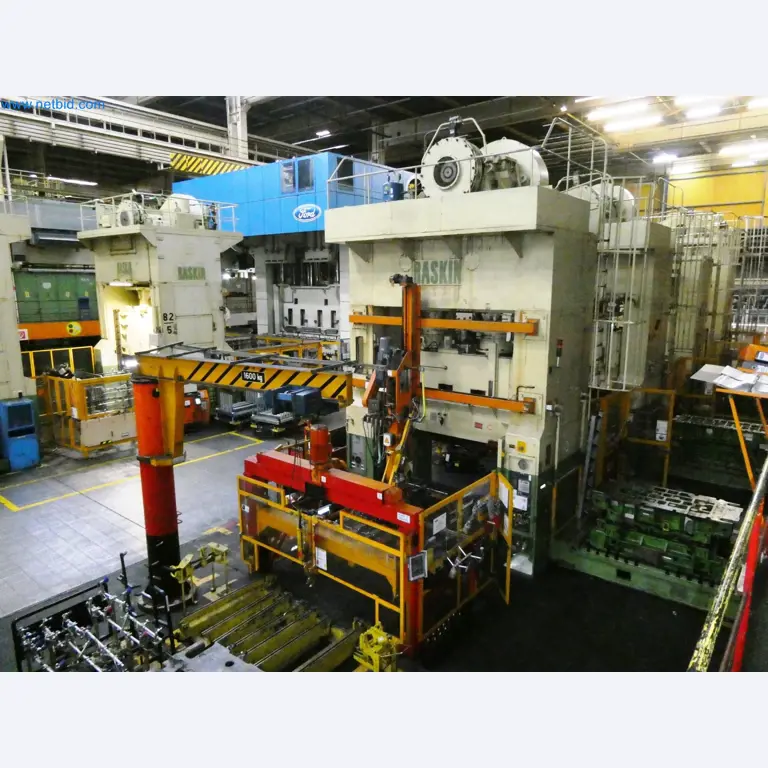

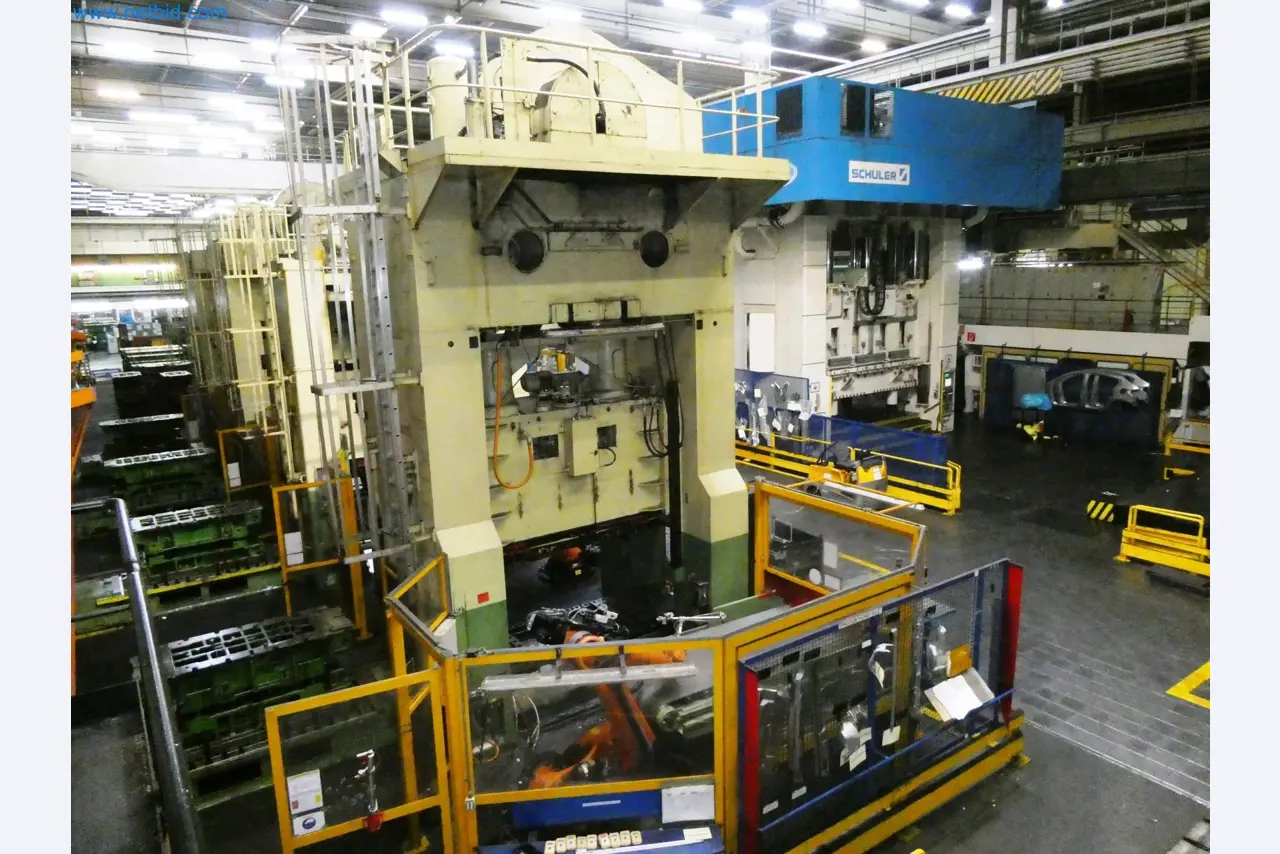

Part of the Auction Press lines from the automotive industry

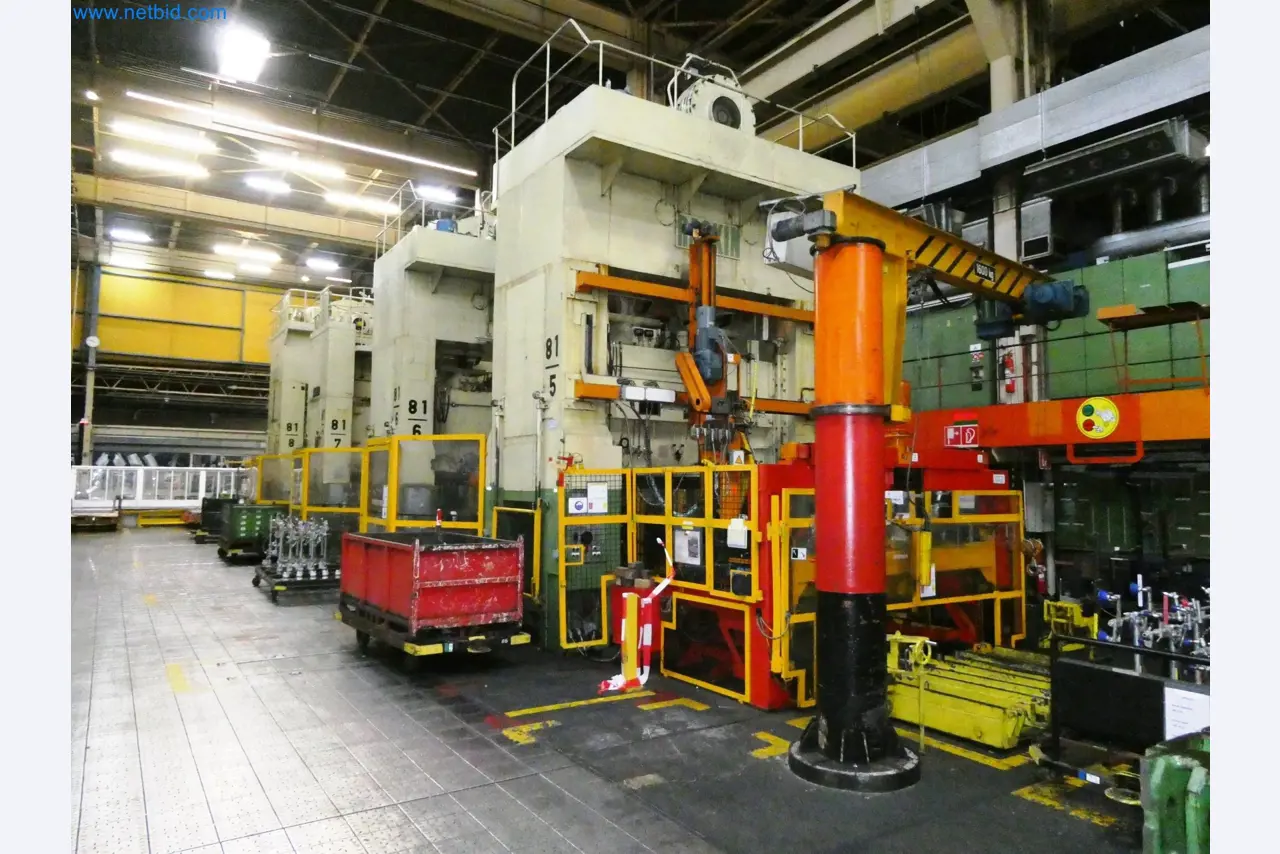

Press line (81) Raskin/KruppTRADING#18844-5004

Details

Product Type

Raskin/Krupp

Description

Last overhaul 2016, consisting of:

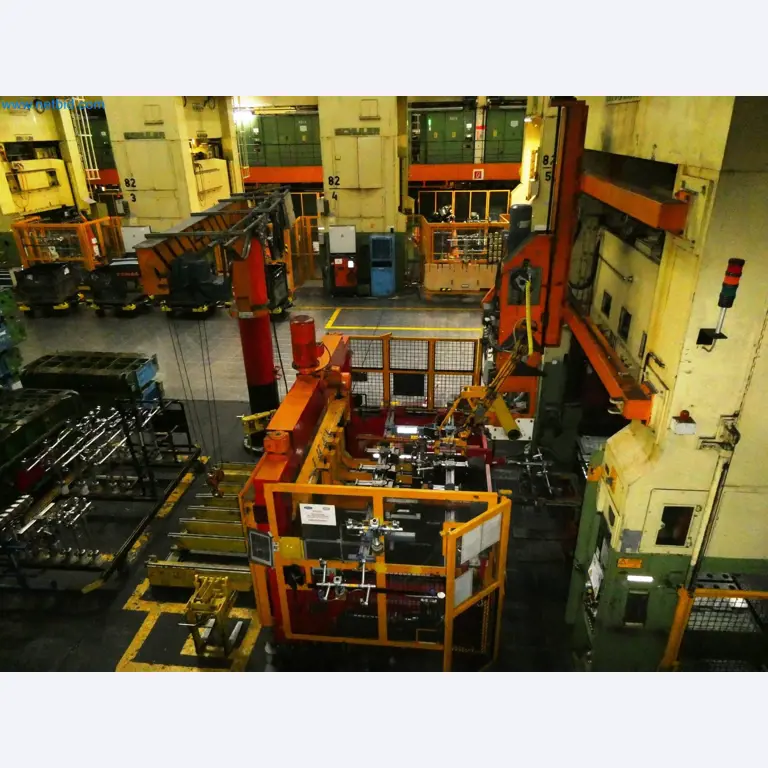

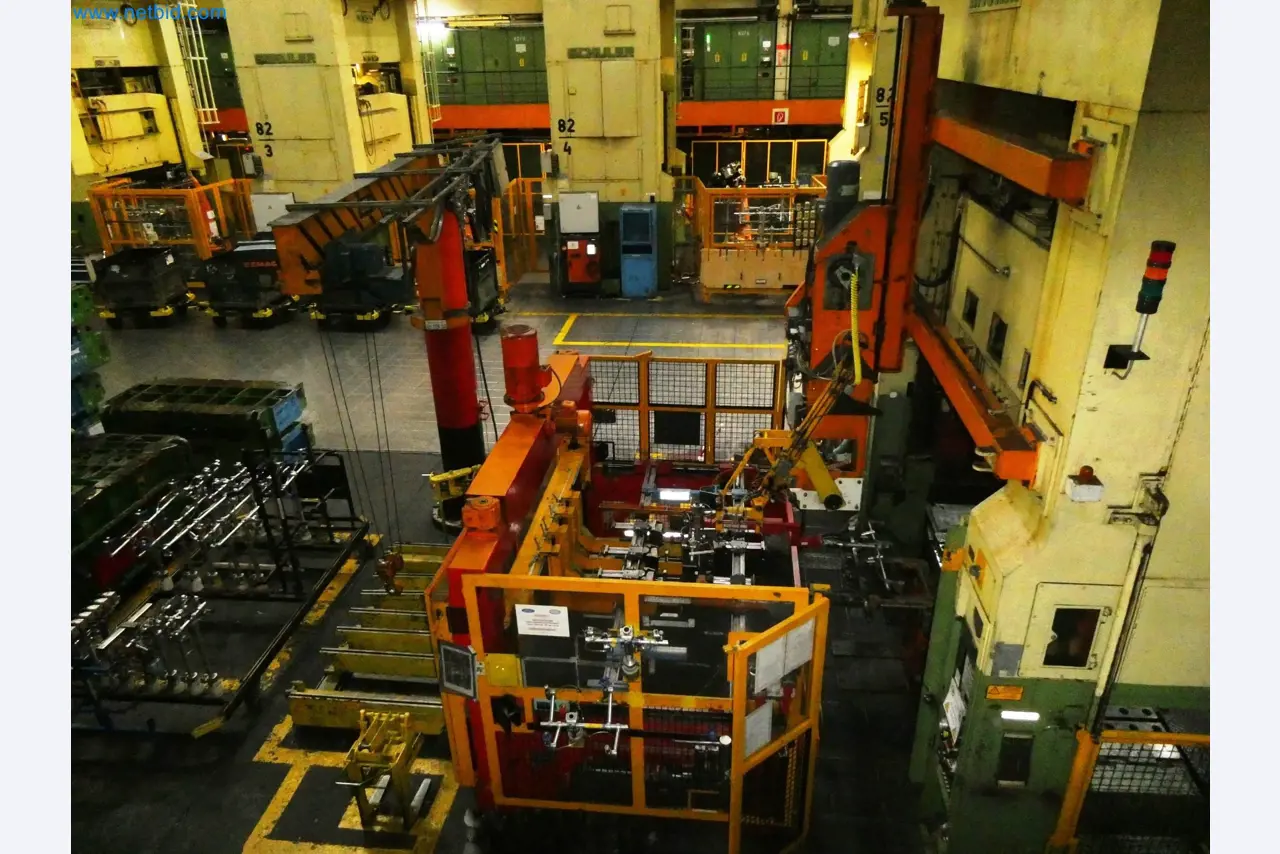

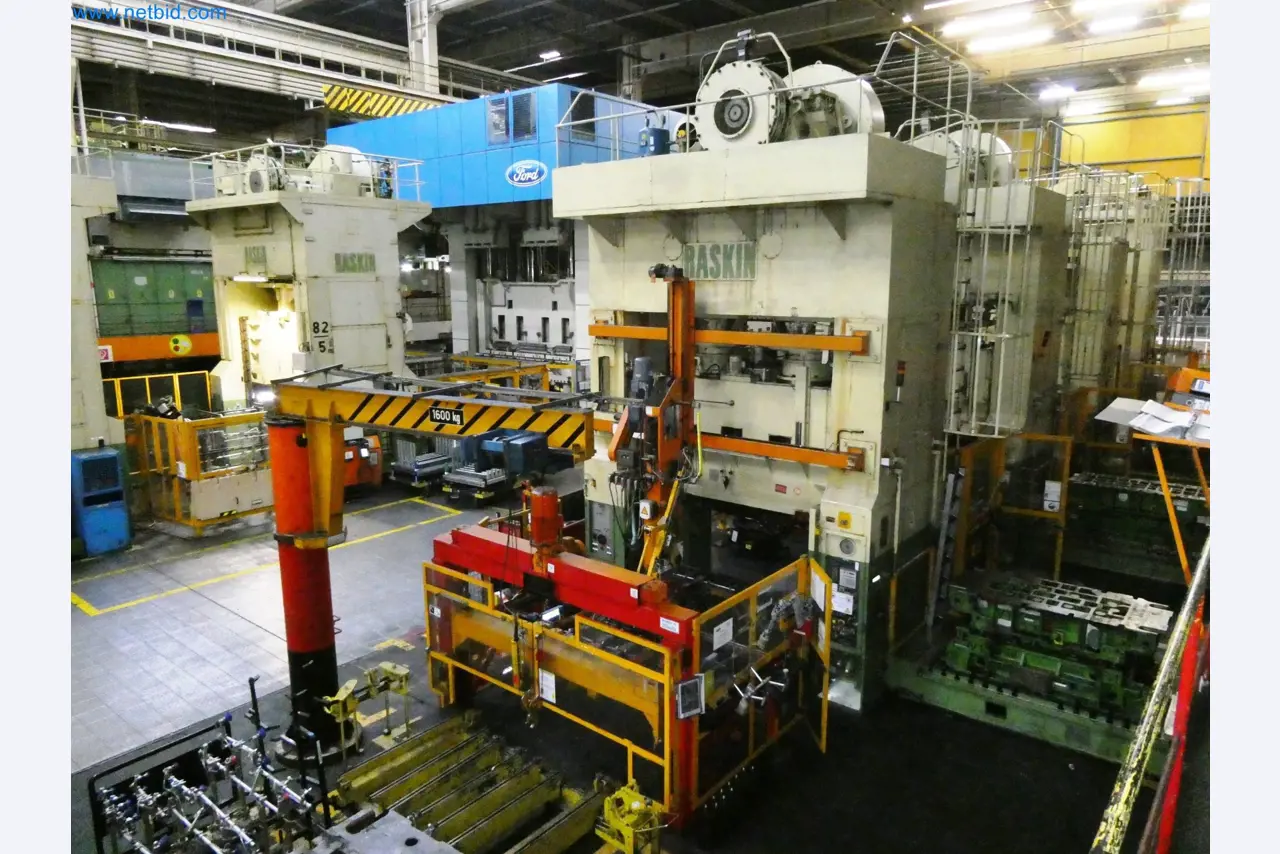

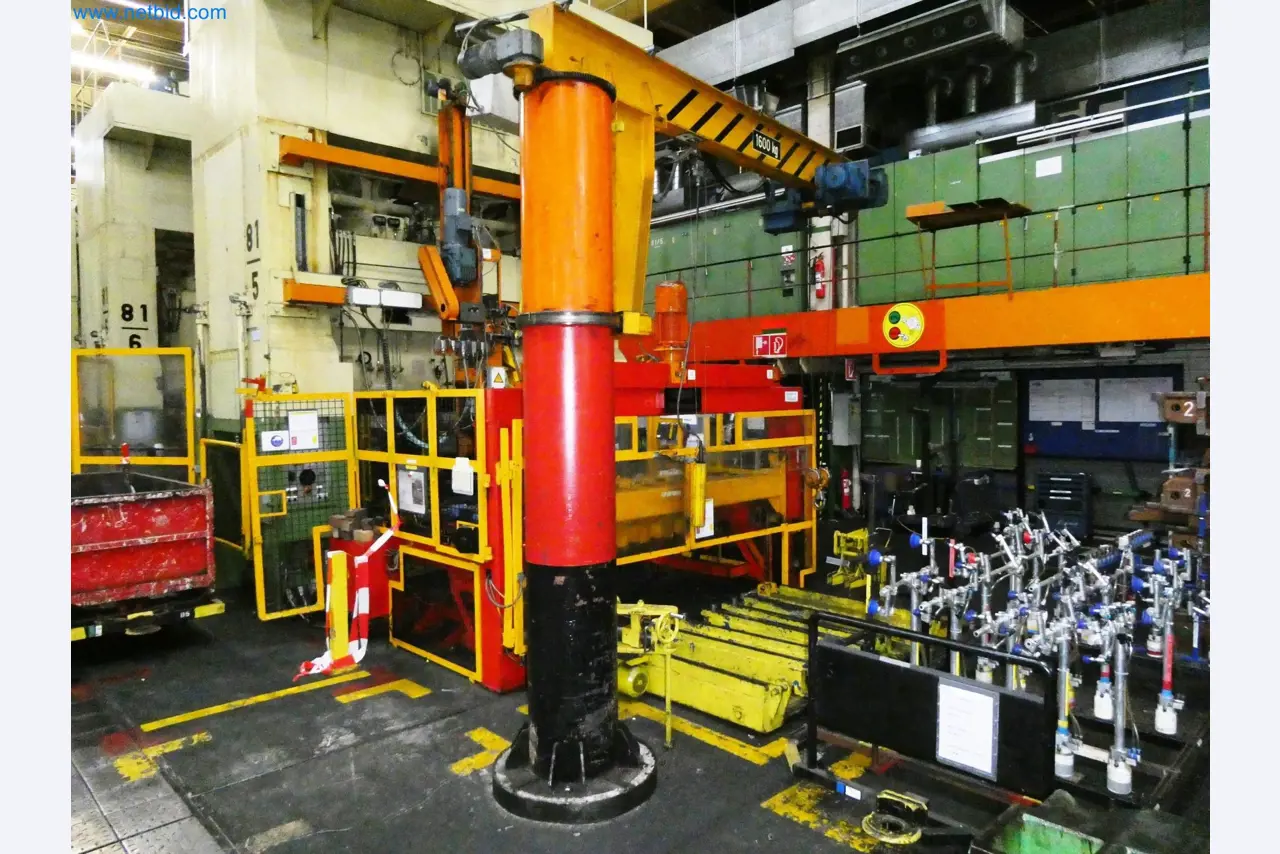

Slewing jib crane, Pfeiffer, type PSE 360XX3500, built 1985, SN 7081, load capacity 1,600 kg, radius 3,500 mm, with crane hook block

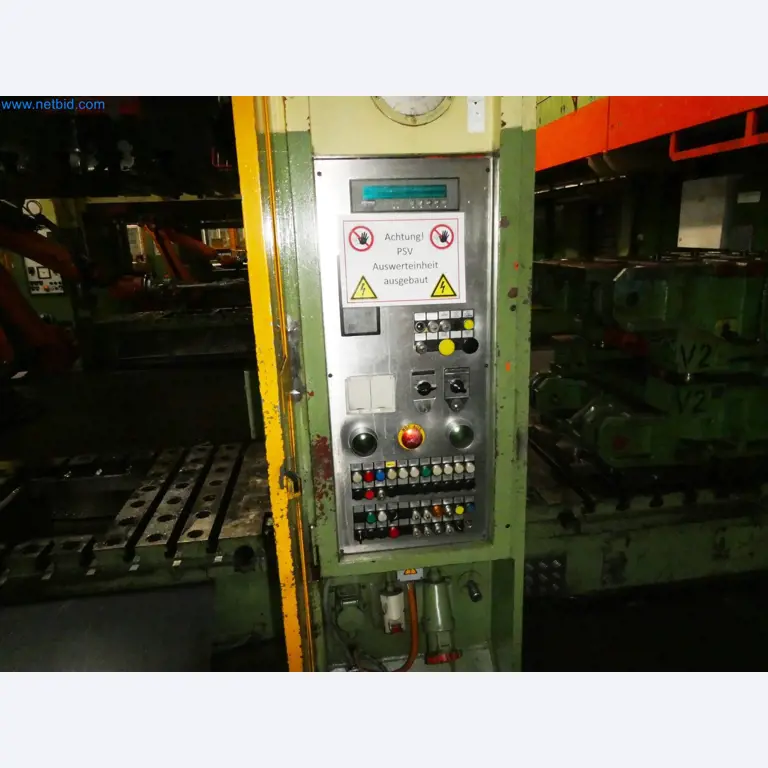

Board automation, manufactured by GMG Automation, system no. 0904400, with pallet changing trolley, control system, manufactured by Klaschka

Gripper automation, manufactured by Olofström, type Doppin Feeder 1400, SN 2753-83-9964815, folder no. 515152, system no. 0600600

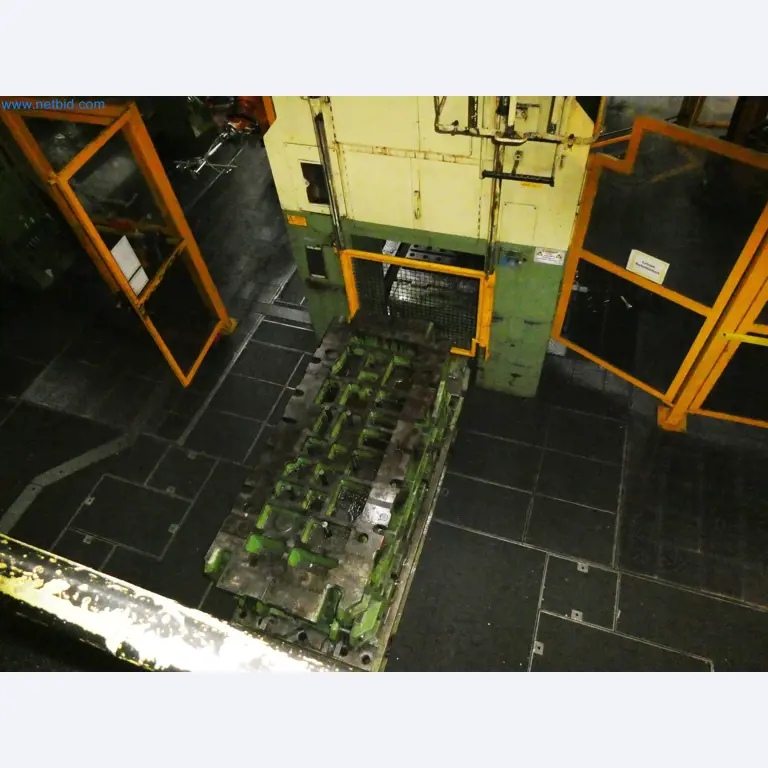

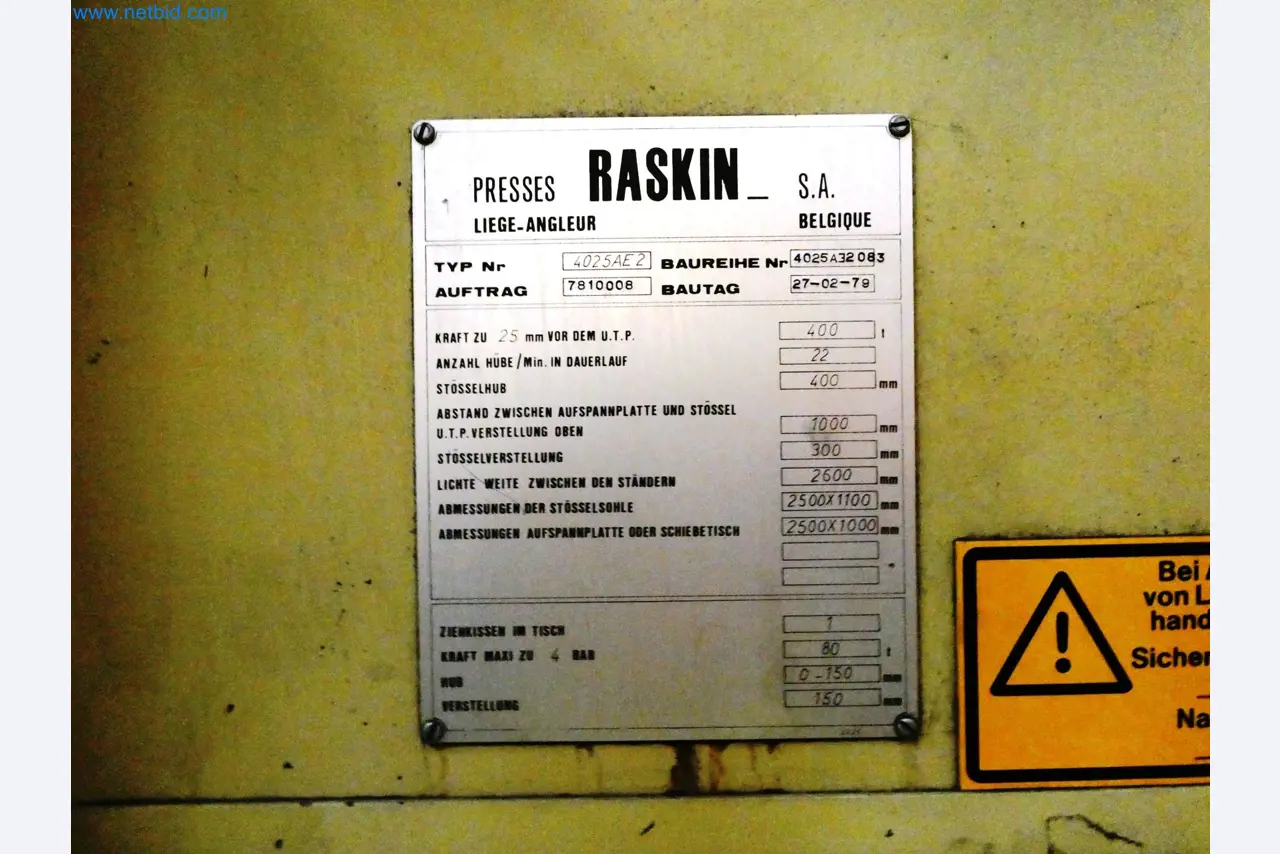

Double column press (81/5), Raskin, type 4025AE2, built approx. 1979, machine no. 0181500, single action, press force approx. 400 t, T-slot clamping plate, approx. 2,600 x 1,000 mm, with 2-fold sliding table, Siemens control system, type S5

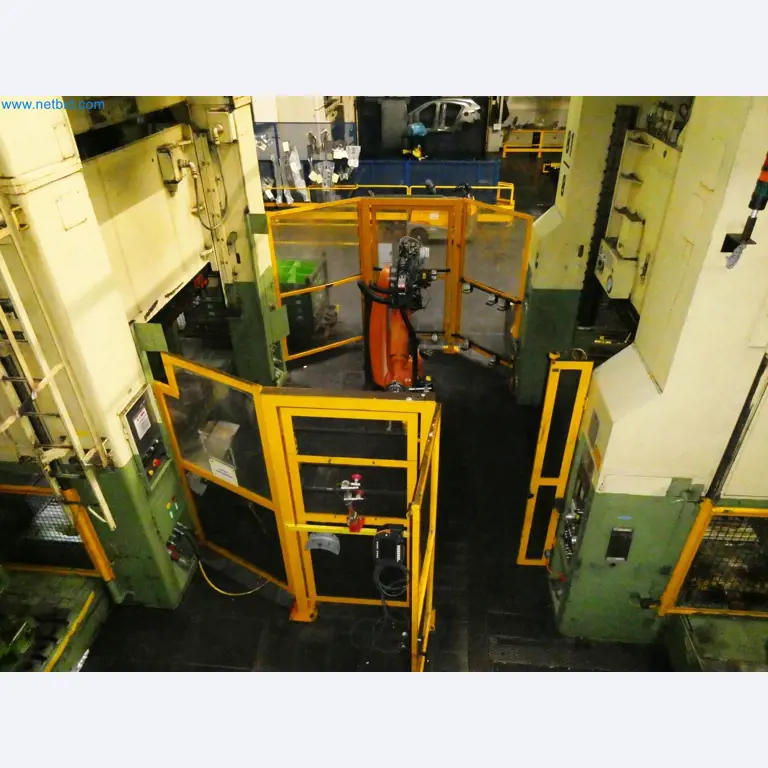

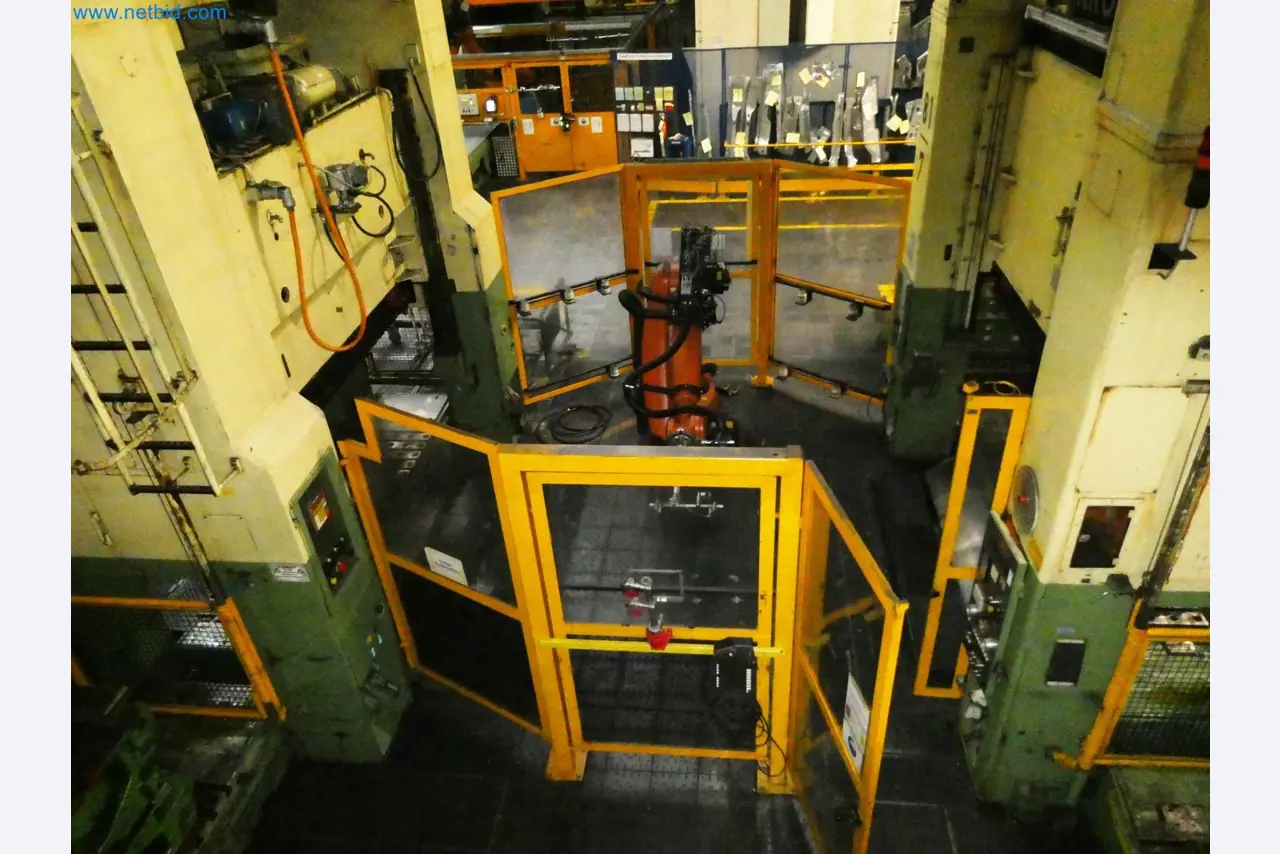

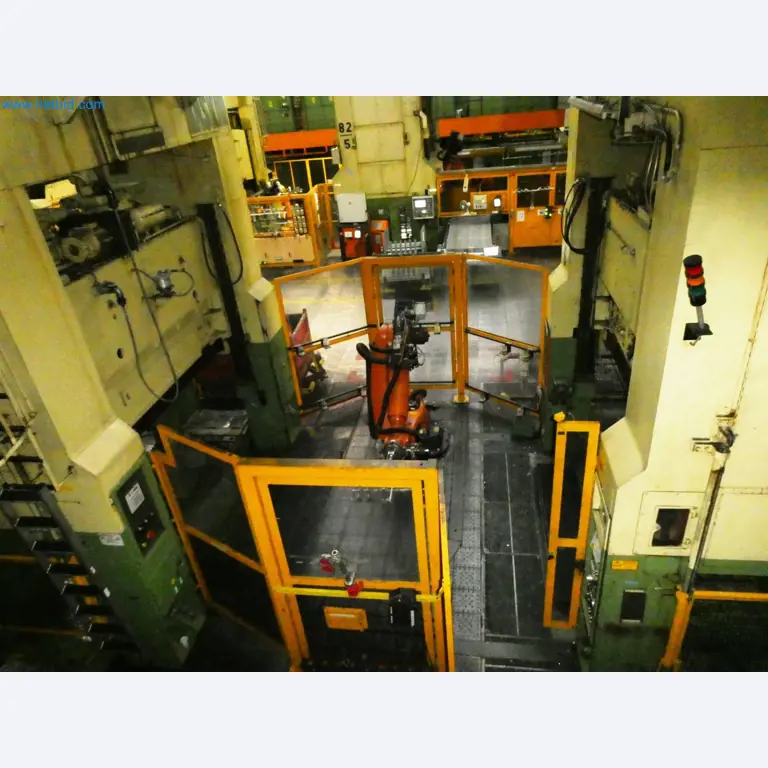

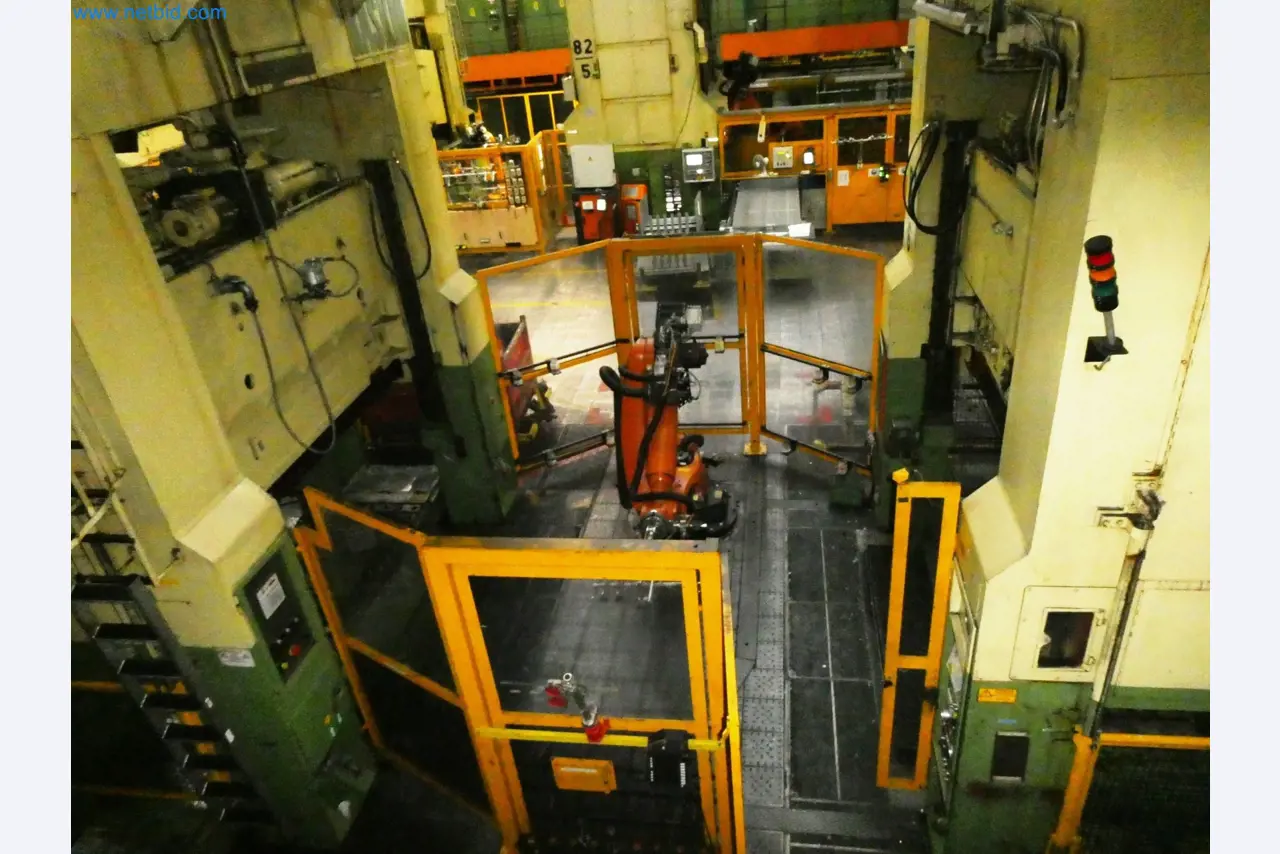

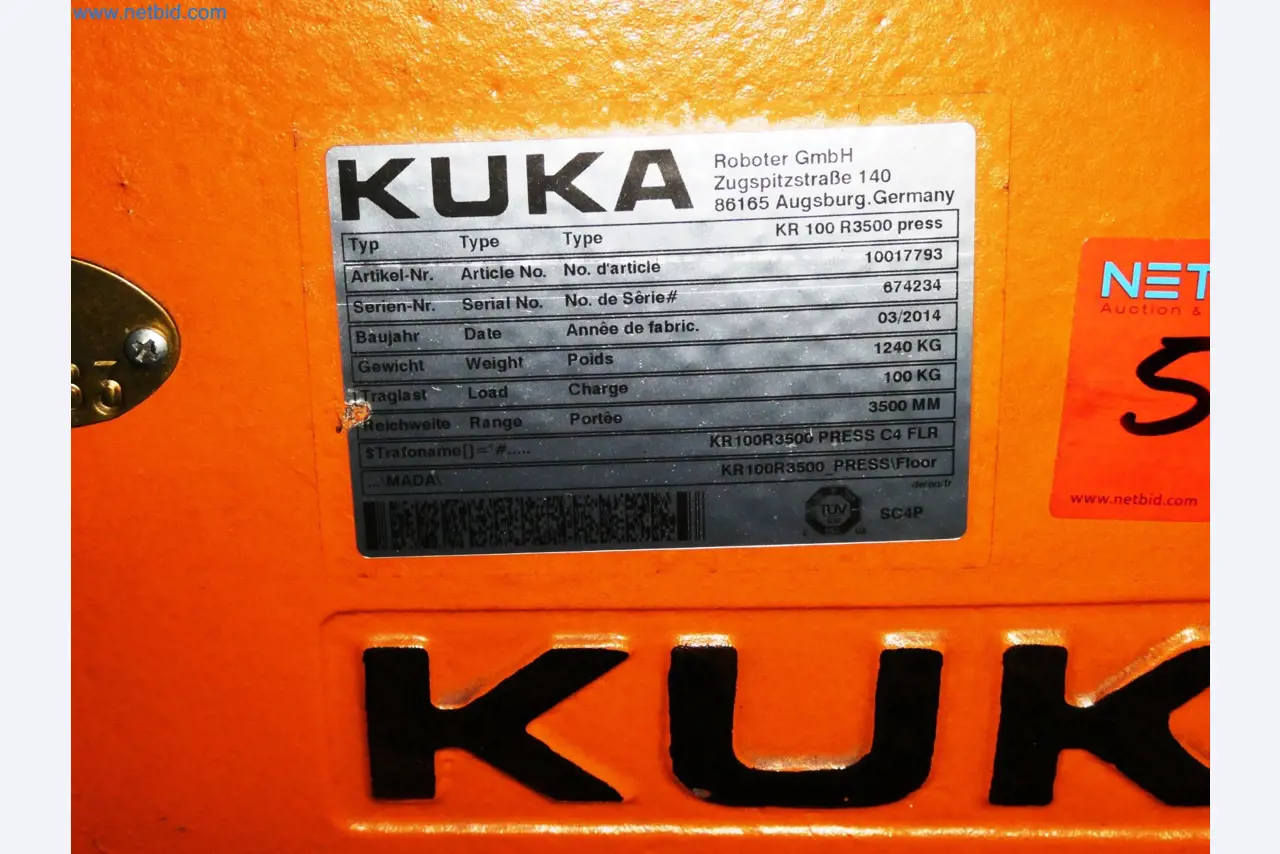

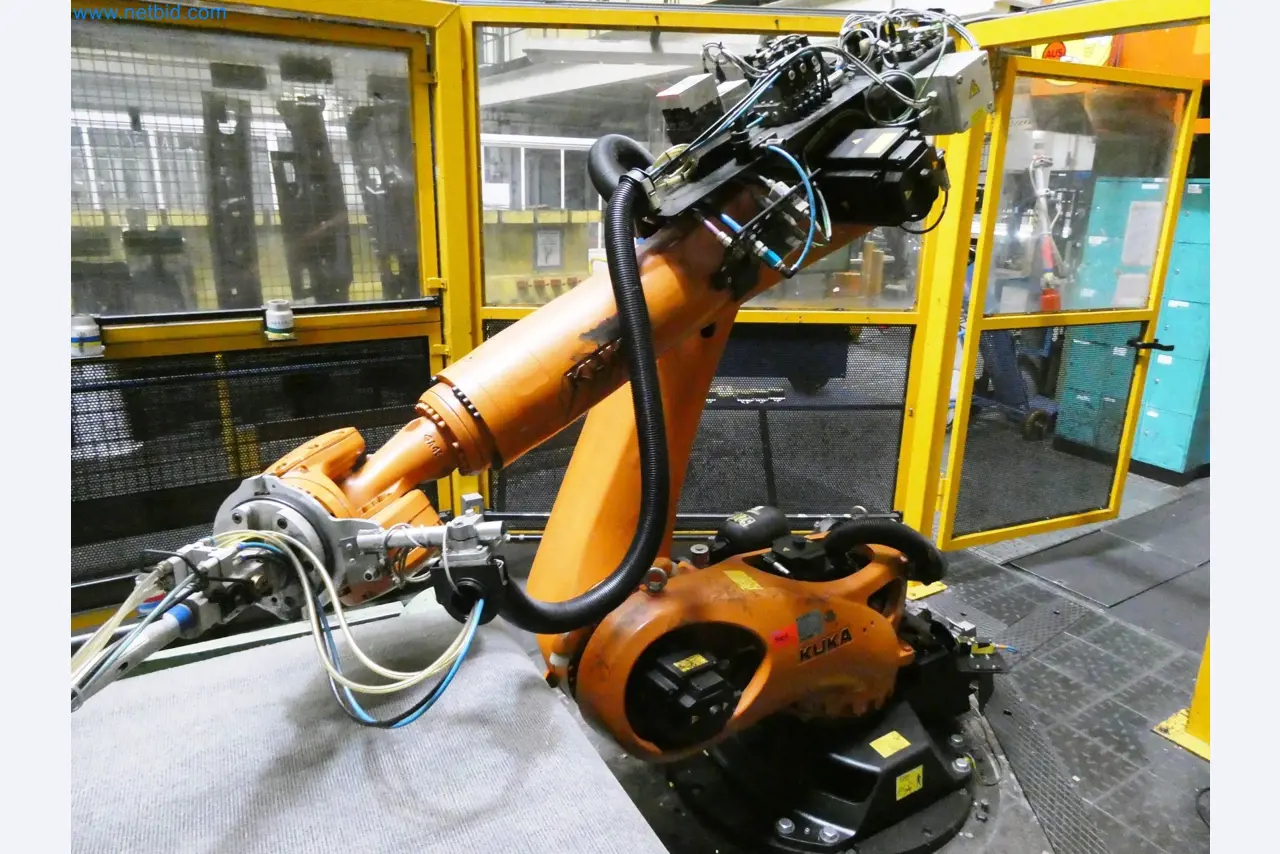

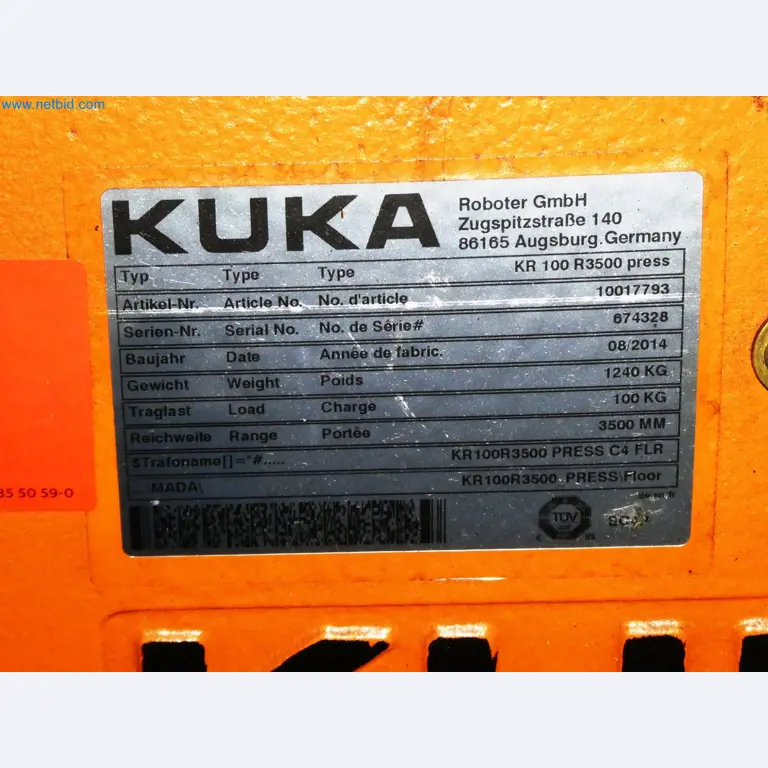

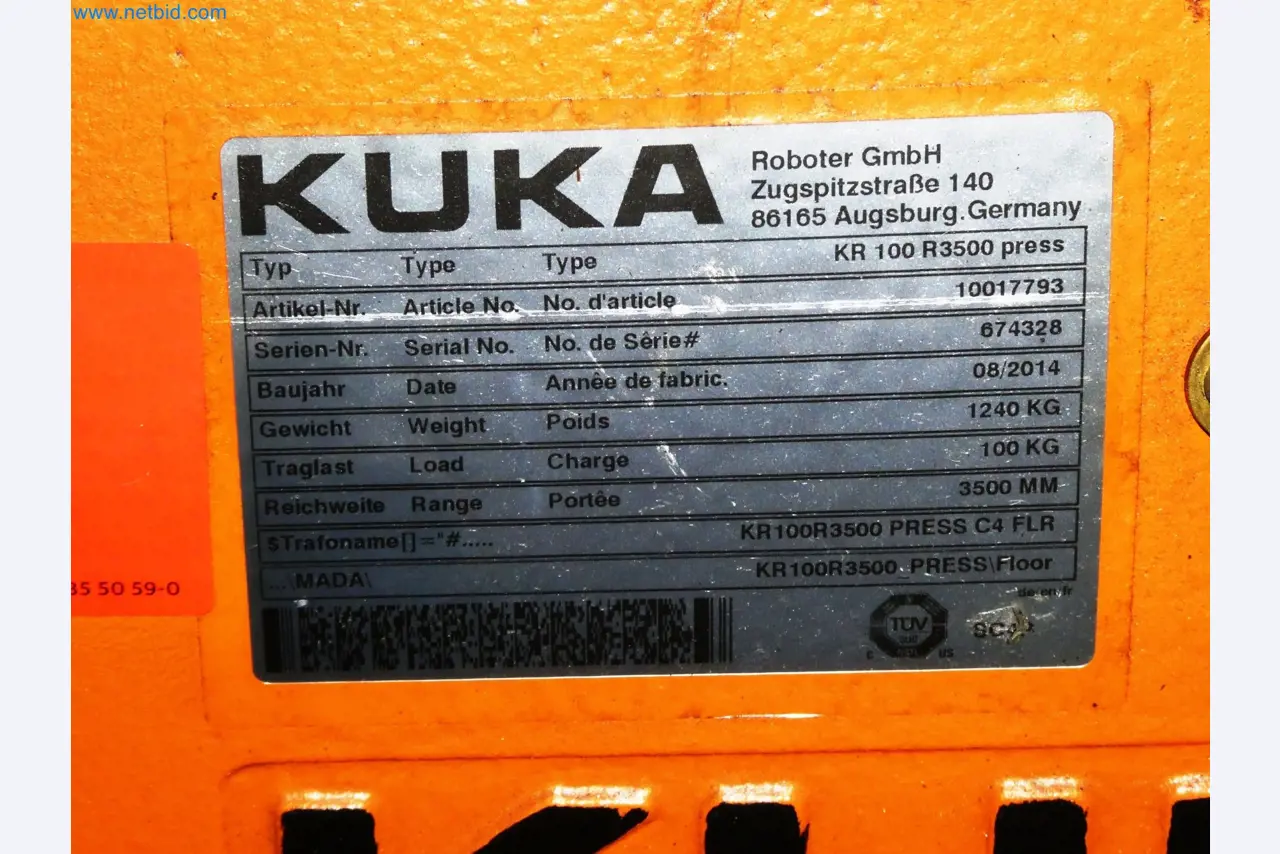

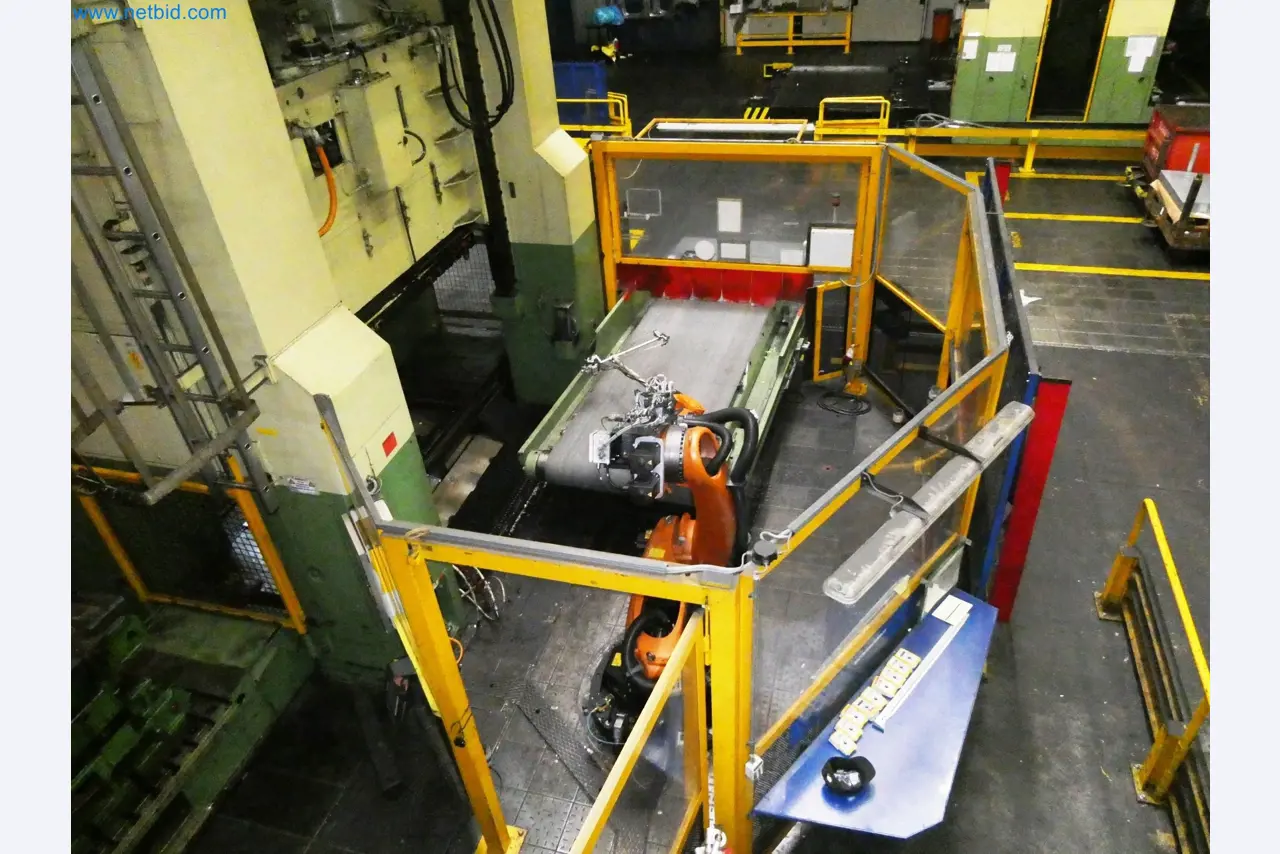

6-axis robot, manufactured by Kuka, type KR 100 R3500 Press, year 2014, SN 674234, system no. 18D4400, weight 1,240 kg, load capacity 100 kg, throat depth 3,500 mm, control system, type KRC4, SN 243768, system no. 3024600, with press linkage, manufactured by Kuka, year 2014

Double column press, manufactured by Raskin, type 4025AE2, built approx. 1979, press force approx. 400 t, single action, table size 2,600 x 1,000 mm, with 2-fold sliding table, control system manufactured by Siemens, type S5

6-axis robot, manufactured by Kuka, type KR 100 R3500 Press, year 2014, SN 674231, system no. 1806800, weight 1,240 kg, load capacity 100 kg, throat depth 3,500 mm, control system, type KRC4, system no. 3024700, with press linkage, manufactured by Kuka, year 2014

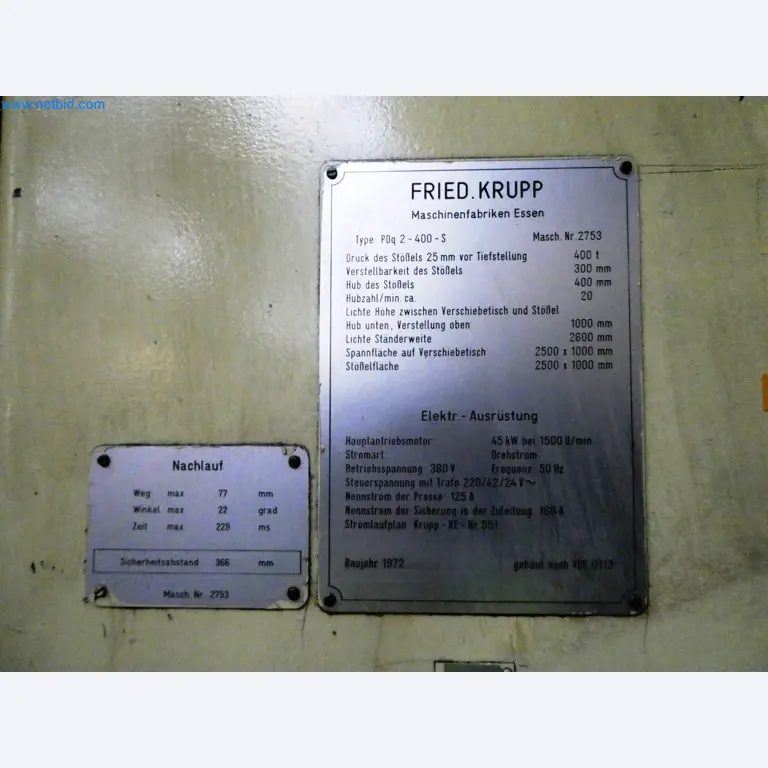

Double-column press, Krup, type PDQ 2-400-S, built approx. 1972, SN 2753, ram pressure 400 t, single action, ram adjustment 300 mm, ram stroke 400 mm, stroke rate approx. 20, clearance height between sliding table and ram approx. 1,000 mm, column width approx. 2,600 mm, clamping area approx. 2,500 x 1,000 mm, drive motor 45 kW, with 2-fold sliding table

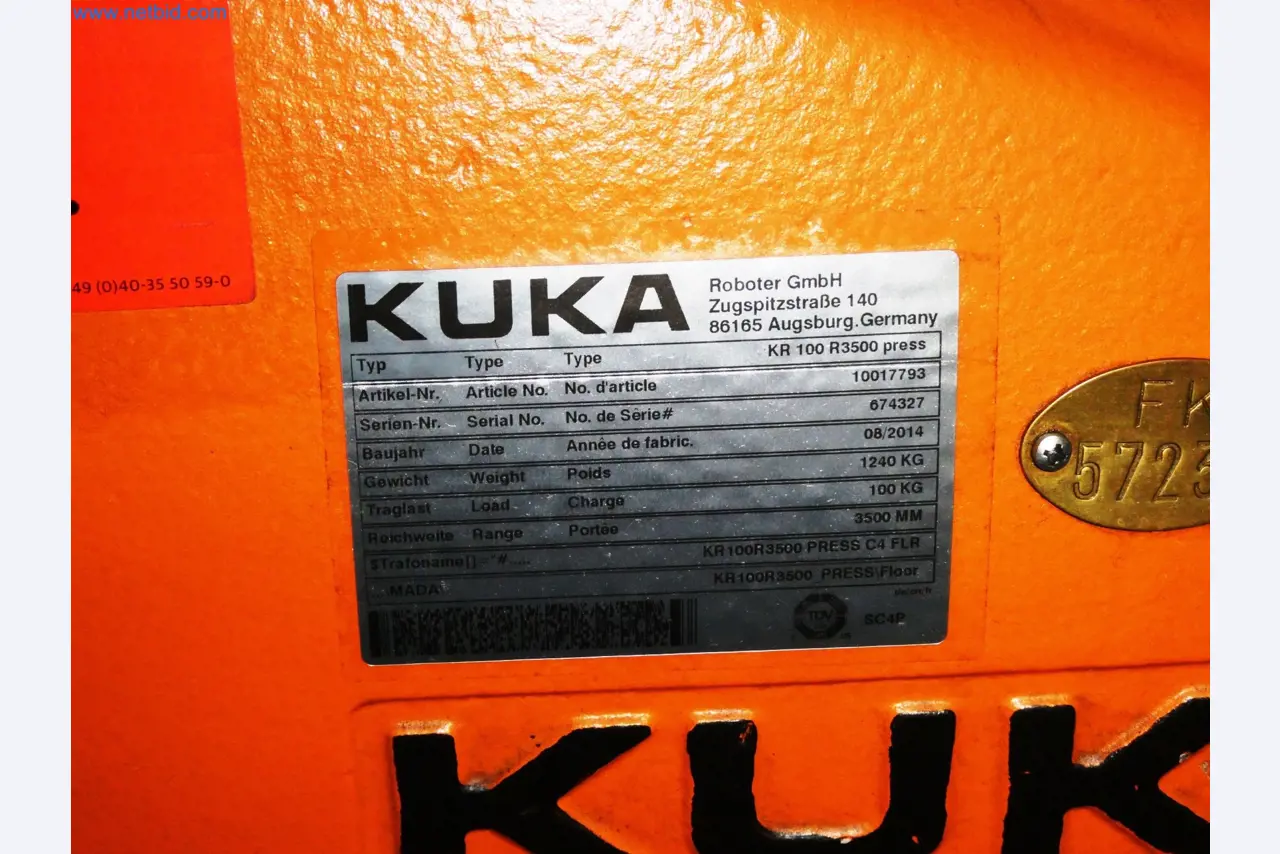

6-axis robot, manufactured by Kuka, type KR 100 R3500 Press, year 2014, SN 674327, system no. 1808400, weight 1,240 kg, load capacity 100 kg, throat depth 3,500 mm, control, type KRC4, SN 243769, system no. 3027900, with press linkage, manufactured by Kuka, year 2014,

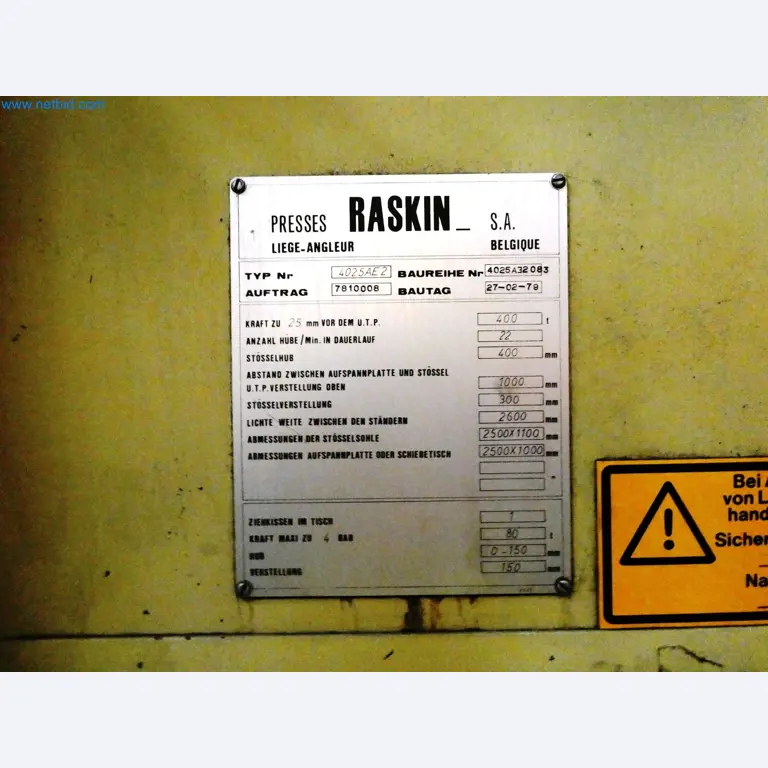

Double column press, Raskin, type 4025AE2, built 1979, SN 4025A32083, order no. 7810008, press force approx. 400 t, single action, stroke rate 22/min, ram stroke 400 mm, distance between clamping plate and ram 1.000 mm, ram adjustment 300 mm, clearance between uprights 2,600 mm, table size 2,500 x 1,000 mm, clamping surface 2,500 x 1,000 mm, retractable cushion, press force 80 t, adjustable 0-150 mm, with 2-fold sliding table

6-axis robot, manufactured by Kuka, type KR 100 R3500 Press, year 2014, SN 674328, system no. 1808300, weight 1,240 kg, load capacity 100 kg, throat depth 3,500 mm, control, type KRC4, SN 243818, system no. 3065800, with press linkage, manufactured by Kuka, year 2014

Belt conveyor, Bürner Maschinenbau, system no. 1501800, belt size approx. 4,000 x 1,200 mm

Safety fence system for shielding the spaces between the presses and robot cells, counting device, lighting, monitoring system, switch cabinets on the gallery

System available from December 2025

Location

- Deutschland/ Halle B/ Stamping/ Linie 81

Dates

Inspection

Only by prior written registration and appointment at weyand@netbid.com

Please note the access requirements, which can be found in the auction conditions.

Please note the access requirements, which can be found in the auction conditions.

Pickup

By arrangement.

Auction Terms

Due to the access requirements, we need the following information from you for a viewing appointment

Complete company name, name and contact details

Which production areas are of interest

Preferred date and time

Number of participants and names

Special conditions:

Special conditions:

- Access requirements

- HSE specifications

- Different auction conditions

Parts of this page have been machine translated. The German original text applies.

Your individual consultation

Our experts will be happy to advise you. Call +49 40 355059-132 or write to service@netbid.com