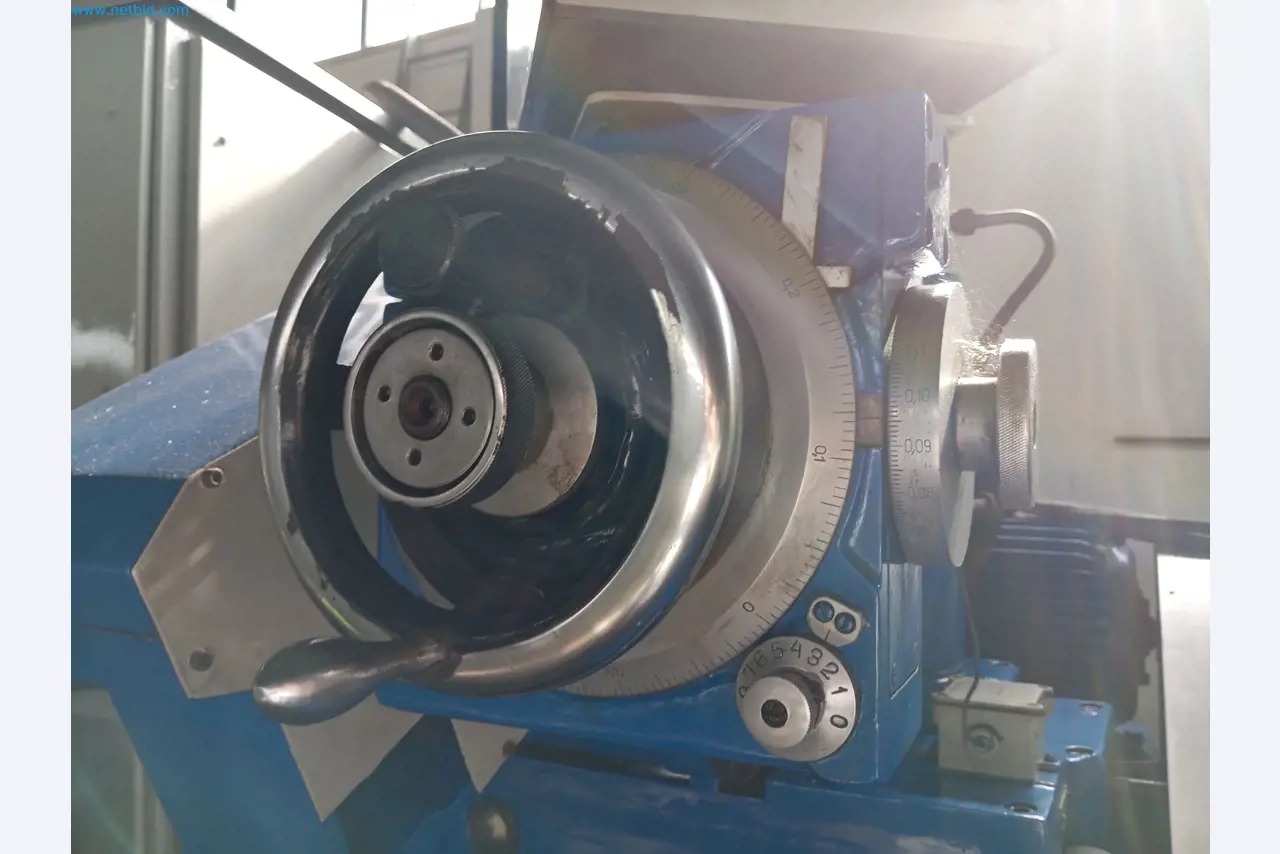

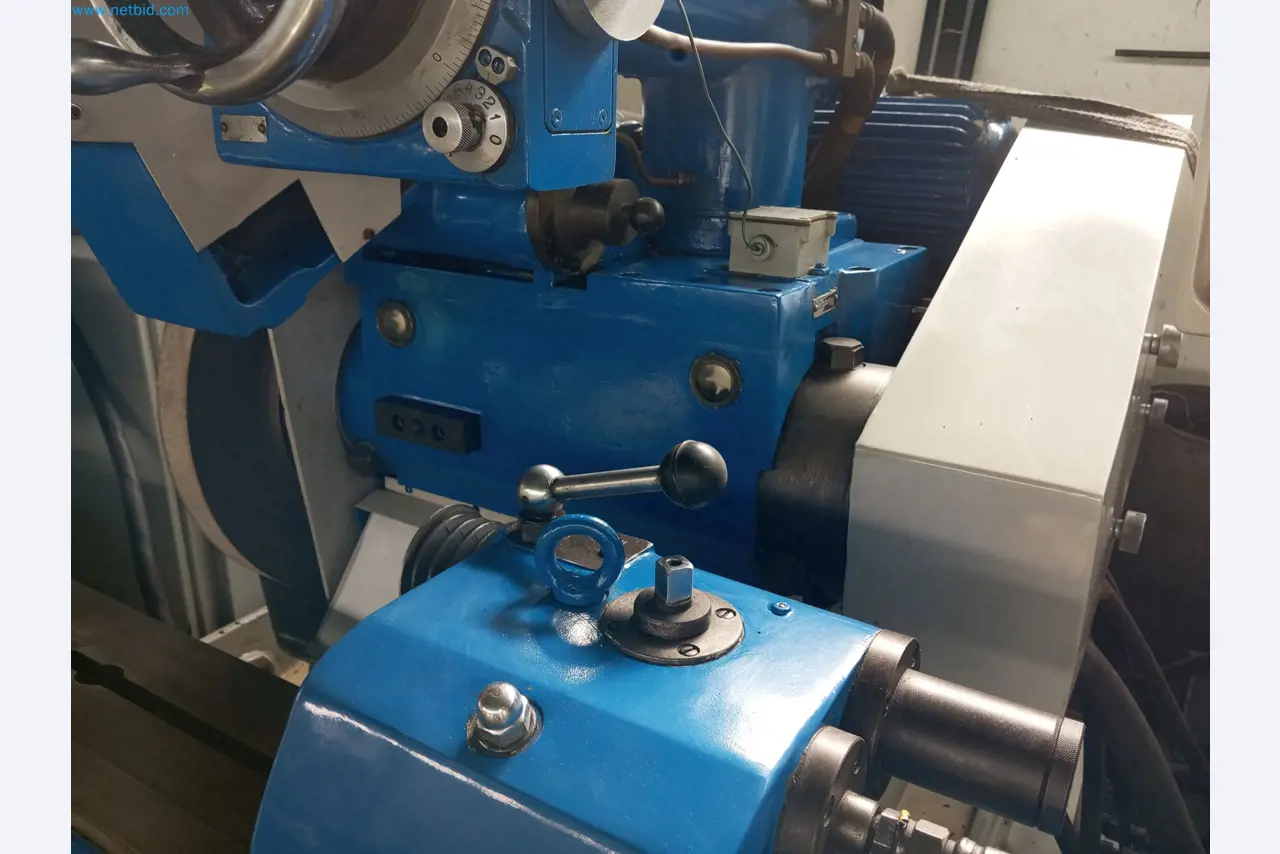

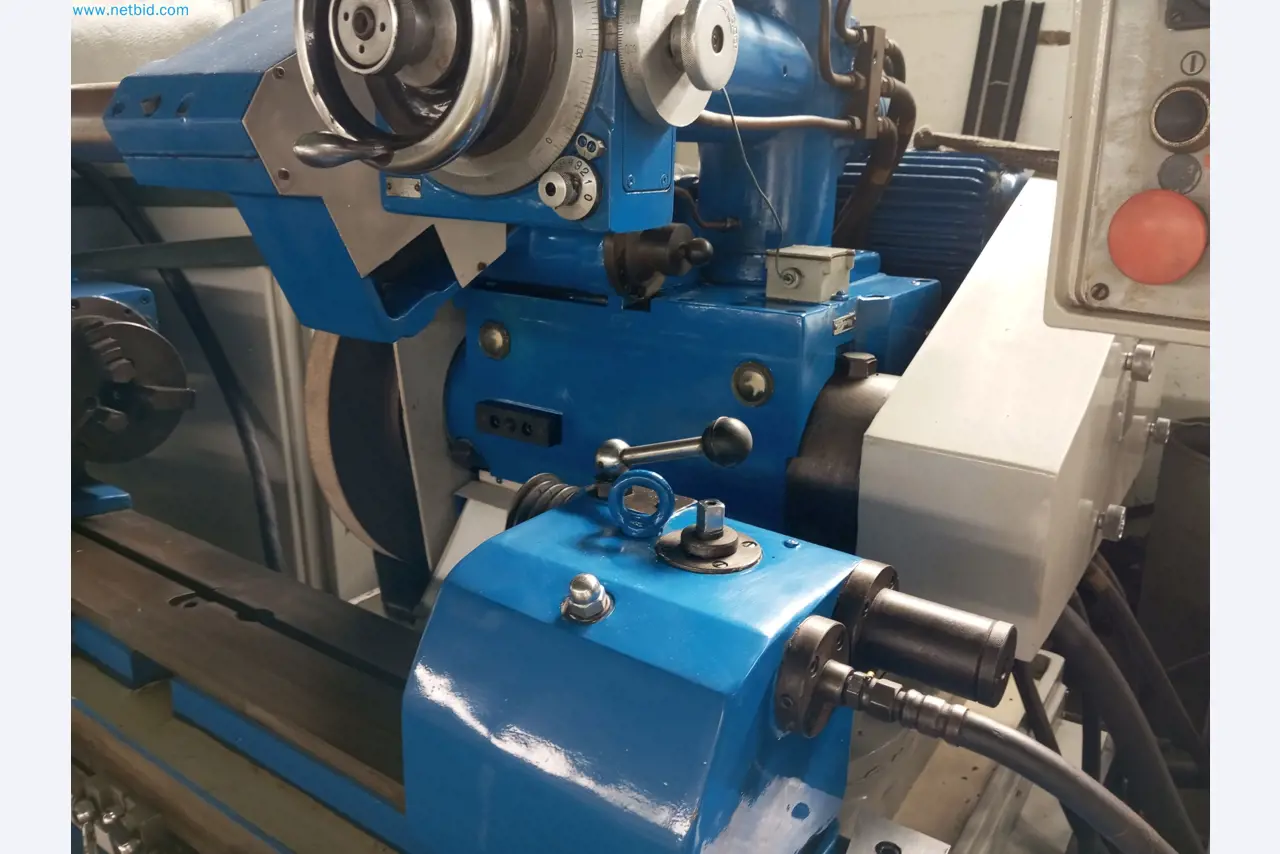

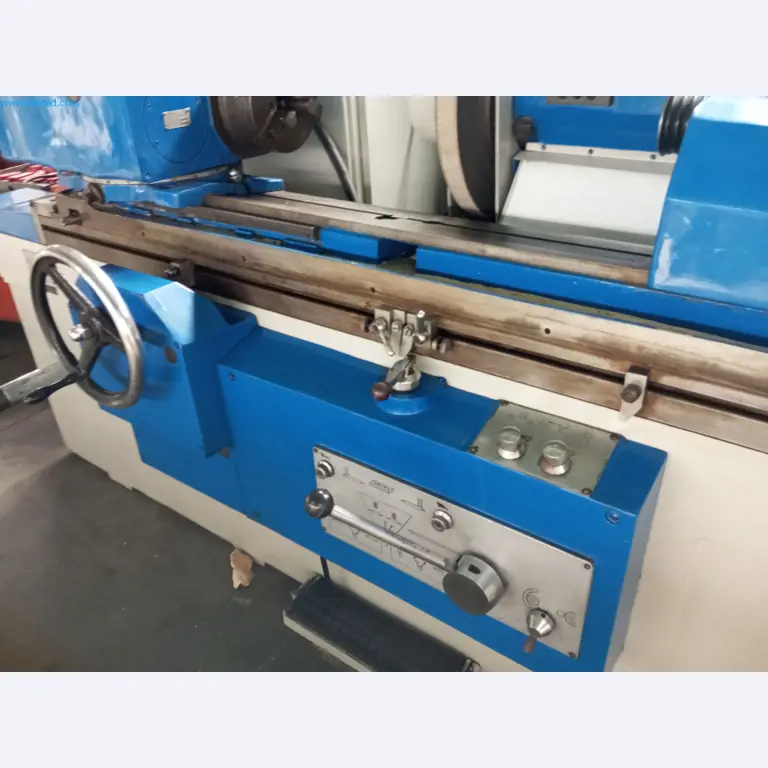

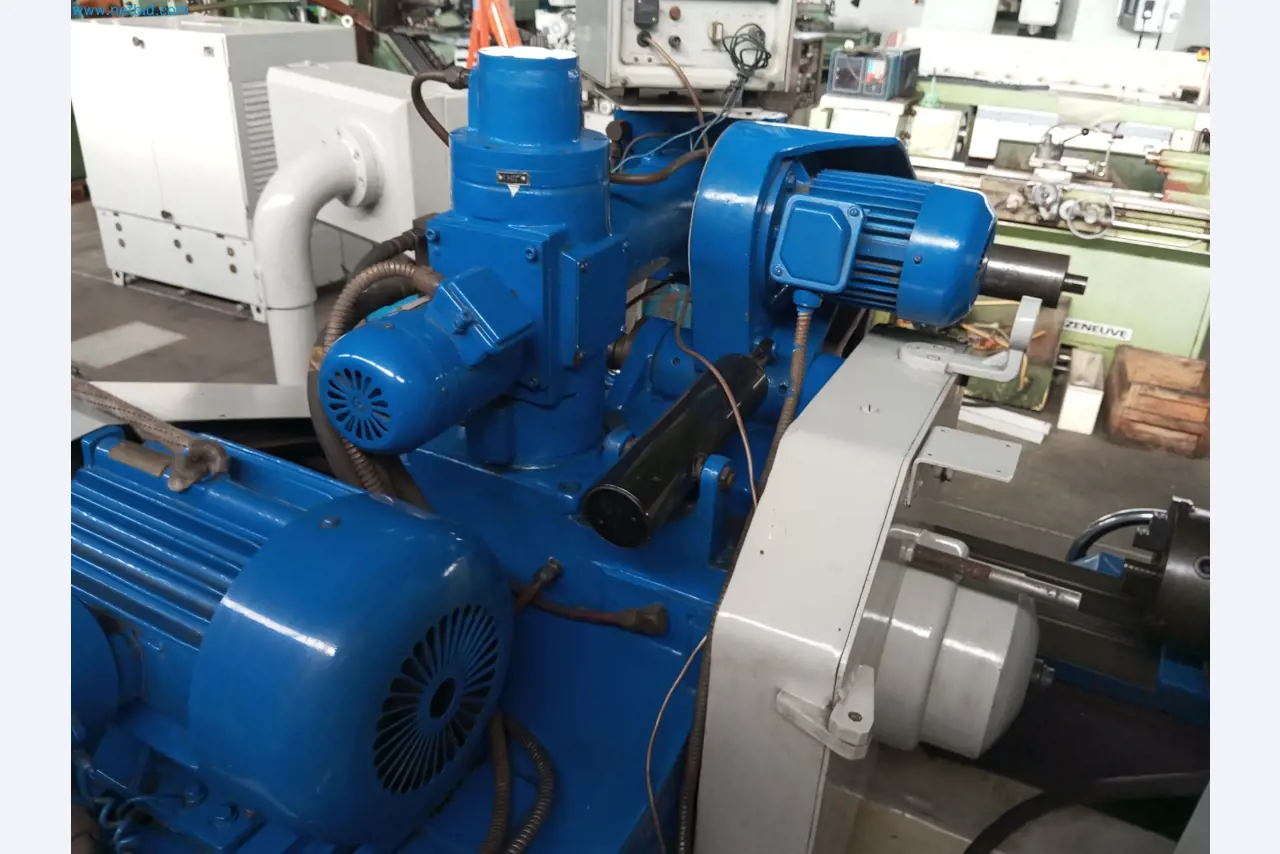

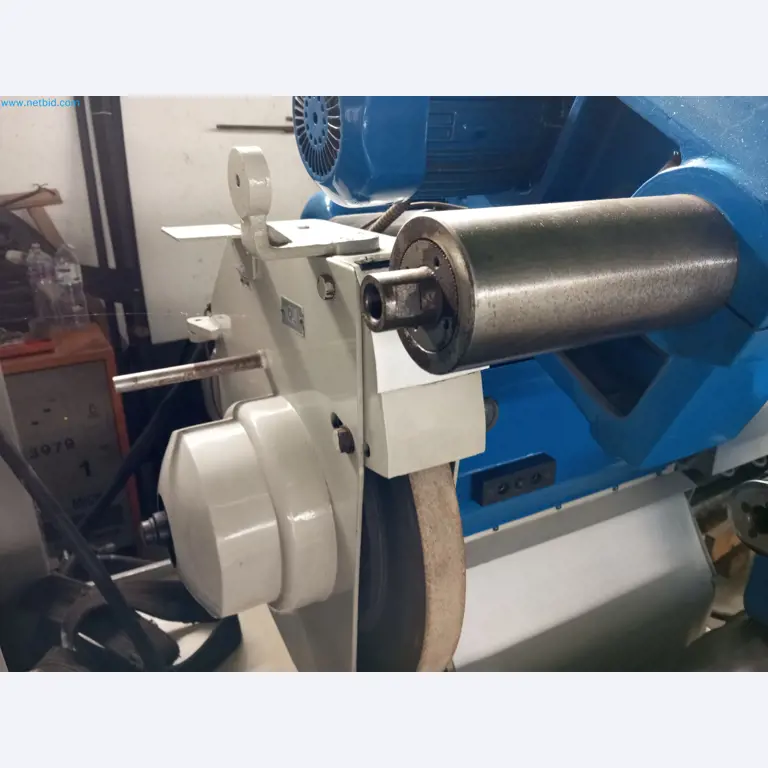

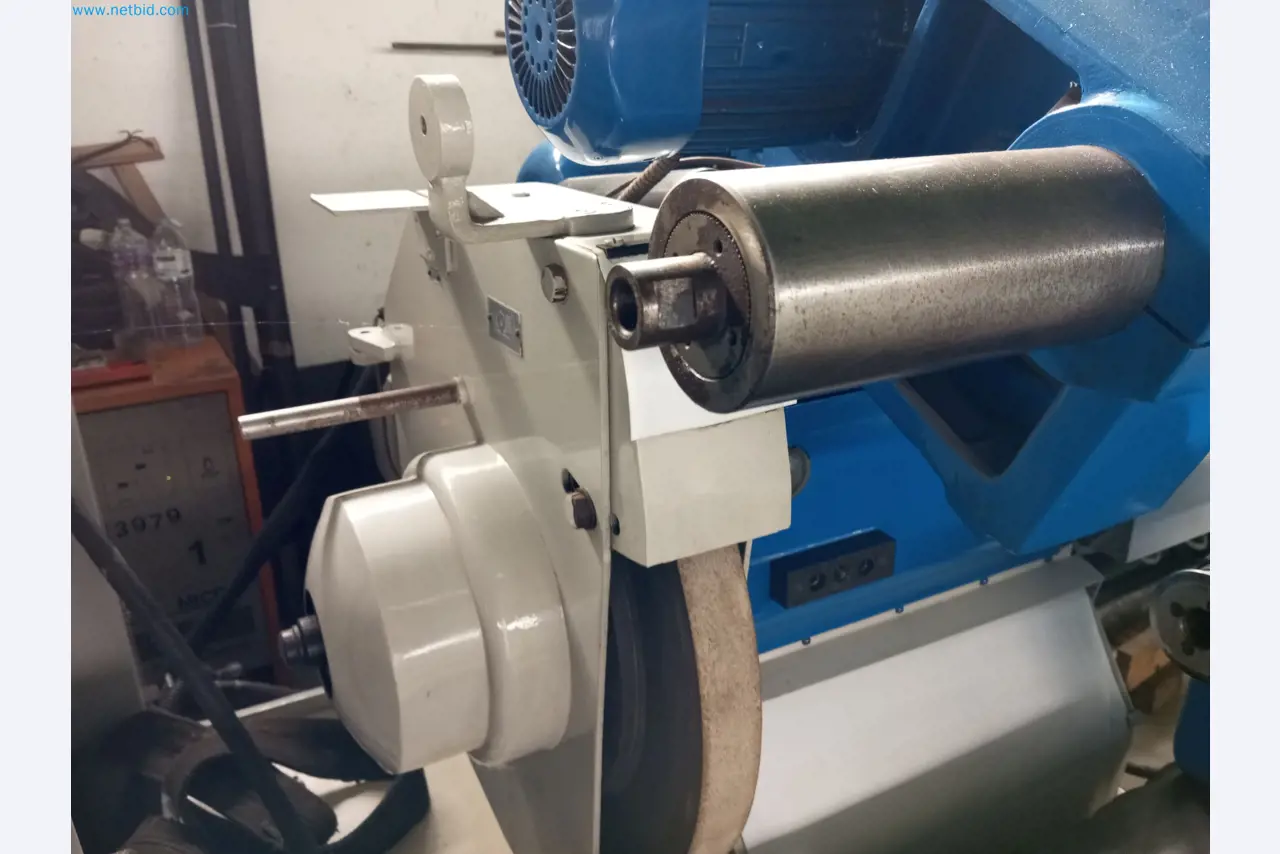

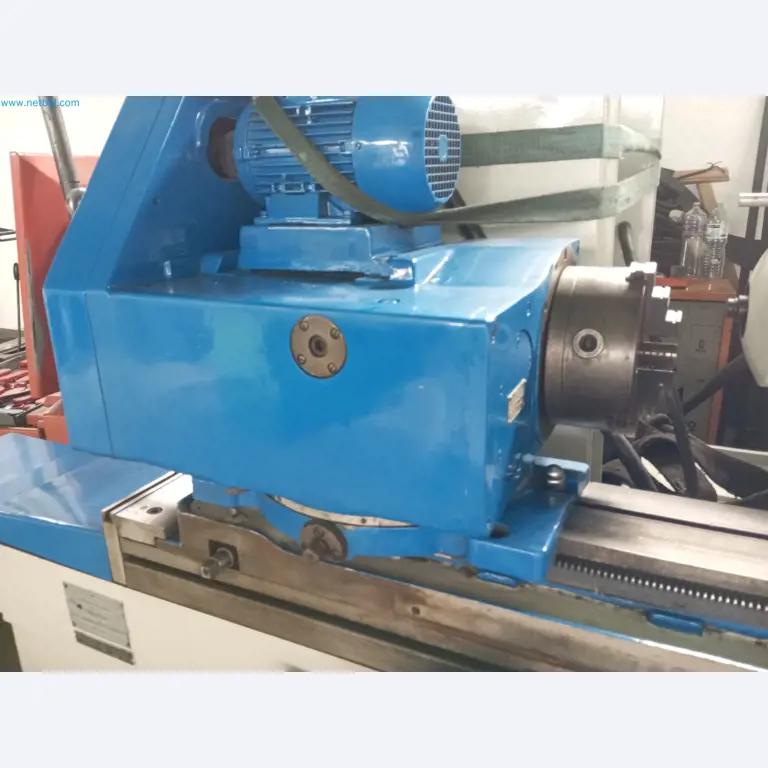

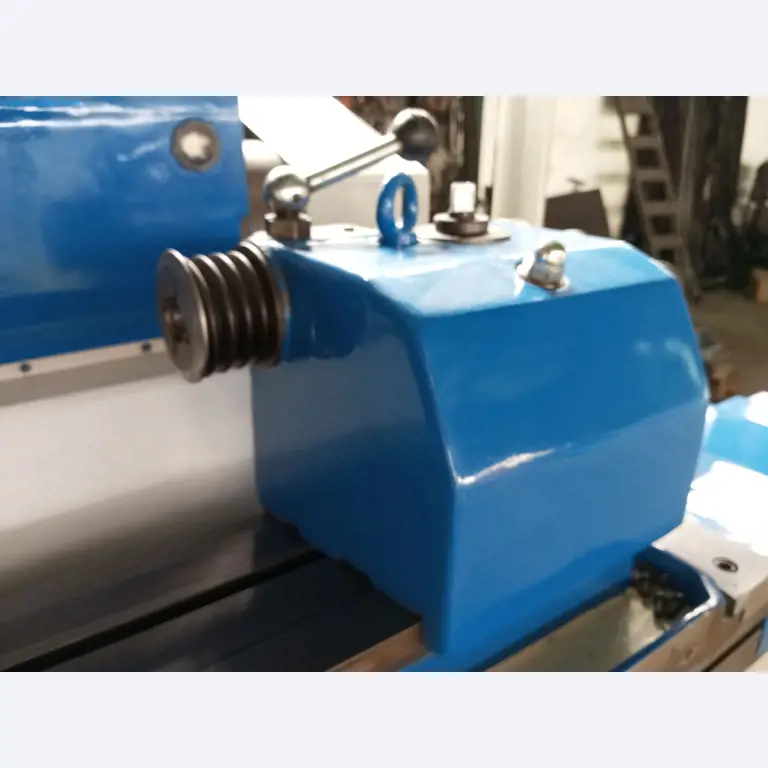

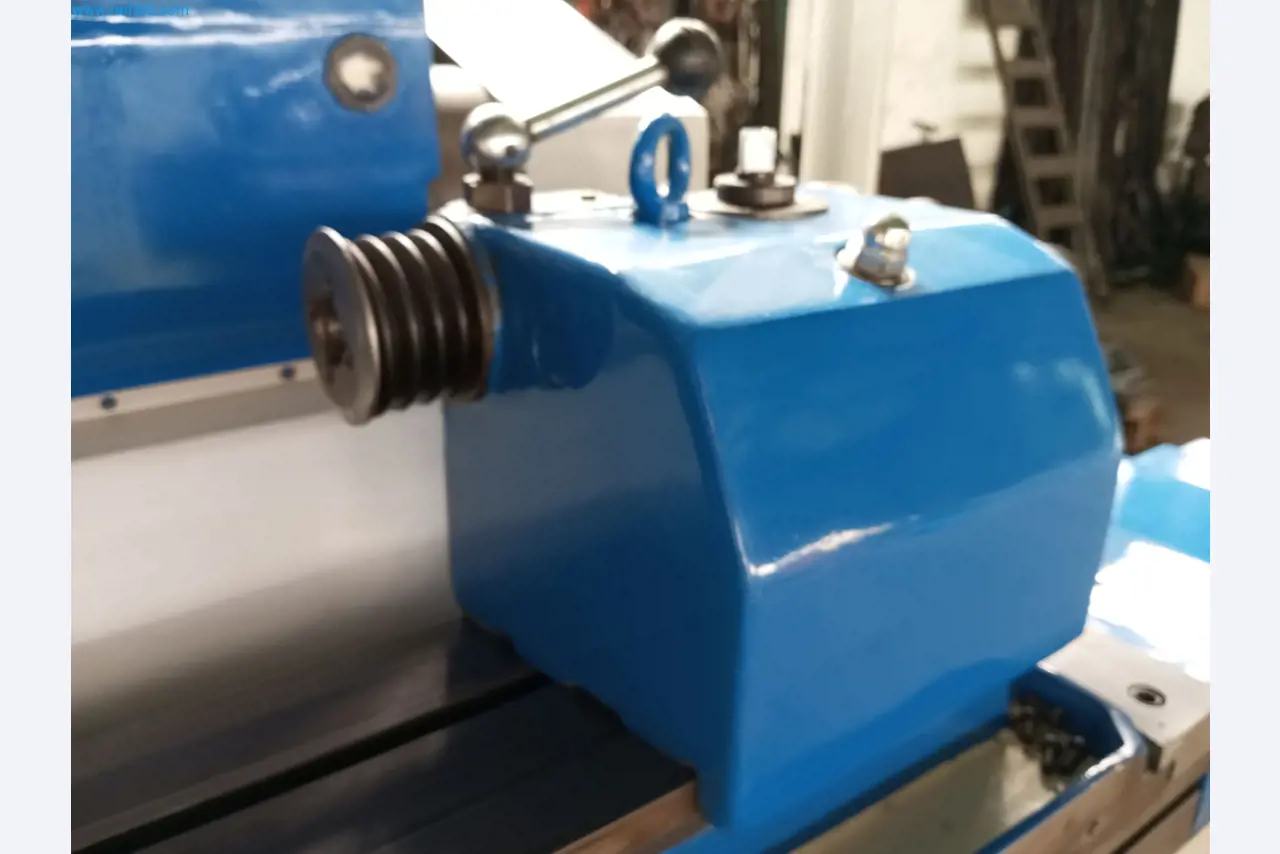

Cylindrical Grinding Machine STANKIMPORT 3Y131TRADING#19114-OM06 (A19113-85)

Details

Product Type

STANKIMPORT

Type

3Y131

Description

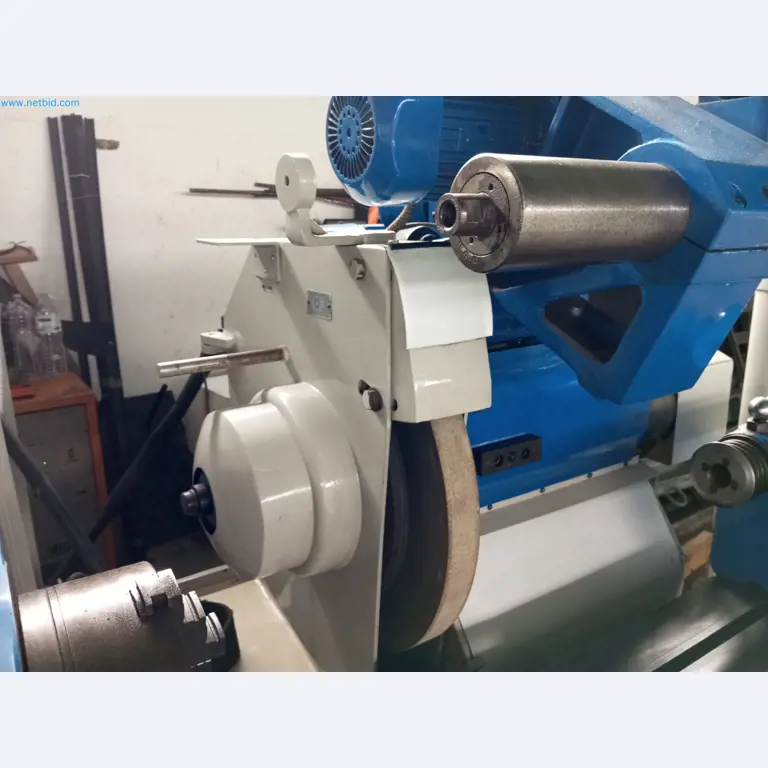

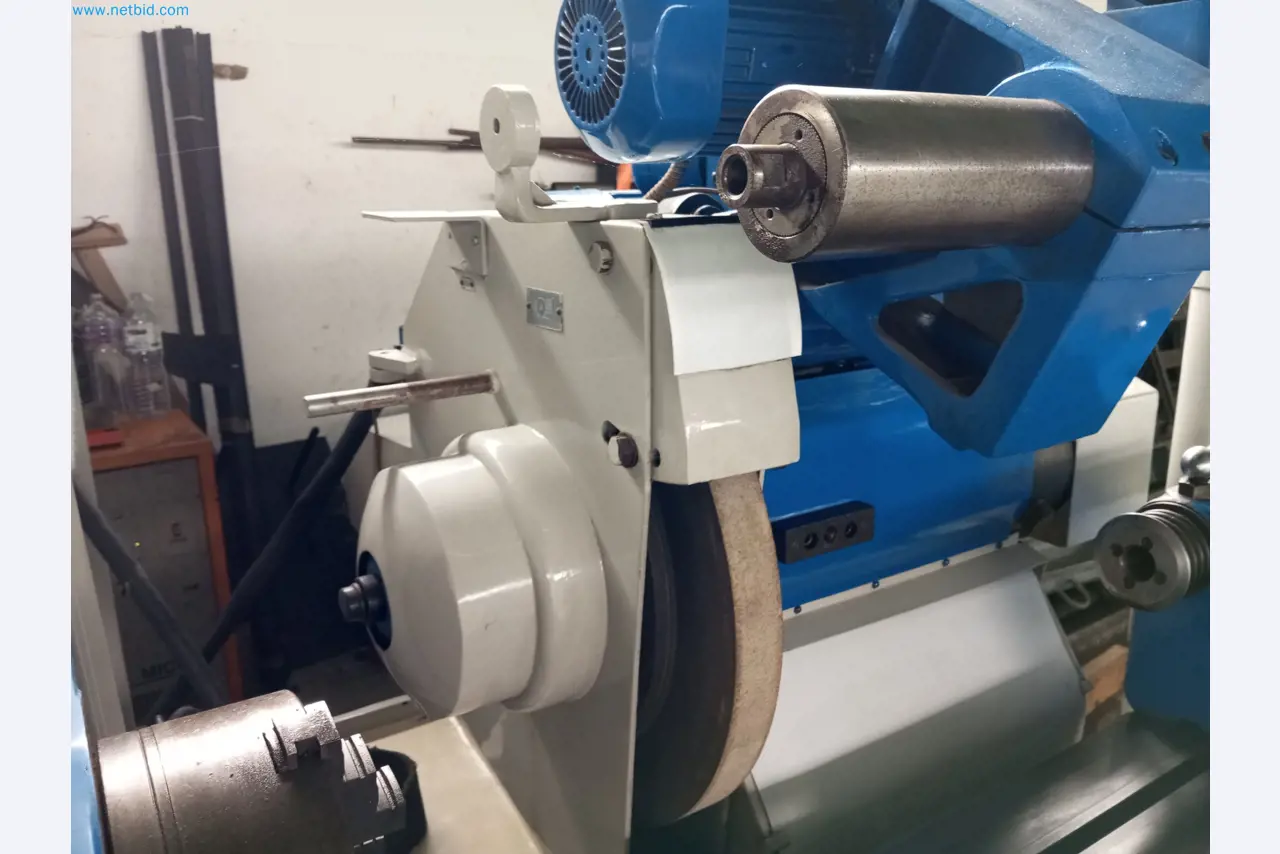

Stankoimport Cylindrical Grinding

Grinding Accuracy:

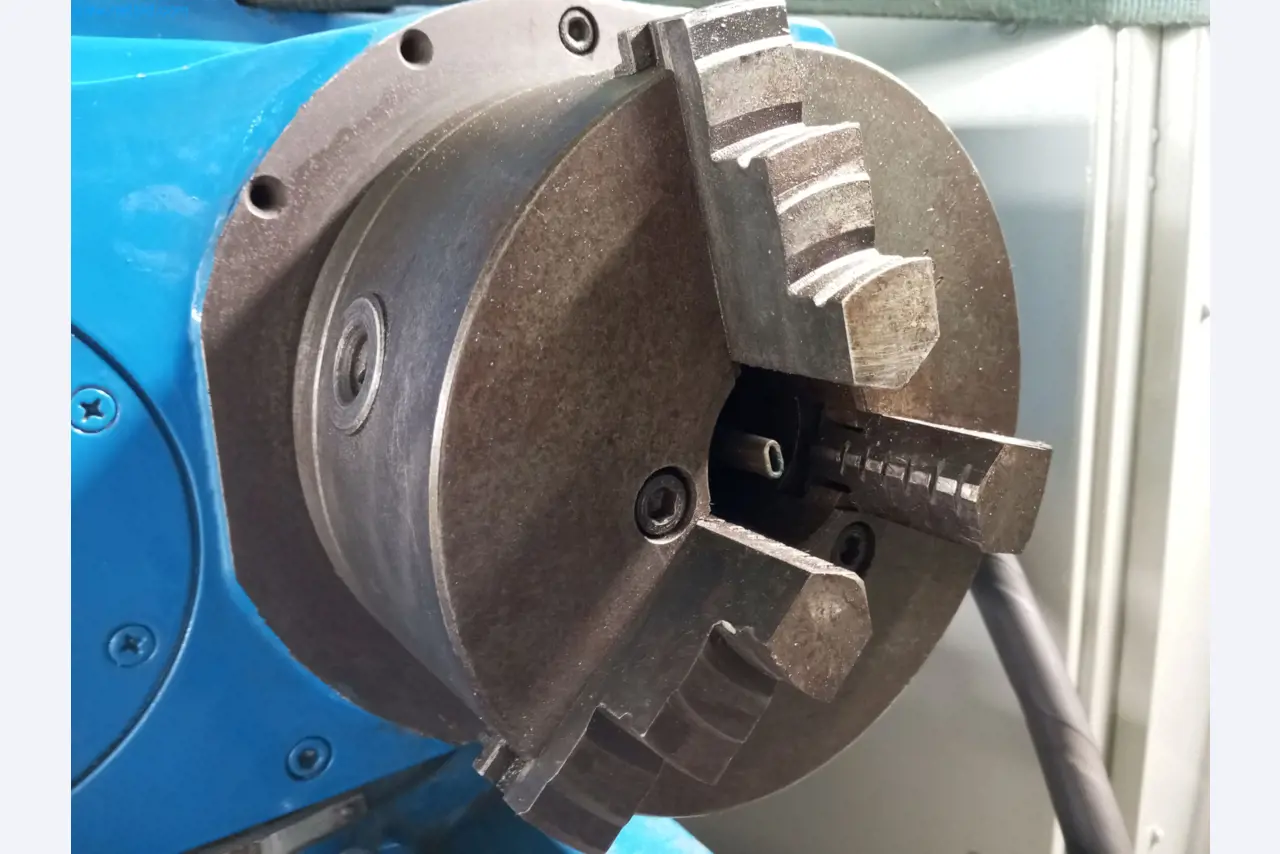

– The Stankoimport cylindrical grinding machine is designed to offer high precision in finishing cylindrical parts, reaching very strict tolerances.

– Allows grinding of both external and internal surfaces of parts, with the ability to perform complex operations such as creating cones.

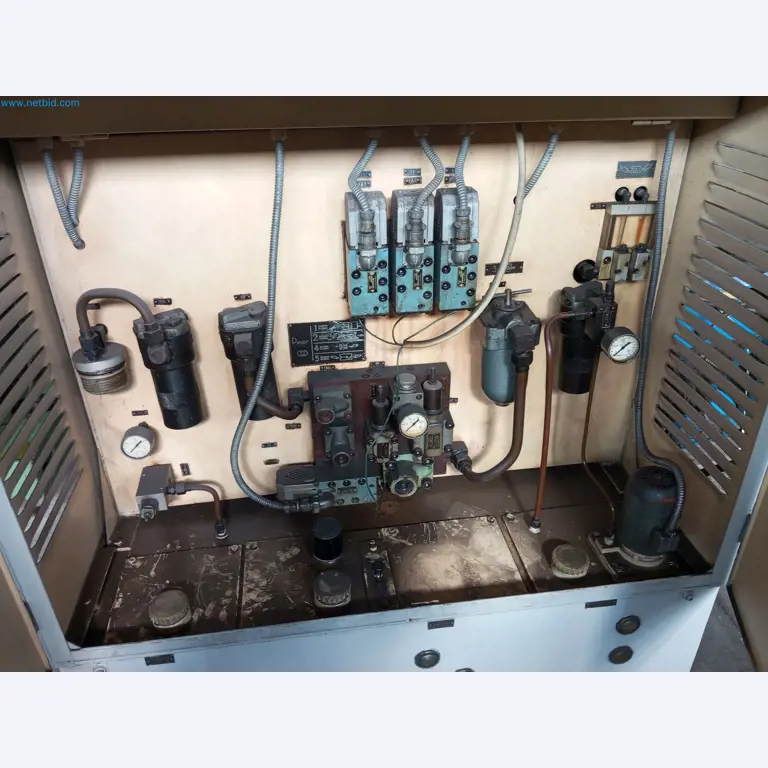

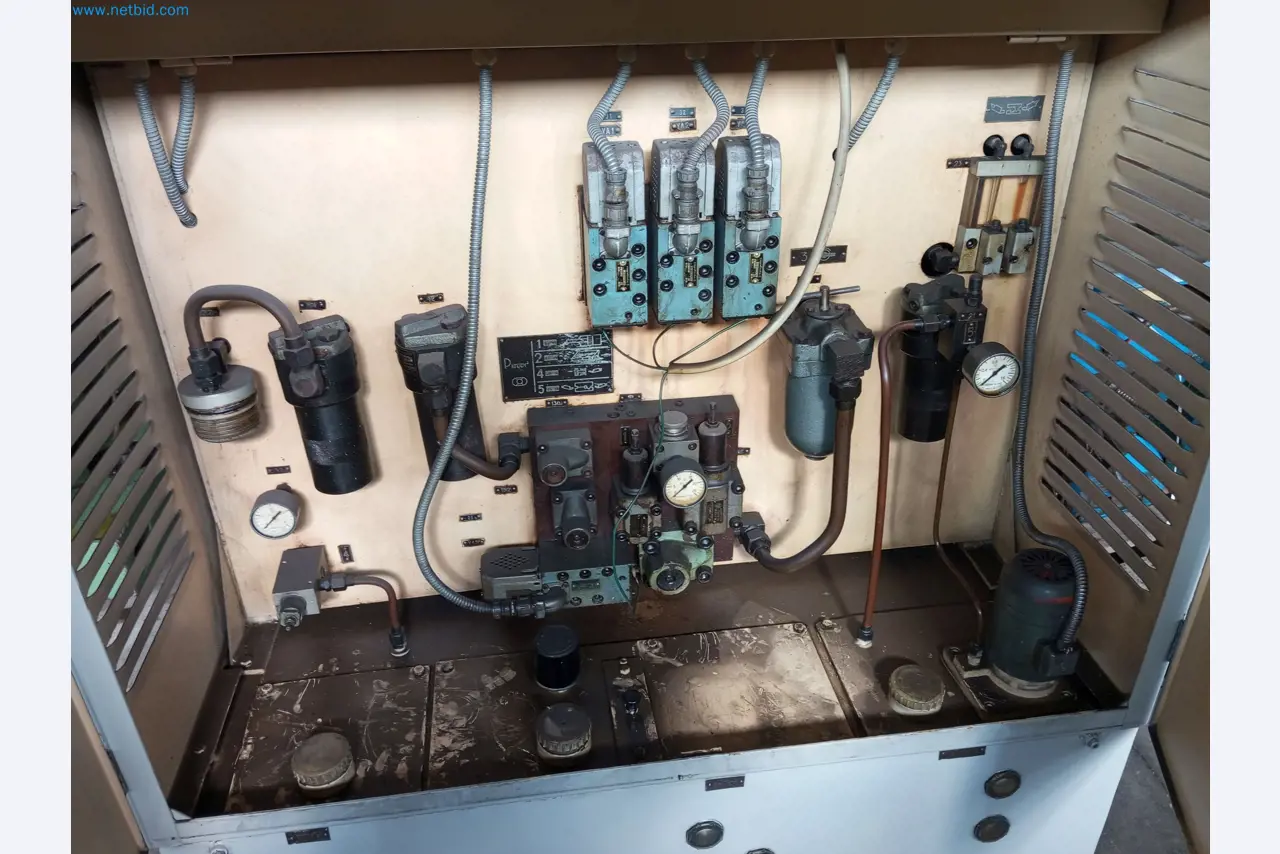

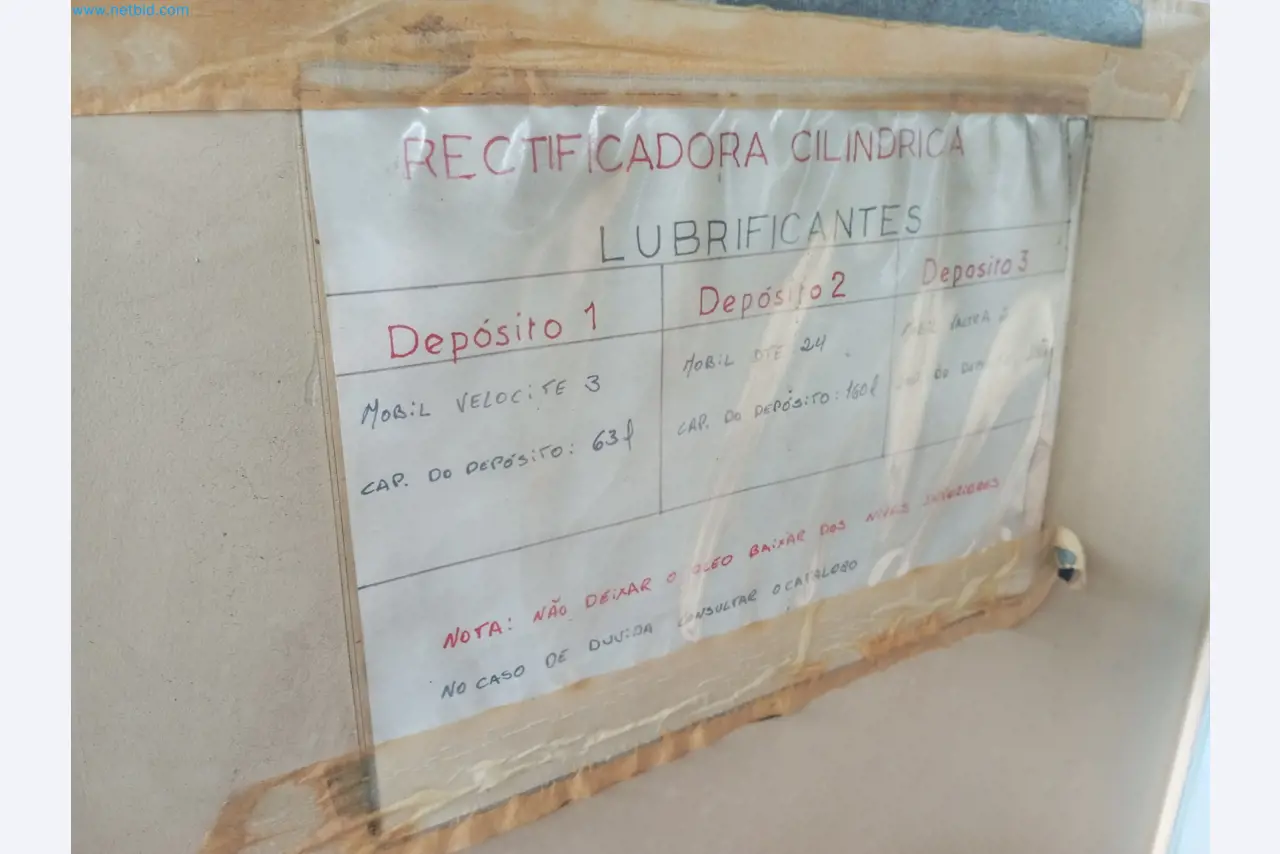

Cooling System:

– Equipped with a cooling system that prevents the part and the grinding wheel from overheating during operation, ensuring a quality finish and extending the useful life of the grinding wheel.

Automation and Control:

– semi-automatic control systems, allowing greater efficiency and precision.

– Intuitive control panel that makes it easy to adjust grinding parameters.

Typical Applications:

– Automotive Industry: Grinding of components such as axles, crankshafts, and pistons.

– Tool Industry: Production of pins, shafts and other parts that require high dimensional precision.

– Machinery Manufacturing: Finishing of high-precision cylindrical parts, such as spindles and hydraulic cylinders.

Typical Specifications:

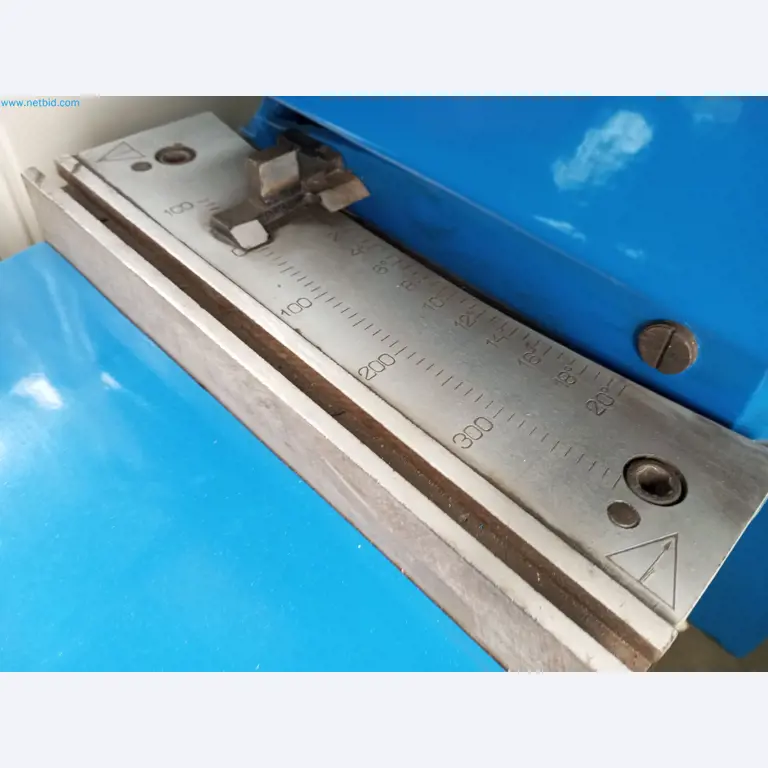

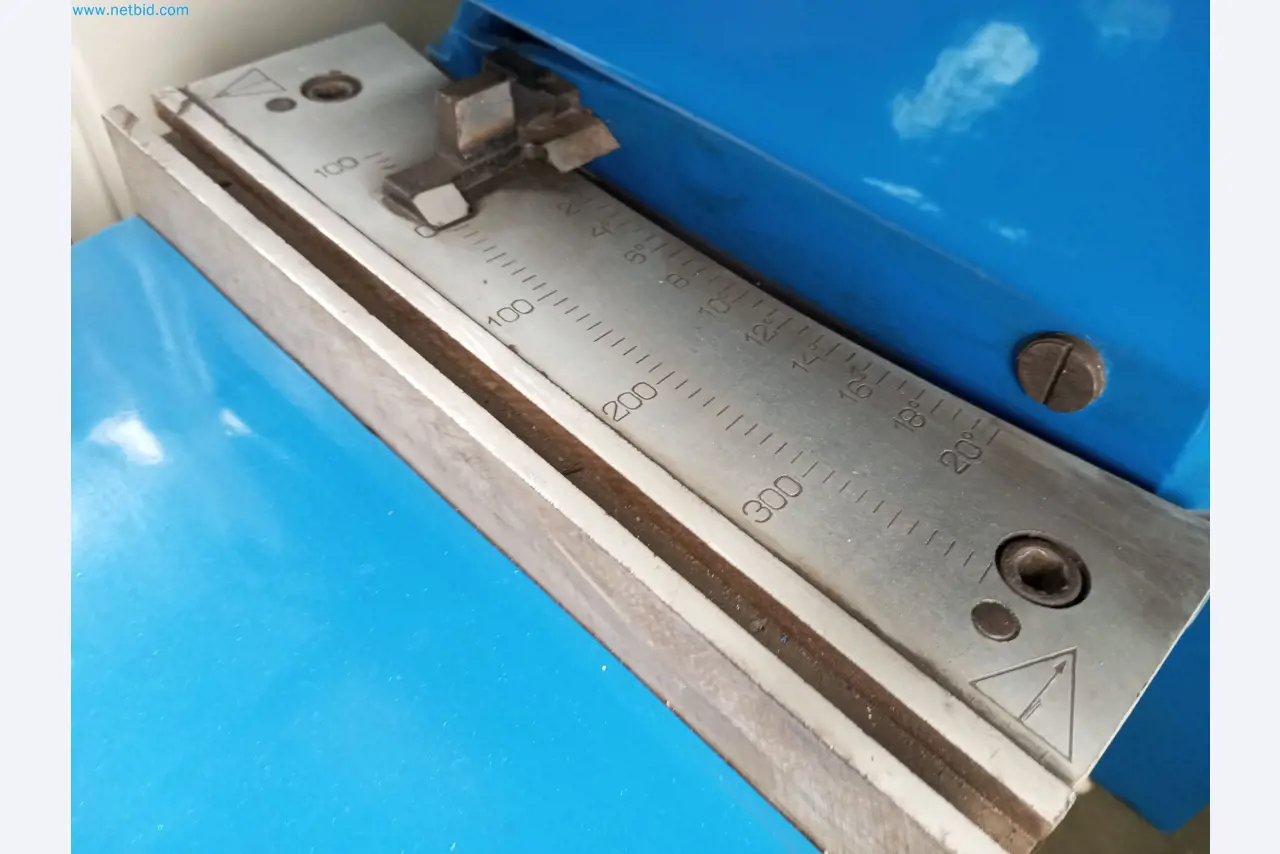

– Maximum External Grinding Diameter: between 200 mm and 500 mm

– Maximum Grinding Length: capable of working with parts from 500 mm to 2000 mm in length.

– Grinding Wheel Speed: Adjustable, normally between 1000 and 3000 RPM.

– Main Motor Power: from 3 kW to 15 kW

– Weight: between 3000 kg and 8000 kg

Approximate dimensions: 415 x 235 x 215 mm

Weight: 5000 kg

Additional mandatory dismantling & loading on truck cost of: 200€

Grinding Accuracy:

– The Stankoimport cylindrical grinding machine is designed to offer high precision in finishing cylindrical parts, reaching very strict tolerances.

– Allows grinding of both external and internal surfaces of parts, with the ability to perform complex operations such as creating cones.

Cooling System:

– Equipped with a cooling system that prevents the part and the grinding wheel from overheating during operation, ensuring a quality finish and extending the useful life of the grinding wheel.

Automation and Control:

– semi-automatic control systems, allowing greater efficiency and precision.

– Intuitive control panel that makes it easy to adjust grinding parameters.

Typical Applications:

– Automotive Industry: Grinding of components such as axles, crankshafts, and pistons.

– Tool Industry: Production of pins, shafts and other parts that require high dimensional precision.

– Machinery Manufacturing: Finishing of high-precision cylindrical parts, such as spindles and hydraulic cylinders.

Typical Specifications:

– Maximum External Grinding Diameter: between 200 mm and 500 mm

– Maximum Grinding Length: capable of working with parts from 500 mm to 2000 mm in length.

– Grinding Wheel Speed: Adjustable, normally between 1000 and 3000 RPM.

– Main Motor Power: from 3 kW to 15 kW

– Weight: between 3000 kg and 8000 kg

Approximate dimensions: 415 x 235 x 215 mm

Weight: 5000 kg

Additional mandatory dismantling & loading on truck cost of: 200€

Location

- 2430-000 Marinha Grande

Dates

Inspection

Visits are only possible after prior registration at carrico@netbid.com.

Pickup

05. Jan 2026 - 30. Jan 2026

Collection is only possible after prior registration at carrico@netbid.com.

Contact Person

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com